Technical Contents

Engineering Guide: Cnc Laser Operator Vacancies

Engineering Insight: The Critical Role of CNC Laser Operators in Precision Manufacturing

In the world of high-precision CNC machining, the performance of advanced machinery is only as reliable as the expertise behind it. At Wuxi Lead Precision Machinery, we recognize that CNC laser operator vacancies are not merely staffing needs—they represent pivotal roles in maintaining the integrity, accuracy, and repeatability essential to modern industrial manufacturing. As components grow more complex and tolerances shrink to micrometer levels, the human element in laser operation remains irreplaceable.

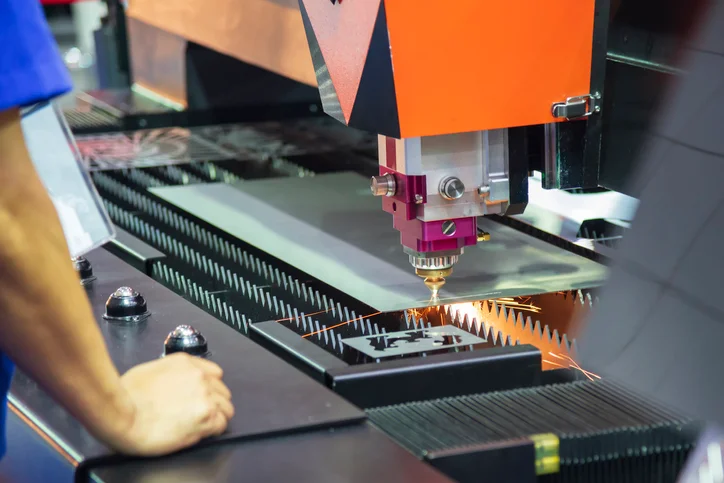

Precision in laser cutting and CNC machining is not solely a function of machine capability; it is a synergy between advanced technology and skilled operation. A CNC laser operator must possess a deep understanding of material behavior, laser dynamics, and programming logic. They are responsible for setting up, calibrating, and monitoring laser systems to ensure each cut meets exact dimensional and surface finish specifications. Even the most sophisticated fiber laser systems can produce suboptimal results without an operator trained to interpret real-time feedback, adjust parameters, and maintain process consistency.

At Wuxi Lead Precision Machinery, our standards are shaped by our experience delivering components for mission-critical applications, including projects tied to Olympic infrastructure and defense systems. These high-stakes environments demand flawless execution, where a deviation of even 0.01 mm can compromise structural integrity or performance. Our CNC laser operators are trained to meet these exacting standards, ensuring that every part produced adheres to ISO 2768-mK and other international precision benchmarks.

We invest heavily in operator training, combining theoretical knowledge with hands-on experience on state-of-the-art equipment. This includes mastery of nested programming, kerf compensation, and thermal distortion management—skills that differentiate a competent operator from a truly exceptional one.

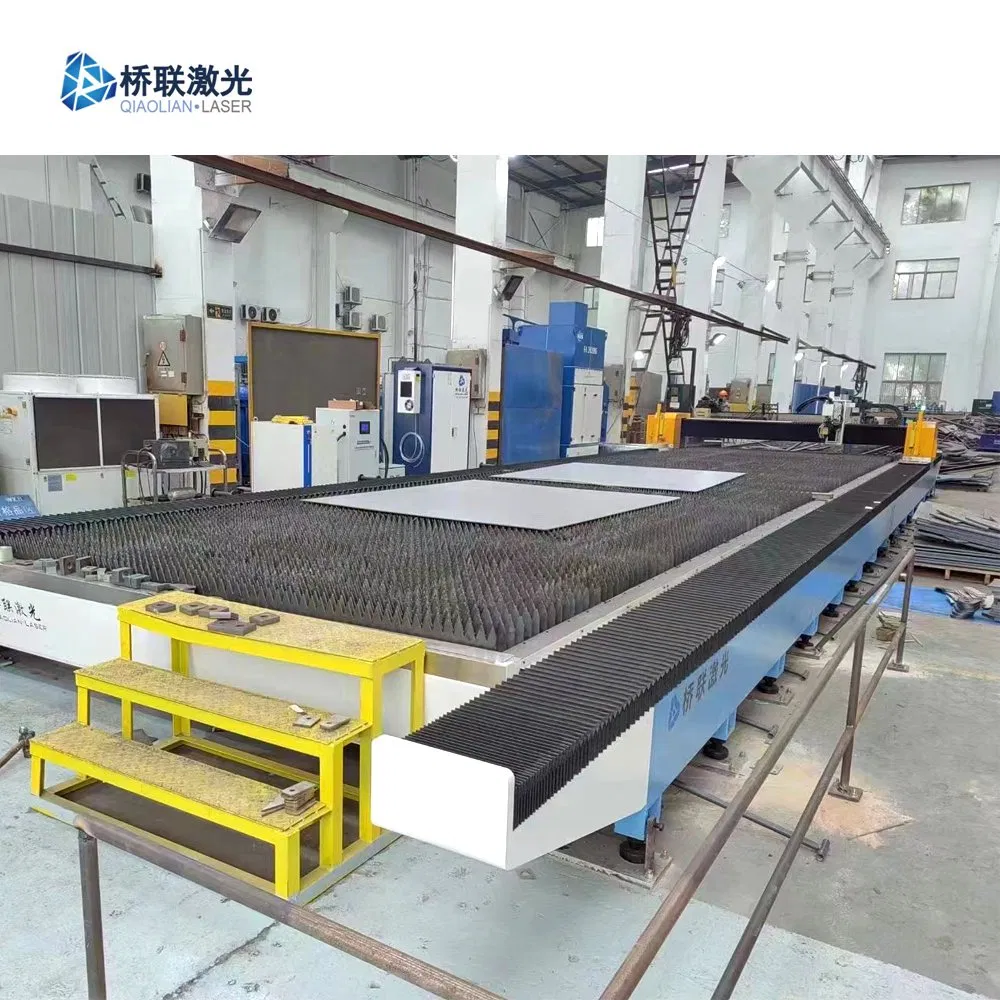

The following table outlines key specifications and capabilities of our standard CNC laser systems, reflecting the environment in which our operators work:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Max Power Output | 12 kW |

| Cutting Thickness (Steel) | Up to 25 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Max Table Size | 3000 mm × 15000 mm |

| Control System | Siemens 840D Solution Line |

| Supported Materials | Carbon Steel, Stainless Steel, Aluminum, Brass |

| Tolerance Range (Standard) | ±0.1 mm (can achieve ±0.05 mm with fine tuning) |

Filling CNC laser operator vacancies with professionals who understand the gravity of precision is central to our operational philosophy. At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer trust, one micron at a time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery operates at the forefront of complex component manufacturing, leveraging advanced multi-axis technology to deliver uncompromising precision for mission-critical industries. Our core competency resides in the mastery of 5-axis CNC machining centers, enabling the production of geometrically intricate parts in a single setup. This capability eliminates cumulative error from multiple fixtures, significantly enhancing part accuracy, surface integrity, and overall process efficiency. Our Haas, DMG MORI, and Makino 5-axis platforms feature high-torque spindles, thermal compensation systems, and rigid constructions designed for sustained sub-micron repeatability across diverse materials including aerospace-grade aluminum alloys, medical titanium, and hardened tool steels. Complex contours, deep cavities, and undercuts are executed with exceptional fidelity, meeting the stringent demands of aerospace structural components, biomedical implants, and high-performance fluid dynamics systems where geometry directly impacts function.

Integral to our manufacturing excellence is a fully integrated, multi-stage quality control protocol anchored by state-of-the-art Coordinate Measuring Machine (CMM) inspection. Every critical feature undergoes rigorous verification against CAD nominal data using our Zeiss CONTURA and Hexagon GLOBAL S 07.10.06 CMMs, equipped with advanced tactile and optical probing systems. This metrology backbone ensures dimensional conformity extends beyond simple length measurements to encompass complex GD&T callouts, true position, profile tolerances, and surface form analysis. Inspection data is meticulously documented and traceable, providing comprehensive quality assurance dossiers essential for regulated sectors like aerospace (AS9100) and medical device manufacturing (ISO 13485). Real-time feedback from CMM results directly informs process adjustments, creating a closed-loop system that continuously optimizes machining parameters and sustains capability.

Our commitment to precision is quantifiably defined by the tight tolerances consistently achieved across our production spectrum. The following table represents our standard achievable capabilities under controlled environmental conditions for machined features, reflecting the synergy between our advanced equipment, skilled operators, and robust quality systems. Mastery of these parameters defines the elite technical environment our CNC laser operators work within.

| Material Type | Tolerance Range | Surface Finish (Ra) |

|---|---|---|

| Aluminum Alloys | ±0.005 mm | 0.4 – 0.8 μm |

| Stainless Steels | ±0.008 mm | 0.8 – 1.6 μm |

| Titanium Alloys | ±0.010 mm | 1.6 – 3.2 μm |

| Engineering Plastics | ±0.020 mm | 1.6 – 6.3 μm |

Operating within this high-precision ecosystem demands exceptional skill and attention to detail from our CNC laser operators. They are not merely machine tenders but critical partners in the quality chain, responsible for meticulous program validation, real-time process monitoring, first-article inspection coordination, and proactive identification of potential deviations. We provide comprehensive training on our specific machine kinematics, probing routines, and quality documentation protocols, empowering operators to fully utilize our technical infrastructure. This environment attracts and develops top-tier talent seeking to work with cutting-edge technology on components where absolute precision is non-negotiable. The result is a manufacturing capability that transforms the most challenging engineering designs into reality, consistently meeting and exceeding the exacting standards of global high-tech industries.

Material & Finish Options

Material selection is a critical factor in precision CNC laser operations, directly influencing machining efficiency, part performance, and final product quality. At Wuxi Lead Precision Machinery, we emphasize informed material choices tailored to the functional and environmental demands of end-use applications. Among the most widely utilized materials in high-precision manufacturing are aluminum, steel, and titanium—each offering distinct mechanical properties and processing behaviors under laser conditions.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly suitable for aerospace, automotive, and electronics applications where lightweight components with high dimensional stability are required. During CNC laser cutting, aluminum demands precise parameter control due to its high reflectivity and thermal conductivity, which can affect beam absorption and edge quality. Proper assist gas selection, typically nitrogen, ensures clean, oxide-free cuts.

Steel—particularly stainless and alloy variants—offers superior strength, durability, and wear resistance. It is the material of choice for industrial machinery, medical devices, and structural components exposed to high stress or corrosive environments. Carbon steel responds well to laser cutting with oxygen assist gas, enabling fast processing speeds and a smooth surface finish. Stainless steel, on the other hand, benefits from nitrogen-assisted cutting to maintain its corrosion-resistant properties and achieve a clean, burr-free edge. Thermal deformation must be carefully managed through optimized cutting paths and cooling strategies.

Titanium and its alloys deliver exceptional performance in extreme conditions, combining high tensile strength, low density, and outstanding resistance to heat and corrosion. These properties make titanium indispensable in aerospace, defense, and biomedical engineering. However, its low thermal conductivity and high reactivity at elevated temperatures require stringent process controls during laser machining. Inert shielding gases such as argon or helium are often used to prevent oxidation and ensure metallurgical integrity.

Following CNC laser fabrication, post-processing surface treatments further enhance material performance. Anodizing is a key finishing process, especially for aluminum components. This electrochemical treatment creates a durable, corrosion-resistant oxide layer that can also be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior wear resistance for high-stress applications.

Understanding the interplay between material characteristics and laser processing parameters enables optimal outcomes in precision manufacturing. The following table summarizes key properties and processing considerations for these core materials:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Laser Cutting Assist Gas | Common Applications | Recommended Post-Process |

|---|---|---|---|---|---|

| Aluminum | 90–700 | 120–240 | Nitrogen | Aerospace, Electronics | Anodizing (Type II / III) |

| Stainless Steel | 500–900 | 15–25 | Nitrogen / Oxygen | Medical, Industrial Equipment | Passivation, Polishing |

| Titanium | 900–1200 | 6–7 | Argon / Helium | Aerospace, Biomedical | Laser Etching, Passivation |

Selecting the appropriate material and finish ensures that components not only meet design specifications but also perform reliably in demanding operational environments. At Wuxi Lead Precision Machinery, our CNC laser operators are trained to master these material dynamics, ensuring precision, consistency, and quality in every production run.

Manufacturing Process & QC

Precision Production Process: From Design to Zero-Defect Delivery

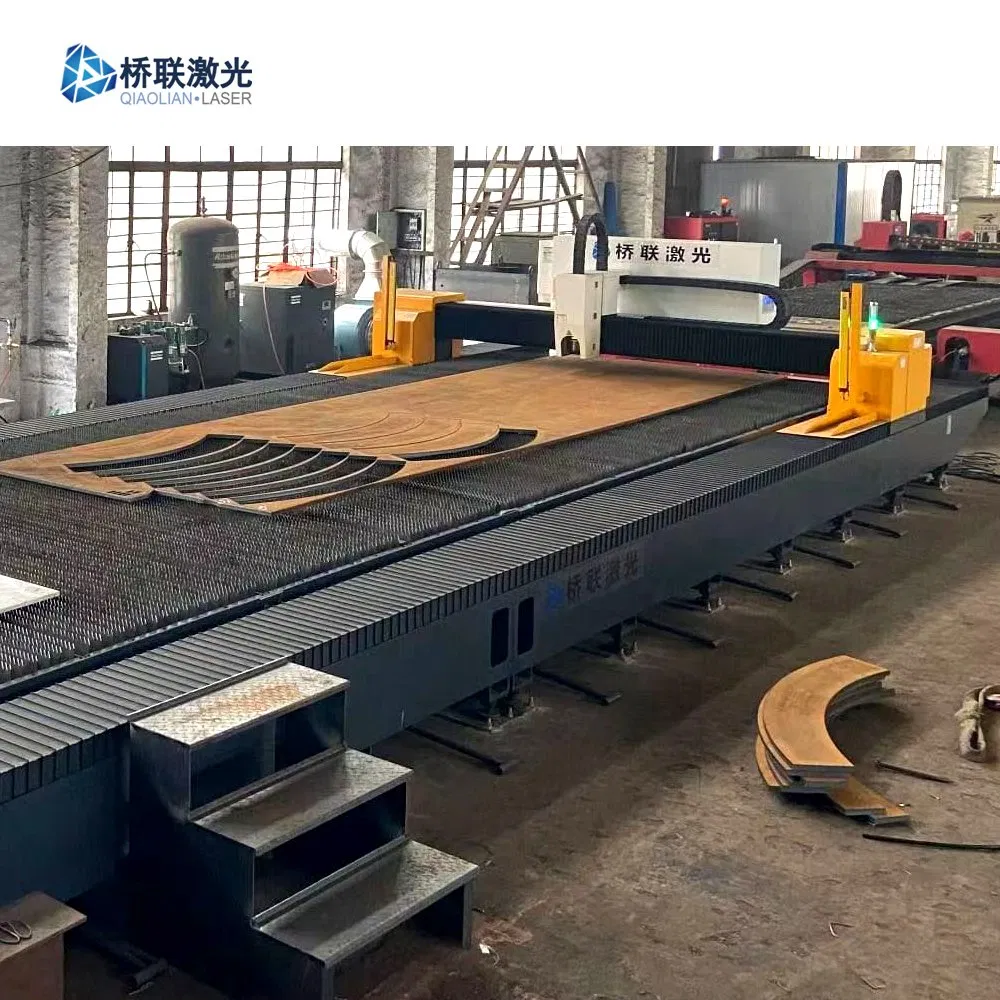

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and efficiency, forming the backbone of our reputation in high-precision CNC laser cutting. We meticulously guide every component from initial concept to final shipment through three rigorously controlled phases: Design, Prototyping, and Mass Production. This integrated approach, executed by our highly skilled CNC laser operators, ensures adherence to the strictest tolerances demanded by aerospace, medical, and semiconductor clients, achieving our core objective of Zero Defects.

The journey begins with collaborative Design. Our engineering team works closely with the client, utilizing advanced CAD/CAM software to translate specifications into optimized laser cutting programs. Material properties, thermal dynamics, and geometric complexity are analyzed to determine optimal parameters—power, speed, gas type, and focal point—before any physical work commences. This digital validation phase is critical; it prevents costly errors downstream and establishes the foundational blueprint for precision. Our operators are trained to scrutinize these programs, ensuring they align with machine capabilities and material behavior.

Prototyping follows immediately, serving as the definitive physical validation step. Using the approved program, our CNC laser operators produce a limited batch of components on the exact production equipment. This phase is not merely about creating a sample; it is intensive metrological verification. Every critical dimension, edge quality, and feature is measured against the original CAD model using coordinate measuring machines (CMMs) and optical comparators. Any deviation triggers immediate program refinement and re-cutting. Only when the prototype batch consistently meets all specifications—verified through documented inspection reports—is the process released for full-scale manufacturing.

Mass Production leverages the validated process under stringent statistical process control (SPC). Our CNC laser operators execute the program with micron-level precision, continuously monitoring machine performance and component output. Real-time data on kerf width, edge squareness, and dimensional stability is fed into our quality management system. Crucially, this phase incorporates layered inspection protocols: automated in-process checks, defined sampling plans per AS9102 or client-specific requirements, and 100% final inspection for critical features. Operator vigilance and proactive intervention are paramount; they are empowered to halt production at the first sign of parameter drift, ensuring non-conforming parts never progress. This relentless focus on process stability and immediate corrective action is how we guarantee Zero Defects in every shipment.

The table below summarizes the core specifications and quality controls inherent to each phase of our production process.

| Phase | Key Activities | Quality Control Method | Output Standard |

|---|---|---|---|

| Design | CAD/CAM programming, Parameter optimization, Thermal simulation | Digital validation, Program verification | Approved digital program, Simulation report |

| Prototyping | Initial cutting run, Metrological verification | 100% CMM/optical inspection, Dimensional analysis | Signed-off prototype, FAI report |

| Mass Production | High-volume cutting, Real-time parameter monitoring | SPC charts, Defined sampling (AQL 0.0), 100% critical feature inspection | Zero-defect batch, Full traceability documentation |

This seamless integration of engineering rigor, operator expertise, and relentless quality focus defines Wuxi Lead’s production excellence. Our CNC laser operators are not just machine tenders; they are critical guardians of the Zero Defects mandate, ensuring every component meets the exacting standards our global clients demand.

Why Choose Wuxi Lead Precision

Partner with Lead Precision to Elevate Your Manufacturing Capabilities

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and efficiency define success in modern CNC manufacturing. As a leader in high-end CNC machining solutions, we specialize in delivering advanced laser cutting systems and precision-engineered components tailored to the most demanding industrial applications. Our expertise extends beyond machinery—we cultivate long-term partnerships with manufacturers who require consistent quality, technical excellence, and scalable production capacity.

If you are exploring CNC laser operator vacancies or seeking to enhance your production team’s capabilities, aligning with Lead Precision means access to state-of-the-art technology, comprehensive training, and engineering support that ensures optimal performance from day one. Our CNC laser systems are engineered for micron-level accuracy, high throughput, and seamless integration into automated production lines. Whether your focus is aerospace, automotive, medical devices, or industrial equipment, our solutions are built to meet international standards and exceed operational expectations.

We do not simply supply machines—we deliver complete manufacturing ecosystems. Our team of CNC engineers and application specialists work closely with clients to optimize cutting parameters, material handling, and workflow efficiency. This collaborative approach ensures that your laser operators are not only well-trained but also supported by a responsive technical network that minimizes downtime and maximizes productivity.

For companies aiming to fill CNC laser operator roles, partnering with Lead Precision provides a strategic advantage. We offer operator onboarding programs, detailed machine documentation, and real-time troubleshooting support to accelerate ramp-up times and ensure consistent output quality. Our commitment to precision engineering is matched by our dedication to customer success.

To learn more about integrating our CNC laser systems into your production environment or to discuss how we can support your hiring and training initiatives for CNC laser operators, contact us today. Our engineering team is ready to provide technical specifications, conduct virtual demonstrations, and assist in workforce development planning.

Reach out to begin a conversation that drives precision, performance, and partnership forward.

Technical Specifications of Lead Precision CNC Laser Systems

| Parameter | Specification |

|---|---|

| Laser Power Range | 1 kW – 12 kW (Fiber) |

| Maximum Cutting Speed | Up to 120 m/min |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass |

| Max Material Thickness (Steel) | Up to 30 mm |

| Control System | Siemens, Fanuc, or proprietary CNC interface |

| Operating Environment | 5°C – 40°C, humidity 30%–80% (non-condensing) |

| Machine Lifetime (MTBF) | >30,000 hours |

Contact us at [email protected] to schedule a consultation or request a detailed capabilities overview.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.