Technical Contents

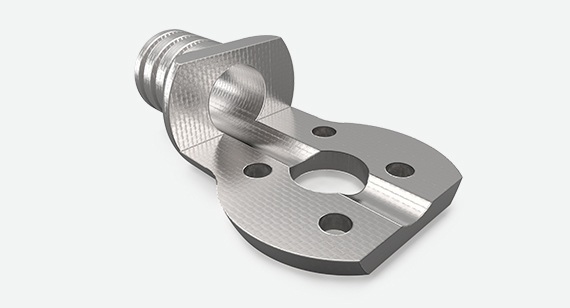

Engineering Guide: Metal Fusion Parts

Engineering Insight: The Critical Role of Precision in Metal Fusion Parts

In the realm of advanced manufacturing, metal fusion parts represent the convergence of material science, thermal dynamics, and micron-level engineering. These components, typically produced through processes such as laser powder bed fusion or electron beam melting, are increasingly deployed in mission-critical applications where failure is not an option. At Wuxi Lead Precision Machinery, we recognize that the true value of metal fusion lies not just in its ability to create complex geometries, but in its capacity to deliver repeatable, high-precision outputs under stringent tolerances.

Precision in metal fusion parts begins with design integrity and extends through every phase of production—from raw material selection to post-processing and metrology. Even minor deviations in layer thickness, thermal gradient control, or build orientation can result in residual stress, warping, or compromised mechanical properties. This is especially critical in sectors such as aerospace, defense, and high-performance sports equipment, where component reliability directly impacts safety and performance.

Our experience at Wuxi Lead has been shaped by projects demanding the highest standards of quality and consistency. We have supported engineering teams developing components for Olympic-level athletic equipment, where marginal gains in weight reduction and structural efficiency can determine podium outcomes. Similarly, our work with defense contractors has involved producing lightweight, high-strength fusion parts for unmanned systems and precision-guided platforms—applications where environmental resilience and dimensional accuracy are non-negotiable.

What sets Wuxi Lead apart is our integrated approach to process control. We utilize in-situ monitoring systems, real-time thermal imaging, and closed-loop feedback mechanisms to ensure each build adheres to exact specifications. Our post-processing protocols—including stress relieving, hot isostatic pressing (HIP), and precision machining—are designed to eliminate variability and achieve final tolerances down to ±0.02 mm.

Material selection further underscores our engineering rigor. We work with a range of high-performance alloys, including Ti-6Al-4V, Inconel 718, and AlSi10Mg, each chosen for specific mechanical and thermal characteristics. Every material batch undergoes full certification and traceability, ensuring compliance with international standards such as ISO 9001 and AS9100.

The following table outlines typical specifications achievable at Wuxi Lead for custom metal fusion parts:

| Parameter | Typical Capability | Precision Range |

|---|---|---|

| Layer Thickness | 20–60 μm | Adjustable per application |

| Build Volume | Up to 500 x 500 x 500 mm | Custom configurations |

| Dimensional Tolerance | ±0.02 mm (post-machining) | ±0.1 mm (as-built) |

| Surface Roughness (Ra) | 8–15 μm (as-built) | <3 μm (polished) |

| Materials | Ti-6Al-4V, Inconel 718, AlSi10Mg, 316L, Maraging Steel | Full material traceability |

| Post-Processing Options | HIP, CNC machining, polishing, coating | Application-specific |

At Wuxi Lead Precision Machinery, precision is not a target—it is the foundation. Our expertise in metal fusion reflects a commitment to engineering excellence, proven in applications where performance cannot be compromised.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Fusion Part Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal fusion part production, leveraging advanced subtractive technologies to achieve the geometric complexity and dimensional integrity demanded by aerospace, medical, and energy sector applications. Our core competency lies in transforming fused metal components—whether from DMLS, EBM, or binder jetting processes—into fully finished, mission-critical parts meeting the most stringent industry specifications. This requires capabilities far beyond basic machining, focusing on precision, material science understanding, and rigorous validation.

Our foundation is a dedicated fleet of state-of-the-art 5-axis CNC machining centers, including DMG MORI and Hermle platforms. These systems enable simultaneous 5-axis interpolation, essential for accessing intricate internal features and complex contours inherent in as-fused geometries without requiring multiple setups. This capability minimizes cumulative error, preserves critical datum relationships, and significantly reduces lead times compared to 3-axis alternatives. We specialize in machining challenging fusion alloys such as Inconel 718, Ti-6Al-4V, CoCr, and aluminum variants, utilizing optimized cutting strategies, high-precision tooling, and advanced coolant delivery to manage heat, prevent part distortion, and achieve superior surface finishes directly from the machine. Complex internal channels, thin walls, and organic shapes are routinely produced with exceptional fidelity to the original CAD model.

Quality assurance is non-negotiable and integrated at every stage. All critical features undergo comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMMs), including Hexagon GLOBAL S and Brown & Sharpe systems with sub-micron accuracy. Our certified metrology technicians perform full 3D dimensional analysis against CAD nominal data, generating detailed inspection reports (including GD&T verification) traceable to NIST standards. This data-driven approach ensures every part meets or exceeds customer specifications before shipment, providing absolute confidence in dimensional conformance and functional performance. Statistical process control (SPC) methodologies are applied to monitor capability and drive continuous improvement.

Achieving the tight tolerances required for high-performance fusion parts demands this integrated approach of advanced machining and metrology. The following table details our standard achievable tolerance ranges under optimal conditions for common features on machined fusion components:

| Feature Type | Standard Tolerance Range | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Up to 100 mm; tighter possible per spec |

| Geometric (GD&T) | ±0.010 mm (±0.0004″) | Position, Profile, Runout common |

| Hole Diameter | +0.005 / -0.000 mm | Reamed/ground holes; size dependent |

| Surface Finish (Ra) | 0.8 µm (32 µin) | Machined; finer achievable via polish |

| Angular Features | ±0.005° | Critical for assembly interfaces |

Wuxi Lead’s technical capability transcends mere equipment ownership. It represents a holistic system—combining elite 5-axis CNC machining, NIST-traceable CMM validation, deep material expertise, and rigorous process control—specifically engineered to overcome the unique challenges of finishing metal fusion parts. We transform near-net shapes into precision components ready for immediate, reliable integration into your most demanding assemblies, ensuring performance and longevity in the field. Partner with us for fusion part manufacturing where tolerance adherence is absolute and quality is quantifiable.

Material & Finish Options

Material Selection for High-Performance Metal Fusion Parts

Selecting the right material is critical in custom metal manufacturing, especially for precision components used in aerospace, automotive, medical, and industrial applications. At Wuxi Lead Precision Machinery, we specialize in metal fusion processes such as CNC machining and precision casting, enabling us to work with high-grade aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties, thermal characteristics, and corrosion resistance, making them suitable for specific operational environments.

Aluminum alloys, particularly 6061 and 7075, are widely used for their excellent strength-to-weight ratio and machinability. These alloys are ideal for applications requiring lightweight components without sacrificing structural integrity. Aluminum also exhibits good thermal conductivity and electrical performance, making it a preferred choice in heat sinks, enclosures, and aerospace frames. When combined with anodizing, aluminum gains enhanced surface hardness and corrosion resistance. Type II and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior wear resistance for high-stress environments.

Steel, especially stainless steel grades 304 and 316, delivers high tensile strength, durability, and excellent resistance to oxidation and chemical exposure. Grade 316, with its molybdenum content, provides superior performance in marine and corrosive environments. Steel components are often selected for structural parts, fasteners, and equipment housings where long-term reliability and load-bearing capacity are essential. While steel does not anodize like aluminum, it can be finished through passivation, polishing, or coating processes to enhance surface protection and aesthetic quality.

Titanium, primarily Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosion. It is frequently used in aerospace, medical implants, and high-performance automotive systems. Titanium’s biocompatibility and non-magnetic properties make it indispensable in medical and marine applications. Although more challenging to machine due to its low thermal conductivity and high reactivity at elevated temperatures, titanium delivers unmatched performance in critical applications where failure is not an option.

Below is a comparison of key mechanical and physical properties for commonly used materials in metal fusion part production.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 276 | Moderate to High | Anodizing (Type II/III) |

| Aluminum 7075 | 2.81 | 572 | 503 | Moderate | Hard Anodizing |

| Stainless Steel 304 | 8.0 | 515 | 205 | High | Passivation, Polishing |

| Stainless Steel 316 | 8.0 | 580 | 290 | Very High | Electropolishing |

| Titanium Ti-6Al-4V | 4.43 | 950 | 880 | Excellent | Bead Blasting, Coating |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application demands, environmental exposure, and lifecycle requirements. Our engineering team ensures optimal performance by matching material properties with functional design, delivering precision metal fusion parts that meet global quality standards.

Manufacturing Process & QC

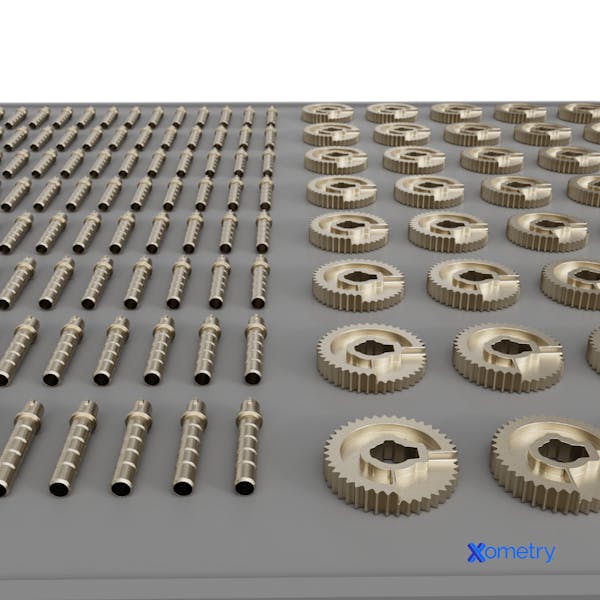

Precision Metal Fusion Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our metal fusion process for critical aerospace, medical, and energy components is engineered for absolute reliability. We execute a rigorously controlled sequence—Design, Prototyping, Mass Production—integrated with real-time quality assurance to achieve Zero Defects. This methodology, refined over decades of high-stakes manufacturing, ensures every component meets exacting performance and safety standards.

Design Phase: Engineering Flaw Prevention

Our process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team scrutinizes CAD models for thermal dynamics, residual stress points, and material behavior under fusion conditions. We identify potential microstructural weaknesses or geometric instabilities before material is cut, preventing 80% of common production defects. Material selection is validated against ASTM/AMS standards, with explicit thermal treatment protocols defined. This phase culminates in a digitally signed-off blueprint, locking in parameters that guarantee first-time-right production.

Prototyping: Metrology-Grade Validation

Prototyping is not a simple trial run; it is a full-scale validation of the thermal and mechanical process chain. Using the exact production-grade EOS M 400-4 or TRUMPF TruPrint 5000 systems, we build functional prototypes under serial-production conditions. Every layer is monitored via in-situ melt pool analysis and thermal imaging. Post-build, components undergo CT scanning for internal porosity, CMM verification of critical datums, and destructive testing per customer-specified protocols. Only when prototypes consistently achieve target mechanical properties and dimensional stability do we release the process for mass production.

Mass Production: Closed-Loop Zero Defects Execution

Serial production leverages our integrated quality ecosystem. Each build job runs with real-time monitoring of oxygen levels, layer adherence, and beam focus—automatically halting production if parameters drift beyond ±0.5% tolerance. Every component receives a unique digital passport tracking material lot, machine calibration status, and operator certifications. Final inspection employs automated optical comparators and 100% coordinate measuring machine (CMM) validation against the original CAD model. Statistical process control (SPC) data is analyzed hourly, enabling predictive adjustments that maintain CpK > 2.0. This closed-loop system ensures zero non-conforming parts reach the customer.

Critical Process Specifications

The following table defines our standard capabilities for metal fusion production:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Tolerance | ±0.025 mm to ±0.1 mm | ISO 2768-m, AS9100 |

| Surface Finish | Ra 1.6 µm (as-built) to Ra 0.4 µm (post-processed) | ASTM E3, ISO 1302 |

| Materials | Ti-6Al-4V, Inconel 718, 17-4 PH SS, AlSi10Mg, CoCr | AMS, ASTM, ISO 21563 |

| Build Volume | Up to Ø 400 x 400 mm | Machine-specific |

| Certifications | Material Certs, Heat Treat Reports, NDT Reports, Full Traceability | Nadcap, EN 9100, ISO 9001 |

Wuxi Lead’s fusion process transforms design intent into mission-critical hardware through uncompromising process discipline. By embedding quality at every phase—from thermal simulation to final inspection—we deliver metal fusion parts where failure is not an option. Partner with us for production that meets the highest standards of precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Fusion Parts

At Wuxi Lead Precision Machinery, we don’t just manufacture metal fusion components—we engineer performance. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering high-precision metal fusion parts tailored to the exacting demands of aerospace, energy, medical, and advanced industrial applications. When you partner with us, you gain access to a fully integrated production ecosystem backed by over 15 years of engineering excellence and a relentless commitment to quality.

Our advanced metal fusion capabilities leverage state-of-the-art laser powder bed fusion (LPBF) and direct energy deposition (DED) technologies, enabling us to produce complex geometries, internal channels, and lightweight lattice structures that traditional manufacturing methods simply cannot achieve. Every part is built to meet stringent international standards, with full traceability, material certification, and in-process inspection to ensure dimensional accuracy and mechanical integrity.

What sets Lead Precision apart is our end-to-end engineering collaboration. From initial concept review and design for additive manufacturing (DfAM) optimization to post-processing, heat treatment, and precision machining, we manage every stage under one roof. This vertical integration ensures faster turnaround, tighter tolerances, and consistent quality control across production runs—whether you require a single prototype or high-volume batches.

We work with a wide range of high-performance alloys, including titanium (Ti6Al4V), Inconel 718 and 625, stainless steels (316L, 17-4 PH), aluminum (AlSi10Mg), and tool steels (Maraging Steel, H13). Our materials are rigorously tested and processed in controlled, inert environments to eliminate contamination and ensure repeatable microstructural properties.

Our facility is ISO 9001:2015 certified, equipped with in-house metrology labs featuring coordinate measuring machines (CMM), optical scanning, and metallographic analysis. We provide comprehensive inspection reports, including first article inspection (FAI) and PPAP documentation, ensuring full compliance with your technical and regulatory requirements.

For mission-critical components where performance, reliability, and precision matter, Wuxi Lead Precision Machinery is the partner you can trust. We combine cutting-edge technology with deep engineering insight to turn your most demanding designs into high-performance reality.

| Specification | Capability |

|---|---|

| Build Envelope (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20 – 60 μm |

| Positional Accuracy | ±0.1 mm |

| Surface Roughness (as-built) | Ra 10 – 15 μm (can be polished to Ra <1 μm) |

| Supported Materials | Ti6Al4V, Inconel 718/625, 316L, 17-4 PH, AlSi10Mg, Maraging Steel |

| Post-Processing | HIP, heat treatment, stress relieving, CNC machining, polishing, coating |

| Quality Standards | ISO 9001:2015, full material traceability, NDT options |

Contact us today to discuss your next project. Send your CAD files and technical requirements to [email protected] and let our engineering team provide a rapid assessment, DfAM feedback, and competitive quotation. At Lead Precision, we don’t just build parts—we build partnerships that drive innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.