Technical Contents

Engineering Guide: Cnc Prototyping Georgia

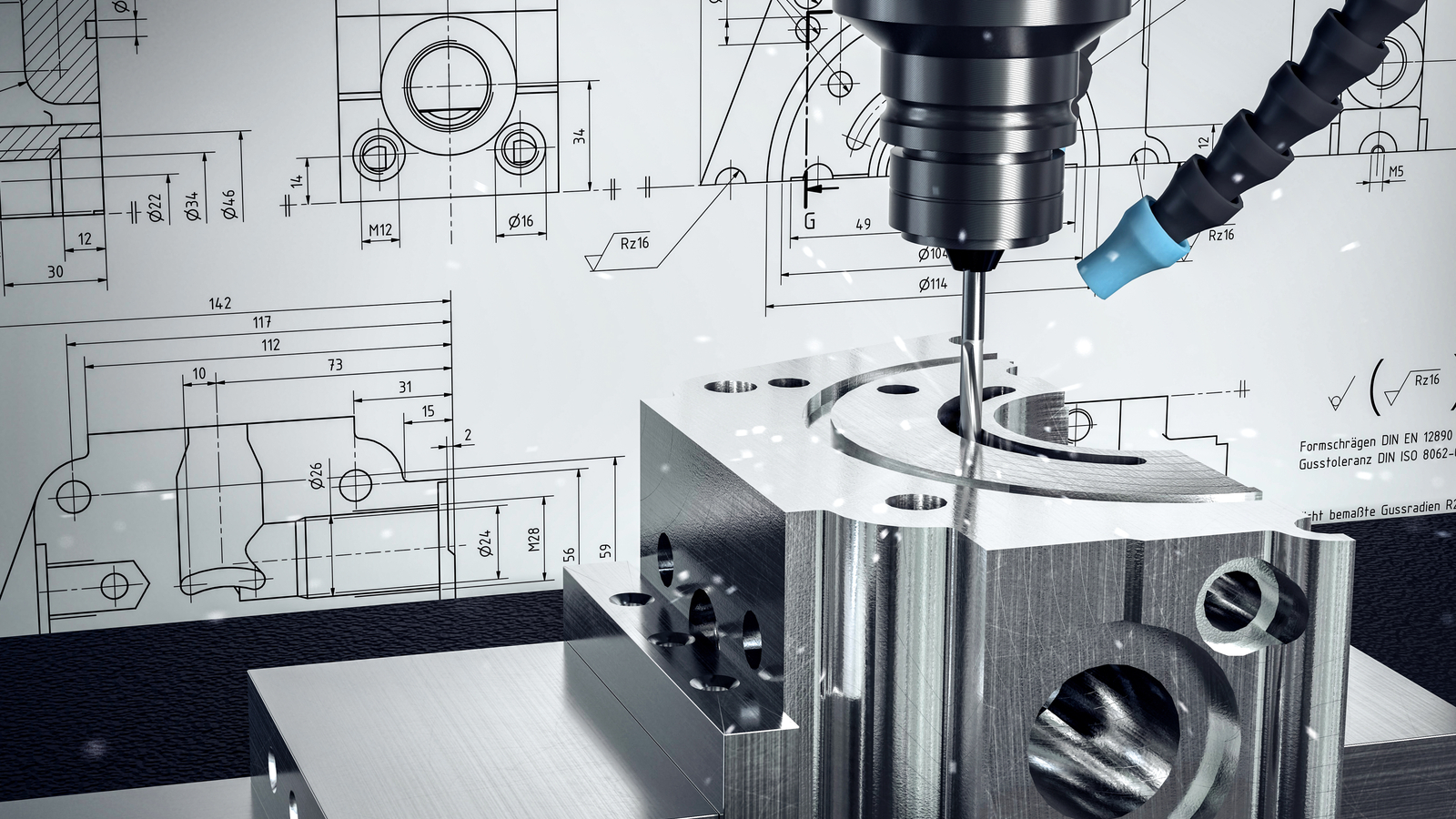

Engineering Insight Precision as the Non-Negotiable Foundation for CNC Prototyping in Georgia

Georgia’s manufacturing landscape, particularly within aerospace, defense, and advanced industrial sectors, demands prototypes that transcend mere concept validation. For Georgia-based engineers and procurement leaders, the prototype is the critical bridge between design intent and production reality. In this high-stakes environment, dimensional precision is not merely desirable; it is the absolute prerequisite for functional testing, regulatory compliance, and ultimately, securing production contracts. Sub-micron deviations in a turbine blade mockup or a hydraulic manifold prototype can invalidate test data, delay certification, and erode client confidence. The cost of rework or failure at the prototype stage, especially when targeting demanding industries prevalent in Georgia, far exceeds the investment in achieving first-article perfection through advanced CNC capabilities.

Wuxi Lead Precision Machinery understands this imperative at its core. Our engineering philosophy is forged in environments where failure is not an option. We have delivered mission-critical CNC prototypes and components for Olympic Games timing systems, where accuracy measured in thousandths of a millimeter directly impacted world records and medal outcomes. Similarly, our work for Tier-1 defense contractors involves prototypes subjected to rigorous military specifications (MIL-STD), operating under extreme vibration, temperature, and pressure conditions. This experience instills a discipline that transcends geography: the relentless pursuit of geometric accuracy, surface integrity, and material consistency from the very first prototype run. It means implementing multi-axis machining strategies, in-process metrology, and stringent environmental controls not as optional extras, but as standard operating procedure. For Georgia manufacturers competing globally, partnering with a supplier whose precision pedigree is proven in the world’s most unforgiving applications mitigates risk and accelerates time-to-market.

The tangible output of this precision-focused engineering is reflected in our core machining capabilities, consistently achieved across diverse prototype projects:

| Specification Category | Capability Range | Industry Application Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) standard | Aerospace actuators, medical implants |

| Surface Finish (Ra) | 0.8 µin (0.02 µm) to 32 µin (0.8 µm) | Hydraulic components, optical mounts |

| Feature Repeatability | ±0.00005″ (1.27 µm) | Precision instrumentation, sensors |

| Material Compatibility | Aluminum 7075-T6, Titanium Ti-6Al-4V, Inconel 718, PEEK, PTFE | Defense housings, aerospace brackets |

| Max Work Envelope (Mill) | 2000 x 1000 x 800 mm | Large-scale industrial prototypes |

Precision in CNC prototyping for Georgia’s advanced manufacturers is the cornerstone of engineering credibility and program success. It transforms prototypes from static models into reliable predictors of production performance. Wuxi Lead Precision Machinery leverages its hard-won experience in Olympic and military-grade manufacturing to ensure that every prototype shipped to Georgia meets the uncompromising standards required by its most sophisticated industries. This commitment to measurable, repeatable accuracy is how we help Georgia innovators convert design vision into certified, production-ready reality.

Precision Specs & Tolerances

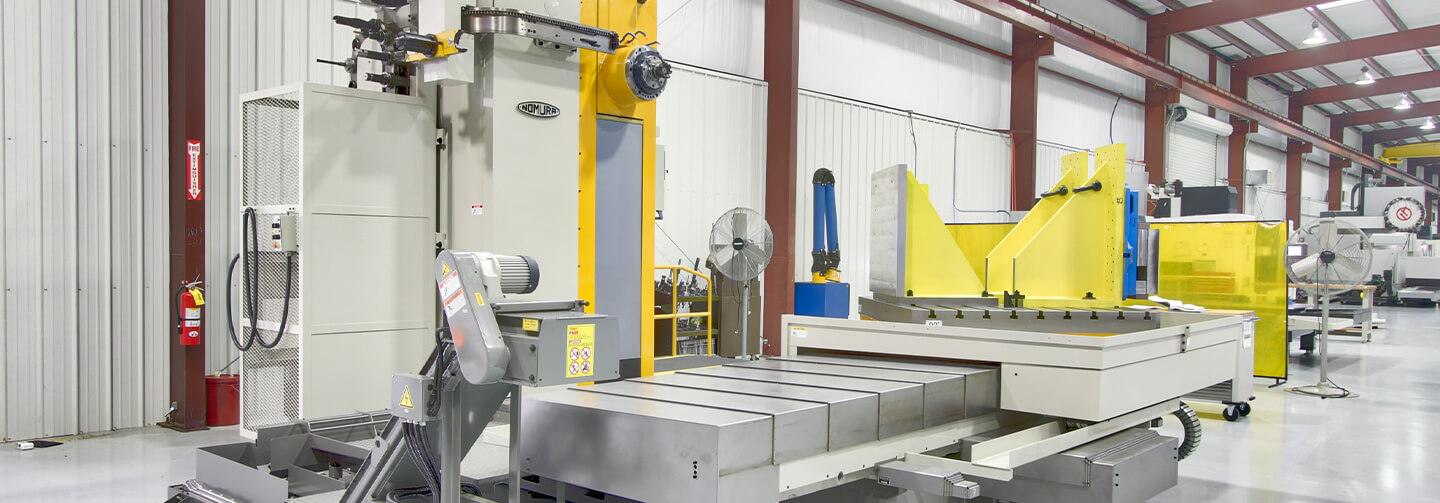

Wuxi Lead Precision Machinery delivers advanced CNC prototyping solutions tailored to meet the rigorous demands of high-end manufacturing sectors, including aerospace, medical, automotive, and industrial equipment. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across five planes, significantly reducing setup times and enhancing part consistency. This capability is particularly critical in prototyping applications where design validation, fit, and function must be precisely replicated in real-world conditions.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring dimensional stability across both one-off prototypes and low-volume production runs. We work with a wide range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), brass, and engineering plastics such as PEEK and Delrin. Each material is processed using optimized cutting strategies to maintain structural integrity and surface quality.

Quality control is integrated at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with sub-micron resolution, providing full traceability and compliance with ISO 10360 standards. Our inspection protocols include first-article inspection reports (FAIR), dimensional reports, and material certifications upon request. This metrology-backed approach ensures that every prototype meets or exceeds client specifications.

In addition to hardware, our engineering team leverages advanced CAM software to simulate toolpaths and detect potential collisions before machining begins. This digital validation process minimizes waste, accelerates turnaround, and enhances repeatability—key advantages when iterating through multiple prototype versions.

The following table outlines the standard tolerances we achieve across various feature types using our 5-axis CNC and inspection systems:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, Micrometers |

| Hole Diameter | ±0.05 mm | ±0.0125 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.05 mm | ±0.025 mm | CMM |

| Flatness | 0.05 mm | 0.01 mm | CMM, Surface Plate |

| Perpendicularity | 0.05 mm | 0.02 mm | CMM, Dial Indicator |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Surface Roughness Tester |

These tolerances are consistently maintained across diverse component sizes, from miniature medical components to larger aerospace housings. At Wuxi Lead Precision Machinery, our combination of advanced CNC technology, precision metrology, and engineering expertise ensures that every prototype is a true representation of final production quality—delivering confidence in design validation and performance testing.

Material & Finish Options

Material Selection for Precision CNC Prototyping in Georgia

Material choice fundamentally impacts the performance, manufacturability, and cost of CNC prototypes. For Georgia-based engineering teams developing aerospace components, medical devices, or industrial machinery, selecting the optimal alloy and finish is critical for validating designs under real-world conditions. Wuxi Lead Precision Machinery leverages extensive experience machining demanding materials to ensure your Georgia prototype meets exact functional requirements while accelerating time-to-market.

Aluminum 6061-T6 remains the premier choice for structural prototypes requiring an exceptional strength-to-weight ratio and excellent machinability. Its inherent corrosion resistance and weldability make it ideal for aerospace brackets, drone frames, and fluid handling systems common in Georgia’s growing defense and manufacturing sectors. While softer than steel, its thermal conductivity facilitates efficient heat dissipation in electronics enclosures. Steel 304 stainless steel is indispensable for applications demanding superior strength, hardness, and resistance to harsh environments or sterilization. Medical instrument housings, food processing equipment, and high-wear fixtures prototyped in 304 leverage its non-magnetic properties and robust corrosion resistance, though machining requires optimized toolpaths and rigid setups to manage work hardening. Titanium Grade 5 (Ti-6Al-4V) is the benchmark for high-stress, weight-critical applications where extreme strength, fatigue resistance, and biocompatibility are non-negotiable. Georgia aerospace innovators rely on titanium for landing gear components and engine parts, while medical device developers use it for surgical implants; however, its low thermal conductivity and chemical reactivity necessitate specialized tooling, controlled feeds/speeds, and strict contamination protocols during machining.

Surface finishing, particularly anodizing, significantly enhances aluminum prototype functionality and aesthetics. Type II (Sulfuric Acid) anodizing provides a durable, decorative oxide layer with excellent dye absorption for color-coding or branding, suitable for non-critical structural parts. For Georgia clients requiring maximum wear and corrosion resistance in demanding applications, Type III (Hardcoat) anodizing delivers a much thicker, harder ceramic-like surface. This finish is essential for hydraulic components, marine hardware, or any part subject to abrasion or severe environmental exposure, though dimensional tolerances must be meticulously accounted for during the process.

Wuxi Lead Precision Machinery provides Georgia engineers with precise material data and process expertise to select the optimal combination. Our CNC prototyping services utilize advanced multi-axis machining centers and stringent quality control, ensuring materials perform as predicted in your final application. We manage the complexities of titanium machining and anodizing integration, delivering prototypes that accurately reflect production intent for confident design validation.

| Material | Tensile Strength (MPa) | Machinability Rating | Common Georgia Prototype Applications |

|---|---|---|---|

| Aluminum 6061-T6 | 310 | Excellent | Aerospace brackets, drone frames, enclosures |

| Steel 304 | 515 | Good | Medical instruments, food processing parts |

| Titanium Grade 5 | 900 | Fair | Aerospace components, surgical implants |

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept to CAD

The foundation of any successful CNC prototyping and production initiative begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we collaborate closely with clients in Georgia and across North America to translate conceptual ideas into detailed 3D CAD models. Our engineering team employs advanced design validation techniques, including finite element analysis (FEA) and geometric dimensioning & tolerancing (GD&T), ensuring that every component meets functional, material, and environmental requirements before any material is cut. This phase also includes manufacturability analysis (DFM), where we optimize part geometry for CNC machining efficiency, minimizing waste and cycle time while maximizing structural integrity. All designs are reviewed and approved digitally using secure cloud-based platforms, enabling seamless collaboration across time zones.

Prototyping: Validating Performance with Zero Defects

Once the design is finalized, we transition into the prototyping stage—where precision becomes tangible. Utilizing state-of-the-art 3-, 4-, and 5-axis CNC machining centers, we fabricate initial prototype batches with tight tolerances as low as ±0.005 mm. These prototypes are not merely visual models; they are fully functional parts, machined from the actual production-grade materials specified by the client, including aluminum alloys, stainless steel, titanium, and engineering plastics. Each prototype undergoes rigorous in-process and post-process inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Our zero-defect philosophy is enforced through real-time quality monitoring and non-conformance tracking, ensuring every prototype meets or exceeds performance benchmarks. Clients in Georgia receive comprehensive inspection reports and sample parts within 7–10 days, enabling rapid validation and design iteration if necessary.

Mass Production: Scalable Excellence with Consistent Quality

Upon prototype approval, Wuxi Lead seamlessly scales into high-volume production without compromising precision or consistency. Our automated production lines, integrated with IoT-enabled machine monitoring systems, ensure process stability across thousands of parts. We implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols to maintain dimensional accuracy and detect deviations before they propagate. All finished components undergo 100% visual inspection and batch sampling for metrological verification. With a proven track record in serving aerospace, medical, and industrial automation sectors, we guarantee on-time delivery and full traceability—from raw material certification to final packaging.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Standard Materials | Aluminum 6061, 7075; Stainless Steel 303, 304, 316; Titanium Grade 5; Brass; Engineering Plastics (PEEK, Delrin) |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Surface Finish | Ra 0.8 µm standard; down to Ra 0.2 µm with polishing |

| Machining Capabilities | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; Swiss machining |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9100D (aerospace compliant) |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days, scalable |

From design to delivery, Wuxi Lead Precision Machinery ensures that every CNC prototype and production run meets the highest standards of precision, reliability, and repeatability—empowering Georgia-based manufacturers with globally competitive, defect-free components.

Why Choose Wuxi Lead Precision

Elevate Your Georgia Prototyping Projects with Global Precision Engineering

Georgia’s advanced manufacturing sector demands rapid, flawless CNC prototyping to maintain competitive advantage in aerospace, medical, and defense industries. Local workshops often face capacity constraints or lack the multi-axis capabilities required for complex geometries, leading to project delays and compromised quality. Wuxi Lead Precision Machinery bridges this gap with ISO 9001-certified production directly from our Wuxi facility, engineered to meet stringent U.S. technical standards while leveraging China’s cost efficiency. Our streamlined workflow integrates seamlessly with Georgia-based engineering teams, ensuring your prototypes arrive within 10–15 business days—without sacrificing micron-level accuracy.

We specialize in turning intricate 3D models into functional prototypes using aerospace-grade materials, including titanium Ti-6Al-4V, Inconel 718, and medical-grade PEEK. Our 5-axis milling and Swiss-type turning centers achieve tolerances down to ±0.005 mm, validated through real-time SPC monitoring and CMM inspection reports provided with every shipment. Unlike regional vendors limited to 3-axis machining, we eliminate secondary operations through single-setup complexity, reducing your time-to-test by up to 40%. The table below summarizes our technical capabilities for critical prototyping applications:

| Specification | Capability | Industry Standard Compliance |

|---|---|---|

| Positional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Roughness | Ra 0.4 μm (machined) | ASME B46.1 |

| Max Work Envelope | 1,200 x 800 x 750 mm | Custom fixtures available |

| Material Range | Aluminum 7075-T6, Stainless 17-4PH, Titanium, Composites | AMS, ASTM, ISO |

| Lead Time (Prototype) | 10–15 business days | Includes FAI documentation |

This precision translates to reduced non-recurring engineering costs and accelerated validation cycles for Georgia innovators. Our engineers collaborate directly with your R&D team via encrypted CAD portals, providing DFM feedback within 24 hours to preempt manufacturability issues. With dedicated U.S. time zone support (8:00 AM–5:00 PM EST) and bonded logistics partners, we ensure seamless integration into your supply chain—no import expertise required on your end.

Initiate your next prototyping project with confidence. Email [email protected] with your 3D model and technical requirements to receive a validated quote within 4 business hours. Include project deadlines and material specifications for priority scheduling. Our technical sales team will coordinate a virtual kickoff within 24 hours of RFQ submission, assigning a dedicated project engineer to oversee your prototype from CAD review to certified delivery. For urgent Georgia-based defense or medical projects requiring ITAR-compliant handling, reference “GEORGIA RAPID RESPONSE” in your subject line to activate expedited processing. Partner with Lead Precision to transform design intent into high-fidelity reality—on time, to spec, and within budget.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.