Technical Contents

Engineering Guide: Sheet Metal Die Design

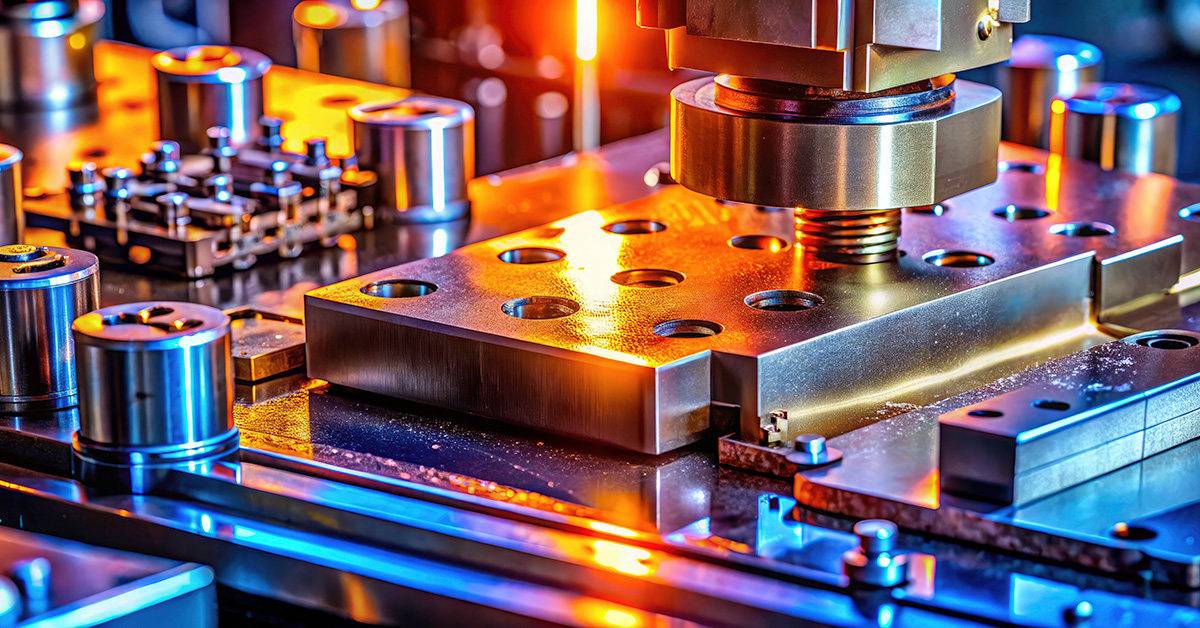

Engineering Insight: The Critical Role of Precision in Sheet Metal Die Design

In the realm of high-performance manufacturing, sheet metal die design stands as a cornerstone of operational excellence. The accuracy, repeatability, and longevity of a die directly influence the quality of stamped components, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we approach die design not merely as a fabrication task, but as an engineering discipline where micron-level precision defines success.

Precision in die design ensures that each stamping operation produces parts within strict dimensional tolerances, critical for applications in aerospace, defense, and high-end industrial equipment. Even minor deviations in die geometry can lead to material springback, inconsistent forming, or premature tool wear—issues that cascade into costly rework, downtime, and compromised product integrity. Our engineering team employs advanced simulation software and finite element analysis (FEA) to model material behavior, stress distribution, and tool life under real-world conditions. This predictive capability allows us to optimize die profiles, clearance settings, and load distribution before any metal is cut.

With over two decades of specialized experience, Wuxi Lead Precision Machinery has delivered mission-critical die solutions for projects requiring the highest levels of reliability. Our involvement in precision components for Olympic-standard equipment and military-grade systems underscores our commitment to excellence. These applications demand more than compliance with ISO or GB standards—they require a culture of zero-defect engineering, rigorous material traceability, and full-process validation.

Our die manufacturing process integrates high-grade tool steels, precision CNC machining, and hardened surface treatments to ensure durability under high-cycle operations. Each die undergoes comprehensive inspection using coordinate measuring machines (CMM) and laser scanning to verify alignment and dimensional fidelity. This end-to-end control enables us to consistently achieve tolerances down to ±0.01 mm, a benchmark essential for complex multi-stage progressive dies.

Below are key performance specifications achieved through our precision die design and manufacturing process:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.01 mm |

| Surface Finish (Ra) | 0.4 – 0.8 µm |

| Tool Steel Grades | SKD11, D2, DC53, H13 (custom options) |

| Hardness Range | 58–62 HRC |

| Die Life (cycles) | 1M – 10M+ (depending on application) |

| Inspection Method | CMM, Laser Scan, Optical Comparator |

| Compliance Standards | ISO 9001, GB/T 1800, MIL-STD-883 (select projects) |

At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is engineered into every phase of design and production. Our expertise in sheet metal die development continues to support global clients who demand reliability, performance, and consistency at the highest level.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Die Fabrication

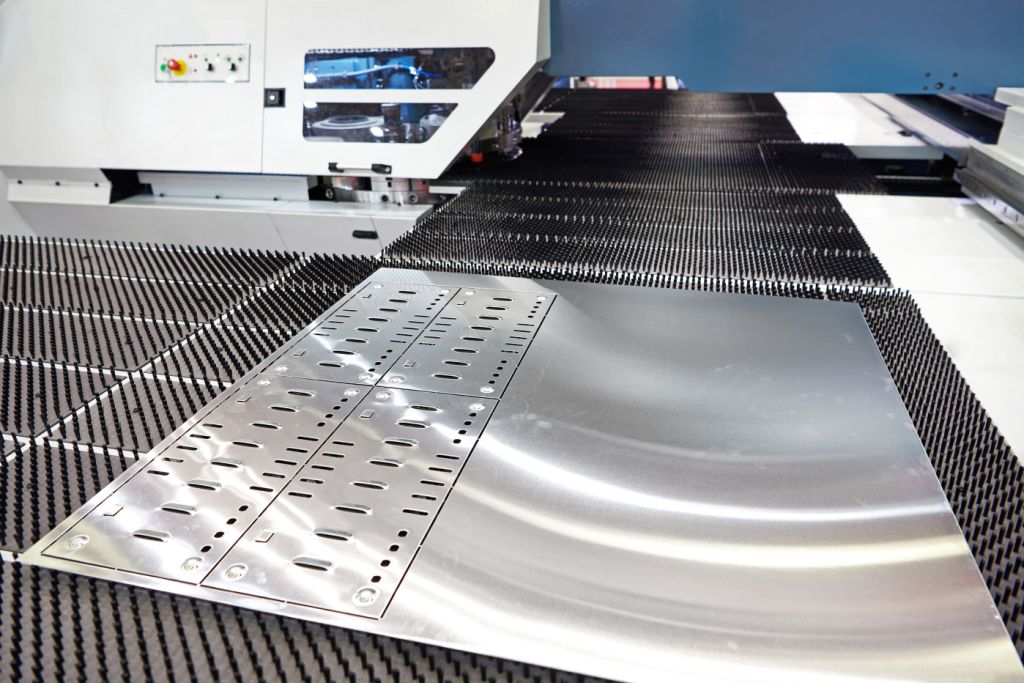

At Wuxi Lead Precision Machinery, our sheet metal die design and fabrication capabilities are engineered for uncompromising accuracy and repeatability in high-mix, low-volume production. We specialize in complex progressive, compound, and transfer dies for aerospace, medical, and automotive applications where dimensional stability directly impacts final part functionality. Our integrated workflow begins with advanced 3D simulation using Siemens NX to validate forming sequences and springback compensation, eliminating costly physical tryouts. This digital-first approach ensures optimal material flow and minimizes stress concentrations critical for high-strength alloys like 7075-T6 aluminum and 301 stainless steel.

Central to our precision is a dedicated 5-axis CNC machining cell featuring DMG MORI CTX beta 1250 and Makino D200Z machines. These platforms enable single-setup machining of intricate die cavities, pierce punches, and stripper plates with sub-5-micron positional accuracy. Multi-axis contouring capability allows us to produce complex organic geometries—such as deep-drawn automotive body panels or medical implant housings—without manual repositioning, reducing cumulative error sources. All critical surfaces are machined to Ra 0.4 µm finish using solid carbide tooling with real-time tool wear compensation, ensuring consistent edge integrity for burr-free shearing.

Quality assurance is governed by our ISO 17025-accredited metrology lab. Every die component undergoes 100% CMM inspection using Zeiss CONTURA systems with VAST XT gold probes, delivering traceable measurements to ±0.0004 inches (10 µm). We implement statistical process control (SPC) on critical features, with real-time data feeds to operators for immediate process adjustment. Surface texture analysis via Bruker optical profilers verifies micro-finish compliance, while hardness testing with Wilson Tukon units confirms material integrity post-heat treatment. This rigorous protocol ensures dies consistently produce sheet metal parts meeting ISO 2768-mK or tighter tolerances over 500,000+ cycles.

The following table summarizes achievable tolerances for production-ready dies across common materials:

| Material Thickness | Dimensional Tolerance | Angular Tolerance |

|---|---|---|

| 0.5 – 1.0 mm | ±0.025 mm | ±0.25° |

| 1.0 – 2.0 mm | ±0.050 mm | ±0.35° |

| 2.0 – 3.0 mm | ±0.075 mm | ±0.50° |

| > 3.0 mm | ±0.100 mm | ±0.75° |

Note: Tolerances assume standard tool steel (A2/D2) and are validated per ASME Y14.5 GD&T standards. Tighter specifications achievable with client-specific process validation.

We extend capabilities beyond machining through in-house heat treatment (vacuum hardening to 58-62 HRC) and surface engineering (TiN/TiCN PVD coatings). Our engineers collaborate from DFM review through first-article inspection, providing detailed capability reports with CMM heat maps and forming analysis. For mission-critical components—such as fuel system brackets or surgical instrument housings—this integrated precision ecosystem delivers dies that eliminate scrap, reduce press downtime, and ensure production stability from day one. Precision is non-negotiable; it is engineered into every process step.

Material & Finish Options

Material Selection in Sheet Metal Die Design: Engineering for Performance and Finish

Selecting the appropriate material in sheet metal die design is a critical step that directly influences the durability, performance, and cost-efficiency of both the tooling and the final fabricated component. At Wuxi Lead Precision Machinery, we emphasize a material-first approach, aligning substrate properties with operational demands such as load, temperature, corrosion exposure, and required surface finish. The three most prevalent materials in high-precision sheet metal fabrication—aluminum, steel, and titanium—each offer distinct advantages tailored to specific industrial applications.

Aluminum is widely favored for its excellent strength-to-weight ratio and superior machinability. It is particularly effective in applications where weight reduction is paramount, such as in aerospace and automotive components. Its high thermal conductivity also makes it ideal for heat dissipation in electronic enclosures. However, aluminum’s lower hardness compared to steel means it may not be suitable for high-wear tooling or long production runs. For die design, aluminum is often used in prototyping and low-volume production due to faster machining times and reduced tool wear.

Steel, particularly tool steel and stainless variants, remains the backbone of industrial die manufacturing. Its high tensile strength, wear resistance, and dimensional stability under repeated stress make it ideal for high-volume stamping and forming operations. Cold-rolled steel offers tight tolerances and smooth surface finishes, while stainless steel provides corrosion resistance for applications in harsh environments such as marine or medical equipment. Although heavier and more challenging to machine than aluminum, steel’s longevity and repeatability justify its use in production-critical tooling.

Titanium, though less common due to its cost and machining complexity, delivers unmatched performance in extreme conditions. With exceptional strength-to-density ratio and resistance to oxidation at elevated temperatures, titanium is employed in aerospace, defense, and high-performance automotive sectors. Its biocompatibility also makes it suitable for medical device fabrication. In die design, titanium components are typically reserved for specialized tooling exposed to high thermal and mechanical stress.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding or aesthetic customization. The anodized layer is integral to the base metal, ensuring it does not chip or peel. While steel and titanium do not anodize in the traditional sense, they benefit from alternative treatments such as passivation, plating, or powder coating.

Below is a comparative overview of key material properties relevant to sheet metal die design.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum | 110–570 | 2.7 | Moderate to High | Prototypes, enclosures, aerospace | Yes |

| Steel | 370–2000 | 7.8 | Low to High (varies) | Stamping dies, structural parts | No |

| Titanium | 900–1200 | 4.5 | Very High | Aerospace, medical, defense | No (specialized processes only) |

Understanding material behavior and finish compatibility ensures optimal die life, part quality, and production efficiency. At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver dies that meet the exacting standards of modern manufacturing.

Manufacturing Process & QC

Sheet Metal Die Design: Precision Execution from Concept to Volume Production

At Wuxi Lead Precision Machinery, our sheet metal die design process rigorously eliminates defects before metal meets tool. We enforce a closed-loop methodology spanning Design, Prototyping, and Mass Production, ensuring geometric integrity and functional reliability for aerospace, automotive, and medical applications. Every phase integrates real-time data analytics and cross-functional validation to achieve Zero Defects—a non-negotiable standard for our global clients.

Design: Engineering Defect Prevention at the Source

Our engineers commence with advanced CAD/CAM simulation using Siemens NX, modeling stress distribution, springback, and material flow for alloys ranging from aluminum 5052 to stainless steel 304. Finite Element Analysis (FEA) validates punch-die clearance tolerances down to ±0.02mm, while Design for Manufacturability (DFM) reviews preempt burrs, warpage, or misalignment. Critical dimensions undergo Geometric Dimensioning and Tolerancing (GD&T) scrutiny against ASME Y14.5 standards, ensuring compatibility with downstream assembly. This phase concludes with a digital twin of the die, approved via client-coordinated virtual sign-off to lock specifications before physical prototyping.

Prototyping: Validating Performance Under Production Conditions

Prototyping transcends simple validation; it is a controlled stress test. We fabricate functional prototypes using rapid tooling on HAAS UMC-750 5-axis machining centers, achieving ±0.01mm positional accuracy. Each prototype undergoes 500-cycle accelerated life testing on our 300-ton Minster press, with in-die sensors monitoring tonnage, alignment, and part ejection. Statistical Process Control (SPC) charts track critical outputs like hole concentricity and edge straightness. If deviations exceed 1.33 Cpk thresholds, we initiate root-cause analysis using Fishbone diagrams and recalibrate the digital twin—never proceeding until all metrics meet Zero Defects criteria.

Mass Production: Sustaining Perfection at Scale

Volume production leverages our automated stamping cells with integrated vision systems and IoT-enabled presses. Real-time data from load cells and laser scanners feed into our MES platform, triggering automatic die adjustments for thermal drift or material batch variations. Every 100th part undergoes automated CMM inspection against the original CAD model, with deviations >0.03mm halting the line instantly. Our Six Sigma-driven approach maintains process capability indices (Cpk) ≥1.67 across 10,000+ part runs, supported by preventive maintenance cycles calibrated to tooling wear analytics.

The table below summarizes our production capabilities for critical die specifications:

| Parameter | Capability Range | Tolerance Control | Validation Method |

|---|---|---|---|

| Press Tonnage | 100–1000 tons | ±1.5% | In-situ load cells |

| Linear Tolerance | 0.05–500 mm | ±0.02 mm | CMM (Zeiss CONTURA) |

| Angular Tolerance | 0°–180° | ±0.1° | Optical comparator |

| Surface Roughness (Ra) | 0.4–3.2 µm | ±0.2 µm | Profilometer (Mitutoyo) |

| Production Speed | 50–1200 strokes/min | ±2 strokes | Encoder monitoring |

Wuxi Lead’s process delivers Zero Defects by treating design as predictive science, prototyping as forensic validation, and production as self-correcting execution. We guarantee ≤50 PPM defect rates through relentless process discipline—not post-production sorting. Partner with us to transform your sheet metal specifications into flawless reality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Sheet Metal Die Design Solutions

When precision, durability, and performance define your manufacturing success, partnering with a trusted expert in sheet metal die design becomes essential. At Wuxi Lead Precision Machinery, we specialize in engineering high-performance dies tailored to the exacting demands of modern sheet metal fabrication. With over 15 years of experience serving global OEMs and Tier-1 suppliers, we deliver engineered solutions that enhance productivity, reduce downtime, and ensure consistent part quality across high-volume production environments.

Our team of senior die designers and CNC engineers combines deep technical expertise with advanced simulation software to optimize every stage of die development. From progressive dies and transfer dies to compound and forming dies, we design for maximum efficiency, material utilization, and tool life. Every die is manufactured using premium-grade tool steels, heat-treated to precise specifications, and machined on state-of-the-art 5-axis CNC systems to ensure micron-level accuracy.

We understand that no two production lines are identical. That’s why our engineering approach is fully collaborative—starting with a detailed analysis of your part geometry, material type, production volume, and press specifications. This ensures that the final die design integrates seamlessly into your existing workflow, minimizing setup time and maximizing throughput.

Our quality assurance protocols are aligned with ISO 9001 standards, and we perform rigorous in-house testing—including strip testing, blanking clearance analysis, and wear resistance validation—before delivery. We also provide comprehensive documentation, including 3D models, assembly drawings, maintenance guidelines, and spare parts lists, to support long-term operational reliability.

Whether you’re launching a new product line or upgrading legacy tooling, Wuxi Lead Precision Machinery offers the technical depth and manufacturing agility to bring your vision to life. We serve industries ranging from automotive and aerospace to industrial equipment and consumer electronics, consistently meeting tight tolerances and complex forming requirements.

Below are key technical specifications that define our die-making capabilities:

| Specification | Capability |

|---|---|

| Die Type | Progressive, Transfer, Compound, Forming, Blanking |

| Material Compatibility | Mild Steel, Stainless Steel, Aluminum, Copper Alloys |

| Maximum Die Size | 2,500 mm × 1,200 mm × 800 mm |

| Tolerance | ±0.02 mm |

| Tool Steel Options | SKD11, D2, Cr12MoV, H13, ASP-23 |

| Surface Treatment | TiN, TiCN, DLC, Nitriding, Hard Chrome Plating |

| CAD/CAM Software | UG NX, SolidWorks, AutoCAD, Mastercam |

| Production Lead Time | 4–8 weeks (depending on complexity) |

Partnering with us means gaining a long-term engineering ally committed to innovation, precision, and on-time delivery. We support clients worldwide with end-to-end project management, real-time progress updates, and post-installation technical assistance.

For expert consultation on your next sheet metal die project, contact us today at [email protected]. Let Wuxi Lead Precision Machinery power your production with dies built to perform.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.