Technical Contents

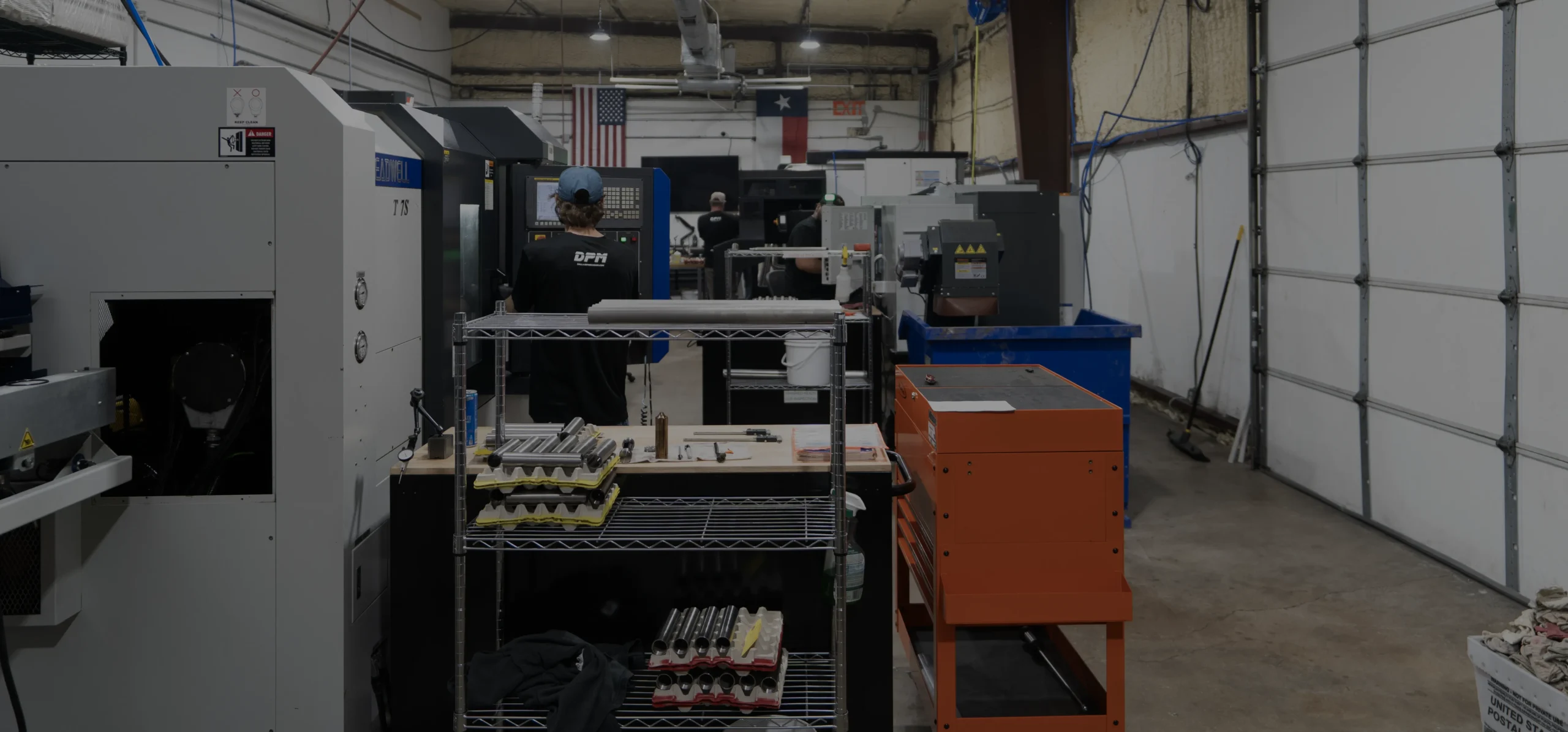

Engineering Guide: Dallas Machine Shop

Engineering Insight: The Uncompromising Role of Precision in Modern Custom Metal Manufacturing

In the world of high-performance manufacturing, precision is not merely a target—it is the foundation upon which reliability, performance, and innovation are built. For a Dallas machine shop operating at the forefront of aerospace, defense, and advanced industrial sectors, the margin for error is not measured in thousandths of an inch, but in tenths. At Wuxi Lead Precision Machinery, we understand that precision transcends equipment capability; it is a philosophy embedded in engineering rigor, process control, and a relentless pursuit of perfection.

Our experience in delivering mission-critical components for Olympic-grade equipment and military-grade systems has reinforced a fundamental truth: when failure is not an option, precision must be engineered into every phase of production. From initial design validation to final inspection, tolerances of ±0.0002″ are not exceptional—they are standard. Whether machining complex titanium housings for unmanned aerial systems or producing high-cycle aluminum components for precision sporting equipment, dimensional accuracy directly impacts function, safety, and longevity.

The challenge for any advanced machine shop, whether in Dallas or Dongguan, lies not just in achieving tight tolerances, but in maintaining them across batches, materials, and production environments. Thermal stability, tool wear compensation, and real-time metrology are not optional add-ons—they are integral to a precision workflow. At Lead Precision, we employ multi-axis CNC machining centers with in-process probing and coordinate measuring machines (CMMs) calibrated to ISO 17025 standards. This ensures traceability and repeatability, critical for clients requiring documentation to AS9100 or MIL-STD-883 compliance.

Material selection further underscores the need for precision engineering. Aluminum 7075-T6, Inconel 718, and 17-4 PH stainless steel behave differently under stress and thermal load. Our engineering team conducts detailed finite element analysis (FEA) and thermal modeling to anticipate deformation, allowing for preemptive compensation in tool paths. This proactive approach eliminates post-machining corrections and reduces lead time without sacrificing quality.

We have supported Dallas-based innovators in transitioning from prototype to production by aligning our precision capabilities with their design intent. Our collaboration often begins at the drawing stage, where we provide Design for Manufacturability (DFM) feedback to optimize geometry, reduce part count, and improve yield—all while preserving the performance envelope.

Precision, at its core, is a commitment to excellence. It is what enables a component to perform flawlessly in a satellite deployment mechanism or a high-stakes defense application. For machine shops and their clients, partnering with a manufacturer that has proven its precision under the most demanding conditions is not just strategic—it is essential.

| Specification | Detail |

|---|---|

| Standard Tolerance | ±0.0002″ (5 µm) |

| Maximum Tolerance Capability | ±0.00004″ (1 µm) |

| Materials Processed | Aluminum 7075-T6, Inconel 718, 17-4 PH SS, Titanium Grade 5, Tool Steels |

| Quality Standards | ISO 9001:2015, AS9100D, ISO 17025 (Calibration) |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Surface Roughness Testers, Hardness Testers |

| Typical Applications | Aerospace Actuators, Military Sensors, Olympic Timing Systems, Semiconductor Components |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions engineered to meet the rigorous demands of high-value industries including aerospace, medical, and energy. Our technical foundation centers on state-of-the-art 5-axis CNC machining, enabling the production of highly complex geometries with exceptional accuracy and reduced lead times. Unlike conventional 3-axis systems, our 5-axis platforms perform simultaneous multi-directional cutting, eliminating secondary setups and minimizing cumulative error. This capability is critical for components requiring intricate contours, deep cavities, or tight positional tolerances across multiple faces—such as turbine blades, surgical implants, and hydraulic manifolds. Supported by high-rigidity spindles (up to 24,000 RPM) and dynamic tool changers, we machine challenging materials including titanium alloys, Inconel, hardened steels, and exotic composites while maintaining micron-level precision.

Quality assurance is integrated at every production stage through our comprehensive metrology suite. All critical dimensions undergo verification via Zeiss and Hexagon Coordinate Measuring Machines (CMMs), programmed to ISO 10360-2 standards for traceable accuracy. Our CMM workflow includes pre-production fixture validation, in-process first-article inspection, and full FAI (First Article Inspection) reporting per AS9102 requirements. Statistical Process Control (SPC) data is monitored in real time, ensuring deviations are corrected before batch completion. This systematic approach guarantees consistent conformance to geometric dimensioning and tolerancing (GD&T) callouts, surface finish specifications, and material integrity requirements demanded by Tier-1 aerospace and defense partners.

The following table details our standard achievable tolerances across common feature types, validated under controlled environmental conditions (20°C ±0.5°C):

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / High-Precision Micrometer |

| Angular Features | ±0.005° | ±0.001° | CMM / Optical Comparator |

| Positional Tolerance | ±0.015 mm | ±0.005 mm | CMM (GD&T Analysis) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| True Position (Ø) | 0.025 mm | 0.010 mm | CMM (Vector Analysis) |

Our commitment extends beyond equipment specifications. Engineers collaborate directly with Dallas-based clients during DFMA (Design for Manufacturing and Assembly) reviews to optimize part geometry for cost-efficient production without sacrificing performance. Real-time production data dashboards provide transparency into work-in-progress status, while AS9100-compliant documentation packages—including material certifications, heat treatment records, and full inspection reports—ensure seamless integration into your quality systems. By combining 5-axis agility with uncompromising metrology rigor, Wuxi Lead Precision Machinery becomes a seamless extension of your high-mix, low-volume manufacturing ecosystem, delivering components that consistently exceed stringent aerospace and industrial specifications. Partner with us to transform complex designs into mission-critical realities.

Material & Finish Options

Material Selection for High-Precision CNC Components

Selecting the appropriate material is critical in custom metal manufacturing, particularly when producing high-precision components for aerospace, medical, automotive, and industrial applications. At Wuxi Lead Precision Machinery, we specialize in machining complex parts from aluminum, steel, and titanium—each offering distinct mechanical properties, cost considerations, and performance characteristics. Understanding these materials ensures optimal part functionality, longevity, and cost-efficiency.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications requiring lightweight components without sacrificing structural integrity. The 6061 and 7075 alloys are commonly used in aerospace and automotive industries due to their weldability and high fatigue resistance. Aluminum also responds exceptionally well to anodizing, enhancing surface hardness and wear resistance.

Steel, particularly stainless steel grades such as 304 and 316, provides superior strength, durability, and resistance to high temperatures and corrosion. It is ideal for components exposed to harsh environments or requiring stringent hygiene standards, such as in medical devices or food processing equipment. While heavier than aluminum, steel offers excellent dimensional stability and can be machined to tight tolerances. Finishing options include passivation, polishing, and coating, depending on the operational environment.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. It exhibits an outstanding strength-to-density ratio, exceptional corrosion resistance, and biocompatibility, making it indispensable in aerospace, defense, and implantable medical devices. Although more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term performance in aggressive environments justifies its use in mission-critical components.

Surface Finishing: The Role of Anodizing

Anodizing is a key surface treatment for aluminum components, creating a durable, corrosion-resistant oxide layer that also allows for color coding and improved aesthetic quality. Type II (sulfuric acid) anodizing is commonly used for general-purpose applications, offering moderate wear resistance and dyeability. Type III, or hard anodizing, produces a thicker, harder coating suitable for high-wear environments. At Wuxi Lead, we ensure precise control over anodizing thickness and sealing processes to meet MIL-SPEC and ASTM standards.

Below is a comparative overview of key material properties for common alloys used in precision CNC machining.

| Material | Alloy Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Automotive | Excellent |

| Aluminum | 7075-T6 | 572 | 2.8 | Defense, High-Performance Parts | Good |

| Stainless Steel | 304 | 505 | 8.0 | Medical, Food Processing | Moderate |

| Stainless Steel | 316 | 570 | 8.0 | Marine, Chemical Processing | Moderate |

| Titanium | Ti-6Al-4V | 950 | 4.4 | Aerospace, Medical Implants | Fair |

Material and finish selection directly impacts performance, cost, and production lead time. At Wuxi Lead Precision Machinery, we collaborate closely with engineering teams to match material properties with application demands, ensuring every component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Integrated Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components is engineered for uncompromising quality and efficiency, specifically designed to meet the rigorous demands of high-end B2B clients like those in the Dallas manufacturing sector. We execute a seamless, closed-loop workflow spanning Design, Prototyping, and Mass Production, all governed by our Zero Defects philosophy. This integrated approach eliminates costly iterations and ensures first-time-right outcomes, directly supporting your project timelines and operational reliability.

The process initiates with collaborative Design and Engineering. Our team works directly with your specifications, applying deep expertise in geometric dimensioning and tolerancing (GD&T) and Design for Manufacturability (DFM). Utilizing advanced CAD/CAM software (Siemens NX, Mastercam), we rigorously analyze part geometry, material selection, and machining strategies. This phase identifies potential manufacturability issues early, optimizes toolpaths for precision and speed, and ensures the design is inherently robust for high-volume production. Clear communication and digital file validation with your Dallas engineering team are critical steps before any metal is cut.

Prototyping follows as a vital validation stage, not merely a sample check. We produce functional prototypes using the exact materials, tooling, and CNC processes designated for full production. These prototypes undergo comprehensive metrology, including CMM inspection against the master CAD model and rigorous functional testing per your application requirements. This step confirms dimensional accuracy, material properties, and assembly fitment, providing tangible proof of concept and allowing for any final, minor refinements before committing to mass production. Client sign-off on the prototype is mandatory, ensuring absolute alignment.

Mass Production leverages the validated process with military-grade discipline. Components are manufactured on our state-of-the-art CNC machining centers (DMG MORI, Makino) under strict environmental controls. Our Zero Defects system is operational at every station: Statistical Process Control (SPC) monitors critical dimensions in real-time, automated in-process gauging provides instant feedback, and 100% final inspection is standard using calibrated CMMs and optical comparators. Traceability is absolute, with material certificates, process parameters, and inspection data digitally linked to each part batch. This systematic execution guarantees consistent conformance to your most demanding specifications.

Key Production Capabilities & Quality Metrics

| Parameter | Specification | Relevance to Dallas Clients |

|---|---|---|

| Dimensional Tolerance | Standard: ±0.005 mm; Capable: ±0.001 mm | Meets aerospace, medical, and semiconductor specs |

| Material Range | Aluminum Alloys, Stainless Steels (300/400), Titanium, Inconel, Brass, Plastics | Supports diverse high-performance applications |

| Primary Equipment | 5-Axis Milling, Precision Turning, Grinding, EDM | Complex geometries, tight tolerances, fine finishes |

| Quality System | ISO 9001:2015 Certified, Full SPC Implementation, 100% Final Inspection | Ensures predictable, auditable quality output |

| Lead Time (Typical) | Prototypes: 7-15 days; Production: Optimized per volume | Balances speed with uncompromised precision |

This disciplined progression from validated design through rigorously tested prototyping to controlled mass production is the cornerstone of our Zero Defects commitment. For Dallas machine shops requiring flawless, high-mix, low-to-medium volume metal components, Wuxi Lead delivers not just parts, but guaranteed performance and reduced supply chain risk. We transform your precision requirements into reality, on time, every time.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Metal Manufacturing Excellence

When your Dallas machine shop demands precision, consistency, and scalability in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery ensures your operations remain at the forefront of industrial innovation. As a trusted leader in high-accuracy CNC machining and custom fabrication, we specialize in delivering mission-critical components for aerospace, medical, energy, and advanced industrial sectors. Our facility in Wuxi, China, combines advanced technology with rigorous quality control to meet the most demanding international standards—ensuring seamless integration with your production pipeline.

Our engineering team collaborates directly with clients to optimize part design, material selection, and manufacturing processes. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem supports rapid turnaround without compromising precision. We utilize state-of-the-art 5-axis CNC machining centers, Swiss-type lathes, and multi-axis milling equipment, all maintained to ISO 9001:2015 standards. Every component undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators, guaranteeing dimensional accuracy down to ±0.0002 inches.

By outsourcing to Wuxi Lead Precision Machinery, Dallas-based manufacturers gain a strategic advantage through cost-effective production, reduced lead times, and consistent quality. We manage every stage—from raw material sourcing to final packaging—with full traceability and real-time reporting. Our logistics network ensures reliable delivery to North America within 25–30 days, with expedited options available for urgent requirements.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 2000 mm × 1200 mm × 800 mm |

| Tolerance Range | ±0.0002 in (5 µm) |

| Surface Finish | As fine as Ra 0.4 µm (16 µin) |

| Materials Processed | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Inconel, Brass, Tool Steels |

| Secondary Operations | Heat Treatment, Passivation, Anodizing, Plating, Laser Marking |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Documentation |

| Lead Times | 15–25 days typical (varies by complexity and volume) |

We understand the unique challenges faced by precision machine shops in Dallas—capacity constraints, skilled labor shortages, and fluctuating material costs. Our partnership model is designed to alleviate these pressures by serving as an extension of your manufacturing capability. With transparent communication, engineering support, and scalable capacity, we help you meet client deadlines confidently and cost-effectively.

Take the next step toward operational excellence. Contact us today at [email protected] to discuss your custom metal manufacturing needs. Let Wuxi Lead Precision Machinery become your trusted offshore partner, delivering precision-engineered components that uphold the highest standards of quality and reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.