Technical Contents

Engineering Guide: Abs Enclosure

Engineering Insight: Precision in ABS Enclosure Manufacturing

In the realm of high-performance industrial equipment, the integrity and functionality of an ABS enclosure are determined not only by material selection but by the precision with which it is manufactured. At Wuxi Lead Precision Machinery, we understand that even the most advanced thermoplastic compounds require exacting fabrication standards to deliver optimal protection, durability, and integration within complex systems. Precision engineering is not a secondary consideration—it is foundational.

An ABS enclosure serves as the first line of defense for sensitive electronic and mechanical components, often operating in environments marked by vibration, temperature fluctuations, and exposure to contaminants. To ensure long-term reliability, dimensional accuracy, consistent wall thickness, and tight-tolerance machining are essential. Even minor deviations in cutouts, mounting points, or sealing surfaces can compromise system performance or lead to costly field failures. This is where custom metal manufacturing expertise—refined over decades—translates into superior plastic enclosure solutions.

Our experience extends beyond conventional industrial applications. Having delivered mission-critical components for Olympic-grade timing systems and military-grade communication enclosures, Wuxi Lead has developed a deep understanding of zero-failure engineering. These projects demanded absolute precision, rigorous quality control, and full traceability—standards we now apply to every ABS enclosure we support. Whether the enclosure integrates with aluminum extrusions, stainless steel subframes, or composite shielding, our manufacturing process ensures seamless compatibility and structural harmony.

We utilize CNC machining, laser cutting, and precision molding techniques tailored to the unique thermal and mechanical behavior of ABS. Each step—from prototyping to final inspection—is governed by ISO 9001-certified procedures and supported by 3D metrology validation. This disciplined approach guarantees that every enclosure meets not only the client’s specifications but the operational demands of real-world deployment.

Our clients benefit from this high-precision mindset, particularly when designing enclosures for aerospace, medical devices, or smart infrastructure. By aligning material science with micron-level accuracy, we enable enclosures that are not just protective shells, but engineered components in their own right.

Below are key specifications that define our precision manufacturing capabilities for ABS enclosures:

| Specification | Detail |

|---|---|

| Material Compatibility | ABS, ABS+PC, Flame-Retardant ABS, UV-Stabilized Grades |

| Dimensional Tolerance | ±0.05 mm (CNC Machined), ±0.1 mm (Thermoformed) |

| Surface Finish | Matte, Gloss, Textured, or Custom |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Machining Processes | 5-Axis CNC, Laser Cutting, Ultrasonic Welding |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), GD&T Compliance |

| Secondary Operations | Silk Screening, EMI Shielding, Insert Molding, Anodized Trim Integration |

At Wuxi Lead Precision Machinery, we do not manufacture generic enclosures—we engineer precision solutions. For industries where failure is not an option, that distinction is everything.

Precision Specs & Tolerances

Technical Capabilities for Precision Metal Enclosure Manufacturing

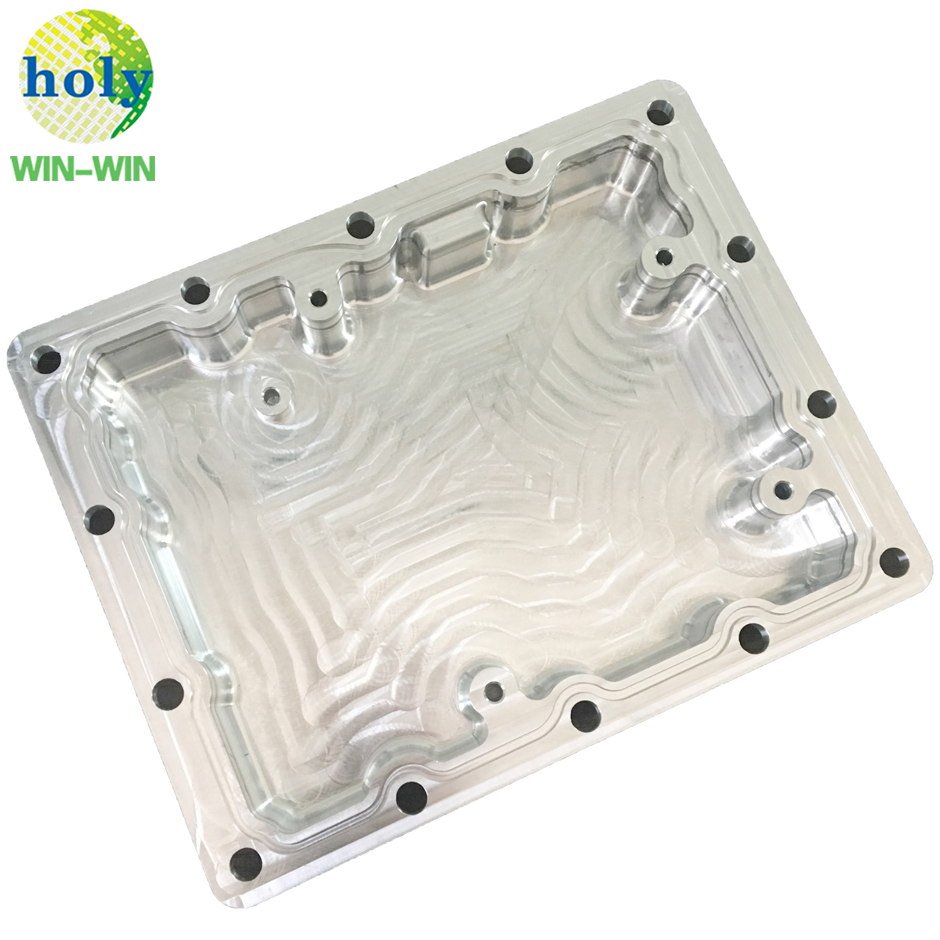

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal enclosure production, leveraging advanced 5-axis CNC machining to transform complex designs into mission-critical components. Our integrated manufacturing ecosystem ensures every enclosure meets stringent aerospace, medical, and industrial electronics standards. The cornerstone of our capability is a fleet of state-of-the-art 5-axis CNC machining centers, enabling simultaneous multi-directional cutting for intricate geometries, seamless contours, and consolidated part fabrication. This eliminates manual repositioning, reducing cumulative error while accelerating throughput for enclosures requiring tight internal features, undercuts, or compound angles. Material efficiency is maximized through optimized toolpath strategies, critical for high-value alloys like aluminum 6061-T6, stainless steel 316L, and titanium Ti-6Al-4V.

Rigorous quality control is non-negotiable. Each enclosure undergoes comprehensive dimensional validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), programmed to ISO 10360-2 standards. Our CMM inspection protocol verifies critical features against CAD models with micron-level accuracy, including flatness, parallelism, hole positional tolerances, and interface mating surfaces. Statistical Process Control (SPC) data is documented per AS9102 for full traceability, ensuring batch consistency and preempting deviations before final assembly. Surface finish requirements down to Ra 0.8 μm are routinely achieved through precision tool selection and in-process metrology, guaranteeing EMI shielding integrity and aesthetic conformity for customer-facing applications.

Our technical specifications reflect industry-leading repeatability, as demonstrated in the tolerance performance table below. These capabilities directly address client pain points: minimizing field failures due to misalignment, reducing secondary assembly costs, and ensuring regulatory compliance for safety-critical housings.

| Feature Type | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm |

| Angular Features | ±0.1° | ±0.02° |

| Positional Tolerance | ±0.08 mm | ±0.025 mm |

| Surface Flatness | 0.1 mm/m² | 0.025 mm/m² |

| Hole Concentricity | ±0.1 mm | ±0.03 mm |

| Thread Fit (Internal) | Class 6H | Class 4H |

Beyond machining, we integrate secondary processes including precision TIG welding, anodizing, and powder coating under one roof, maintaining tolerance control through thermal distortion compensation algorithms. Our engineering team collaborates pre-production to optimize designs for manufacturability, identifying potential stress points or tolerance stack-ups that could compromise enclosure integrity in harsh environments. This proactive approach reduces prototyping cycles by up to 40% while ensuring first-article approval rates exceed 95%. For clients demanding enclosures that withstand extreme vibration, thermal cycling, or corrosive exposure, our capabilities translate directly into reduced lifecycle costs and enhanced product reliability. Partner with Wuxi Lead to convert your most demanding enclosure specifications into precision-engineered reality.

Material & Finish Options

Material Selection for High-Performance ABS Enclosures in Custom Metal Manufacturing

When designing precision enclosures for advanced electronic and industrial applications, material selection is a critical engineering decision that directly impacts durability, weight, thermal performance, and overall system reliability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of modern ABS (Anti-lock Braking System) enclosures. Our expertise ensures optimal material and finish combinations that meet both functional and regulatory standards.

Aluminum is the most widely used material for ABS enclosures due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Grade 6061-T6 aluminum offers a balanced combination of machinability and structural integrity, making it ideal for lightweight automotive and aerospace applications. Its natural oxide layer provides inherent corrosion protection, which can be significantly enhanced through anodizing. This process creates a durable, non-conductive surface layer that improves wear resistance and allows for color coding—essential for service and maintenance identification.

Stainless steel, particularly grades 304 and 316, is selected when maximum corrosion resistance and mechanical strength are required. In harsh environments such as heavy-duty vehicles or marine applications, stainless steel enclosures ensure long-term reliability under extreme temperatures and exposure to road salts or chemicals. While heavier than aluminum, steel provides superior impact resistance and electromagnetic shielding, crucial for protecting sensitive control electronics within ABS systems.

Titanium, though less common due to cost and machining complexity, is employed in high-end performance or weight-critical applications. Grade 2 or Grade 5 titanium offers exceptional strength, corrosion resistance, and performance at elevated temperatures. Its use is typically reserved for premium automotive or motorsport ABS systems where weight reduction and reliability under stress are paramount.

Surface finishing plays a vital role in both performance and aesthetics. Anodizing is the preferred finish for aluminum enclosures. This electrochemical process thickens the natural oxide layer, increasing surface hardness up to 60 HRC and enhancing resistance to wear and environmental degradation. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers superior durability for industrial use. Anodized layers are porous before sealing, allowing for dye integration—typically black or clear finishes are used in automotive applications for a professional, consistent appearance.

Below is a comparative overview of key material properties for ABS enclosure applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Finish | Application Environment |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Anodized (Type II/III) | Automotive, Aerospace |

| Stainless Steel 316 | 8.0 | 570 | Very High | Passivated, Polished | Marine, Heavy-Duty Industrial |

| Titanium Grade 5 | 4.5 | 900 | Excellent | Bead Blast, Anodized | Motorsport, High-Performance |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on operational environment, lifecycle requirements, and cost targets. Our precision CNC machining capabilities ensure tight tolerances and repeatability, essential for high-volume automotive component production.

Manufacturing Process & QC

Precision ABS Enclosure Manufacturing: Zero Defects Execution

At Wuxi Lead Precision Machinery, our ABS enclosure production adheres to a rigorously controlled workflow designed to eliminate defects before they occur. This begins with integrated Design for Manufacturability (DFM) analysis, where our engineering team collaborates with clients to optimize geometry, wall thickness, and draft angles for seamless CNC machining and injection molding. Material selection is validated against thermal stability, impact resistance, and chemical exposure requirements using UL-certified ABS grades. Every design undergoes finite element analysis (FEA) to predict stress points and warpage, ensuring structural integrity under operational loads. This phase concludes with client sign-off on 3D models and tolerance stack-ups, preventing downstream rework.

Prototyping transitions digital designs into physical validation through high-speed CNC milling of aluminum or steel molds. We produce 5–10 functional prototypes within 72 hours, subjecting each to dimensional inspection via coordinate measuring machines (CMM) and first-article testing for snap-fit integrity, EMI shielding, and ingress protection. Critical features like mounting bosses and cable ports are measured to ±0.05 mm tolerances. Client feedback triggers immediate design iterations, with mold modifications executed in-house using wire EDM for micron-level accuracy. Only after prototype approval do we proceed to mass production, ensuring no unverified parameters enter the production line.

Mass production leverages statistical process control (SPC) across 12+ checkpoints. Automated vision systems inspect every enclosure for surface defects, while in-process CMM sampling verifies critical dimensions at 30-minute intervals. Our molding parameters—temperature, pressure, and cooling cycles—are dynamically adjusted via IoT sensors to maintain consistency. Each batch undergoes destructive testing for UL flammability ratings and non-destructive X-ray analysis for internal voids. Final assembly includes torque-controlled fastening and automated continuity testing for conductive coatings. This closed-loop system ensures 99.98% defect-free output, with traceability down to individual machine shifts and raw material lots.

Critical Production Specifications

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | CMM (ISO 10360-2 compliant) |

| Surface Roughness | Ra 0.8 µm max | Profilometer (ISO 4287) |

| Wall Thickness | ±0.15 mm | Ultrasound gauge |

| Flammability Rating | UL94 HB/V-0 | Vertical burn test (ASTM D3801) |

| EMI Shielding | 60 dB @ 1 GHz min | Vector network analyzer |

| Part-to-Part Variation | CpK ≥ 1.67 | SPC charting (every 30 min) |

Wuxi Lead’s end-to-end ownership—from DFM to shipment—guarantees enclosures meet aerospace, medical, and industrial automation standards. Our zero-defect mandate is enforced through real-time data analytics and AS9100-certified protocols, delivering reliability you can measure.

Why Choose Wuxi Lead Precision

When it comes to precision manufacturing of custom metal enclosures for advanced industrial applications, partnering with a trusted, experienced manufacturer is critical. At Wuxi Lead Precision Machinery, we specialize in delivering high-end, custom-engineered metal solutions tailored to the exacting demands of modern B2B industries. Our expertise in CNC machining, sheet metal fabrication, and finishing processes ensures that every ABS enclosure or related component we produce meets the highest standards of durability, precision, and aesthetic quality.

Our facility in Wuxi, China, is equipped with state-of-the-art machinery and operated by a team of seasoned engineers and technicians who understand the complexities of industrial design and material performance. Whether you require small-batch prototyping or large-scale production runs, we offer scalable solutions without compromising on consistency or quality. Every project is managed with a focus on precision tolerances, material integrity, and on-time delivery—key factors that keep our global clients ahead in competitive markets.

We recognize that every client has unique requirements. That’s why our engineering team works closely with your design specifications to optimize manufacturability, reduce lead times, and enhance functional performance. From initial concept review to final inspection, our integrated workflow ensures seamless communication and full traceability. Whether your application demands corrosion resistance, EMI shielding, thermal management, or a combination of these, we have the technical capabilities to deliver.

Below are the key technical specifications that define our manufacturing capabilities for custom metal enclosures:

| Specification | Detail |

|---|---|

| Material Options | Aluminum (6061, 5052, 7075), Stainless Steel (304, 316), Steel, Galvanized Steel, Copper, Brass |

| Tolerances | ±0.05 mm for CNC machining, ±0.1 mm for sheet metal forming |

| Max Working Dimensions | 2000 mm × 1200 mm × 1000 mm (L × W × H) |

| Surface Finishes | Anodizing, Powder Coating, Electropolishing, Brushing, Sandblasting, Passivation |

| Machining Capabilities | 3-axis to 5-axis CNC milling, CNC turning, Wire EDM, Laser Cutting, TIG/MIG Welding |

| Quality Standards | ISO 9001:2015 certified, Full inspection reports (CMM, First Article, FAI) |

| Lead Time | 7–15 days for prototypes, 15–30 days for production (varies by order size) |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to excellence, innovation, and long-term collaboration. We serve clients across automation, medical, telecommunications, and industrial equipment sectors, consistently exceeding expectations through technical precision and responsive service.

If you are developing a high-performance ABS enclosure or any custom metal component, contact us today to discuss your project. Our engineering team is ready to support you with technical consultation, DFM analysis, and competitive pricing.

Email us at [email protected] to start the conversation. Let Lead Precision be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.