Technical Contents

Engineering Guide: Custom Molding Plastic

Engineering Insight Precision in Custom Molding Plastic

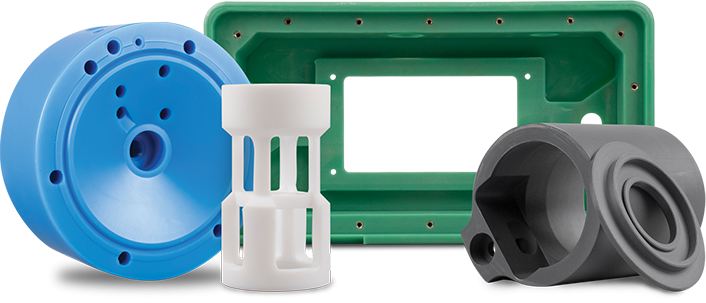

Achieving dimensional stability and functional reliability in custom plastic molding demands micron-level precision rarely emphasized in standard manufacturing guides. Plastic materials inherently exhibit complex behaviors during injection—thermal expansion, shrinkage, and warpage—that directly impact part performance. Without rigorous control over cavity pressure, cooling rates, and material flow dynamics, even minor deviations cascade into assembly failures or premature wear. This is where advanced engineering discipline becomes non-negotiable. At Wuxi Lead Precision Machinery, we treat plastic molding with the same uncompromising standards applied to aerospace-grade metal components. Our process begins with finite element analysis (FEA) to simulate material behavior under exact production conditions, ensuring gate placement, cooling channel geometry, and ejection sequences eliminate stress concentrations before a single pellet is melted.

Wuxi Lead’s expertise in precision engineering transcends material boundaries. Our foundational work on Olympic-grade timing system components—where tolerances below ±0.01mm ensured flawless event measurement—and critical military hardware requiring zero-failure operation under extreme environments directly informs our plastic molding protocols. These projects demanded absolute predictability in material response, a capability we systematically transfer to polymer applications. Precision here isn’t merely about meeting drawings; it’s about anticipating how molecular orientation affects long-term part integrity in dynamic operational settings. For instance, optimizing injection velocity profiles for medical-grade polycarbonate prevents micro-fractures that could compromise sterile barriers after repeated autoclave cycles.

The following specifications reflect our production capabilities for custom plastic molding, validated through ISO 9001-certified processes and continuous in-cavity pressure monitoring:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Linear Tolerance | ±0.02 mm to ±0.05 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.05 µm to 1.6 µm | ISO 4287 |

| Material Compatibility | Engineering Thermoplastics (PEEK, PSU, PPSU), LCP, Medical-Grade Resins | USP Class VI / ISO 10993 |

| Max Shot Weight | 2,500 grams | ISO 11473 |

| Cavity Pressure Control | ±1.5 bar accuracy | Real-time Sensing |

This level of control directly mitigates common failure modes: sink marks in thick-walled enclosures, flash in micro-connector housings, or inconsistent thread engagement in fluidic assemblies. Partners selecting Wuxi Lead gain access to process validation data traceable to individual production lots—a necessity for regulated industries where component traceability is legally mandated. Ultimately, precision in plastic molding isn’t a cost center; it’s the foundation for reducing scrap, accelerating time-to-market, and ensuring end-product longevity in mission-critical applications. Our cross-material engineering rigor ensures your plastic components perform with the reliability your systems demand.

Precision Specs & Tolerances

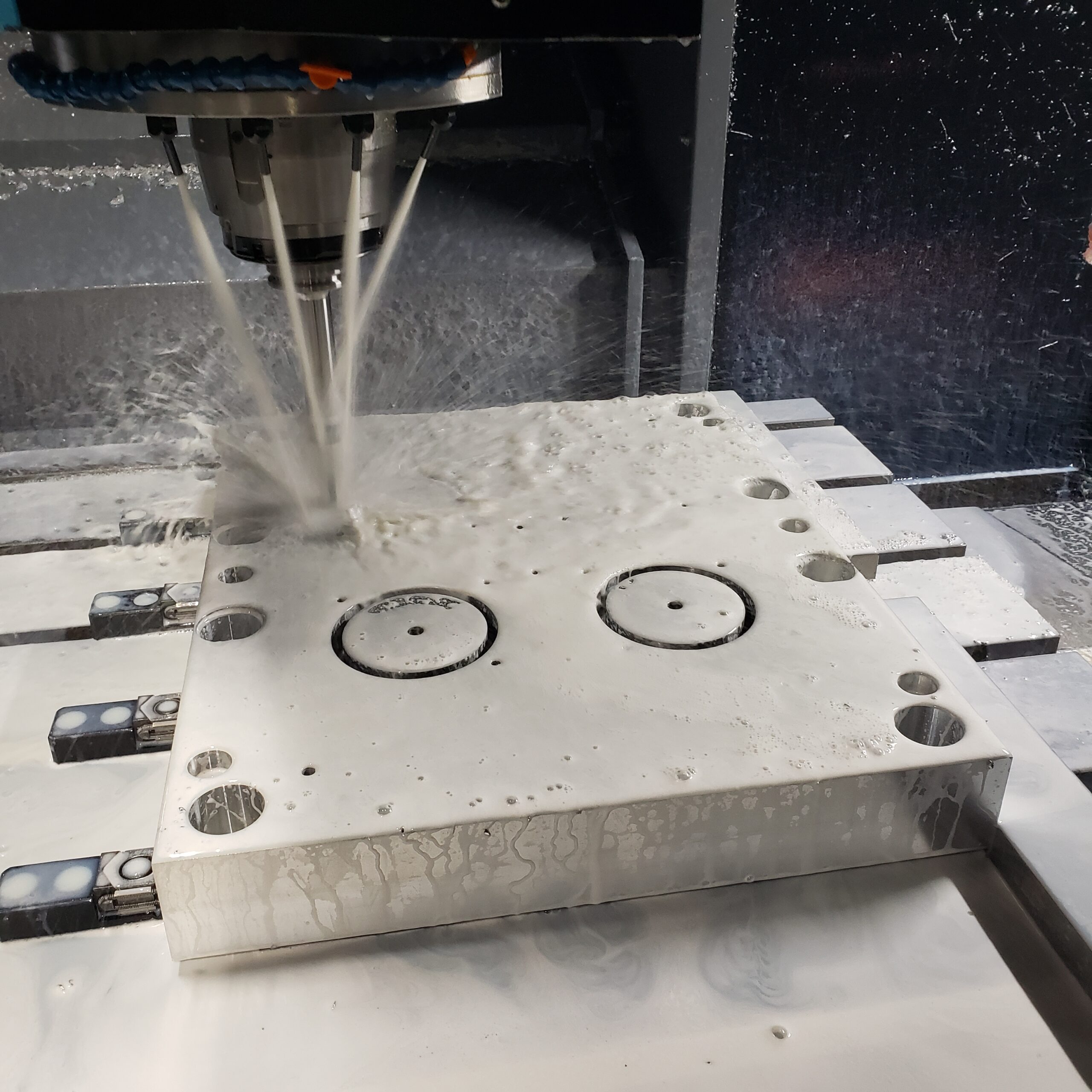

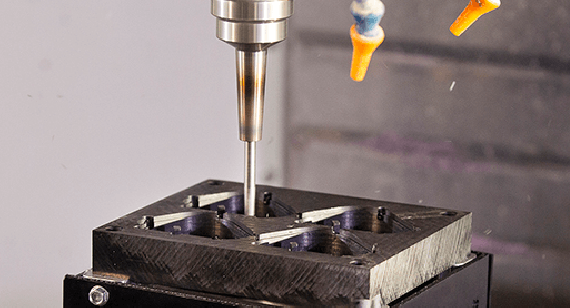

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications. At the core of our production floor is a fully integrated suite of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing superior access to intricate features and undercuts that are unattainable with conventional 3-axis equipment. This capability is particularly critical when manufacturing molds, dies, and precision structural components used in aerospace, medical devices, and high-performance automotive systems.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and reduced cycle times. Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAD/CAM software to optimize toolpaths, minimize material waste, and maintain tight tolerances throughout production. We support a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and tool steels, ensuring compatibility with the most rigorous operational environments.

Quality control is embedded into every stage of our manufacturing process. All critical dimensions and geometric features are verified using Coordinate Measuring Machine (CMM) inspection, providing metrology-grade validation of part conformity. Our CMM systems operate with sub-micron resolution, enabling full compliance with ISO 10360 standards. Data from inspections is documented and traceable, supporting full quality documentation packages for audit and certification purposes. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness gauges to validate material and finish specifications.

We maintain strict environmental controls in our inspection lab to eliminate thermal drift and ensure measurement repeatability. First-article inspections, in-process checks, and final audits are standard procedures across all production runs, whether prototypes or high-volume orders. This disciplined approach to quality ensures that every custom-machined component meets or exceeds customer specifications.

The following table outlines our standard machining capabilities and achievable tolerances:

| Specification | Performance |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.010 mm |

| Geometric Tolerance (GD&T) | ±0.008 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope (5-axis) | 1200 x 800 x 600 mm |

| Minimum Feature Size | 0.5 mm radius |

| Repeatability (CMM-verified) | ±0.003 mm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance protocols to deliver custom metal components that meet the highest standards of precision and reliability. Our technical capabilities are designed to support innovation in industries where performance and consistency are non-negotiable.

Material & Finish Options

Material Selection Guidance for Precision Metal Components

Wuxi Lead Precision Machinery clarifies a critical distinction: our expertise lies in custom metal manufacturing via CNC machining, not plastic molding. For high-integrity metal components—essential in aerospace, medical, and defense applications—material and finish selection directly impact performance, longevity, and cost-efficiency. We focus exclusively on aluminum, steel, and titanium alloys, engineered for extreme precision and reliability.

Aluminum alloys like 6061-T6 offer an optimal strength-to-weight ratio and excellent machinability, ideal for structural frames and housings where weight reduction is critical. Steel variants such as 304 and 316 stainless provide superior hardness and corrosion resistance for marine or chemical environments. Titanium Grade 5 (Ti-6Al-4V) delivers unmatched strength-to-weight properties and biocompatibility, making it indispensable for surgical implants and aerospace components. Each material must align with your operational stresses, environmental exposure, and regulatory requirements.

Surface finishing, particularly anodizing, enhances durability and functionality. Type II (sulfuric acid) anodizing improves corrosion resistance and paint adhesion for aluminum parts, while Type III (hardcoat) anodizing creates a wear-resistant layer up to 100µm thick for high-friction applications. Note that anodizing applies solely to aluminum; steel requires passivation or plating, and titanium benefits from acid etching or plasma spray coatings. Selecting the wrong finish accelerates part failure—we rigorously validate all specifications against your use case.

Below are key material properties for common alloys we machine to ±0.005mm tolerance:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Max Operating Temp (°C) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | Moderate | Enclosures, brackets | 120 |

| Stainless 316 | 570 | Excellent | Marine hardware, valves | 870 |

| Titanium Grade 5 | 900 | Exceptional | Aircraft fittings, implants | 400 |

Material choice must balance upfront cost against lifecycle value. While titanium commands a premium, its fatigue resistance often reduces replacement frequency in critical systems. Similarly, hardcoat anodizing adds initial cost but eliminates premature wear in moving assemblies. At Wuxi Lead, we conduct material suitability analysis during quoting—sharing test reports and failure-mode simulations to prevent field failures.

Never default to generic material grades. A medical device housing requires 316L stainless for biocompatibility, not standard 304. An unmanned aerial vehicle bracket demands 7075-T6 aluminum, not 6061, for high-stress zones. Our engineering team collaborates to match your load diagrams, environmental specs, and certification needs to the optimal alloy and finish. Contact us with your performance requirements—we deliver data-driven material validation, not assumptions. Precision begins with the right foundation.

Manufacturing Process & QC

The production process for custom molding plastic components at Wuxi Lead Precision Machinery follows a disciplined, three-phase methodology: Design, Prototyping, and Mass Production. This structured approach ensures precision, repeatability, and zero-defect output tailored to high-end industrial applications.

Design begins with a collaborative engineering review, where our technical team works directly with client specifications to optimize part geometry, material selection, and mold flow dynamics. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate thermal behavior, stress distribution, and potential shrinkage to preemptively resolve manufacturing challenges. Design for manufacturability (DFM) principles are rigorously applied to eliminate inefficiencies and ensure dimensional stability. This phase culminates in a finalized digital model and a detailed process plan approved by both engineering and client stakeholders.

Prototyping follows design validation, where we produce functional prototypes using high-precision CNC-machined aluminum molds or 3D-printed tooling, depending on complexity and volume requirements. These prototypes undergo comprehensive testing, including fit checks, mechanical performance evaluation, and environmental exposure trials. Feedback from this stage is systematically integrated to refine the design and process parameters. Our prototyping cycle typically delivers first-article parts within 10–15 business days, enabling rapid iteration and accelerated time-to-market.

Mass Production is initiated only after prototype approval and process sign-off. We employ state-of-the-art all-electric and hybrid hydraulic injection molding machines from global leaders such as ENGEL and Sumitomo, ensuring sub-micron repeatability and energy-efficient operation. Each production run is governed by Statistical Process Control (SPC), with real-time monitoring of critical parameters including melt temperature, injection pressure, and cycle time. Automated vision inspection systems and coordinate measuring machines (CMM) verify part conformity to tolerances as tight as ±0.005 mm. Our cleanroom molding facilities support medical and optical-grade components, while robotic part handling minimizes human intervention, reducing contamination and variability.

Throughout all phases, traceability is maintained via our integrated Manufacturing Execution System (MES), which logs material batches, machine settings, and inspection data for every lot. This enables full auditability and rapid root-cause analysis if any deviation occurs. Our zero-defect philosophy is enforced through preventive maintenance schedules, operator certification programs, and continuous improvement cycles based on Six Sigma principles.

The table below outlines key capabilities across the production workflow.

| Process Phase | Equipment Used | Lead Time | Tolerance Range | Materials Supported |

|---|---|---|---|---|

| Design | Siemens NX, SolidWorks, Moldflow | 5–7 days | N/A | Engineering resins, TPE, PEEK, PC, ABS |

| Prototyping | CNC Aluminum Molds, 3D Printed Tooling | 10–15 days | ±0.02 mm | Prototype-grade thermoplastics |

| Mass Production | ENGEL, Sumitomo Injection Molding | 3–6 weeks | ±0.005 mm | Production-grade engineering plastics |

This end-to-end control ensures that every custom molding plastic component meets the highest standards of quality, performance, and consistency required by aerospace, medical, and advanced industrial sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Custom Plastic Molding Excellence

In custom plastic molding, the mold is everything. Precision engineering at the micron level directly dictates part integrity, dimensional stability, and production efficiency. As a leader in high-precision metal manufacturing, Wuxi Lead Precision Machinery bridges the critical gap between advanced metal tooling and flawless plastic component realization. Our mastery in CNC-machined steel and aluminum molds ensures your plastic parts meet the most stringent aerospace, medical, and industrial specifications—where failure is not an option.

We understand that plastic molding success hinges on mold geometry, thermal management, and material science integration. Our engineers collaborate with you from concept to量产, applying decades of metal fabrication expertise to eliminate common pitfalls: sink marks, warpage, and inconsistent cycle times. By leveraging ISO 9001-certified processes and 5-axis CNC technology, we deliver molds that achieve repeatability within ±0.002mm—translating to zero-defect plastic components batch after batch. This is not just tooling; it is the foundation of your product’s reliability.

Our technical capabilities are engineered for complexity. Whether you require micro-molding for medical connectors or large-scale structural components, we optimize mold design for your specific resin, pressure, and temperature profile. The table below summarizes how our metal manufacturing rigor elevates plastic molding outcomes:

| Capability | Specification | Impact on Plastic Molding |

|---|---|---|

| Mold Tolerance | ±0.002 mm | Eliminates flash, ensures perfect part mating |

| Surface Finish | Ra 0.05 µm (Mirror) | Reduces ejection force, enhances part aesthetics |

| Material Compatibility | P20, H13, Stainless Steel | Supports aggressive resins (PEEK, PSU) and high-cycle production |

| Lead Time | 15-25 days (T1 sample) | Accelerates time-to-market without compromising quality |

| Quality Validation | CMM + Moldflow Analysis | Predicts and prevents warpage, sink, and stress points |

Choosing Wuxi Lead Precision means partnering with engineers who speak the language of polymers and metals fluently. We do not merely fabricate molds; we solve your production challenges through metallurgical insight and process intelligence. When your application demands thermal stability under 300°C or sub-micron feature accuracy, our tooling becomes your competitive advantage.

The cost of mold imperfection extends far beyond rework—it erodes brand trust and market position. Let us prove how precision metal manufacturing transforms plastic molding outcomes. Contact our engineering team today to discuss your project specifications, material requirements, and volume needs. We will provide a detailed feasibility assessment and timeline within 24 hours.

Schedule your confidential engineering consultation now. Email [email protected] with “Custom Molding Precision Review” in the subject line. Include your part drawings or application details, and our senior CNC engineers will respond with actionable solutions—not sales pitches. In high-stakes manufacturing, precision is non-negotiable. Partner with the standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.