Technical Contents

Engineering Guide: Moldes De Inyeccion

Engineering Insight: The Critical Role of Precision in Injection Molds

In the realm of custom metal manufacturing, injection molds—commonly referred to as moldes de inyeccion—serve as the backbone of high-volume, repeatable production across industries ranging from automotive and aerospace to medical devices and consumer electronics. At Wuxi Lead Precision Machinery, we recognize that the performance, longevity, and consistency of these molds are directly tied to one fundamental attribute: precision.

Precision in mold design and fabrication is not merely a matter of tight tolerances; it is a comprehensive engineering discipline that encompasses material selection, thermal management, surface finish, alignment, and structural integrity. Even micron-level deviations can result in part defects, increased cycle times, premature wear, or catastrophic mold failure. For mission-critical applications—such as those in defense, aerospace, or Olympic-grade sporting equipment—such inconsistencies are unacceptable.

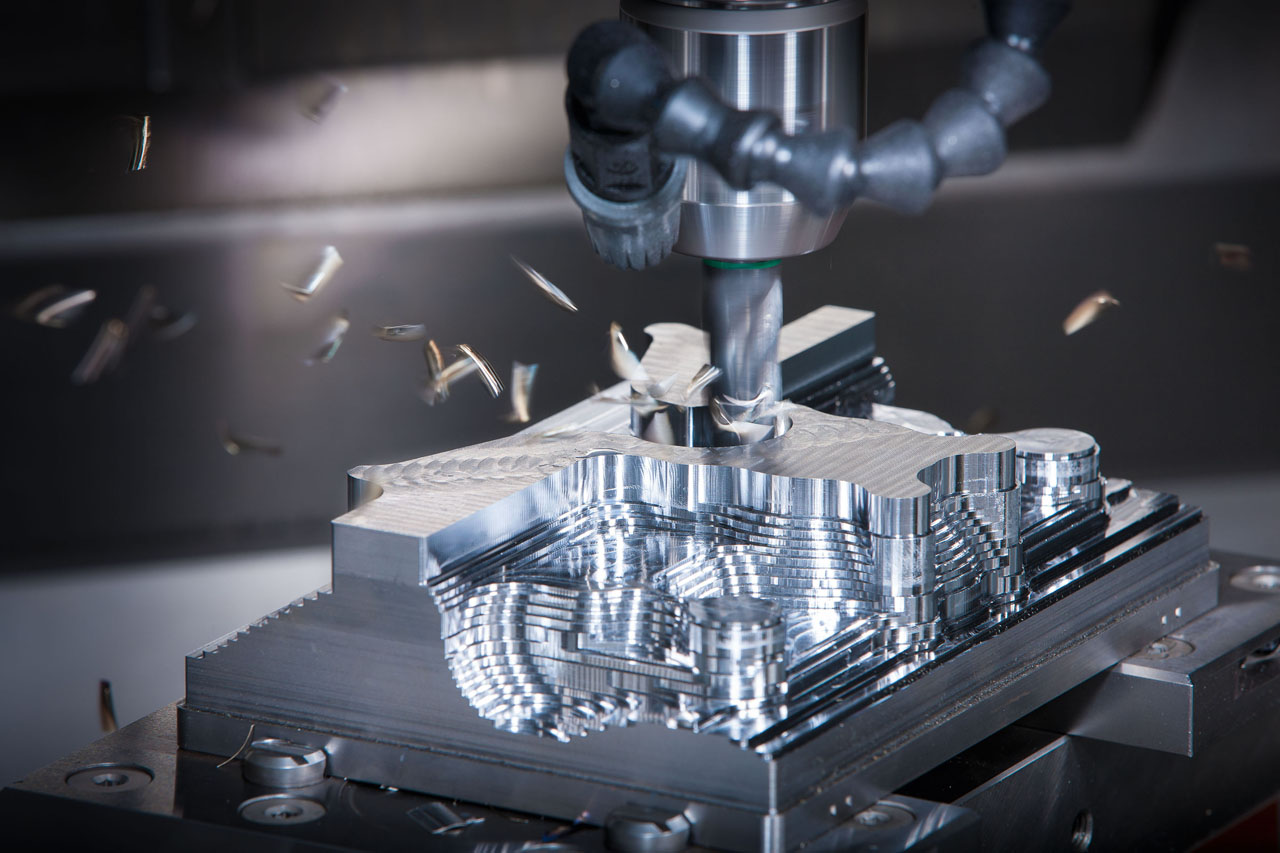

Wuxi Lead Precision Machinery has cultivated a reputation for excellence through decades of specialized work in high-precision mold manufacturing. Our expertise has been validated through participation in projects demanding the highest levels of reliability, including components used in Olympic training systems and precision parts for military-grade equipment. These applications require molds that perform under extreme conditions, with zero margin for error. Our engineering team leverages advanced CNC machining, electrode discharge machining (EDM), and 3D metrology to ensure every cavity, core, and runner system meets exacting specifications.

One of the defining characteristics of our mold production process is the integration of Design for Manufacturing (DFM) principles at the earliest stages. By simulating mold flow, thermal distribution, and stress points prior to fabrication, we preemptively address potential issues such as warping, sink marks, or incomplete filling. This proactive approach not only enhances part quality but also extends mold life and reduces downtime in production environments.

Furthermore, our molds are constructed using premium-grade tool steels and surface treatments—such as nitriding and PVD coatings—to resist wear, corrosion, and thermal fatigue. Each mold undergoes rigorous inspection using coordinate measuring machines (CMM) and laser scanning to verify dimensional accuracy against the original CAD model.

The table below outlines the key precision specifications consistently achieved across our injection mold projects:

| Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Tolerance | ±0.01 mm | ±0.002 mm |

| Surface Finish (Cavity/Core) | Ra 0.2 µm | Ra 0.05 µm |

| Parallelism | ≤ 0.01 mm | ≤ 0.003 mm |

| Mold Life | 500,000 cycles | 1,000,000+ cycles |

| Material Options | P20, H13, S136, 718 | Maraging Steel, Stainless Tool Steel |

| Lead Time (Average) | 4–6 weeks | 6–8 weeks |

At Wuxi Lead Precision Machinery, precision is not an added feature—it is the foundation of every mold we produce. Our proven track record in high-stakes manufacturing environments underscores our ability to deliver injection molds that meet the most stringent global standards. When performance, reliability, and repeatability are non-negotiable, our engineering expertise ensures success.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Injection Molds

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing for high-performance injection molds. Our technical foundation integrates advanced multi-axis machining with rigorous metrology, ensuring molds meet the exacting demands of automotive, medical, and electronics applications where dimensional stability and longevity are non-negotiable. We specialize in transforming complex geometries into production-ready tooling through a tightly controlled engineering-to-manufacturing workflow.

Our core capability centers on state-of-the-art 5-axis CNC machining centers. These systems enable single-setup machining of intricate mold components—including conformal cooling channels, deep ribs, and undercuts—eliminating cumulative errors from multiple fixtures. High-speed milling with micron-level positioning accuracy ensures superior surface finishes directly off the machine, reducing hand polishing time by up to 40% while maintaining critical draft angles and parting line integrity. Material efficiency is maximized through optimized toolpaths for hardened tool steels like H13 and S136, preserving thermal stability during high-cycle production.

Quality control is embedded at every stage, not merely as a final checkpoint. All critical mold components undergo comprehensive inspection using Zeiss CONTURA CMM systems with 0.5μm volumetric accuracy. Our metrology protocol includes full 3D scanning against CAD nominal data, geometric dimensioning and tolerancing (GD&T) validation per ASME Y14.5 standards, and thermal growth compensation analysis. Each report details actual measurements against specified tolerances, including form deviations, positional accuracy of ejector pins and inserts, and sealing surface flatness—providing clients with full traceability for first-article approval.

The following table details our standard achievable tolerances for critical mold features, validated through our CMM process. These specifications reflect our baseline capability for mold components in hardened tool steels (up to 52 HRC) and are consistently maintained across production runs:

| Feature Category | Capability Description | Standard Tolerance |

|---|---|---|

| Core/Cavity Dimensions | Critical sealing surfaces, part geometry | ±0.005 mm |

| Slider & Lifter Alignment | Motion path parallelism, engagement points | ±0.008 mm |

| Cooling Channel Position | Conformal channel location to cavity | ±0.020 mm |

| Ejector Pin Holes | Diameter, straightness, positional offset | H7 / ±0.010 mm |

| Parting Line Flatness | Mating surfaces across A/B plates | 0.010 mm per 100 mm |

This precision directly translates to reduced trial-and-error cycles during mold commissioning, extended tool life exceeding 1 million cycles, and consistent part quality for your end products. Our engineering team collaborates closely with clients during the design phase to identify tolerance-critical zones, ensuring manufacturability without compromising functional requirements. By combining 5-axis agility with metrology-driven process control, Wuxi Lead provides the dimensional certainty that high-volume injection molding demands—turning complex designs into reliable, high-yield production assets.

Material & Finish Options

Material selection for injection molds is a critical decision that directly impacts mold longevity, production efficiency, surface quality, and overall cost-effectiveness. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance injection molds, leveraging advanced material science and precision engineering to meet the rigorous demands of industries such as automotive, medical devices, and consumer electronics. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal requirements, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype molds and low-to-medium volume production. Their high thermal conductivity enables faster cooling cycles, reducing cycle times and increasing throughput. Aluminum is also easier to machine, allowing for quicker lead times and lower tooling costs. However, its lower hardness and wear resistance make it less suitable for long production runs or abrasive materials. For applications requiring rapid iteration and cost-effective prototyping, aluminum remains an optimal choice.

Steel, especially tool steels like P20, H13, and S136, is the standard for high-volume injection molding. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. P20 is commonly used for molds with moderate corrosion resistance requirements, while H13 excels in applications involving high thermal stress due to its excellent toughness and heat-check resistance. Stainless tool steels such as S136 provide enhanced corrosion resistance, making them ideal for molds exposed to PVC or other corrosive resins. Steel molds typically have a longer service life, often exceeding hundreds of thousands of cycles with proper maintenance.

Titanium and its alloys are less common but offer exceptional strength-to-density ratios and corrosion resistance. While not typically used for full mold bases due to cost and machinability constraints, titanium finds niche applications in mold inserts or components requiring extreme durability and lightweight performance. Its biocompatibility also makes it suitable for medical-grade molding applications.

Surface finishing plays a vital role in mold performance and part quality. Anodizing, particularly hard anodizing, is a key surface treatment for aluminum molds. This electrochemical process increases surface hardness, improves wear resistance, and enhances corrosion protection. Hard anodized layers can reach up to 50–75 µm in thickness with a hardness of 500–700 HV, significantly extending the service life of aluminum molds. Decorative anodizing also allows for aesthetic customization, though it is less relevant in industrial mold applications.

Below is a comparative overview of key material properties relevant to injection mold performance.

| Material | Hardness (HV) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Corrosion Resistance | Best Use Case |

|---|---|---|---|---|---|

| Aluminum 7075 | 150–200 | 130 | 10,000–100,000 | Low to Moderate | Prototypes, low-volume production |

| P20 Steel | 280–320 | 30 | 100,000–500,000 | Moderate | Medium to high-volume production |

| H13 Steel | 450–500 | 35 | 500,000+ | Moderate | High thermal stress applications |

| S136 Steel | 500–520 | 25 | 1M+ | High | Corrosive resin molding |

| Titanium Ti-6Al-4V | 350–400 | 7 | 500,000+ (inserts only) | Very High | Specialized, high-durability inserts |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application-specific requirements, ensuring optimal performance, durability, and return on investment.

Manufacturing Process & QC

Precision Injection Mold Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our custom injection mold production process is engineered for absolute reliability and zero-defect outcomes. We integrate advanced engineering with rigorous quality control across three critical phases, ensuring your final components meet the most demanding specifications consistently. This disciplined approach minimizes risk, reduces time-to-market, and delivers exceptional ROI for high-volume manufacturing.

The process begins with Collaborative Design & Engineering. Our engineers work directly with your team to translate part geometry into a robust mold design. We perform comprehensive Design for Manufacturability (DFM) analysis, optimizing gate locations, cooling channels, and ejection systems using Moldflow simulation. This phase identifies potential defects like warpage, sink marks, or air traps before metal is cut. Material selection is critical; we specify premium pre-hardened or tool steels (e.g., NAK80, S136, H13) based on part complexity, resin type, and production volume, ensuring optimal thermal stability and wear resistance. All designs undergo stringent internal review against ASME Y14.5 geometric dimensioning standards.

Precision Prototyping & Validation follows design finalization. We manufacture a single-cavity prototype mold using our high-accuracy CNC machining centers, wire EDM, and surface grinding equipment, achieving tolerances down to ±0.002mm. This prototype undergoes rigorous testing on our in-house injection molding presses. We analyze first-article parts using CMM, optical comparators, and material testing to validate dimensional accuracy, surface finish, and mechanical properties against your CAD model and material specifications. Any deviations trigger immediate design or process adjustments. This phase is non-negotiable; it de-risks full-scale production and confirms the mold’s capability to produce conforming parts consistently.

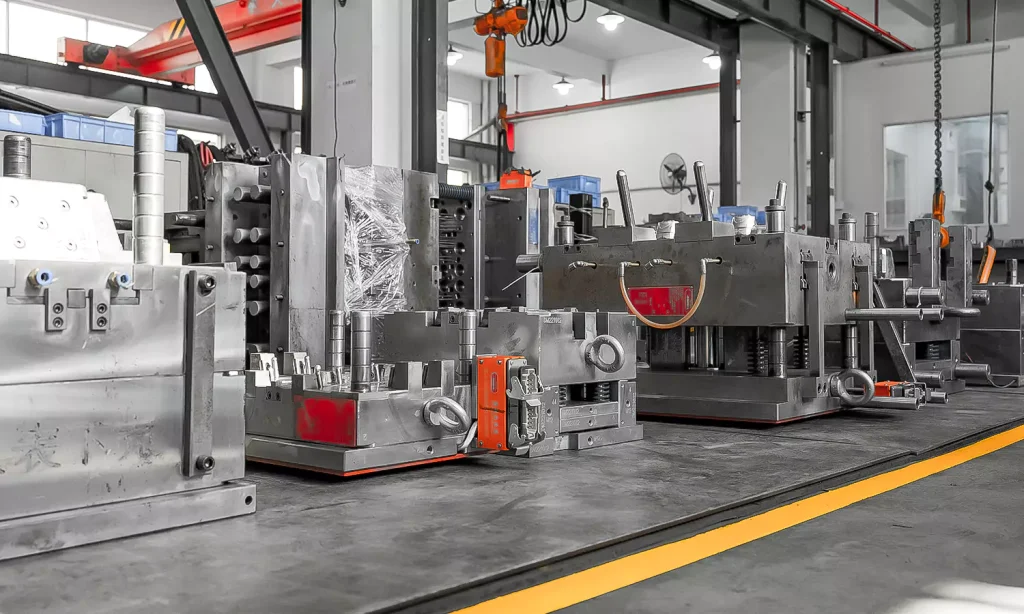

Zero-Defect Mass Production leverages the validated prototype process at scale. Our multi-cavity production molds are manufactured with the same uncompromising precision, incorporating hardened cores, precision-guided inserts, and conformal cooling for uniform thermal management. Real-time process monitoring is central to our zero-defect mandate. We deploy cavity pressure sensors, temperature controllers, and automated vision systems on every press. Each cycle is measured against established SPC control limits. Any parameter drift triggers automatic press shutdown before non-conforming parts are produced. Full traceability—from raw material certificates to individual cavity performance data—is maintained throughout the production run. Final inspection utilizes automated optical inspection (AOI) systems alongside manual AQL sampling, guaranteeing 100% compliance before shipment.

This integrated methodology, combining predictive engineering, empirical validation, and closed-loop process control, is why Wuxi Lead delivers molds capable of 1,000,000+ cycles with zero field defects. We transform design intent into flawless manufacturing reality.

Wuxi Lead Premium Mold Specifications

| Parameter | Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|

| Machining Tolerance | ±0.010 mm | ±0.002 mm |

| Surface Finish (Cavity) | Ra 0.8 µm | Ra 0.2 µm (Mirror Grade) |

| Mold Steel Hardness | 28-32 HRC | 38-42 HRC (Pre-Hardened) |

| Cooling Uniformity | ΔT ≥ 5°C | ΔT ≤ 2°C |

| Expected Life Cycle | 500,000 shots | ≥ 1,000,000 shots |

| First Pass Yield | 85-90% | 99.5%+ |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Mold Manufacturing Solutions

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and performance are non-negotiable in the world of custom metal manufacturing. As a trusted leader in the design and production of high-performance injection molds, we specialize in delivering tailor-made solutions that meet the exacting standards of global industries—from automotive and medical devices to consumer electronics and industrial automation. When you partner with Lead Precision, you are not just sourcing a mold—you are gaining a strategic manufacturing ally committed to innovation, quality, and on-time delivery.

Our engineering team combines decades of industry experience with cutting-edge CNC machining, EDM, and surface finishing technologies to produce molds that deliver consistent, high-volume production with minimal downtime. Every mold we manufacture undergoes rigorous quality control, including CMM inspection, mold flow analysis, and trial runs, ensuring dimensional accuracy and optimal performance from day one. We work closely with your design and production teams to optimize part geometry, material selection, and cooling systems, reducing cycle times and enhancing part quality.

We pride ourselves on transparency, communication, and technical support throughout the entire project lifecycle. From initial concept and 3D modeling to final validation and after-sales service, our engineers provide real-time updates and collaborative problem-solving to keep your project on track. Whether you require single-cavity prototypes or multi-cavity production molds capable of millions of cycles, we deliver robust, long-lasting tooling solutions engineered for performance and efficiency.

Our state-of-the-art facility in Wuxi, China, is equipped to handle complex mold designs with tight tolerances and advanced features such as hot runners, lifters, unscrewing mechanisms, and sequential valve gating. We support a wide range of materials, including P20, 718, H13, S136, and other hardened steels, ensuring compatibility with demanding production environments and corrosive resins.

Below are key specifications that define our injection mold manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 2000 mm × 1500 mm × 1200 mm |

| Maximum Mold Weight | 10,000 kg |

| Tolerance | ±0.005 mm |

| Surface Finish | Mirror polish (SPI A1), texture, EDM finish |

| Mold Base Standards | LKM, FUTABA, DME, or custom |

| Runner Systems | Cold runner, hot runner (Yudo, Hasco, Mold-Masters) |

| Lead Time | 4–12 weeks (depending on complexity) |

| Quality Inspection | CMM, 3D scanning, mold trial reports |

| Industries Served | Automotive, Medical, Electronics, Packaging |

Partnering with Wuxi Lead Precision Machinery means investing in precision, durability, and long-term value. We are ready to support your next injection molding project with engineering excellence and responsive service. Contact us today at [email protected] to discuss your requirements and discover how we can elevate your manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.