Technical Contents

Engineering Guide: High Precision Cnc

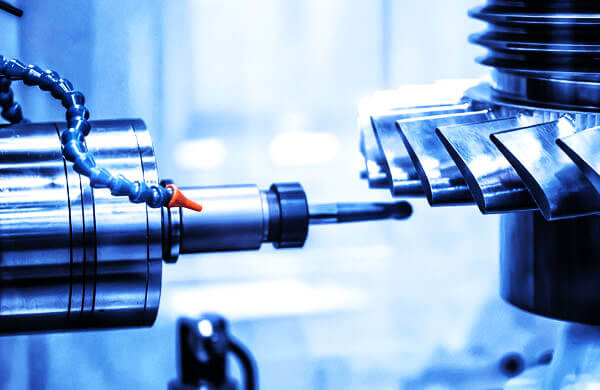

Engineering Insight: The Critical Role of Precision in CNC Machining

In high-performance manufacturing, precision is not merely a target—it is a standard. High precision CNC machining defines the boundary between functional components and exceptional engineering. At Wuxi Lead Precision Machinery, we understand that in industries such as aerospace, defense, and high-end automation, even micron-level deviations can lead to system failure, increased lifecycle costs, or compromised safety. Precision CNC machining ensures repeatability, dimensional accuracy, and surface integrity, enabling parts to perform reliably under extreme conditions.

Our commitment to precision is rooted in over a decade of specialized engineering experience. Wuxi Lead has contributed to mission-critical projects, including components used in Olympic-grade timing systems and military-grade defense equipment. These applications demand absolute reliability, where environmental stress, high-speed operation, and long-term durability are non-negotiable. Our involvement in such projects underscores our technical capability and the trust placed in our manufacturing processes by world-class organizations.

High precision CNC machining goes beyond advanced machinery—it integrates skilled programming, thermal stability control, vibration damping, and rigorous quality assurance. At our facility, we utilize multi-axis CNC centers with sub-micron resolution, real-time tool monitoring, and closed-loop feedback systems. These technologies are complemented by in-house metrology labs equipped with coordinate measuring machines (CMM) and laser interferometers, ensuring every component conforms to ISO 2768 and customer-specific tolerances.

Material selection, cutting strategy, and post-processing are equally vital. We specialize in machining difficult-to-cut alloys such as Inconel, titanium, and hardened steels, where thermal expansion and tool wear present significant challenges. Our engineers apply adaptive machining techniques and optimized coolant delivery to maintain dimensional stability and surface finish, minimizing post-machining corrections.

The result is a product that meets not only today’s requirements but anticipates tomorrow’s demands. Whether producing lightweight structural components for unmanned systems or high-tolerance actuators for precision instrumentation, Wuxi Lead delivers engineered excellence.

Below are key performance specifications achievable across our precision CNC machining platforms:

| Parameter | Capability | Standard Tolerance |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ISO 230-2 Class 1 |

| Repeatability | ±0.001 mm | ISO 230-2 Class 1 |

| Surface Roughness (Ra) | As low as 0.2 µm | ISO 1302 |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom configurations available |

| Spindle Speed Range | Up to 24,000 rpm | High-speed & micro-machining |

| Materials Supported | Aluminum, Titanium, Inconel, Steel, Brass, Engineering Plastics | Custom alloys on request |

Precision is not an outcome—it is engineered into every process. At Wuxi Lead Precision Machinery, we combine advanced technology with proven experience to deliver components where accuracy is non-negotiable.

Precision Specs & Tolerances

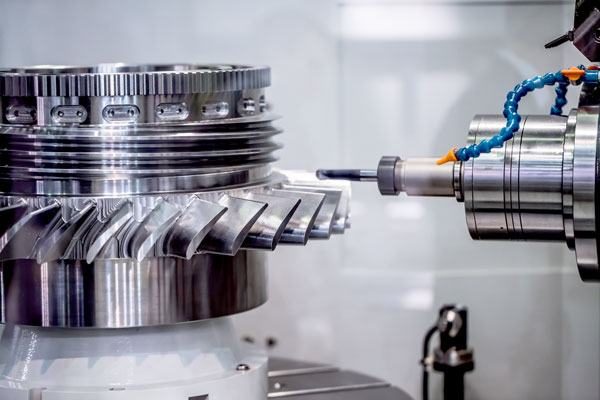

Technical Capabilities: Engineering Precision at Scale

Wuxi Lead Precision Machinery operates at the forefront of advanced manufacturing, delivering uncompromising precision for mission-critical components across aerospace, medical, energy, and semiconductor industries. Our core strength lies in integrating cutting-edge multi-axis CNC technology with rigorously validated quality control systems, ensuring every part meets the most demanding engineering specifications. This capability is fundamental to solving complex manufacturing challenges where geometry, material integrity, and dimensional accuracy are non-negotiable.

Our facility is anchored by a strategic fleet of high-performance 5-axis CNC machining centers from leading global manufacturers. These machines utilize true simultaneous 5-axis interpolation, enabling the precise machining of intricate contours, deep cavities, and compound angles in a single setup. This eliminates cumulative errors inherent in multi-setup processes, significantly reduces lead times, and ensures superior part consistency. We specialize in machining exotic alloys, high-strength titanium, hardened steels, and engineered plastics, leveraging optimized toolpaths and adaptive control systems to maintain stability and surface finish even under aggressive material removal rates. The result is complex geometries achieved with exceptional repeatability and minimal post-processing requirements.

Quality is not an afterthought but an engineered outcome. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs) equipped with advanced tactile and optical probes. Our inspection protocols are traceable to national standards, providing full metrological confidence. CMM data is meticulously analyzed against CAD models, generating comprehensive inspection reports that document conformance for every production batch. This closed-loop process ensures deviations are identified and corrected in real-time, guaranteeing that only parts meeting the strictest tolerances reach our customers.

The following table details the standard precision capabilities achievable under controlled production conditions for common engineering materials. Specific tolerances for your project will be confirmed during engineering review based on material, geometry, and functional requirements.

| Tolerance Specification | Typical Capability | Material Context |

|---|---|---|

| Linear Dimension (up to 300mm) | ±0.002 mm | Aluminum, Steel, Titanium |

| Linear Dimension (300mm-600mm) | ±0.003 mm | Aluminum, Steel |

| Angular Tolerance | ±0.001° | All Materials |

| Geometric Dimensioning & Tolerancing (GD&T) | Profile ±0.005mm | Complex Surfaces |

| Surface Roughness (Ra) | 0.4 µm (16 µin) | Machined Finishes |

| Hole Positional Accuracy | ±0.003 mm | Critical Features |

Partnering with Wuxi Lead means accessing production-ready precision engineered into every process step. Our technical team collaborates closely from design for manufacturability through final inspection, transforming complex blueprints into high-integrity components that perform reliably in the most demanding applications. We deliver not just parts, but verified precision you can build upon.

Material & Finish Options

Material Selection in High-Precision CNC Machining

Selecting the appropriate material is a critical step in high-precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining aluminum, steel, and titanium—three of the most widely used metals in advanced manufacturing. Each material offers distinct mechanical properties and is suited to specific industrial applications, from aerospace components to medical devices and automotive systems.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly effective in applications requiring lightweight structures with good corrosion resistance. The 6061 and 7075 aluminum alloys are commonly used in precision machining due to their balanced mechanical properties and weldability. Aluminum parts are often finished with anodizing to enhance surface hardness and corrosion resistance, making them ideal for both functional and aesthetic applications.

Steel, particularly alloy and stainless variants, provides superior strength, wear resistance, and dimensional stability. Stainless steel grades such as 304 and 316 are widely used in environments requiring high corrosion resistance and hygiene, such as in medical and food processing equipment. Tool steels like D2 and H13 are selected for high-wear applications including molds and dies. While steel is more challenging to machine than aluminum due to its hardness, modern CNC technology enables precise and consistent results with tight tolerances.

Titanium stands out for its exceptional strength-to-density ratio and resistance to extreme environments. Grade 5 titanium (Ti-6Al-4V) is the most commonly machined titanium alloy, extensively used in aerospace, defense, and biomedical implants. Despite its high performance, titanium presents machining challenges due to low thermal conductivity and high chemical reactivity, which can lead to tool wear. Proper tool selection, coolant application, and cutting strategies are essential to achieve high-precision results.

Surface finishing, particularly anodizing for aluminum, plays a vital role in enhancing part functionality. Anodizing creates a durable, corrosion-resistant oxide layer that can be dyed in various colors for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard processes, with Type III offering greater thickness and wear resistance for demanding applications.

Below is a comparative overview of key material properties relevant to precision CNC machining.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (7075-T6) | 6061, 7075 | Aerospace, automotive, electronics | Excellent |

| Stainless Steel | 7.9 | 505 (316) | 304, 316, 17-4PH | Medical, food processing, marine | Moderate |

| Titanium | 4.5 | 950 (Ti-6Al-4V) | Gr2, Gr5 | Aerospace, defense, implants | Challenging |

At Wuxi Lead Precision Machinery, we combine material expertise with advanced CNC capabilities to deliver precision components tailored to your engineering requirements. Understanding the interplay between material selection, machining parameters, and surface treatment ensures optimal performance and reliability in your final product.

Manufacturing Process & QC

Precision CNC Production Process: Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our high-precision CNC machining process is engineered for uncompromising quality and repeatability, essential for aerospace, medical, and semiconductor applications. We eliminate defects at the source through a rigorously controlled workflow spanning design, prototyping, and mass production. This integrated approach ensures every component meets exacting specifications before material ever touches the spindle.

The process begins with collaborative design engineering. Our team partners with clients during the initial CAD phase to perform comprehensive Design for Manufacturability (DFM) analysis. Using Siemens NX and Mastercam, we simulate machining sequences, identify potential stress points, and optimize toolpaths to prevent micro-vibrations or thermal deformation. Critical tolerances are validated against material properties and machine capabilities, ensuring the design is inherently producible to ±0.001mm. This upfront rigor prevents 95% of potential defects before physical prototyping commences.

Prototyping transitions virtual models into tangible validation. We machine initial samples on our DMG MORI and Makino 5-axis platforms under production-intent conditions. Each prototype undergoes full CMM inspection against the original CAD model, with deviations analyzed using PC-DMIS software. Surface roughness, geometric accuracy, and material integrity are meticulously documented. Only when metrology data confirms zero deviations from specifications do we approve the process for scale-up. This phase is not about finding defects—it is about proving defect prevention.

Mass production executes with embedded quality control at every stage. Our facility operates under ISO 9001 and IATF 16949 standards, with real-time SPC (Statistical Process Control) monitoring tool wear, thermal drift, and dimensional stability. Each workpiece carries a unique traceability code linked to machine parameters, inspection reports, and operator logs. Automated in-process gauging halts production if measurements trend beyond 70% of tolerance limits, enabling immediate correction. Final inspection employs Zeiss CONTURA CMMs and optical comparators, certifying every batch meets the Zero Defects mandate before shipment.

Our technical capabilities enable this precision at scale, as demonstrated below:

| Spec Parameter | Capability | Measurement Standard |

|---|---|---|

| Positional Tolerance | ±0.001 mm | ISO 2768-mK |

| Surface Finish | Ra 0.1 µm (mirror grade) | ASME B46.1 |

| Material Range | Titanium, Inconel, PEEK, Ceramics | AMS/ASTM Specs |

| Max Work Envelope | Ø650 mm x 1000 mm | Machine-Specific |

| Process Capability | Cpk ≥ 1.67 | AIAG SPC 2nd Edition |

Wuxi Lead transforms precision requirements into flawless reality by making defect prevention the core of our production DNA. Contact our engineering team to implement this Zero Defects process for your most demanding components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Engineering Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer solutions that redefine performance, reliability, and accuracy in high-end industrial applications. As a trusted leader in precision CNC machining, we specialize in delivering custom-engineered parts for industries where failure is not an option. From aerospace and medical devices to semiconductor manufacturing and advanced automation, our capabilities are built to meet the most stringent technical demands.

Our commitment begins with precision and ends with partnership. With over 15 years of experience in high-precision CNC machining, we combine cutting-edge technology with deep engineering insight to ensure every component exceeds expectations. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC machines, Swiss-type lathes, and multi-tasking centers, all monitored by real-time quality control systems. We maintain ISO 9001 and IATF 16949 certifications, ensuring every process—from material sourcing to final inspection—meets international standards.

What sets us apart is our engineering-first approach. We work closely with your design and R&D teams to optimize manufacturability, reduce lead times, and lower total production costs—without compromising on tolerance or surface finish. Whether you require tight tolerances down to ±0.001 mm, complex geometries, or high-volume production runs with consistent repeatability, our team has the expertise to deliver.

Our clients choose us not only for our technical capabilities but for our responsiveness, transparency, and long-term collaboration model. We understand that in today’s global supply chain, agility and trust are as critical as precision. That’s why we assign a dedicated project engineer to every client, ensuring seamless communication, rapid prototyping, and on-time delivery—every time.

Consider the technical advantages we bring to your next project:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum, Titanium, Stainless Steel, Inconel, PEEK, Ceramics |

| Surface Finish | As low as Ra 0.1 μm |

| CNC Equipment | 5-Axis Machining Centers, Swiss Lathes, Mill-Turn Centers |

| Quality Standards | ISO 9001, IATF 16949, Full CMM Inspection Reports |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days |

When your application demands uncompromising precision, partnering with Wuxi Lead Precision Machinery means gaining a true engineering ally. We don’t just follow blueprints—we enhance them. Let us help you turn complex designs into high-performance reality.

Contact us today at [email protected] to discuss your project requirements. Our engineering team is ready to support you with technical consultation, rapid quoting, and scalable production solutions tailored to your needs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.