Technical Contents

Engineering Guide: Ejector Pins Injection Molding

Engineering Insight: Ejector Pins in Injection Moulding – The Critical Role of Precision

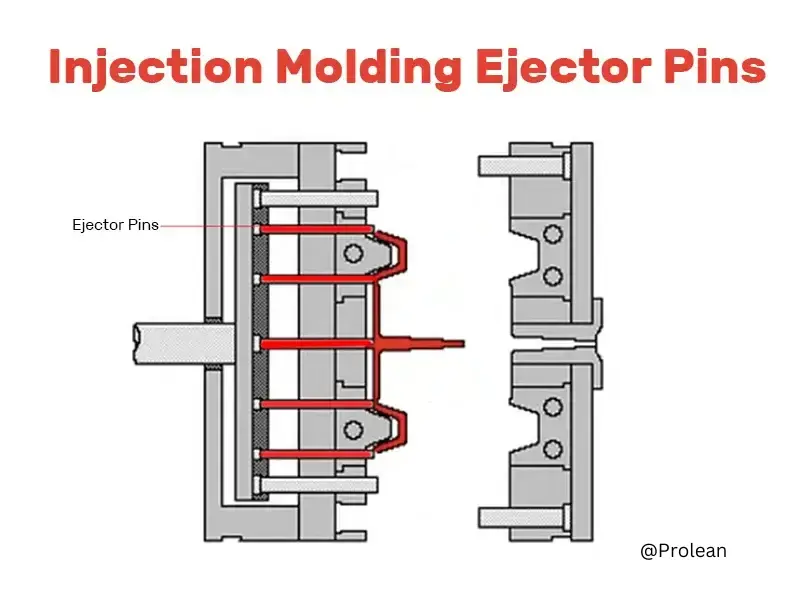

In the high-stakes domain of injection moulding, the performance and longevity of a mould are often determined not by its largest components, but by the smallest and most precisely engineered elements—ejector pins. These slender, hardened steel components are responsible for the controlled ejection of finished plastic parts from the mould cavity. While seemingly simple in function, their design, material selection, and dimensional accuracy directly influence part quality, cycle time, and overall production efficiency.

At Wuxi Lead Precision Machinery, we understand that even a micron-level deviation in ejector pin geometry can result in part damage, flash formation, or premature wear. Our engineering team approaches ejector pin design with the same rigor applied to mission-critical aerospace or defence components—fields where our manufacturing expertise has been validated through projects supporting Olympic-grade equipment and military-grade hardware. This experience instills a culture of uncompromising precision, where repeatability and reliability are non-negotiable.

The operational environment within an injection mould is extreme: high pressure, rapid cycling, and thermal fluctuations demand materials and surface treatments that resist deformation and galling. Standard ejector pins may suffice for low-volume runs, but for high-volume, high-precision manufacturing, custom-engineered solutions are essential. We specialize in tailoring ejector pins to exact client specifications, including custom diameters, lengths, tip geometries, and surface coatings such as TiN (Titanium Nitride) or DLC (Diamond-Like Carbon) to enhance wear resistance and reduce friction.

Our in-house CNC micro-machining and grinding capabilities ensure tolerances held within ±0.001 mm, with concentricity and straightness optimized to prevent binding or misalignment during ejection. Each pin undergoes rigorous inspection using coordinate measuring machines (CMM) and optical profilometry, ensuring compliance with international standards such as ISO 4000 and DIN 1530.

Beyond dimensional accuracy, we integrate thermal and stress analysis during the design phase to predict performance under real-world conditions. This proactive engineering approach minimizes downtime and extends mould life—critical advantages in industries where production continuity is paramount.

| Specification | Standard Range | Custom Capability | Notes |

|---|---|---|---|

| Diameter Tolerance | h6 (ISO 286-2) | ±0.001 mm | Precision-ground |

| Length | 20–300 mm | Up to 500 mm | Custom lengths available |

| Material | SKD61, H13, M2 | Custom alloys | Heat-treated to 52–58 HRC |

| Surface Finish | Ra ≤ 0.2 µm | Ra ≤ 0.05 µm | Polished or coated |

| Coatings | TiN, CrN, DLC | Customer-specified | Enhanced wear resistance |

| Straightness | ≤ 0.01 mm/m | ≤ 0.005 mm/m | Verified via laser alignment |

At Wuxi Lead Precision Machinery, our commitment to excellence in ejector pin manufacturing reflects our broader philosophy: precision is not an option—it is the foundation. Whether supporting high-speed consumer goods production or mission-critical industrial applications, our engineered solutions deliver consistent, reliable performance under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities for Precision Ejector Pin Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical ejector pins engineered for demanding injection molding applications where reliability and dimensional integrity are non-negotiable. Our integrated manufacturing ecosystem, centered on advanced multi-axis machining and rigorous metrology, ensures pins consistently meet the exacting tolerances required for high-cavitation molds, long production runs, and complex part geometries. We understand that pin failure or premature wear directly impacts cycle time, part quality, and overall production cost; our capabilities are specifically designed to eliminate these risks through superior material selection, process control, and verification.

Our core manufacturing strength lies in dedicated 5-axis CNC milling and grinding centers. These state-of-the-art machines enable the complete machining of ejector pins—including precision-ground shanks, complex head geometries, and critical tip profiles—in a single setup. This eliminates cumulative errors inherent in multi-operation processes, ensuring exceptional concentricity between functional surfaces. We specialize in machining challenging tool steels such as H13, SKD61, and pre-hardened P20 to exact customer specifications, utilizing optimized cutting strategies and high-precision tooling to achieve superior surface finishes directly off the machine. The simultaneous 5-axis capability is essential for producing pins with non-standard head angles, undercuts, or intricate tip features demanded by modern mold designs, significantly reducing lead times without compromising accuracy.

Quality assurance is not a final step but an embedded process throughout production. Every ejector pin undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols verify all critical dimensions defined in the engineering drawing, including diameter tolerances, straightness, concentricity, total indicated runout (TIR), and surface roughness. Inspection reports provide full traceability, documenting actual measured values against specified tolerances with NIST-traceable calibration. This data-driven approach guarantees conformance and provides customers with verifiable proof of quality for their internal quality systems and audits. We strictly adhere to international standards while also accommodating specific customer inspection requirements.

The following table details our standard and achievable tight tolerance capabilities for critical ejector pin parameters, reflecting the precision attainable through our integrated CNC and CMM processes:

| Parameter | Standard Tolerance | Tight Tolerance (Agreement Required) |

|---|---|---|

| Diameter (Shank/Tip) | ±0.005 mm | ±0.002 mm |

| Straightness | 0.01 mm / 100 mm | 0.005 mm / 100 mm |

| Concentricity (Tip) | 0.01 mm TIR | 0.005 mm TIR |

| Surface Roughness (Ra) | 0.4 μm | 0.2 μm |

| Tip Angle | ±0.5° | ±0.2° |

| Head Geometry | ±0.02 mm | ±0.01 mm |

This combination of advanced 5-axis CNC manufacturing, stringent CMM-based inspection, and a commitment to documented precision ensures Wuxi Lead Precision Machinery produces ejector pins that maximize mold uptime, extend component life, and contribute directly to the stability and profitability of our customers’ injection molding operations. We partner with mold makers to solve complex ejection challenges through engineered manufacturing solutions.

Material & Finish Options

Material Selection for Ejector Pins in Injection Molding

Selecting the appropriate material for ejector pins is critical to ensuring longevity, dimensional stability, and performance under repeated thermal and mechanical stress in injection molding applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-precision molding systems. Our engineering expertise enables clients to make informed decisions between aluminum, steel, and titanium based on operational demands, mold complexity, and production volume.

Aluminum is often chosen for prototype molds or low-volume production due to its excellent machinability and thermal conductivity. It allows for rapid heat dissipation, reducing cycle times during testing phases. However, aluminum lacks the hardness and wear resistance required for long production runs, making it less suitable for ejector pins subjected to frequent ejection cycles. Surface treatments such as hard anodizing can improve surface hardness and corrosion resistance, but even anodized aluminum remains inferior to steel or titanium in high-stress environments.

Steel, particularly tool steels like H13, P20, or S136, is the most widely used material for ejector pins in industrial injection molding. These alloys offer high tensile strength, excellent wear resistance, and the ability to maintain dimensional accuracy under elevated temperatures. Through precision heat treatment and grinding processes, steel ejector pins achieve the necessary hardness (typically 48–54 HRC) to withstand repeated contact with molded parts and cavity surfaces. Stainless variants such as 420 stainless steel also provide enhanced corrosion resistance, ideal for molds processing abrasive or corrosive resins.

Titanium represents the premium choice for applications demanding extreme durability, lightweight performance, and resistance to galling. With a superior strength-to-density ratio and excellent performance at elevated temperatures, titanium ejector pins are ideal for high-cycle molds and aerospace or medical applications where contamination and wear must be minimized. Though more costly and challenging to machine, titanium’s natural oxide layer provides inherent corrosion resistance, reducing the need for additional surface treatments.

Anodizing is a common finish applied to aluminum components, including mold bases or non-critical ejector elements. This electrochemical process thickens the natural oxide layer, enhancing surface hardness up to 600 HV and improving wear and corrosion resistance. While beneficial for aluminum, anodizing is not applicable to steel or titanium in the conventional sense—these materials rely on nitriding, chrome plating, or PVD coatings for surface enhancement.

Below is a comparative overview of key material properties relevant to ejector pin performance.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum | 15–30 (anodized) | 300–400 | 150–200 | Moderate | Prototypes, low-volume molds |

| Steel (H13) | 48–52 | 1,500–1,800 | 30–35 | Low to Moderate | High-volume industrial molds |

| Titanium | 35–40 | 900–1,100 | 7–8 | High | Aerospace, medical, high-cycle |

Material selection directly impacts mold efficiency, maintenance intervals, and part quality. Wuxi Lead Precision Machinery supports clients in matching material and finish options to specific production requirements, ensuring optimal performance and cost-effectiveness across the mold lifecycle.

Manufacturing Process & QC

Precision Ejector Pin Production: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our ejector pin manufacturing process for injection molding applications is engineered to eliminate defects before they reach the production floor. We integrate advanced engineering controls across three critical phases, ensuring every pin meets micron-level tolerances and withstands extreme cyclic stresses. The foundation begins in Design, where our engineers collaborate with clients to translate cavity geometry and ejection force requirements into optimized pin specifications. Utilizing GD&T standards and finite element analysis (FEA), we simulate thermal expansion, deflection under load, and wear patterns. Material selection—primarily premium H13, SKD61, or custom tool steels—is validated against resin chemistry and mold temperature profiles to prevent galling or corrosion. This phase concludes with a digitally signed-off 3D model, incorporating client feedback and ISO 2768-mK tolerancing protocols.

Prototyping transforms validated designs into physical test assets under controlled conditions. Each prototype pin undergoes rigorous metrology using Zeiss coordinate measuring machines (CMM) to verify concentricity (≤0.002 mm), taper accuracy (±0.001°), and tip geometry. We then subject pins to accelerated life testing in client-simulated molds, monitoring for deformation at 10,000+ ejection cycles. Critical dimensions are re-measured post-testing; any deviation beyond 50% of tolerance triggers immediate design refinement. This phase includes surface integrity validation via profilometry and micro-hardness mapping, ensuring the core remains ductile while the surface achieves target hardness. Only prototypes passing 100% of functional and dimensional checks advance to mass production.

Mass Production executes at scale with embedded zero-defect safeguards. Our CNC grinding and EDM centers operate under Statistical Process Control (SPC), with real-time monitoring of spindle load, coolant pressure, and dimensional drift. Every pin is 100% inspected for diameter tolerance, straightness, and surface finish using automated optical comparators before laser-etching traceable serial numbers. In-process audits sample hardness (HRC 52-56) and concentricity hourly, while final inspection cross-references against the original FEA model. Material certificates, heat treatment logs, and inspection reports are digitally archived for full traceability. This closed-loop system reduces defect escape risk to <10 PPM, preventing catastrophic mold damage and costly downtime for clients.

Wuxi Lead Ejector Pin Critical Specifications

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Diameter Tolerance | ±0.001 mm to ±0.005 mm | ISO 286-2 (IT3-IT5) |

| Concentricity | ≤ 0.002 mm | ISO 1101 |

| Surface Roughness | Ra ≤ 0.05 µm | ISO 1302 |

| Hardness | HRC 52-56 (core) | ASTM E18 |

| Tip Angle Tolerance | ±0.001° | Custom GD&T |

| Straightness | ≤ 0.003 mm/m | ISO 1101 |

This seamless transition from design validation through prototyping rigor to SPC-driven mass production guarantees ejector pins that deliver consistent ejection performance, extended mold life, and true zero-defect reliability for high-volume manufacturing. Wuxi Lead Precision Machinery operates at the intersection of metallurgical science and precision engineering to protect your production continuity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Ejector Pins for Injection Molding

At Wuxi Lead Precision Machinery, we specialize in the design and production of high-performance ejector pins tailored to the rigorous demands of modern injection molding applications. As a trusted name in custom metal manufacturing, we understand that precision, durability, and consistency are non-negotiable in high-volume production environments. Our engineering team combines decades of industry experience with advanced CNC machining capabilities to deliver ejector pins that exceed international standards.

Injection molding success hinges on every component performing flawlessly under pressure. Ejector pins, though small in size, play a critical role in part ejection, cycle time efficiency, and mold longevity. Poorly manufactured pins lead to premature wear, sticking, or part damage—costly issues that disrupt production and compromise quality. At Lead Precision, we eliminate these risks through strict material selection, precision grinding, and rigorous quality control. Whether you require standard configurations or fully customized solutions, our team works closely with your engineers to match your exact specifications and operational requirements.

We manufacture ejector pins from premium-grade tool steels, including SKD61, SKH51, and custom alloys, ensuring optimal hardness, wear resistance, and thermal stability. Each pin undergoes precision grinding to achieve tight tolerances, mirror-like surface finishes, and perfect concentricity. Our in-house heat treatment processes further enhance durability, allowing pins to withstand thousands of cycles without deformation or failure.

Our commitment to excellence is reflected not only in our products but also in our service. We offer rapid prototyping, fast turnaround times, and comprehensive technical support throughout the product lifecycle. From initial consultation to final delivery, Lead Precision ensures a seamless partnership backed by ISO 9001-certified quality management systems.

Below are the standard specifications we support. All parameters can be customized based on your mold design and application needs.

| Specification | Standard Range / Option |

|---|---|

| Pin Diameter | 0.5 mm – 25.0 mm |

| Pin Length | 10 mm – 500 mm (custom lengths available) |

| Material Options | SKD61, SKH51, H13, Stainless Steel, Custom Alloys |

| Hardness | 50–60 HRC (adjustable) |

| Surface Finish | Ra ≤ 0.05 µm (mirror finish) |

| Tolerance | ±0.005 mm (tighter on request) |

| Coating Options | TiN, TiCN, DLC, Nitriding |

| Applications | Plastic Injection Molding, Die Casting, LSR Molding |

When performance matters, partner with a manufacturer that understands the science behind the steel. Contact us today to discuss your ejector pin requirements. Our engineering team is ready to provide technical guidance, material recommendations, and custom solutions that elevate your molding process.

Email us at [email protected] to start the conversation. Let Wuxi Lead Precision Machinery be your precision partner in injection molding excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.