Technical Contents

Engineering Guide: Cnc Machine Image

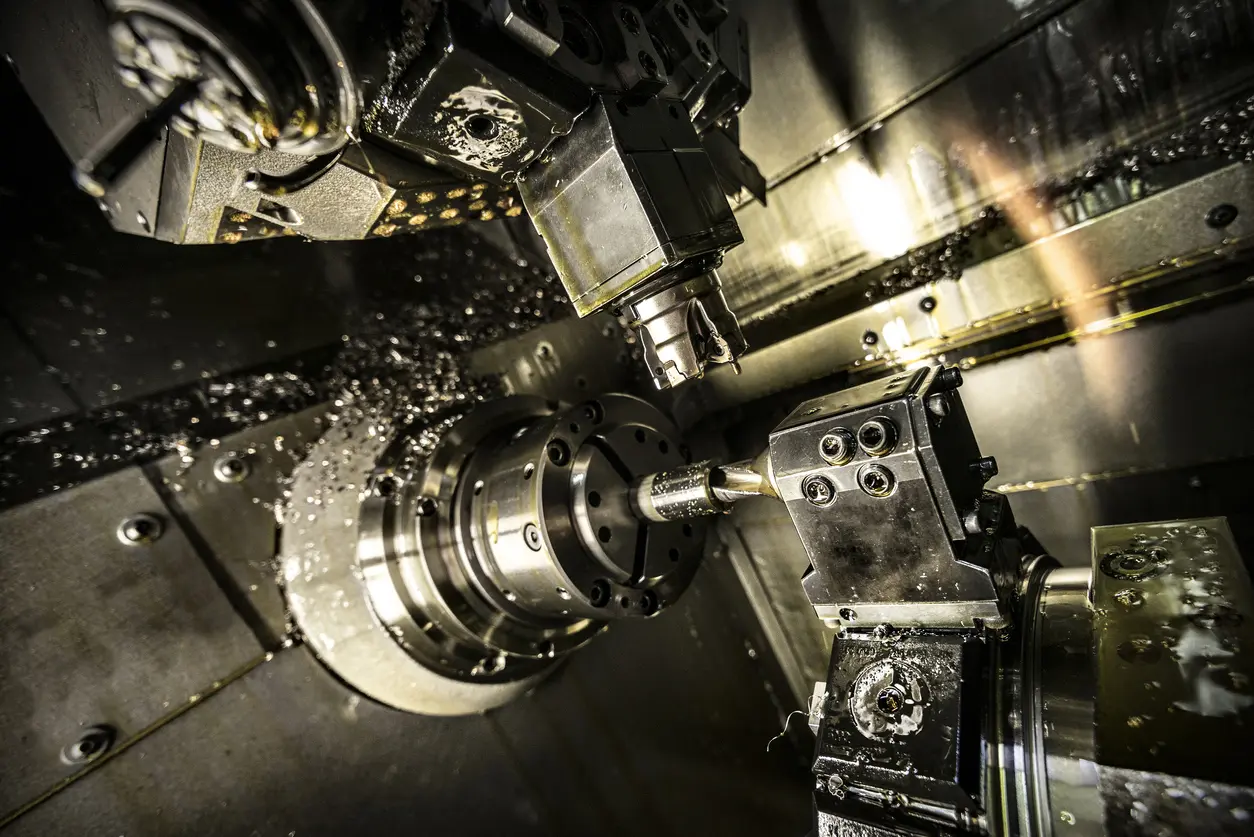

Engineering Insight: The Critical Meaning of CNC Machine Image in Precision Manufacturing

In precision CNC machining, the term machine image transcends visual representation. It defines the machine’s intrinsic ability to maintain dimensional accuracy, geometric fidelity, and repeatability across extended production cycles under real-world operational conditions. This concept is the cornerstone of high-integrity manufacturing, where deviations measured in microns directly impact component functionality, assembly integrity, and end-product performance. At Wuxi Lead Precision Machinery, we treat machine image not as a theoretical specification but as a measurable engineering outcome validated through rigorous process control and environmental compensation systems.

A compromised machine image manifests as thermal drift, positional inaccuracy, or surface finish inconsistencies—errors that cascade into costly scrap, rework, and delayed time-to-market. For aerospace turbine blades or medical implants, where tolerances routinely fall below ±0.003 mm, such deviations are non-negotiable. Our engineering philosophy centers on proactive mitigation: granite base structures for vibration damping, real-time thermal compensation algorithms, and laser-calibrated linear encoders ensure the machine’s true operational image aligns with design intent across 24/7 production. This precision foundation enabled us to deliver mission-critical components for Olympic biomechanics sensors and military-grade navigation systems, where zero-failure operation is mandated.

The following specifications exemplify our approach to achieving and sustaining machine image integrity in production environments:

| Parameter | Specification | Industry Standard | Lead Precision Implementation |

|---|---|---|---|

| Positioning Accuracy | ISO 230-2: ≤ ±0.005 mm | ≤ ±0.010 mm | ≤ ±0.002 mm (laser verified) |

| Repeatability | ISO 230-2: ≤ 0.003 mm | ≤ 0.006 mm | ≤ 0.001 mm |

| Thermal Drift Compensation | NMTBA: ≤ 0.010 mm/m | ≤ 0.020 mm/m | ≤ 0.003 mm/m (active cooling) |

| Surface Finish (Ra) | Aerospace: ≤ 0.4 µm | ≤ 0.8 µm | ≤ 0.2 µm (5-axis optimized) |

These metrics are not isolated laboratory achievements. They reflect our integrated workflow: from finite element analysis (FEA) of machine rigidity during design to in-process probing and statistical process control (SPC) during manufacturing. For instance, our military contracts demanded 100% traceability for components operating in extreme temperatures. By embedding thermal stability protocols directly into the CNC control loop, we achieved consistent image fidelity where competitors faced recalibration downtime. Similarly, Olympic project requirements for micro-precision athletic sensors necessitated sub-micron repeatability—achieved through our proprietary spindle thermal management system.

Ultimately, machine image defines your production capability ceiling. At Wuxi Lead, we engineer this capability into every system, ensuring your most demanding projects transition from blueprint to flawless reality. Partner with us to transform precision from a specification into your competitive advantage.

Precision Specs & Tolerances

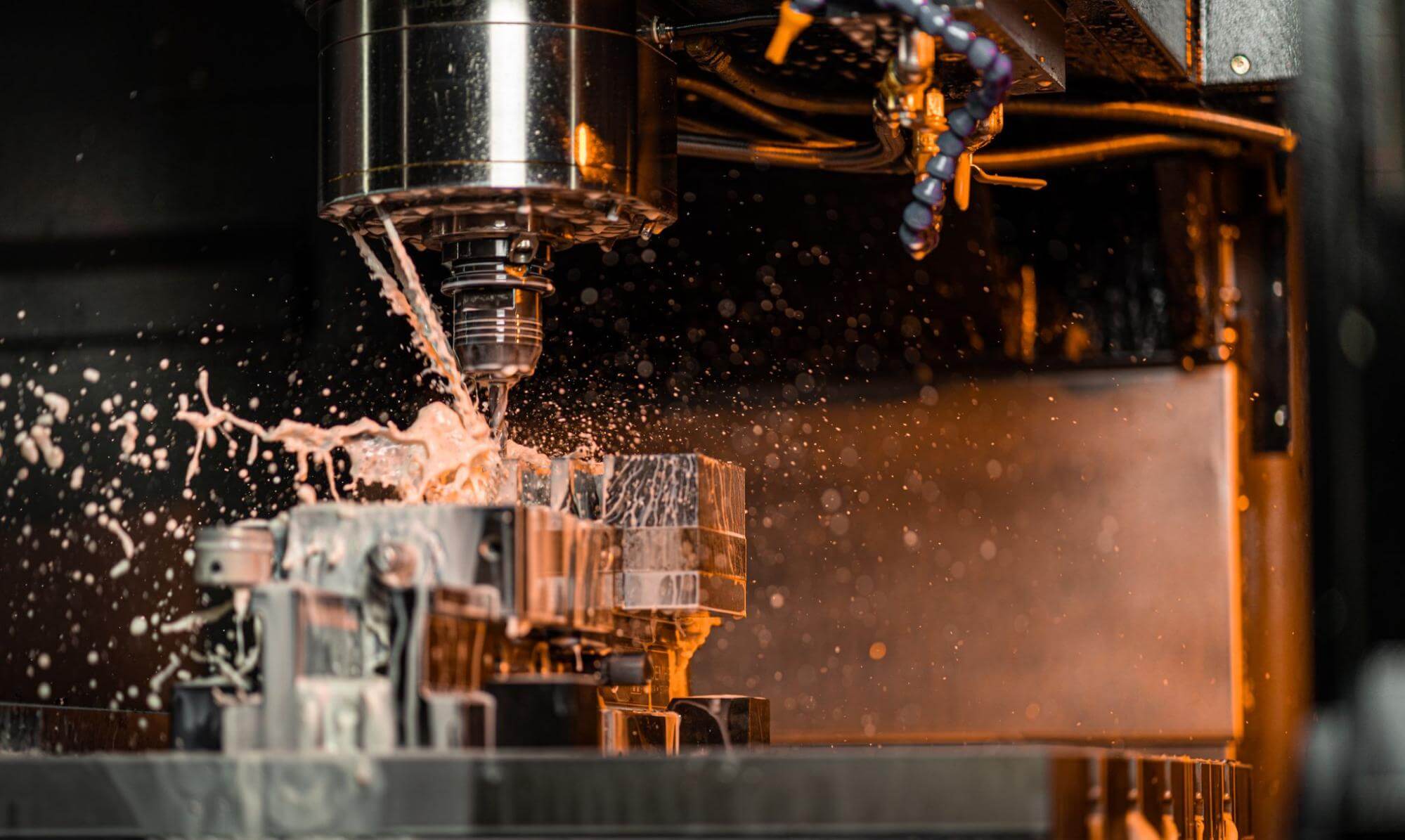

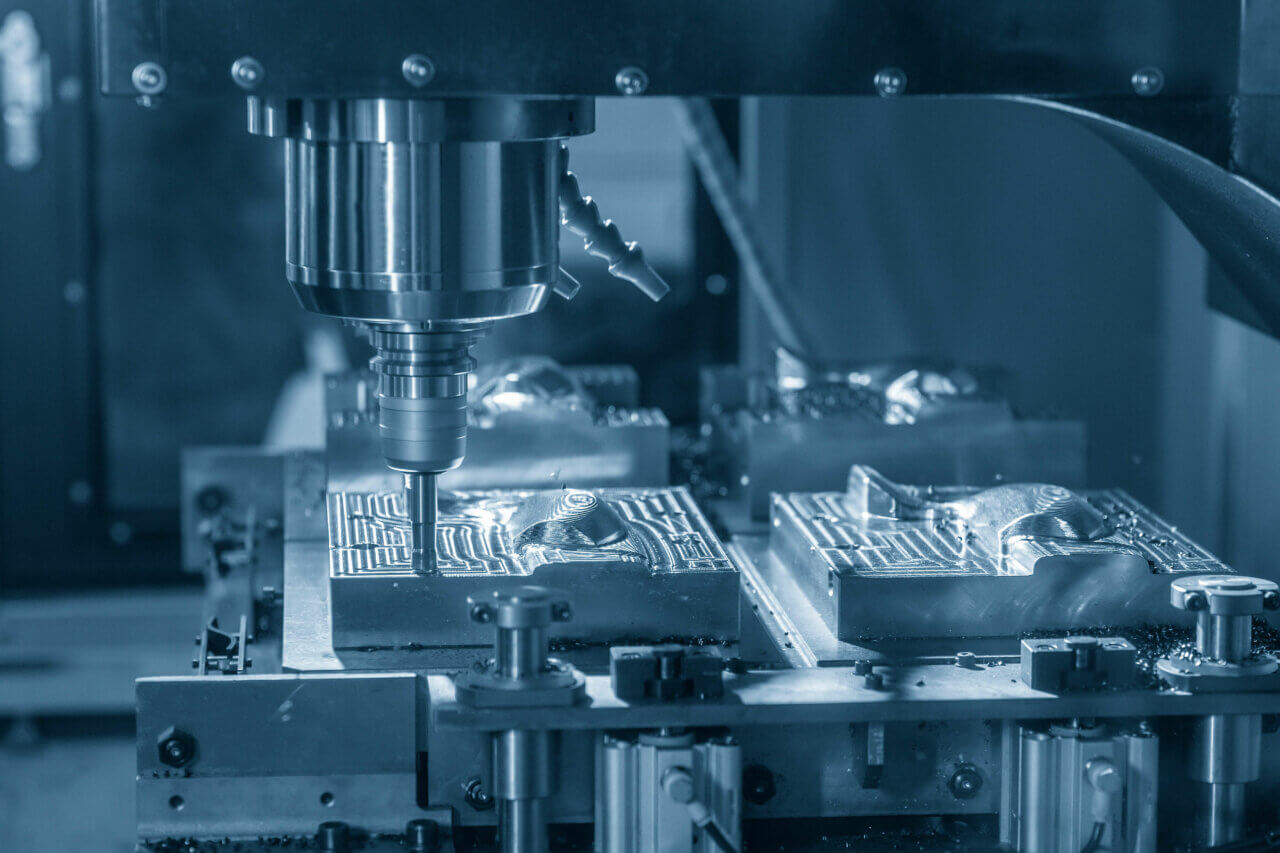

Wuxi Lead Precision Machinery stands at the forefront of advanced CNC manufacturing, delivering precision-engineered components for aerospace, medical, automotive, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across five planes, significantly reducing setup time and enhancing part consistency. This capability supports the production of intricate contours, deep cavities, and multi-faceted components that are common in high-performance applications.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure optimal performance and process stability. All equipment is maintained to OEM standards and operated by certified CNC programmers and machinists with over a decade of industry experience. We utilize advanced CAM software to generate optimized toolpaths, minimizing cycle times while maintaining micron-level precision. Materials processed include aluminum alloys, stainless steel, titanium, Inconel, and engineering plastics, all machined under controlled environmental conditions to prevent thermal distortion.

Quality is integral to our manufacturing philosophy. Every component undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our QC process includes first-article inspection, in-process checks, and final validation, with detailed inspection reports provided upon request. The CMM system is calibrated annually to ISO 17025 standards and integrated with PC-DMIS software for high-accuracy 3D measurement and data analysis.

The following table outlines the standard tolerances we consistently achieve across various dimensional and geometric features:

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | CMM, Micrometers |

| Hole Diameter | ±0.008 mm | ±0.003 mm | Air Gauges, CMM |

| Position Tolerance | ±0.010 mm | ±0.005 mm | CMM, GD&T Analysis |

| Flatness | 0.005 mm | 0.002 mm | CMM, Surface Plate |

| Surface Roughness | Ra 0.8 µm | Ra 0.2 µm | Profilometer |

| Angular Features | ±0.005° | ±0.002° | CMM, Optical Comparator |

These tolerances reflect our commitment to repeatability and quality assurance across production runs, from prototypes to high-volume orders. With integrated design-for-manufacturability (DFM) reviews and rapid turnaround times, Wuxi Lead Precision Machinery provides a seamless transition from concept to certified, high-integrity components. Our technical capabilities are not only defined by machinery but by the expertise and discipline applied at every stage of production.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting the optimal material is critical for balancing performance, cost, and manufacturability in precision CNC applications. At Wuxi Lead Precision Machinery, we prioritize materials that deliver dimensional stability, strength-to-weight ratios, and compatibility with stringent finishing processes. Below, we detail key considerations for aluminum, steel, and titanium—three pillars of high-end industrial manufacturing—alongside essential insights on anodizing finishes.

Aluminum alloys, particularly 6061-T6, dominate aerospace and automotive sectors due to their lightweight nature and excellent machinability. With high thermal conductivity and corrosion resistance, aluminum minimizes tool wear during CNC milling while enabling complex geometries. However, its lower hardness necessitates careful fixturing to prevent deformation under high cutting forces. Steel alloys like 4140 offer superior tensile strength and wear resistance for tooling, shafts, and structural components. Though harder to machine than aluminum, its durability in high-stress environments justifies the extended cycle times. Titanium 6Al-4V excels in medical implants and defense applications where extreme strength-to-weight ratios and biocompatibility are non-negotiable. Its low thermal conductivity requires specialized tooling and slower feeds to avoid work hardening, but the payoff is unmatched performance in corrosive or high-temperature settings.

Anodizing transforms aluminum surfaces, enhancing corrosion resistance and wear properties while allowing color customization. Type II (sulfuric acid) anodizing provides standard protection for consumer electronics, whereas Type III (hardcoat) delivers mil-spec thicknesses for military or aerospace use. Note that anodizing adds dimensional tolerance considerations—typically 0.001–0.002 inches per surface—requiring pre-finishing adjustments. Steel and titanium cannot be anodized; instead, we recommend passivation for stainless steel or plasma electrolytic oxidation for titanium to achieve similar performance gains.

Material specifications must align with your application’s mechanical and environmental demands. The table below summarizes critical properties for common CNC materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Key Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.70 | 9/10 | Enclosures, brackets |

| Steel 4140 | 655 | 7.85 | 6/10 | Gears, hydraulic parts |

| Titanium 6Al-4V | 900 | 4.43 | 4/10 | Aircraft components, implants |

At Wuxi Lead, our engineering team collaborates with clients to optimize material selection against your functional requirements and production constraints. We leverage advanced CNC capabilities—including 5-axis milling and Swiss turning—to maximize yield across all three material families while maintaining ±0.005mm tolerances. Partner with us to transform material science into precision-engineered reality.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for uncompromising precision, consistency, and zero-defect outcomes. Rooted in advanced CNC machining technologies and stringent quality control, our workflow integrates three core phases: Design, Prototyping, and Mass Production. Each phase is synchronized to ensure seamless transition from concept to final component, meeting the exacting standards of aerospace, medical, automotive, and industrial clients worldwide.

Design begins with a collaborative assessment of the client’s engineering specifications, including 3D CAD models, material requirements, geometric tolerances, and functional intent. Our engineering team performs comprehensive Design for Manufacturability (DFM) analysis, identifying potential challenges in tool access, surface finish, and dimensional stability. Finite Element Analysis (FEA) and CNC simulation software are employed to validate performance under operational loads and thermal conditions. This proactive approach eliminates design flaws before physical production, reducing risk and accelerating time-to-market.

Prototyping follows design validation, where initial components are machined using high-precision 5-axis CNC centers. These prototypes are subjected to full metrological inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning. Material certifications, hardness testing, and surface roughness analysis ensure alignment with technical specifications. Client feedback is incorporated at this stage, and iterative refinements are made if necessary. The prototype phase not only verifies design integrity but also certifies the production process itself, including fixturing, tool paths, and inspection routines.

Mass Production is initiated only after formal client approval of the prototype and documented process validation. Our automated CNC cells operate under real-time monitoring, with tool wear sensors, in-process gauging, and environmental controls ensuring repeatability. Each component undergoes 100% critical dimension inspection, with statistical process control (SPC) data logged for traceability. Barcoding and digital work orders track every part through machining, deburring, cleaning, and final inspection. Non-conforming material is quarantined immediately, and root cause analysis is conducted to prevent recurrence—ensuring a true zero-defect output.

Throughout all phases, Wuxi Lead maintains full compliance with ISO 9001:2015 and IATF 16949 standards. Our facility leverages cutting-edge equipment and a culture of continuous improvement to deliver components that meet micron-level accuracy and superior surface quality.

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC Machining Centers |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Plastics (PEEK, Delrin) |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Tolerances Achieved | ±0.01 mm (standard), down to ±0.003 mm (tight tolerance) |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS compliant |

This structured, technology-driven process ensures that every component produced at Wuxi Lead Precision Machinery meets the highest benchmarks in precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing with Lead Precision

When microns determine market leadership, your CNC partner must deliver uncompromising accuracy and operational resilience. At Wuxi Lead Precision Machinery, we engineer solutions for aerospace, medical, and semiconductor manufacturers where tolerances below ±0.002mm are non-negotiable. Our ISO 9001-certified facility in Wuxi integrates German spindle technology with proprietary thermal compensation algorithms, ensuring repeatability across 24/7 production cycles. Unlike commodity machine builders, we co-engineer workflows around your most demanding components—transforming design constraints into competitive advantages through adaptive process validation.

Our five-axis machining centers achieve industry-leading stability through rigid Meehanite cast iron frames and FANUC i-Series controls. Below are critical specifications defining our production capability for high-mix, low-volume applications:

| Specification | Performance Metric | Verification Method |

|---|---|---|

| Positioning Accuracy | ±0.0015 mm | Laser Interferometer (ISO 230-2) |

| Repeatability | ±0.0008 mm | 30-Part Statistical Study |

| Spindle Runout | ≤0.0005 mm | Dial Indicator (DIN 4003) |

| Thermal Drift Control | <2μm/°C (0-40°C ambient) | Real-time RTD Monitoring |

| Surface Finish | Ra 0.2 μm (aluminum) | Profilometer (ISO 4287) |

This precision is sustained through our closed-loop quality ecosystem. Every machine undergoes 72-hour burn-in testing with simulated G-code loads, while our in-house metrology lab—equipped with Zeiss CONTURA CMMs—validates first-article inspections against your CAD models. We eliminate supply chain volatility via dual-sourced critical components (spindles from IBAG and SKF) and maintain 30% spare capacity for urgent prototyping. For medical device clients, our cleanroom-compatible machining cells comply with ISO 13485 documentation protocols, reducing FDA submission risks.

Partnering with Lead Precision means accessing engineering collaboration, not transactional machining. Our technical team dissects your geometric dimensioning challenges during the quoting phase, proposing fixture optimizations that reduce cycle times by 18–33% on average. When your project demands hardened steel milling at 60 HRC or thin-wall aluminum structures under 0.5mm thickness, our process scientists develop custom toolpaths validated through modal analysis—preventing chatter before metal meets cutter.

Initiate your precision partnership today. Email [email protected] with your component drawings and tolerance requirements. Our applications engineers will respond within 4 business hours with a feasibility assessment, including recommended machine configuration and timeline. For urgent RFQs, reference project code LP-CTA2024 to expedite technical review. Let us prove why global innovators trust Wuxi Lead Precision Machinery to turn impossible tolerances into production reality. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.