Technical Contents

Engineering Guide: Prototype Makers

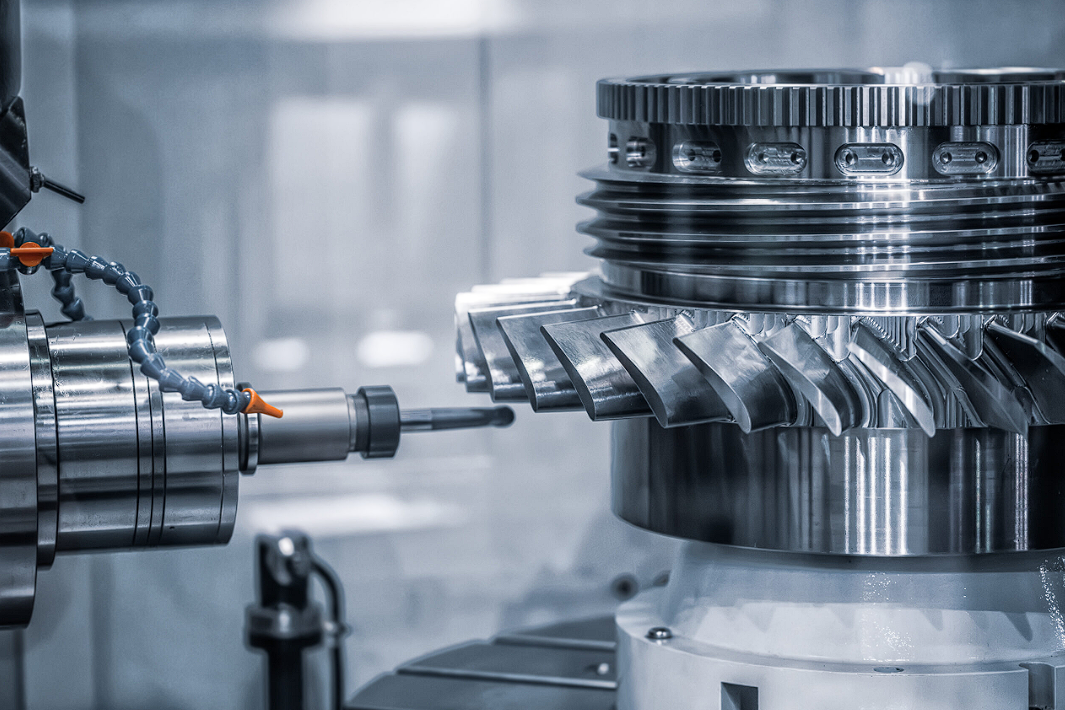

Engineering Insight: The Critical Role of Precision in Prototype Development

In the world of custom metal manufacturing, precision is not merely a performance metric—it is the foundation of innovation, reliability, and functional integrity. For prototype makers engaged in advanced product development, especially within aerospace, defense, medical, and high-performance industrial sectors, the margin for error is effectively zero. At Wuxi Lead Precision Machinery, we understand that a prototype is more than a preliminary model; it is the first physical manifestation of engineering intent, and its accuracy directly influences downstream design validation, testing, and eventual production scalability.

Precision in prototyping ensures dimensional consistency, material integrity, and functional compatibility with mating components. Even deviations measured in microns can lead to catastrophic performance failures during stress testing or system integration. This level of accuracy demands not only advanced CNC machining capabilities but also deep engineering expertise in material behavior, thermal stability, and geometric tolerancing. Our facility in Wuxi integrates multi-axis CNC milling, turning, and grinding systems with real-time in-process metrology, enabling us to maintain tolerances as tight as ±0.002 mm across complex geometries.

Our experience in delivering mission-critical components for Olympic-standard equipment and military-grade systems has reinforced the non-negotiable nature of precision. These projects required adherence to ISO 2768 and AS9100 standards, full traceability of materials, and rigorous first-article inspection reports (FAIRs). For instance, components developed for precision timing systems in Olympic sports equipment demanded not only micron-level accuracy but also repeatable performance under dynamic loads—conditions that mirror real-world operational stress.

What sets Wuxi Lead apart is our engineering-first approach. We collaborate with prototype makers at the design phase, offering design for manufacturability (DFM) feedback that anticipates machining challenges, minimizes waste, and accelerates time-to-test. This proactive engagement ensures that prototypes are not only dimensionally precise but also optimized for performance and scalability.

Our commitment to precision is validated through continuous investment in technology and talent. Our team includes seasoned CNC programmers and mechanical engineers with over 15 years of experience in high-mix, low-volume production environments. Combined with our state-of-the-art facility, this expertise allows us to handle exotic alloys such as Inconel, titanium, and beryllium copper with the same confidence as standard aluminum or stainless steel.

Below are representative capabilities that support our precision prototyping services:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Copper Alloys |

| Surface Finish | As fine as Ra 0.2 µm |

| Quality Standards | ISO 9001, ISO 2768, AS9100 (compliant) |

| Inspection Equipment | CMM, Optical Comparators, Surface Roughness Testers |

For prototype makers pushing the boundaries of innovation, partnering with a manufacturer that treats precision as a core engineering principle is essential. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we ensure that every prototype performs as intended, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Prototype Excellence

At Wuxi Lead Precision Machinery, we understand that prototype makers demand exceptional technical capability paired with unwavering reliability. Our dedicated focus on high-integrity custom metal manufacturing for the prototyping sector is built upon advanced infrastructure and rigorous process control. We bridge the gap between complex design concepts and functional, test-ready metal components, ensuring your innovation moves swiftly from CAD model to physical validation.

Our core strength lies in our advanced 5-axis CNC machining centers. These sophisticated systems enable the production of highly intricate geometries in a single setup, eliminating cumulative errors inherent in multi-setup processes. This capability is critical for prototypes featuring organic shapes, deep cavities, undercuts, or complex compound angles common in aerospace, medical, and advanced industrial applications. Utilizing continuous multi-axis motion, we achieve superior surface finishes and dimensional accuracy on challenging materials like titanium, Inconel, aluminum alloys, and hardened steels, directly translating your digital model into a precise physical representation. Reduced fixture requirements accelerate iteration cycles, providing sub-72 hour lead times for many critical prototype stages without compromising quality.

Precision is non-negotiable in prototyping, where form, fit, and function must be validated accurately. Every component undergoes our stringent, multi-stage quality control protocol. This begins with comprehensive in-process checks using high-resolution probing systems integrated directly into our CNC machines. The definitive validation step, however, is full First Article Inspection (FAI) and batch verification performed on state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, programmed using DMIS standards, provide traceable, micron-level measurement data against your original CAD model and engineering specifications. This meticulous inspection process guarantees that every dimension, geometric characteristic, and critical feature meets the exacting requirements necessary for reliable prototype testing and subsequent production validation.

The table below details our standard and achievable tolerance capabilities, reflecting the precision inherent in our machining and inspection systems for prototype production:

| Feature Type | Standard Capability | Tight Capability (Requires Specific Process Control) |

|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Angular Dimensions | ±0.1° | ±0.05° |

| Geometric (GD&T) | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) |

| Hole Position | ±0.025 mm (±0.001″) | ±0.010 mm (±0.0004″) |

This commitment to technical excellence – combining cutting-edge 5-axis machining with rigorous CMM-based quality assurance – ensures your prototypes are not merely representations but true functional benchmarks. Wuxi Lead delivers the dimensional integrity and material performance confidence essential for successful design validation and seamless transition into production. Partner with us for prototypes built to exacting standards, where precision engineering meets rapid innovation cycles.

Material & Finish Options

Material Selection for High-Precision Metal Prototypes

Selecting the appropriate material is a critical step in the development of high-performance metal prototypes. At Wuxi Lead Precision Machinery, we support prototype makers with precision manufacturing in aluminum, steel, and titanium—each offering distinct mechanical properties, weight characteristics, and environmental resistance. Understanding these differences enables engineers and designers to optimize for strength, manufacturability, and cost without compromising performance.

Aluminum is widely favored in prototyping due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is a common choice for structural and aerospace applications, offering good weldability and corrosion resistance. It is particularly suitable for prototypes intended for lightweight, high-efficiency systems such as drones, automotive components, and heat sinks. When enhanced surface durability is required, aluminum responds exceptionally well to anodizing—a process that creates a hard, wear-resistant oxide layer while allowing for color customization.

Steel, particularly alloy and stainless variants, delivers superior strength, rigidity, and wear resistance. 304 and 316 stainless steels are ideal for prototypes exposed to harsh or corrosive environments, including medical devices and marine equipment. For high-stress mechanical parts, 4140 or 1045 carbon steel provides excellent fatigue resistance and can be heat-treated to meet stringent performance criteria. While heavier than aluminum, steel remains a cornerstone in industrial prototyping where structural integrity is non-negotiable.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. With a strength-to-density ratio exceeding that of most steels and exceptional resistance to corrosion and high temperatures, titanium is commonly used in aerospace, defense, and medical implant prototypes. Its biocompatibility and fatigue strength make it indispensable in critical environments. However, titanium’s abrasiveness and low thermal conductivity present machining challenges that demand advanced tooling and expertise—capabilities Wuxi Lead Precision Machinery has refined over years of high-tolerance production.

Surface finishes further define a prototype’s functionality and appearance. Anodizing is the most prevalent finish for aluminum, enhancing surface hardness and corrosion resistance. Type II anodizing offers moderate protection with aesthetic versatility, while Type III (hardcoat) delivers industrial-grade durability. For steel, alternatives such as passivation, powder coating, or plating are typically used, while titanium often benefits from bead blasting or chemical passivation to maintain its inert surface.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Key Applications | Recommended Finish |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 6061-T6, 7075-T6 | Aerospace, Automotive, Electronics | Anodizing (Type II/III) |

| Steel | 7.8 | 500–1200 | 304, 316, 4140 | Industrial, Medical, Machinery | Passivation, Powder Coating |

| Titanium | 4.5 | 900–1000 | Ti-6Al-4V (Grade 5) | Aerospace, Defense, Medical | Bead Blasting, Passivation |

Material and finish selection should align with the prototype’s operational environment, lifecycle requirements, and functional testing goals. At Wuxi Lead, we collaborate closely with engineers to ensure optimal material pairing and surface treatment for every custom project.

Manufacturing Process & QC

Engineering Flawless Metal Components: From Concept to Volume Production

At Wuxi Lead Precision Machinery, we understand that transitioning a metal component from initial concept to flawless mass production demands an integrated, rigorously controlled process. Our Zero Defects philosophy is not an aspiration; it is systematically engineered into every phase, eliminating costly iterations and delays for prototype makers scaling to volume. The journey begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners with your designers before metal is cut, scrutinizing CAD models for geometric feasibility, material suitability, and inherent manufacturability risks. We identify potential stress points, tolerance stack-ups, or inefficient tool paths that could compromise quality or yield during production. This proactive DFM stage prevents approximately 70% of defects that typically emerge later, saving significant time and cost.

The Prototyping phase is far more than a simple sample run; it is critical process validation. Utilizing the same high-precision CNC equipment (mills, lathes, grinders) and materials destined for mass production, we manufacture functional prototypes under controlled conditions. Every machining parameter, fixture setup, and inspection protocol mirrors the planned production environment. Dimensional verification against CAD data is exhaustive, employing CMMs, optical comparators, and surface roughness testers. Material properties and functional performance are validated. Crucially, the data generated – cutting forces, thermal behavior, tool wear rates – is meticulously analyzed. This empirical evidence confirms process capability and provides the baseline for Statistical Process Control (SPC) in volume manufacturing, ensuring the prototype truly represents what the production line will deliver.

Mass Production leverages the validated process blueprint. Our automated CNC cells operate under real-time SPC monitoring, with key parameters continuously tracked against the prototype-established control limits. Automated in-process gauging and 100% critical feature inspection protocols are standard. Material traceability from certified mills is maintained throughout. The transition from prototype to production is seamless because the process is proven; there is no “re-learning” how to make the part correctly. This integrated approach, where design insights inform prototyping and prototyping data defines production, is the cornerstone of our Zero Defects commitment. It transforms scaling from a risk-laden leap into a predictable, high-yield operation.

Wuxi Lead Precision Machinery Production Capabilities

| Parameter | Prototype Capability | Mass Production Capability | Key Technology Used |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm (0.0002″) | ±0.002 mm (0.00008″) | 5-Axis CNC, CMM Validation |

| Surface Finish | Ra 0.4 µm (16 µin) | Ra 0.2 µm (8 µin) | Precision Grinding, Polishing |

| Materials | Aluminum, Steel, Titanium, Inconel, Brass | Full range including exotic alloys | Certified Mill Traceability |

| Max Part Size | 1000 x 800 x 600 mm | 2000 x 1500 x 1000 mm | Multi-Tasking Machining Centers |

| Process Control | Full DFM, 100% Inspection | SPC, Automated In-Process Gauging | MES Integration, Real-Time Monitoring |

Zero Defects is engineered, not inspected. By unifying Design, Prototyping, and Mass Production under a single, data-driven quality framework, Wuxi Lead ensures your metal components perform perfectly from the first prototype to the millionth part. This is the precision manufacturing standard for demanding prototype makers.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that prototype makers operate in a world where precision, speed, and reliability define success. Whether you’re developing next-generation aerospace components, medical devices, or advanced industrial systems, your prototypes demand more than just metal shaping—they require engineering integrity, process consistency, and technical partnership. That’s where we come in.

As a leading custom metal manufacturing provider based in Wuxi, China, we specialize in delivering high-precision CNC machining, sheet metal fabrication, and assembly services tailored specifically to the needs of prototype developers and engineering firms worldwide. Our facility is equipped with state-of-the-art machinery and staffed by a team of experienced engineers and machinists who treat every prototype not as a one-off job, but as the foundation of a future-ready product.

What sets us apart is our commitment to seamless collaboration. From initial design review to final delivery, we work alongside your team to optimize manufacturability, reduce lead times, and ensure every component meets exact specifications. Our ISO 9001-certified processes guarantee consistent quality, while our agile production model supports low-volume prototyping as efficiently as mid-volume production runs.

We recognize that prototype makers often face tight deadlines and evolving design requirements. That’s why we offer rapid turnaround times without compromising precision. With advanced 5-axis CNC machining, laser cutting, precision bending, and automated welding capabilities, we handle complex geometries and tight tolerances with ease. Our in-house finishing and assembly services further streamline your supply chain, reducing the need for multiple vendors.

Below are key capabilities that support prototype development and low-volume production:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis, ±0.005 mm tolerance |

| CNC Turning | Diameter up to 300 mm, ±0.01 mm tolerance |

| Laser Cutting | Carbon steel up to 25 mm, stainless steel up to 20 mm |

| Sheet Metal Bending | Up to 2000 mm length, precision press brakes |

| Welding | TIG, MIG, spot welding; certified welders |

| Surface Finishes | Anodizing, powder coating, passivation, plating |

| Materials | Aluminum, stainless steel, carbon steel, brass, copper, titanium |

| Lead Time | Prototypes: 7–12 days; Production: 15–25 days |

| Quality Standards | ISO 9001:2015, full inspection reports, First Article Inspection (FAI) |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally dedicated to your project’s success. We don’t just produce parts—we help bring innovations to life.

Contact us today at [email protected] to discuss your prototype requirements. Let our precision, expertise, and responsiveness become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.