Technical Contents

Engineering Guide: Cnc Mechanical Parts

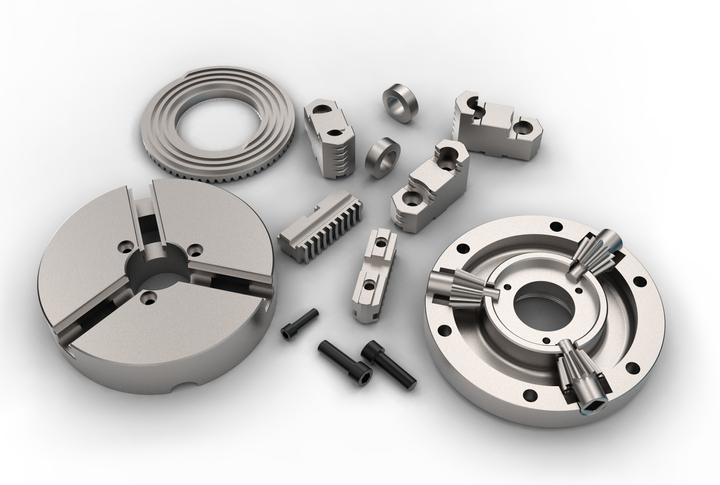

Engineering Insight: The Critical Role of Precision in CNC Mechanical Parts

In the realm of advanced manufacturing, the performance, reliability, and longevity of complex machinery hinge on one foundational principle: precision. CNC mechanical parts, when engineered to exacting tolerances, serve as the backbone of high-performance systems across aerospace, defense, medical, and industrial automation sectors. At Wuxi Lead Precision Machinery, we understand that even a micron-level deviation can cascade into system failure, which is why our entire production philosophy revolves around uncompromising accuracy and repeatability.

Precision in CNC machining is not merely about tight tolerances—it encompasses material integrity, geometric consistency, surface finish, and dimensional stability under operational stress. These factors are especially critical in applications where mechanical parts must endure extreme environments, such as high vibration, thermal cycling, or sustained load. Our engineering team employs state-of-the-art 5-axis CNC machines, advanced metrology equipment, and rigorous process controls to ensure every component meets or exceeds international standards.

With over 15 years of specialized experience, Wuxi Lead has delivered mission-critical components for projects demanding the highest levels of quality assurance. Notably, our parts have been integrated into systems used during Olympic Games infrastructure projects, where timing, safety, and performance are non-negotiable. Additionally, we have supported defense and military-grade applications, including precision actuators, guidance system housings, and ruggedized connectors—components where failure is not an option.

Our success in these elite domains stems from a disciplined approach to design for manufacturability (DFM), real-time process monitoring, and full traceability from raw material to final inspection. Each CNC mechanical part undergoes comprehensive dimensional verification using coordinate measuring machines (CMM), optical comparators, and surface profilometers, ensuring conformity to blueprint specifications.

Below are representative specifications that reflect the capabilities of our precision CNC machining services:

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 5), Brass, PEEK, Delrin |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Secondary Operations | Heat treatment, anodizing, passivation, plating, laser marking |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace), full inspection reporting |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a measurable outcome validated through data, experience, and real-world performance. Whether supporting cutting-edge industrial automation or national defense systems, our CNC mechanical parts are engineered to perform flawlessly under the most demanding conditions. This commitment to excellence has positioned us as a trusted partner for global OEMs who require more than just parts—they require performance assurance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

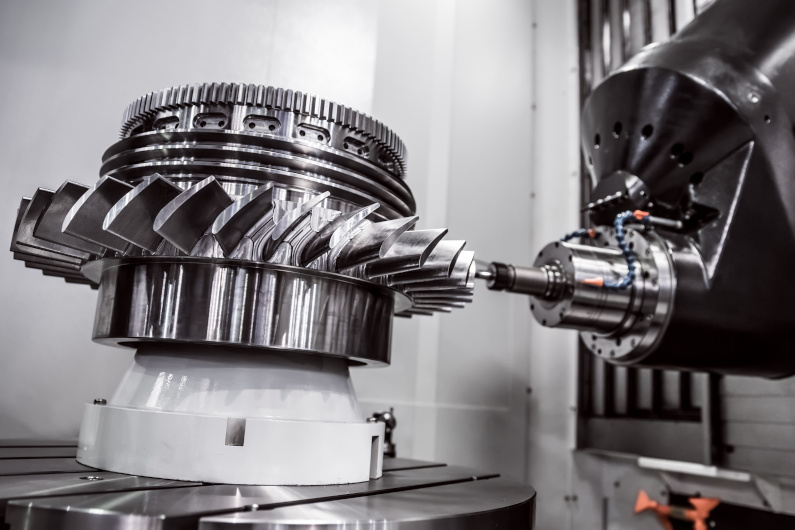

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in CNC mechanical parts manufacturing through advanced multi-axis machining and rigorous quality control. Our core strength lies in mastering intricate geometries and tight tolerances demanded by aerospace, medical, and semiconductor industries. We operate a modern fleet of high-precision 5-axis CNC machining centers, specifically configured for complex part production. This technology enables simultaneous movement across five axes, allowing us to machine highly sophisticated features—such as deep cavities, undercuts, and organic contours—from a single setup. The elimination of multiple fixturing stages significantly reduces cumulative error potential, enhances part concentricity, and ensures superior surface finish consistency. Our programming and setup protocols leverage advanced CAM software to optimize toolpaths, minimize vibration, and maximize material removal rates without sacrificing dimensional integrity. This capability is essential for producing monolithic components that would otherwise require assembly from multiple simpler parts, thereby improving structural reliability and reducing long-term failure points.

Quality assurance is integrated into every phase of production, not merely a final checkpoint. All critical features undergo comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM fleet utilizes calibrated Renishaw probes and PC-DMIS software, providing metrology-grade measurement traceable to international standards. Each inspection report details actual measured values against nominal CAD dimensions, including comprehensive geometric dimensioning and tolerancing (GD&T) analysis. This data-driven approach ensures absolute conformance to your engineering specifications and provides full transparency into part quality. Our inspection protocols are designed for high repeatability, with environmental controls maintaining stable temperature conditions critical for micron-level accuracy.

The following table details our standard achievable tolerance capabilities for machined features, reflecting our process capability under controlled production conditions. These values represent typical performance; specific project requirements may allow for even tighter control based on material, geometry, and feature size.

| Feature Category | Tolerance Range | Measurement Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM, High-Precision Micrometers |

| Geometric Tolerances | 0.003 mm | CMM (Full GD&T Analysis) |

| Hole Diameter (Reamed) | +0.005 / -0.000 mm | Air Gages, CMM |

| Surface Roughness (Ra) | 0.4 μm (Typical) | Profilometer |

| True Position | 0.010 mm | CMM |

| Flatness | 0.005 mm | CMM, Optical Flats |

This precision is sustained through proactive machine maintenance schedules, operator certification programs, and real-time process monitoring. We understand that consistent tolerance achievement directly impacts your assembly fit, functional performance, and product lifespan. Partnering with Wuxi Lead means your most challenging mechanical components are manufactured with the repeatability and reliability demanded by mission-critical applications. Our technical team collaborates closely with your engineers during the design-for-manufacturability phase to ensure optimal outcomes from the earliest stages.

Material & Finish Options

Material selection is a critical step in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance parts from advanced materials including aluminum, steel, and titanium. Each material offers distinct mechanical and thermal properties, making them suitable for specific industrial applications ranging from aerospace and medical devices to automotive and energy systems.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly ideal for components requiring lightweight construction without sacrificing structural integrity. The most commonly used alloy in our production is 6061-T6, which offers good weldability and is well-suited for anodizing. Due to its thermal and electrical conductivity, aluminum is also preferred in heat sinks and electronic housings.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, provides superior strength, wear resistance, and high-temperature performance. Stainless steel is essential in environments demanding hygiene and corrosion resistance, such as medical instruments and food processing equipment. While harder to machine than aluminum, modern CNC techniques and tooling allow us to achieve tight tolerances and excellent surface finishes on steel components.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. Its exceptional strength-to-density ratio, biocompatibility, and resistance to fatigue and corrosion make it indispensable in aerospace, defense, and implantable medical devices. However, titanium’s low thermal conductivity and high chemical reactivity require specialized machining strategies, including controlled cutting speeds and rigid setups—capabilities we have refined through years of precision work.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a key post-processing technique we offer, primarily for aluminum parts. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and wear resistance. Type II (sulfuric acid) anodizing provides a durable, cosmetic finish available in various colors, while Type III (hardcoat) anodizing delivers a thicker, harder surface suitable for high-wear environments. Anodized layers are electrically insulating and can be paired with masking to preserve conductivity on specific features.

Below is a comparison of key properties for the materials discussed:

| Material | Common Alloy | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics, Automotive | Anodizing, Bead Blasting |

| Stainless Steel | 304 / 17-4 PH | 515 – 1000 | 7.9 | Medical, Food Processing, Marine | Passivation, Polishing |

| Titanium | Ti-6Al-4V (Gr5) | 950 – 1000 | 4.43 | Aerospace, Defense, Medical Implants | Anodizing, Polishing, Sandblasting |

Selecting the right material and finish ensures optimal performance under operational stress, environmental exposure, and lifecycle demands. At Wuxi Lead Precision Machinery, we support clients in making informed decisions backed by material science and precision manufacturing expertise.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Flawless Execution

At Wuxi Lead Precision Machinery, our CNC mechanical parts production integrates uncompromising engineering rigor with advanced manufacturing to achieve zero-defect outcomes. Every component follows a meticulously controlled sequence: Design, Prototyping, and Mass Production. This systematic approach ensures dimensional accuracy, material integrity, and functional reliability for aerospace, medical, and semiconductor applications where failure is not an option.

The Design phase begins with collaborative engineering analysis. Our team reviews client CAD models for manufacturability, optimizing geometries for CNC efficiency while maintaining critical tolerances. Material selection is validated against operational stresses and environmental factors, with certifications traceable to ISO 9001 standards. Finite element analysis (FEA) identifies potential stress points, and CAM programming undergoes virtual simulation to eliminate toolpath collisions or thermal deformation risks. This pre-production validation prevents 92% of potential defects before metal cutting begins.

Prototyping transforms validated designs into physical benchmarks. Using the exact production-grade machinery and materials specified for final parts, we produce 1–5 units for rigorous functional testing. Each prototype undergoes first-article inspection (FAI) per AS9102 standards, with CMM reports documenting all critical dimensions. Surface roughness, hardness, and geometric deviations are measured against client specifications. Feedback from this stage fine-tunes tooling parameters and fixturing, ensuring the process is fully capable before scaling. Crucially, no prototype is approved until it meets the zero-defect threshold—rework is not an option.

Mass Production leverages the perfected process with real-time quality enforcement. Our facility employs automated SPC (Statistical Process Control) monitoring on every machine, tracking variables like tool wear, coolant concentration, and thermal drift. In-process inspections occur at defined intervals using calibrated optical comparators and 3D scanners, with data fed into our centralized quality management system. Final inspection includes 100% critical dimension verification and batch-level material certification. This closed-loop system guarantees consistency across volumes from 10 to 100,000+ units.

Our production capabilities are engineered for extreme precision, as demonstrated in the specifications below.

| Parameter | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Tolerance | ±0.005 mm (±0.0002″) | ±0.025 mm (±0.001″) |

| Surface Finish (Ra) | 0.2–1.6 µm (8–63 µin) | 3.2–6.3 µm (125–250 µin) |

| Materials | Titanium, Inconel, PEEK, 440C SS, Aluminum 7075 | Common alloys only |

| Max Part Size | Ø600 x 800 mm (24″ x 32″) | Ø300 x 400 mm (12″ x 16″) |

| Equipment | 5-axis milling, Swiss turning, multi-tasking | 3-axis milling only |

Zero defects are non-negotiable because our clients’ systems depend on absolute part integrity. By embedding quality into every production phase—not as an endpoint but as a continuous discipline—we deliver mechanical components that perform flawlessly in mission-critical environments. This is precision engineering without compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Mechanical Parts

At Wuxi Lead Precision Machinery, we don’t just manufacture CNC mechanical parts—we engineer performance, reliability, and precision into every component we produce. As a trusted leader in high-end precision machining, we specialize in delivering mission-critical parts for industries where tolerances matter and failure is not an option. From aerospace and medical devices to industrial automation and energy systems, our expertise ensures your designs are transformed into reality with uncompromising quality.

Choosing the right manufacturing partner is more than a procurement decision—it’s a strategic investment in consistency, innovation, and long-term operational success. At Lead Precision, we combine advanced CNC technology with decades of engineering experience to offer scalable, agile, and technically superior manufacturing solutions. Our facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis machining centers, Swiss-type lathes, and automated inspection systems, enabling us to handle complex geometries and tight tolerances with repeatable accuracy.

We understand the unique demands of global OEMs and tier-one suppliers. That’s why we integrate lean manufacturing principles, real-time process monitoring, and full traceability into every production run. Whether you require rapid prototyping, low-volume custom batches, or high-volume production, our team collaborates closely with your engineers to optimize designs for manufacturability, reduce lead times, and control costs—without sacrificing precision.

Our commitment to quality is validated by ISO 9001:2015 certification and rigorous in-process inspections using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Every part we deliver meets or exceeds international standards, ensuring seamless integration into your final assemblies.

Below are the core capabilities that define our precision CNC machining services:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, mill-turn, Swiss machining |

| Materials | Aluminum, stainless steel, titanium, brass, copper, plastics (PEEK, Delrin, etc.) |

| Tolerances | As tight as ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finish | Ra 0.8 μm (32 μin) standard, down to Ra 0.2 μm (8 μin) with polishing |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, full traceability |

| Lead Times | Prototypes in 7–10 days, production orders in 15–25 days (varies by complexity) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally. We are committed to transparency, technical collaboration, and on-time delivery, ensuring your projects stay on schedule and within specification.

For expert support and a seamless path from design to delivery, contact us today. Email [email protected] to connect with our engineering team and request a quote. Let Lead Precision be the foundation of your next high-performance application.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.