Technical Contents

Engineering Guide: Electrical Production Services

Engineering Insight: The Critical Role of Precision in Electrical Production Services

In the realm of custom metal manufacturing for electrical production services, precision is not merely a quality benchmark—it is a foundational requirement. Components used in electrical systems, from switchgear enclosures to busbar supports and transformer housings, must adhere to exact dimensional tolerances, material specifications, and surface finishes. Even minor deviations can lead to thermal inefficiencies, electrical arcing, or mechanical misalignment, all of which compromise system integrity and safety.

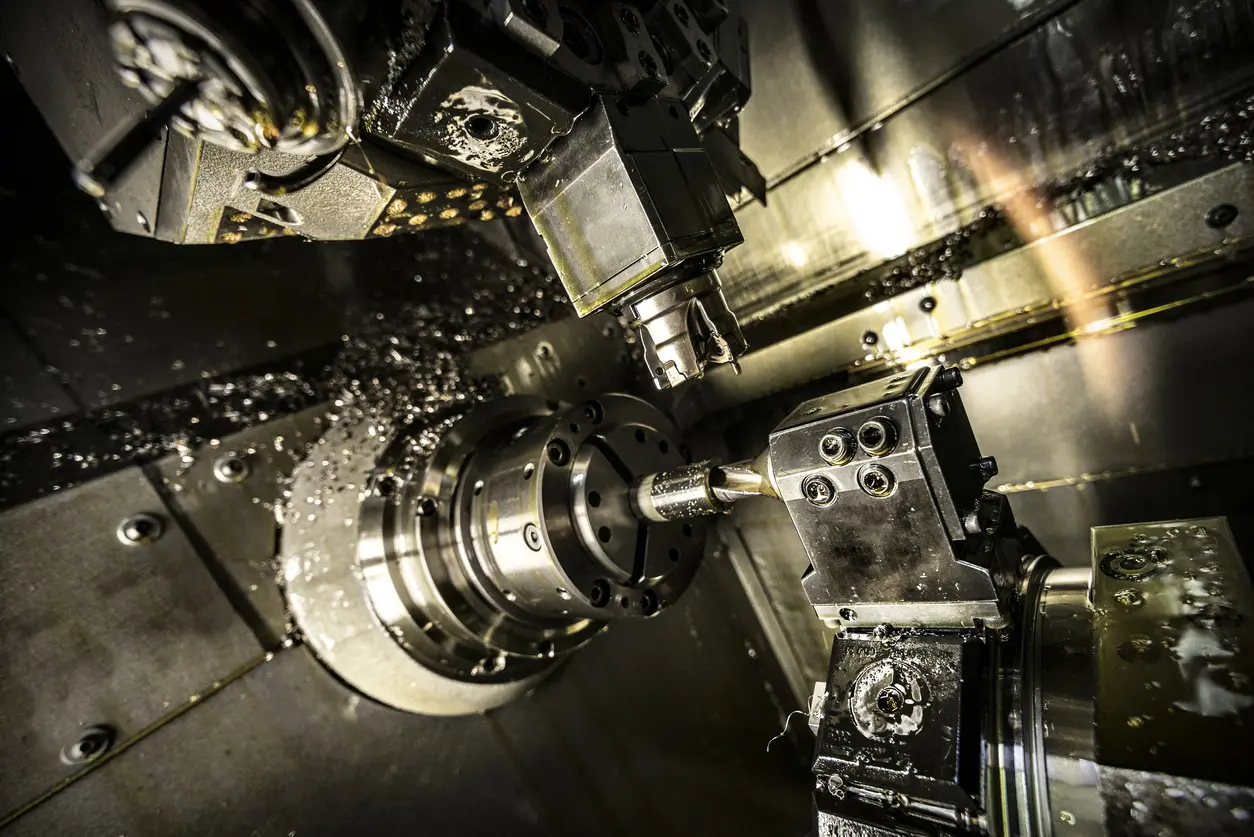

At Wuxi Lead Precision Machinery, we understand that electrical applications demand consistency at the micron level. Our engineering approach integrates advanced CNC machining, laser cutting, and precision forming technologies with rigorous quality control protocols. Every component we produce undergoes comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning to ensure compliance with international standards such as ISO 2768 and IEC 61439.

Our experience in high-stakes sectors—including Olympic infrastructure projects and military-grade power systems—has honed our ability to deliver under exacting conditions. For instance, components fabricated for Olympic venues required not only flawless conductivity and heat dissipation but also rapid deployment and long-term reliability under continuous load. Similarly, military electrical enclosures demanded resistance to vibration, electromagnetic interference, and extreme environmental conditions. These projects reinforced our commitment to precision as a non-negotiable element of performance and safety.

Material selection plays a critical role in achieving precision. We work extensively with aluminum alloys (6061, 5052), stainless steels (304, 316), and copper-based composites, each chosen for their electrical conductivity, corrosion resistance, and structural stability. Our in-house metallurgical analysis ensures material traceability and consistency across production batches.

Beyond machining accuracy, we emphasize design for manufacturability (DFM). Our engineering team collaborates closely with clients during the prototyping phase to optimize geometries, minimize weld distortion, and enhance thermal management—ensuring that every component performs reliably in its operational environment.

The following table outlines key capabilities relevant to electrical production services at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| CNC Machining Tolerance | ±0.005 mm |

| Laser Cutting Accuracy | ±0.02 mm |

| Maximum Part Weight | 500 kg |

| Materials Processed | Aluminum, Stainless Steel, Copper, Brass |

| Surface Finish (Ra) | 0.8–3.2 µm |

| Quality Standards | ISO 9001, ISO 14001, IATF 16949 |

| Testing Equipment | CMM, 3D Scanner, Hardness Tester, Ultrasound |

Precision in electrical production is not an isolated technical achievement—it is the result of integrated engineering, disciplined process control, and deep industry experience. At Wuxi Lead Precision Machinery, we bring this holistic approach to every project, ensuring that our components meet the highest standards of performance, safety, and reliability in critical electrical systems.

Precision Specs & Tolerances

Technical Capabilities for Precision Electrical Production

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions specifically engineered for the demanding requirements of electrical component production. Our core strength lies in integrating high-precision machining with rigorous quality assurance, ensuring components meet the exacting standards essential for power systems, control units, and sensitive electronic assemblies. We understand that electrical applications demand not only dimensional accuracy but also exceptional repeatability, material integrity, and surface finishes that support conductivity, thermal management, and hermetic sealing.

Our primary machining capability centers on state-of-the-art 5-axis CNC milling and turning centers, including HAAS UMC-750 and DMG MORI CTX beta 1250 models. This technology is fundamental for producing complex electrical housings, busbar supports, connector bodies, and heat sink geometries in a single setup. Eliminating multiple fixturing stages significantly reduces cumulative error and enhances positional accuracy critical for components requiring precise alignment of mounting features, mating surfaces, and internal channels. We routinely machine challenging materials like aluminum alloys (6061, 7075), copper alloys (C110, C18150), stainless steels (303, 316), and engineered plastics (PEEK, PTFE) common in electrical systems. The simultaneous 5-axis motion allows us to achieve intricate contours, deep cavities, and undercuts necessary for modern compact electrical designs while maintaining strict geometric tolerances.

Quality verification is non-negotiable in electrical manufacturing. Every critical component undergoes comprehensive inspection using Zeiss CONTURA and Hexagon Global Silver Coordinate Measuring Machines (CMMs). Our certified metrology lab provides full first-article inspection reports (FAIR) and batch-level verification traceable to international standards. We measure complex GD&T callouts, positional tolerances of mounting holes relative to datums, flatness of mating surfaces for EMI shielding, and critical dimensions affecting electrical clearance and creepage distances. This systematic CMM-based approach ensures absolute conformance to your engineering drawings and provides the documented evidence required for regulatory compliance and high-reliability applications.

The following table details our standard achievable tolerances for machined electrical components, reflecting our commitment to precision under controlled production conditions:

| Feature Type | Typical Tolerance Range | Material Consideration | Critical Application Example |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm to ±0.025 mm | Aluminum, Copper, Stainless | Busbar mounting hole position |

| Geometric Tolerances | ±0.010 mm (Position) | All critical alloys | Connector pin alignment |

| Flatness | 0.010 mm per 100 mm | Housings, Heat spreader bases | EMI gasket sealing surfaces |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm | Functional vs. cosmetic areas | Current carrying surfaces, aesthetics |

| Threaded Features | Class 6H/6g | Steel, Brass, Aluminum | Terminal block mounting |

This precision capability, combined with our deep understanding of electrical component functionality and failure modes, allows Wuxi Lead to be a trusted partner. We consistently deliver parts that perform reliably within your assemblies, minimizing field failures and supporting the stringent demands of the global electrical manufacturing sector. Our process ensures your designs translate into robust, high-performance components ready for integration.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, especially for electrical production services where performance, durability, and precision are non-negotiable. At Wuxi Lead Precision Machinery, we understand that the right material and finish combination directly impacts the functionality, longevity, and reliability of electrical components. Aluminum, steel, and titanium are among the most widely used metals in this sector, each offering distinct mechanical and thermal properties suited to specific applications.

Aluminum is favored for its lightweight nature, excellent thermal and electrical conductivity, and strong corrosion resistance. It is ideal for enclosures, heat sinks, and structural components in electrical systems where weight reduction and efficient heat dissipation are key. When paired with anodizing, aluminum gains enhanced surface hardness and dielectric properties, making it even more suitable for high-performance electrical environments.

Steel, particularly stainless and carbon steel, delivers superior strength, wear resistance, and structural integrity. It is commonly used in high-load or high-impact applications such as electrical housings, mounting brackets, and industrial connectors. While heavier than aluminum, steel provides unmatched durability in harsh environments. Surface treatments such as passivation or powder coating are often applied to improve corrosion resistance, though anodizing is not applicable to steel.

Titanium stands out for its exceptional strength-to-density ratio and resistance to extreme temperatures and corrosive environments. Though more costly, it is the material of choice for mission-critical electrical components in aerospace, medical, and defense applications. Its biocompatibility and non-magnetic properties further expand its utility in sensitive electronic systems. Like aluminum, titanium can be anodized to achieve both protective and aesthetic finishes, with the added benefit of color coding for part identification.

Anodizing is a key finishing process for aluminum and titanium components. This electrochemical treatment creates a controlled oxide layer on the surface, significantly improving wear resistance, corrosion protection, and electrical insulation. For electrical production services, anodized finishes also reduce the risk of short circuits by providing a non-conductive barrier. The process allows for precise thickness control and can be tailored to meet specific industry standards, including MIL-A-8625 for military-grade components.

Below is a comparative overview of key material properties relevant to electrical production services.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Electrical Conductivity (% IACS) | Corrosion Resistance | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 40 | High | Yes |

| Stainless Steel 304 | 8.0 | 505 | 2.4 | Very High | No |

| Titanium Grade 5 | 4.4 | 860 | 1.1 | Excellent | Yes |

Selecting the optimal material and finish requires a deep understanding of operational demands. At Wuxi Lead Precision Machinery, we support clients in making informed decisions by combining material science expertise with precision manufacturing capabilities.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our electrical production services begin with rigorous collaborative design engineering. Wuxi Lead Precision Machinery integrates client specifications with deep manufacturing expertise during initial CAD modeling and DFM analysis. Our engineers identify potential production bottlenecks, material constraints, and assembly challenges before physical work commences. This phase ensures geometric complexity, material selection, and tolerances align with both functional requirements and manufacturability. We utilize advanced simulation tools to validate thermal performance, structural integrity, and electrical pathway efficiency under operational loads. Client sign-off on finalized design documentation is mandatory, establishing an immutable baseline for zero-defect execution.

Prototyping: Validating Performance Before Scale

Prototyping transforms validated designs into tangible test units using the same CNC equipment and materials destined for mass production. Each prototype undergoes comprehensive dimensional verification via CMM and functional testing against electrical, thermal, and mechanical benchmarks. This phase isolates design flaws or process gaps invisible in digital models. Clients receive detailed test reports highlighting performance metrics against specifications. Iterative adjustments occur here—never during volume production—to eliminate rework risks. Lead times for certified prototypes average 10–15 business days, providing actionable data to confirm production readiness with zero compromises on quality thresholds.

Mass Production: Zero Defects Through Systematic Control

Volume manufacturing executes under our Zero Defects Framework, where statistical process control (SPC) governs every operation. Automated CNC cells run validated programs with real-time in-process gauging, halting production if deviations exceed ±0.005mm. Each component batch receives full traceability via laser-etched serial numbers linked to material certs and inspection records. Final assemblies undergo 100% functional electrical safety testing per IEC 60601 or client-specific standards. Our cleanroom assembly stations prevent particulate contamination critical for sensitive electrical components. Continuous monitoring of machine health, tool wear, and environmental conditions ensures output consistency. This closed-loop system achieves <50 PPM defect rates, certified through annual第三方 audits.

Key Production Specifications

| Parameter | Capability | Standard Compliance |

|——————–|——————————–|—————————|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Finish | Ra 0.4 µm (machined) | ISO 1302 |

| Materials | Aluminum 6061/7075, Stainless 304/316, Copper Alloys | ASTM/EN/JIS |

| Electrical Testing | Hi-Pot, Continuity, Insulation Resistance | IEC 60950, IEC 62368 |

| Certifications | ISO 9001:2015, ISO 14001, IATF 16949 | Full RoHS/REACH compliance |

This end-to-end process eliminates quality surprises by embedding precision at every stage. Wuxi Lead’s commitment to zero defects isn’t aspirational—it’s engineered into our workflow, delivering electrical components that perform reliably in mission-critical applications worldwide. Clients gain supply chain certainty through documented process control, not post-production inspection.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions. As a leading provider of custom metal manufacturing services in China, we specialize in delivering high-precision, high-reliability parts tailored to the exacting demands of electrical production systems. From prototyping to full-scale production, our end-to-end capabilities ensure that your electrical components meet the highest standards of performance, durability, and consistency.

Our facility in Wuxi integrates advanced CNC machining, precision sheet metal fabrication, and automated welding technologies, enabling us to produce complex geometries and tight-tolerance parts with repeatability and speed. We work extensively with aluminum, stainless steel, copper alloys, and specialty conductive materials, ensuring compatibility with electrical insulation, thermal management, and EMI shielding requirements. Whether you’re developing switchgear, busbar systems, enclosures, or power distribution units, our engineering team collaborates closely with yours to optimize designs for manufacturability, cost-efficiency, and long-term reliability.

What sets Lead Precision apart is our commitment to quality at every stage. Our ISO 9001-certified processes are supported by in-house metrology, 3D scanning, and first-article inspection protocols, ensuring that every component conforms to your specifications. We also offer comprehensive supply chain integration, including kitting, labeling, and JIT delivery, to streamline your assembly operations and reduce lead times.

We understand that in the electrical production industry, precision isn’t optional—it’s essential. A single dimensional deviation or material inconsistency can compromise system safety and performance. That’s why we invest in continuous process improvement, operator training, and cutting-edge equipment to maintain the tightest tolerances and highest surface finishes across every production run.

Below are our core technical capabilities for custom metal manufacturing:

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning; tolerances down to ±0.005 mm |

| Sheet Metal Fabrication | Laser cutting, bending, punching; thickness range: 0.5–6 mm |

| Welding | TIG, MIG, spot welding; certified welders to ISO 3834 standards |

| Materials | Aluminum 5052/6061/7075, stainless steel 304/316, copper, brass, carbon steel |

| Surface Finishes | Anodizing, powder coating, passivation, plating, bead blasting |

| Max Work Envelope | 2000 x 1500 x 800 mm (machining), 3000 x 1500 mm (sheet metal) |

| Quality Control | CMM, optical comparators, hardness testing, first-article inspection reports |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that treats your project as a strategic priority. We serve global clients across industrial automation, renewable energy, rail transit, and high-voltage equipment sectors, providing scalable, responsive, and technically superior manufacturing support.

Take the next step toward precision, reliability, and supply chain confidence. Contact us today at [email protected] to discuss your electrical production requirements. Let Lead Precision be the foundation of your next-generation manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.