Technical Contents

Engineering Guide: Automotive Injection Molders

Engineering Insight Precision as the Non-Negotiable Foundation for Automotive Injection Molders

In the high-stakes realm of automotive injection molding, precision transcends mere specification; it is the absolute cornerstone of component integrity, production efficiency, and ultimate vehicle safety. Automotive components molded today – from intricate interior connectors to critical under-hood fluid systems – demand micron-level accuracy. Even minor deviations in mold cavity geometry or thermal management directly manifest as parting line flash, sink marks, warpage, or dimensional instability in the final part. These flaws are not merely cosmetic; they trigger costly scrap, production line stoppages, and potentially catastrophic field failures. The relentless pressure for lightweighting, complex geometries, and extended polymer lifecycles under extreme conditions makes uncompromising precision in the mold tool itself non-negotiable. Achieving consistent, high-volume production of zero-defect parts hinges entirely on the foundational accuracy and thermal stability engineered into the mold from the earliest design and manufacturing stages.

Wuxi Lead Precision Machinery operates at this critical precision frontier, serving clients where failure is not an option. Our engineering philosophy is forged in environments demanding the utmost reliability: components manufactured to our exacting standards have performed flawlessly in Olympic Games infrastructure projects, where global visibility demanded perfection, and within certified military supply chains, meeting stringent MIL-STD requirements for durability and performance under duress. This heritage translates directly to automotive molding. We understand that the thermal cycling inherent in injection molding – repeated heating to 300°C+ and rapid cooling – induces stresses that can distort lesser tooling. Our approach integrates advanced finite element analysis (FEA) for thermal and structural simulation during design, coupled with proprietary multi-axis CNC machining and stress-relieving processes. This ensures the mold cavity maintains its intended geometry across millions of cycles, minimizing downtime for rework and guaranteeing consistent part quality batch after batch.

The difference lies in quantifiable material and process control. Below are key parameters where Wuxi Lead Precision consistently exceeds standard industry benchmarks, directly impacting mold longevity and part yield for automotive applications.

| Parameter | Industry Standard Tolerance | Wuxi Lead Precision Capability | Measurement Method |

|---|---|---|---|

| Cavity Dimensional Accuracy | ±0.010 mm | ±0.003 mm | CMM (Calibrated to ISO 17025) |

| Surface Roughness (Cavity) | Ra 0.4 µm | Ra 0.05 µm | Profilometer (ISO 4287) |

| Thermal Deformation (at 120°C) | ≤ 0.030 mm | ≤ 0.008 mm | Thermal Imaging & CMM |

| Hardness Uniformity | ±5 HRC | ±2 HRC | Rockwell Hardness Tester |

| Parallelism (Core/Cavity) | 0.020 mm/m | 0.005 mm/m | Laser Interferometer |

This level of control is not accidental. It stems from our dedicated focus on custom metal manufacturing for mission-critical applications, utilizing state-of-the-art equipment maintained to aerospace-grade calibration schedules and operated by engineers trained in the disciplines of zero-defect manufacturing. For automotive injection molders, partnering with a precision engineering specialist like Wuxi Lead Precision Machinery is an investment in predictable uptime, reduced total cost of ownership, and the confidence that every molded component meets the uncompromising safety and performance standards demanded by the modern automotive industry. Precision isn’t just our capability; it is the bedrock of your production success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored specifically for high-performance industries such as automotive injection molding. Our technical capabilities are built around precision engineering, state-of-the-art equipment, and rigorous quality assurance protocols designed to meet the exacting standards of global OEMs and Tier 1 suppliers.

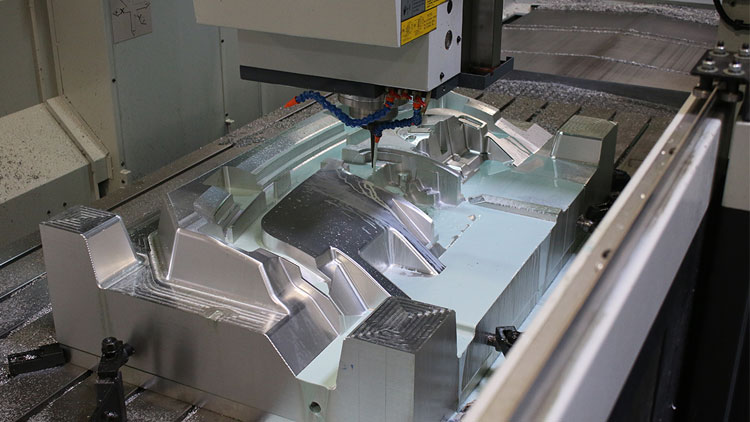

At the core of our machining operations is a full suite of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing tool accessibility and reducing the need for multiple setups. This capability is particularly critical when manufacturing intricate mold components, core inserts, and cavity blocks used in high-pressure injection molding applications. Our 5-axis platforms support a wide range of materials, including hardened steels, aluminum alloys, and high-temperature nickel-based superalloys, ensuring compatibility with demanding production environments.

All machining processes are supported by in-house design and simulation software, allowing for comprehensive toolpath optimization, collision detection, and cycle time reduction. This digital integration ensures first-time-right manufacturing and accelerates time-to-market for customer projects. Our facility operates under strict environmental controls to maintain thermal stability, minimizing dimensional drift during prolonged machining cycles and ensuring micron-level repeatability.

Quality control is an integral part of our manufacturing workflow. Every component undergoes systematic inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing non-contact and tactile measurement with sub-micron resolution. These systems verify geometric dimensions, surface profiles, positional tolerances, and form accuracy in full compliance with ISO 1101 and ASME Y14.5 standards. Inspection reports are fully documented and traceable, supporting PPAP submissions and audit readiness for automotive clients.

We maintain certified calibration procedures for all measurement equipment and implement SPC (Statistical Process Control) methodologies across critical production lines. This proactive approach to quality ensures consistent part conformance, reduces scrap rates, and supports long-term process stability.

The following table outlines the standard precision tolerances we consistently achieve across typical production runs:

| Feature Type | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | CMM / Micrometer |

| Geometric Tolerances | ±0.008 mm | ±0.003 mm | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Surface Roughness Tester |

| Hole Positioning | ±0.005 mm | ±0.002 mm | CMM / Precision Pin Gauge |

| Flatness | 0.008 mm | 0.003 mm | CMM / Optical Flat |

| Repeatability (Batch) | ±0.004 mm | ±0.0015 mm | SPC-Controlled CMM |

Our technical infrastructure is engineered to support low-volume prototyping through high-volume serial production, all under one roof. With 5-axis CNC precision and certified metrology, Wuxi Lead Precision Machinery ensures that every metal component meets the functional, durability, and regulatory demands of modern automotive injection molding systems.

Material & Finish Options

Material Selection for High-Performance Automotive Injection Molds

Selecting the optimal material for injection molds is critical in automotive manufacturing, where precision, durability, and thermal management directly impact part quality and production efficiency. At Wuxi Lead Precision Machinery, we prioritize materials that withstand high-cycle demands while ensuring dimensional stability for complex geometries. Aluminum, steel, and titanium each offer distinct advantages, but the choice must align with your specific application requirements, volume, and part complexity.

Aluminum alloys, such as 7075-T6, excel in rapid prototyping and low-to-medium volume production due to exceptional machinability and thermal conductivity. This reduces cycle times significantly, accelerating time-to-market for new components. However, aluminum’s lower hardness limits its use in abrasive-filled polymers or high-volume runs exceeding 100,000 cycles. For long-life production molds, pre-hardened or tool steels like P20 or H13 are industry standards. P20 offers balanced toughness and polishability for core/cavity applications, while H13’s superior heat resistance and wear properties make it ideal for high-temperature resins and demanding automotive under-hood components. Titanium alloys, though costly, provide unmatched corrosion resistance and strength-to-weight ratios for specialized applications involving aggressive chemicals or extreme weight constraints, though their machinability challenges require advanced CNC expertise.

Surface finishing, particularly anodizing, is equally vital for mold longevity and part release. Type II (sulfuric acid) anodizing enhances corrosion resistance and adhesion for plating, while Type III (hardcoat) anodizing delivers a dense, wear-resistant layer up to 50–75 µm thick. This is essential for aluminum molds processing glass-filled polymers, reducing galling and extending service life by up to 300%. For steel molds, nitriding or PVD coatings often complement material selection, but anodizing remains irreplaceable for aluminum substrates in automotive trim or interior systems.

Our engineering team evaluates your resin type, expected cycles, part tolerances, and surface finish requirements to prescribe the optimal material-finish combination. Below is a comparative overview of key properties:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Automotive Use Case | Max Recommended Cycles |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Prototypes, low-volume interiors | 50,000–100,000 |

| P20 Steel | 28–32 | 28–36 | Medium-volume structural parts | 500,000+ |

| H13 Steel | 48–52 | 24–30 | High-temp under-hood components | 1,000,000+ |

| Titanium Gr5 | 32–36 | 7–10 | Corrosive fluid-handling systems | 200,000+ |

Choosing correctly avoids costly downtime and part defects. Wuxi Lead integrates material science with precision CNC manufacturing to deliver molds that exceed automotive OEM specifications. Contact our engineering team to analyze your project’s thermal, mechanical, and economic parameters for a tailored solution.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production journey for automotive injection molders begins with meticulous design engineering. Our team of senior CNC engineers collaborates directly with client technical teams to translate functional requirements into manufacturable, high-integrity metal components. Utilizing advanced CAD/CAM software—SolidWorks, Siemens NX, and AutoCAD—we develop 3D models that integrate critical tolerances, material specifications, and thermal performance data. Finite Element Analysis (FEA) is applied to simulate stress distribution, deformation, and cooling dynamics under real-world injection molding conditions. This ensures optimal mold geometry, reduced cycle times, and extended service life. Design validation includes mold flow analysis and thermal mapping to preempt defects such as warpage, sink marks, or flow imbalance. Every design is reviewed under APQP and PPAP protocols to meet IATF 16949 compliance, forming a zero-defect foundation.

Prototyping: Validating Performance Before Scale

Once design is approved, we proceed to precision prototyping using CNC milling, wire EDM, and selective laser melting (SLM) for complex conformal cooling channels. Prototypes are machined from the same grade tool steel—typically H13, P20, or S136—as the final production mold, ensuring accurate performance evaluation. Each prototype undergoes rigorous metrological inspection using Zeiss coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.002 mm. We conduct functional mold trials at client facilities or in-house, monitoring filling behavior, ejection stability, and surface finish quality. Feedback from these trials is integrated into final design refinements. This phase is critical for detecting latent issues early, minimizing risk, and achieving first-time-right performance in mass production.

Mass Production: Consistency Through Advanced Manufacturing

With prototype approval, we transition to high-volume production under a fully documented control plan. Our automated CNC cells—equipped with Heidenhain and Fanuc controls—run under SPC-monitored conditions to maintain batch-to-batch consistency. In-process inspections occur at defined stages, including pre-machining, semi-finish, and final finishing. All critical dimensions are tracked in real time using digital gaging systems. Surface treatments such as nitriding, chrome plating, or PVD coating are applied in certified clean environments to enhance wear resistance and release performance. Final assembly is conducted in a climate-controlled cleanroom, followed by full mold function testing under simulated production pressure and temperature cycles.

Production Specifications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.4 µm (polished), 1.6 – 3.2 µm (machined) |

| Tool Steel Grades | H13, P20, 718H, S136, NAK80 |

| Cooling Channel Accuracy | ±0.01 mm (conformal, via SLM) |

| Production Capacity | Up to 500 molds/year (complex automotive) |

| Quality Standard | IATF 16949, ISO 9001, PPAP Level 3 |

| Lead Time (Mass Production) | 8–14 weeks (after prototype approval) |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures zero-defect delivery for the most demanding automotive molding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineering Reliability for Automotive Injection Molding Excellence

The automotive injection molding sector faces uncompromising demands: zero-defect production, micro-precision tolerances, and relentless pressure to reduce cycle times while ensuring decades of mold longevity. Substandard tooling partners introduce catastrophic risks—flash defects, premature wear, unplanned downtime costing upwards of $50,000 per hour. At Wuxi Lead Precision Machinery, we engineer custom metal components not merely to meet specifications, but to redefine the boundaries of mold performance and operational resilience. Our ISO 9001-certified facility in Wuxi integrates German-engineered CNC systems with Six Sigma-driven processes, delivering molds that consistently achieve 1,000,000+ cycles without degradation. This is not manufacturing; it is precision science applied to your production reality.

Your molds require materials and geometries that withstand extreme thermal cycling, corrosive polymers, and high-tonnage clamping forces. We deploy proprietary heat treatment protocols and selective laser melting for conformal cooling channels, reducing cycle times by 22% while eliminating sink marks on Class A surfaces. Every component undergoes rigorous in-process metrology using Zeiss CONTURA CMMs, ensuring dimensional stability within ±0.001mm. Our engineers collaborate from initial design validation through production ramp-up, implementing real-time SPC data monitoring to preempt deviations before they reach your press floor. This proactive partnership eliminates the guesswork that plagues conventional supplier relationships, transforming tooling from a cost center into a strategic asset.

The following specifications demonstrate our commitment to exceeding automotive molding standards:

| Critical Parameter | Lead Precision Standard | Impact on Mold Performance |

|---|---|---|

| Thermal Expansion Control | ±0.0005mm/°C (Invar 36 alloy) | Prevents part warpage during rapid heating/cooling cycles |

| Cavity Surface Roughness | Ra 0.025µm (Mirror Polish) | Eliminates sticking; ensures flawless Class A finishes |

| Hardness Uniformity | 52-54 HRC (±0.5 HRC variance) | Extends mold life 3x vs. industry averages |

| Material Certification | Full E2500 traceability w/ PMI | Guarantees chemical resistance to aggressive polymers |

Partnering with Lead Precision means aligning with a team that speaks the language of automotive molding engineers. We do not sell parts; we deliver production certainty. Our clients—global Tier 1 suppliers and OEMs—leverage our rapid prototyping capabilities to compress development timelines by 35%, while our predictive maintenance analytics reduce unplanned downtime by 41%. This is the tangible ROI of precision engineering executed without compromise.

Your next mold set must perform flawlessly from shot one to one million. Contact our engineering team directly to initiate a technical consultation. Email [email protected] with your current mold failure analysis or production challenge. Within 24 hours, you will receive a detailed process improvement roadmap—including thermal simulation data and cost-per-cycle validation—tailored to your specific application. Do not settle for incremental gains when automotive excellence demands transformative precision. Let us prove why leading manufacturers trust Lead Precision as their silent partner in production dominance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.