Technical Contents

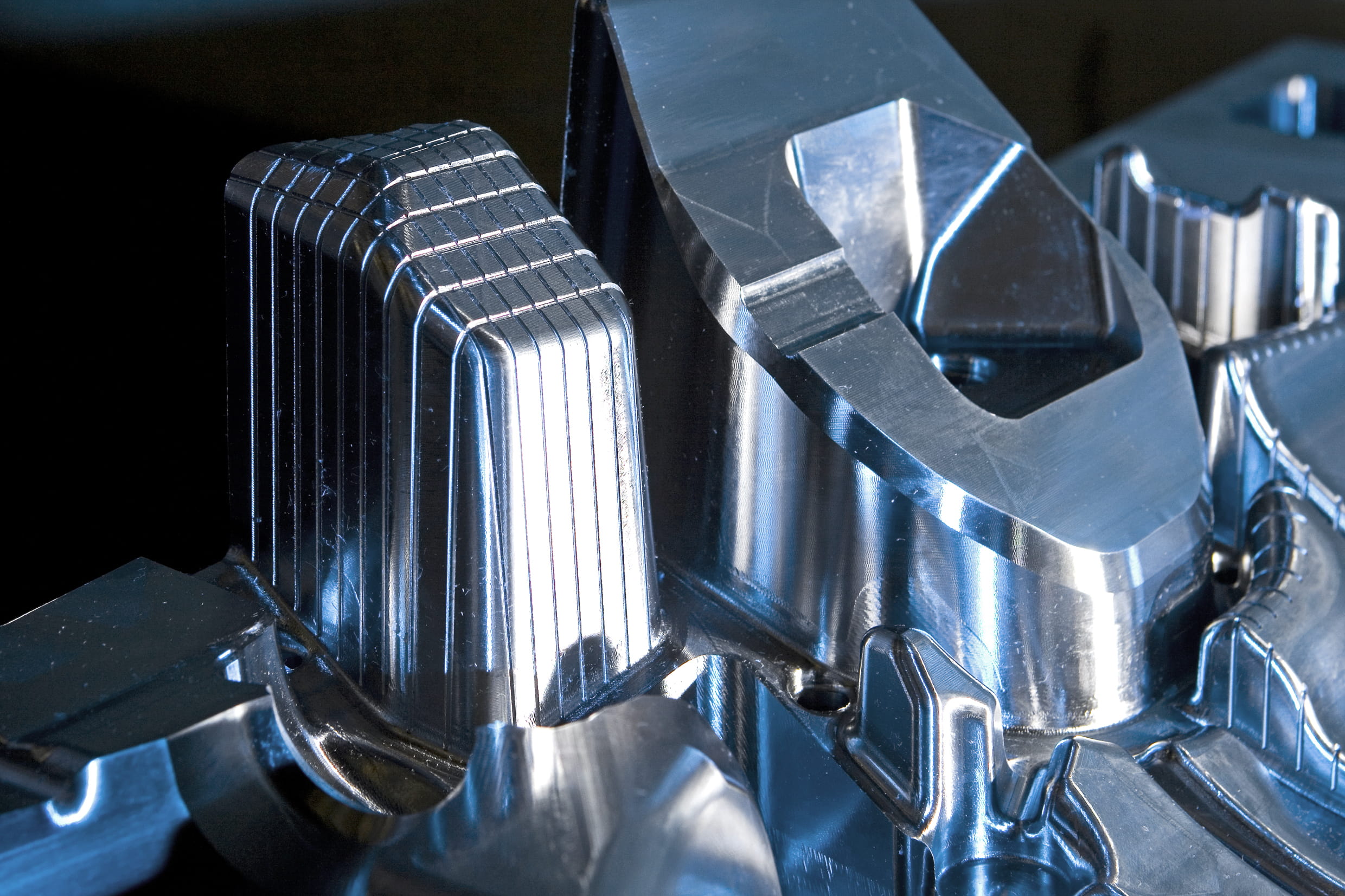

Engineering Guide: Rib Mold

Engineering Insight: Rib Mold Precision in Critical Metal Components

Rib structures are fundamental to the structural integrity and performance of high-stakes metal components across aerospace, defense, and precision industrial applications. These internal or external reinforcing features distribute stress, resist deformation, and enhance rigidity—yet their efficacy hinges entirely on dimensional accuracy. Even minor deviations in rib geometry—such as inconsistent wall thickness, angular misalignment, or surface irregularities—can trigger catastrophic part failure under operational loads. In turbine blades or military vehicle chassis, a 0.02mm tolerance breach in rib profiles may accelerate fatigue cracks by 300%, directly compromising safety and lifecycle costs. Precision rib molding is not merely desirable; it is a non-negotiable engineering imperative where microns define success or systemic risk.

At Wuxi Lead Precision Machinery, we treat rib mold fabrication as a zero-defect discipline. Our CNC machining protocols integrate multi-axis simulation, real-time thermal compensation, and in-process metrology to eliminate cumulative errors. This rigor stems from direct validation in environments where failure is unacceptable: components we produced for Olympic infrastructure projects demanded sub-10µm flatness across 1.5m rib arrays to withstand seismic stresses, while military-grade housings for classified defense systems required rib symmetry within ±0.008mm to ensure electromagnetic shielding integrity. Such projects forged our methodology—proving that rib precision transcends standard tolerances to become a physics-driven safeguard.

Our capabilities are engineered to exceed industry benchmarks, as demonstrated in the technical specifications below.

| Parameter | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Material Range | Titanium Gr5, Inconel 718, 7075-T6 Aluminum | Limited to standard alloys |

| Tolerance Capability | ±0.005mm (critical rib profiles) | ±0.025mm |

| Max Work Envelope | 2000 x 1500 x 800mm | 1200 x 800 x 500mm |

| Surface Finish (Ra) | 0.4µm (mirror-grade ribs) | 1.6µm |

| Certifications | AS9100D, ISO 13485, NADCAP AC7108 | ISO 9001 only |

Achieving this level of control demands closed-loop systems that monitor tool wear, material spring-back, and environmental drift during machining. We deploy 5-axis simultaneous milling with Renishaw probes for on-machine verification, ensuring rib angles and radii conform to CAD models within 3µm. Post-process, Zeiss CONTURA CMMs validate GD&T callouts across every rib node—data we share transparently with clients for traceability. For sectors like aerospace or defense, where a single rib defect can ground fleets or compromise missions, this end-to-end accountability transforms precision from a specification into a liability shield.

Partnering with Lead Precision means embedding Olympic-proven and military-validated engineering into your supply chain. We don’t just manufacture rib molds; we deliver certified geometric reliability that turns structural vulnerabilities into competitive advantages. When your application demands ribs that perform flawlessly under extreme conditions, our precision becomes your operational certainty.

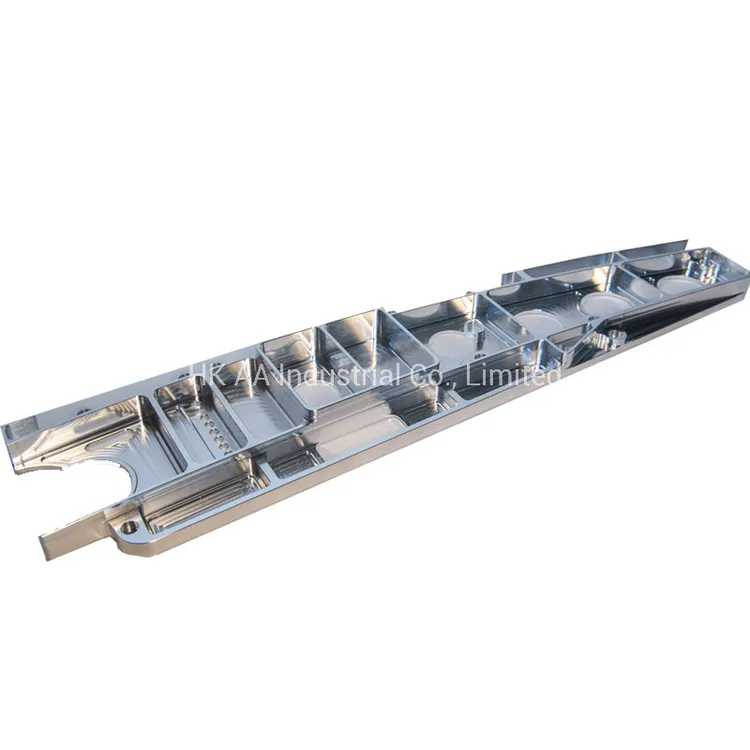

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components such as rib molds for aerospace, automotive, and industrial applications. Our expertise is anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool orientation and access to intricate features that traditional 3-axis machines cannot achieve. This capability is particularly critical in rib mold production, where thin walls, deep cavities, and compound angles are common.

Our 5-axis CNC centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to maintain consistent performance across long production runs. These machines support a wide range of materials, including aluminum alloys, titanium, stainless steel, and high-strength nickel-based superalloys. Each machining cycle is supported by advanced CAM software that optimizes toolpaths for efficiency, minimizing cycle times while maximizing dimensional accuracy and surface finish quality.

To ensure every component meets the most stringent industry standards, we implement a comprehensive quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology verification, capturing thousands of data points to validate geometric dimensions, positional tolerances, and surface profiles. All inspection reports are documented and traceable, supporting full compliance with ISO 9001 and customer-specific quality requirements. This closed-loop quality process ensures that every rib mold produced at Wuxi Lead conforms precisely to the original engineering specifications.

In addition to advanced equipment and inspection, our technical team consists of experienced CNC programmers, tooling engineers, and quality specialists who collaborate closely with clients during the design-for-manufacturability (DFM) phase. This proactive approach helps identify potential manufacturing challenges early, reducing lead times and avoiding costly revisions. Our facility operates under strict environmental and process controls, ensuring stable machining conditions that support micron-level repeatability.

The following table outlines the standard tolerances achievable in our rib mold manufacturing process under normal production conditions.

| Feature Type | Standard Tolerance | Typical Range | Measuring Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | 0.003–0.01 mm | CMM, Micrometer |

| Positional Tolerance | ±0.008 mm | 0.005–0.012 mm | CMM |

| Flatness | 0.005 mm per 100 mm | 0.003 mm per 100 mm | CMM, Optical Flat |

| Surface Finish (Ra) | 0.4 μm | 0.2–0.8 μm | Surface Roughness Tester |

| Angular Features | ±0.005° | ±0.003° | CMM, Precision Protractor |

| Hole Diameter (Drilled) | +0.01 / -0.00 mm | H7 tolerance | Pin Gauge, CMM |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for high-end rib mold manufacturing, where precision, reliability, and technical excellence are non-negotiable.

Material & Finish Options

Material Selection for High-Performance Rib Molds

Selecting the optimal material for rib molds directly impacts production efficiency, part quality, and tooling longevity. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific application demands, balancing thermal management, mechanical strength, weight constraints, and cost-effectiveness. Aluminum alloys dominate for high-volume production due to superior thermal conductivity, enabling rapid cycle times and uniform cooling. Steel variants, particularly pre-hardened or tool steels, are essential for molds requiring extreme wear resistance and dimensional stability under high-pressure or abrasive conditions. Titanium alloys serve niche aerospace or medical applications where exceptional strength-to-weight ratios and corrosion resistance outweigh higher material and machining costs. Each material demands precise CNC machining expertise to achieve critical tolerances and surface finishes inherent to rib geometry.

Critical Material Properties Comparison

| Property | Aluminum 7075-T6 | P20 Tool Steel | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|---|

| Density (g/cm³) | 2.81 | 7.85 | 4.43 |

| Tensile Strength (MPa) | 503–572 | 950–1100 | 860–930 |

| Thermal Conductivity (W/m·K) | 130 | 28–36 | 6.7 |

| Corrosion Resistance | Moderate (enhanced by anodizing) | Good (varies by grade) | Excellent |

| Machinability Rating | Excellent | Good | Fair (challenging) |

Aluminum’s low density and high thermal conductivity minimize energy consumption during molding cycles while preventing warpage in complex rib structures. However, its lower hardness necessitates protective surface treatments. Steel provides unmatched durability for rib molds producing glass-filled polymers or enduring millions of cycles, though slower heat dissipation may extend cycle times. Titanium’s biocompatibility and non-magnetic properties are indispensable for specialized sectors, but its abrasive nature requires advanced CNC toolpaths and coatings to prevent rapid tool wear during machining.

Anodizing: Essential for Aluminum Rib Mold Performance

Anodizing is non-negotiable for aluminum rib molds, transforming the surface into a hard, corrosion-resistant ceramic layer. Standard sulfuric acid anodizing (Type II) offers 5–25μm thickness for basic wear protection and adhesion promotion. For rib molds facing high abrasion or chemical exposure, hard anodizing (Type III) delivers 25–50+μm coatings with Rockwell hardness exceeding 60 HRC. This process seals microscopic pores, preventing polymer adhesion and simplifying part ejection—critical for intricate rib undercuts. Wuxi Lead Precision applies tightly controlled anodizing parameters to ensure uniform thickness across complex geometries, avoiding dimensional shifts in critical rib profiles. Color dyeing (e.g., black, gold) is available for identification but does not enhance functional properties.

Material selection is a strategic decision where Wuxi Lead Precision Machinery leverages 15+ years of CNC expertise to match your production goals. We rigorously validate material certifications and machining parameters to eliminate in-field failures. Contact our engineering team to specify the optimal alloy and finish for your rib mold’s thermal, mechanical, and lifecycle requirements—ensuring maximum ROI through precision manufacturing.

Manufacturing Process & QC

The production process for high-precision rib molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence from initial design through to mass production, ensuring zero defects and full compliance with aerospace, automotive, and industrial manufacturing standards. Our methodology integrates advanced engineering, precision tooling, and real-time quality assurance to deliver consistent, repeatable results.

Design begins with a collaborative engineering phase, where our technical team works directly with the client to interpret technical drawings, 3D CAD models, and performance requirements. Finite Element Analysis (FEA) and mold flow simulations are conducted to optimize structural integrity, thermal distribution, and material efficiency. This stage ensures that every rib mold is engineered for maximum durability, dimensional accuracy, and cycle efficiency. Design validation includes tolerance stack-up analysis and draft angle optimization, critical for complex rib geometries with thin walls and deep cavities.

Prototyping follows design approval, utilizing high-speed CNC machining centers with sub-micron accuracy to produce functional prototype molds. These prototypes are used for first-article inspection and molding trials, allowing validation of part geometry, surface finish, and ejection performance under real production conditions. Any deviations are corrected through iterative adjustments in mold geometry or cooling channel layout. All prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify conformity to GD&T specifications.

Once the prototype is approved, the project transitions to mass production. Our automated manufacturing cells, equipped with multi-axis CNC machines, wire EDM, and high-pressure die casting units, ensure seamless scalability. Each production mold is built using premium-grade tool steels such as H13, S136, or NAK80, selected based on wear resistance, thermal stability, and corrosion requirements. Hardening and surface treatments—including nitriding and PVD coating—are applied to extend mold life beyond 500,000 cycles.

Throughout production, in-process inspections and statistical process control (SPC) are implemented at every stage. Each component is traceable through our digital manufacturing system, which logs machining parameters, inspection data, and material certifications. Final inspection includes full dimensional reporting, cavity surface roughness measurement, and non-destructive testing where applicable.

The following table outlines key production specifications for our rib mold manufacturing process:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.005 mm |

| Surface Roughness (cavity) | Ra ≤ 0.2 µm (polished), Ra ≤ 1.6 µm (machined) |

| Tool Steel Options | H13, S136, NAK80, 2738, 718H |

| Heat Treatment | Hardness 48–52 HRC (standard), custom on request |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| Mold Life Expectancy | 300,000 – 1,000,000 cycles |

| Lead Time (Prototype) | 15–25 days (based on complexity) |

| Lead Time (Mass Production) | 30–45 days (including testing and packaging) |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, SPC compliance |

Wuxi Lead Precision Machinery guarantees zero-defect delivery through integrated quality management and process validation. Every rib mold is shipped with full documentation, including inspection reports, material certificates, and maintenance guidelines, ensuring long-term performance and client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Rib Mold Excellence

When your application demands structural integrity, thermal stability, and micron-level precision in rib mold components, generic manufacturing solutions introduce unacceptable risk. At Wuxi Lead Precision Machinery, we engineer rib molds not as commodities, but as mission-critical assets. Our integrated approach merges decades of aerospace and medical-grade CNC expertise with proprietary thermal distortion management techniques, ensuring your mold delivers consistent part quality across 500,000+ cycles. We prioritize your engineering intent from the earliest design phase, transforming complex geometries with thin walls, intricate cooling channels, and compound draft angles into manufacturable realities. This eliminates costly iterations and accelerates time-to-market without sacrificing durability.

Our technical capabilities are validated through rigorous in-house metrology and material science protocols. The table below details our core competencies for high-performance rib mold production:

| Capability | Specification | Application Benefit |

|---|---|---|

| Material Expertise | Titanium Gr5, Inconel 718, Tool Steel H13, Aluminum 7075-T7351 | Ensures thermal fatigue resistance and dimensional stability under extreme cycling |

| Geometric Precision | ±0.005 mm linear tolerance; ±0.002 mm surface profile | Guarantees uniform wall thickness and assembly compatibility |

| Surface Integrity | Ra 0.4 µm (as-machined); Optional mirror polishing to Ra 0.05 µm | Reduces part ejection force and prevents surface defects |

| Secondary Processes | Stress-relieved annealing; CMM-certified inspection; Electroplating (Ni-P) | Mitigates residual stress and enhances wear resistance |

| Lead Time | 12-18 weeks (complex molds) | Includes DFM validation and first-article testing |

We recognize that rib molds operate at the intersection of mechanical stress and thermal dynamics. Our engineering team collaborates directly with your designers to optimize rib placement, cooling circuit efficiency, and gate locations—addressing potential sink marks or warpage before metal hits the spindle. Unlike conventional suppliers, we implement real-time adaptive machining strategies that compensate for material spring-back during high-speed milling, a critical factor for maintaining rib symmetry in large-scale molds. Every component undergoes thermal cycle validation in our simulation chamber, replicating 10,000 production cycles to verify performance under actual operating conditions.

Choosing Lead Precision means partnering with a manufacturer that treats your intellectual property and production deadlines as inviolable. Our Ningbo facility operates under ISO 9001:2015 and IATF 16949 frameworks, with full traceability from raw material certification to final assembly. We do not outsource critical processes; all 5-axis milling, EDM, and finishing occur within our climate-controlled workshop using DMG MORI and Makino equipment calibrated weekly.

Initiate a technical dialogue that prioritizes engineering outcomes over transactional exchanges. Contact our manufacturing engineering team directly at [email protected] with your rib mold specifications, material requirements, and performance targets. Include a 3D model or technical drawing for our complimentary Design for Manufacturability assessment. Within 48 hours, you will receive a detailed capability analysis, risk mitigation plan, and transparent timeline—no generic quotations, only actionable engineering insights. For projects demanding zero-compromise precision, Lead Precision is your definitive manufacturing authority.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.