Technical Contents

Engineering Guide: Cnc 3 Axis

Engineering Insight: The Critical Role of Precision in CNC 3-Axis Machining

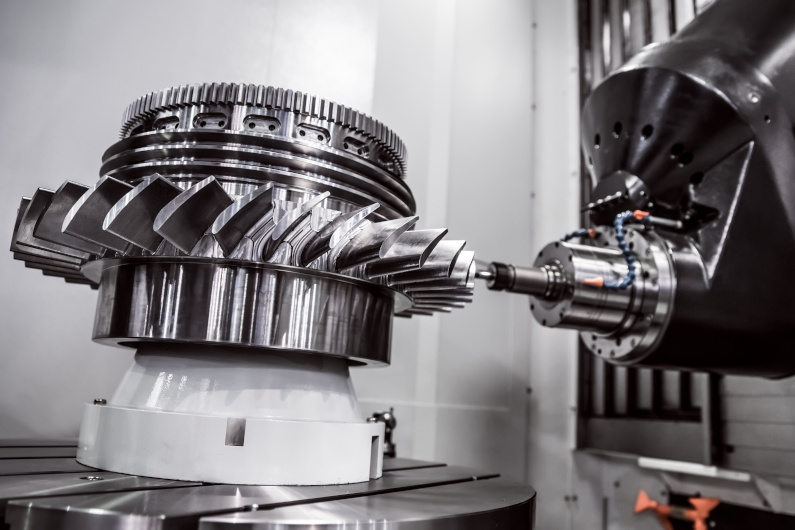

In the realm of precision manufacturing, CNC 3-axis machining remains a foundational technology for producing high-tolerance components across aerospace, defense, medical, and industrial sectors. At Wuxi Lead Precision Machinery, we recognize that the true value of 3-axis CNC systems lies not only in their operational simplicity but in their ability to deliver consistent, repeatable accuracy under demanding production conditions. Precision is not a feature—it is the standard.

Our engineering team has spent over a decade refining the mechanics, control systems, and thermal stability of our 3-axis CNC platforms. This focus stems from our direct involvement in mission-critical projects, including components for Olympic-standard timing systems and precision parts used in military-grade equipment. These applications demand tolerances within ±0.002 mm and surface finishes that meet stringent regulatory and performance benchmarks. The experience gained from such high-stakes environments has shaped our approach to machine design, calibration, and quality assurance.

A 3-axis CNC machine operates on the X, Y, and Z linear axes, enabling milling, drilling, and cutting across flat or planar surfaces. While newer multi-axis systems offer expanded capabilities, the 3-axis configuration excels in efficiency, accessibility, and cost-effectiveness for high-volume, geometrically stable parts. However, achieving micron-level precision requires more than just advanced software—it demands rigid machine construction, high-resolution feedback systems, and meticulous environmental control.

At Lead Precision, our 3-axis CNC centers are built with reinforced cast iron beds to minimize vibration, paired with high-precision linear guides and preloaded ball screws. We integrate FANUC or Siemens controls with real-time error compensation algorithms, ensuring dimensional fidelity across extended production runs. Each machine undergoes a 72-hour thermal stabilization test and laser interferometer calibration before shipment.

The result is a machining platform that not only meets international standards but exceeds them—delivering repeatability, durability, and long-term operational consistency. For industries where failure is not an option, this level of precision is non-negotiable.

Below are the key technical specifications of our flagship 3-axis CNC machining center:

| Parameter | Specification |

|---|---|

| Travel (X/Y/Z) | 800 / 500 / 450 mm |

| Spindle Speed | 8,000 rpm (standard), 12,000 rpm (HSC) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Table Size | 900 × 500 mm |

| Rapid Traverse (X/Y/Z) | 24 / 24 / 20 m/min |

| Control System | FANUC 0i-MF or Siemens 828D |

| Tool Magazine Capacity | 24T (optional 30T) |

| Maximum Workpiece Weight | 800 kg |

| Cooling System | Through-spindle, dual-channel |

Our commitment to precision is validated not only by ISO 9001 certification but by the trust placed in us by clients in defense logistics and high-performance engineering. When reliability, accuracy, and performance converge, the CNC 3-axis platform—when engineered to the highest standard—remains an indispensable asset in modern manufacturing.

Precision Specs & Tolerances

Technical Capabilities: Precision 3-Axis CNC Machining

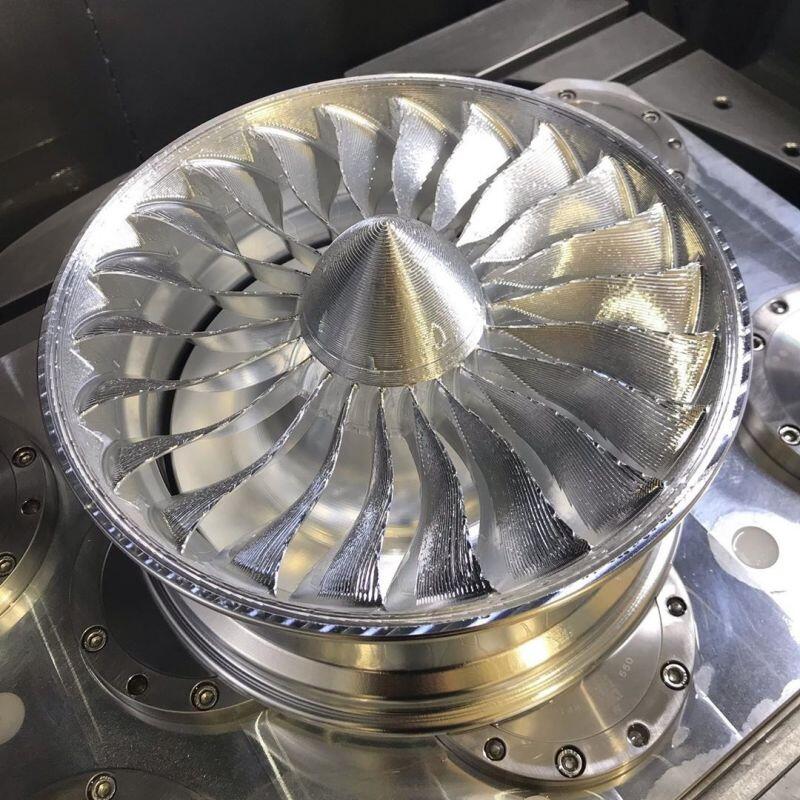

Wuxi Lead Precision Machinery delivers exceptional precision and repeatability in 3-axis CNC machining, engineered for demanding industrial applications. Our modern fleet of FANUC and Siemens-controlled vertical machining centers features robust cast-iron constructions, high-torque spindles (8,000–24,000 RPM), and XYZ travel ranges up to 1,200 x 600 x 500 mm. These systems excel in high-speed contouring, pocketing, drilling, and tapping operations across aerospace structural components, medical device housings, hydraulic manifolds, and automotive powertrain elements. Rigorous thermal compensation systems and precision-ground ball screws ensure micron-level stability during extended production runs, minimizing thermal drift and maintaining dimensional integrity across batch sizes from prototypes to 10,000+ units.

Quality control is integrated at every stage, beginning with material certification and extending through final inspection. All critical features undergo 100% verification using Zeiss and Hexagon Coordinate Measuring Machines (CMMs), operating under ISO/IEC 17025-accredited protocols. Our CMM workflows include automated GD&T analysis, surface roughness validation (Ra 0.4 µm achievable), and full first-article inspection reports traceable to NIST standards. Statistical process control (SPC) data is monitored in real-time, enabling immediate corrective action to sustain ±0.005 mm process capability. This closed-loop methodology guarantees compliance with AS9100, ISO 13485, and IATF 16949 requirements, providing auditable proof of conformance for regulated sectors.

While 5-axis technology addresses complex geometries, 3-axis machining remains the optimal solution for high-volume prismatic parts requiring superior surface finish, tight positional accuracy, and cost efficiency. Our process engineers collaborate with clients during DFx reviews to optimize toolpaths, minimize setups, and eliminate non-value-added operations—reducing lead times by up to 35% without compromising quality. The table below details achievable tolerances for common production scenarios:

| Feature Type | Standard Tolerance (mm) | Standard Tolerance (in) | Typical Applications |

|---|---|---|---|

| Linear Dimensions | ±0.010 | ±0.0004 | Bracket flanges, mounting plates |

| Hole Diameter | ±0.008 | ±0.0003 | Bearing bores, dowel pin locations |

| Positional Accuracy | ±0.005 | ±0.0002 | Bolt circle patterns, porting |

| Flatness | 0.008 per 100 mm | 0.0003 per 4 in | Sealing surfaces, mating faces |

| Surface Roughness (Ra) | 0.8 µm | 32 µin | Cosmetic and functional surfaces |

These specifications represent baseline capabilities; tighter tolerances (e.g., ±0.003 mm linear) are achievable through specialized fixturing, in-process probing, and controlled environmental finishing cells. Wuxi Lead’s 3-axis platform combines operational simplicity with metrology-grade output, ensuring your components meet the most stringent functional and assembly requirements while maximizing throughput. Partner with us to transform design intent into defect-free production reality.

Material & Finish Options

When selecting materials for precision CNC 3-axis machining, understanding the mechanical properties, machinability, and end-use requirements is critical to achieving optimal performance and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of key engineering metals—aluminum, steel, and titanium—each offering unique advantages depending on the application.

Aluminum is one of the most widely used materials in CNC machining due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly favored in aerospace, automotive, and consumer electronics industries where lightweight components are essential. The 6061 and 7075 aluminum alloys are commonly machined, with 6061 offering good weldability and moderate strength, while 7075 provides higher strength at the expense of reduced corrosion resistance. Aluminum is highly machinable, allowing for faster cutting speeds and tighter tolerances, which translates to lower production costs and shorter lead times.

Steel, particularly alloy and stainless steels, is selected when superior strength, durability, and wear resistance are required. Materials such as 4140 alloy steel and 304/316 stainless steel are frequently used in industrial machinery, tooling, and medical devices. While steel is more challenging to machine than aluminum due to higher tool wear and slower cutting speeds, our CNC 3-axis systems are equipped with hardened tooling and precise feed controls to maintain dimensional accuracy and surface integrity. Stainless steel variants also provide excellent resistance to corrosion and high-temperature environments, making them suitable for demanding operational conditions.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in high-performance applications such as aerospace components, medical implants, and marine systems. Its exceptional strength-to-density ratio, biocompatibility, and resistance to extreme environments justify its higher cost and challenging machinability. Titanium requires slower spindle speeds, rigid setups, and specialized cooling techniques to prevent work hardening and tool degradation. At Wuxi Lead, our experienced engineers optimize toolpaths and cutting parameters to ensure consistent quality when machining titanium parts.

For enhanced surface properties and aesthetics, anodizing is a preferred post-processing finish for aluminum components. This electrochemical process increases surface hardness, improves corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is commonly used for decorative and moderate protective purposes, while Type III (hardcoat anodizing) delivers thicker, wear-resistant layers suitable for industrial applications.

Below is a comparative overview of key material properties relevant to CNC 3-axis machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Excellent | Anodizing, Bead Blast | Aerospace, Electronics, Automotive |

| Steel 4140 | 655 | 7.85 | Moderate | Passivation, Painting | Tooling, Shafts, Industrial Parts |

| Stainless 304 | 505 | 8.0 | Fair | Electropolishing | Medical, Food Processing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Poor | Anodizing, Passivation | Aerospace, Medical Implants |

Selecting the right material and finish directly impacts part functionality, longevity, and manufacturing efficiency. At Wuxi Lead Precision Machinery, we support clients in making informed decisions based on application demands, environmental exposure, and performance criteria.

Manufacturing Process & QC

Precision CNC 3-Axis Production Process: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our CNC 3-axis production process is engineered for uncompromising quality and efficiency, eliminating defects before they occur. We integrate advanced engineering with rigorous validation across three critical phases, ensuring every component meets exacting aerospace, medical, and industrial specifications. This seamless workflow transforms concepts into flawless high-volume outputs.

The process begins with collaborative Design Engineering. Our engineers conduct in-depth Design for Manufacturability (DFM) analysis, optimizing part geometry for 3-axis machining constraints while maintaining critical tolerances. Finite Element Analysis (FEA) simulates stress points and material behavior, preventing structural weaknesses. Simultaneously, CAM programming leverages Mastercam and Siemens NX to generate optimized toolpaths, minimizing cycle times and tool wear. This phase includes comprehensive fixture design to ensure absolute workpiece stability during machining, a non-negotiable prerequisite for zero-defect outcomes. Early virtual validation through machine simulation intercepts collisions and inefficiencies, avoiding costly physical trial-and-error.

Prototyping transitions design into tangible validation. Using the same production-grade DMG MORI and HAAS CNC 3-axis centers destined for mass production, we manufacture initial units under identical conditions. First-article inspection employs Zeiss CONTURA CMMs and optical comparators to verify all dimensions against CAD data, with full material certification and hardness testing. Any micro-deviation triggers immediate root-cause analysis—adjusting feeds, speeds, or coolant strategies—before approving the final process. This phase confirms not only dimensional accuracy but also surface finish and functional performance, ensuring the design is truly production-ready.

Mass Production executes with closed-loop precision. Our facility deploys automated tool preseters and in-process probing to monitor tool wear and part alignment in real time, automatically compensating for thermal drift or tool degradation. Every component undergoes 100% critical dimension verification via integrated sensors, with statistical process control (SPC) data streamed to our central quality dashboard. Non-conforming parts are quarantined instantly, preventing downstream contamination. This disciplined approach, combined with operator certification and Six Sigma methodologies, achieves our Zero Defects standard consistently at scale.

Wuxi Lead CNC 3-Axis Production Specifications

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Positioning Accuracy | ±0.005 mm | ISO 230-2 |

| Repeatability | ±0.002 mm | ISO 230-2 |

| Spindle Speed Range | 80 – 8,000 RPM | Factory Calibration |

| Maximum Work Envelope | 1,000 x 600 x 500 mm | Machine Specifications |

| Surface Finish (Ra) | 0.4 – 1.6 µm | ISO 1302 |

| Typical Tolerance | ±0.01 mm | Customer Drawing |

This integrated methodology—where design foresight, prototyping rigor, and intelligent production converge—ensures your components arrive functionally perfect, on schedule, and ready for mission-critical assembly. Wuxi Lead delivers not just parts, but guaranteed performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC 3-Axis Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, consistency, and speed are not just goals—they are requirements. As a leading provider of precision CNC machining solutions in China, we specialize in delivering advanced 3-axis CNC machining services tailored to the exacting standards of aerospace, automotive, medical device, and industrial equipment manufacturers worldwide. When you partner with Lead Precision, you are not just outsourcing a machining task—you are aligning with a team of engineering experts committed to elevating your production capabilities.

Our CNC 3-axis machining centers combine cutting-edge technology with decades of operational expertise to produce complex geometries with micron-level accuracy. Utilizing state-of-the-art equipment and rigorous quality control protocols—including ISO 9001-certified processes—we ensure every component meets or exceeds your specifications. From rapid prototyping to high-volume production runs, our facility is equipped to handle diverse materials such as aluminum, stainless steel, titanium, and engineering plastics with equal precision.

We recognize that every client brings unique challenges and performance expectations. That’s why our engineering team works closely with your design and manufacturing staff from the outset—offering Design for Manufacturability (DFM) analysis, material selection guidance, and process optimization to reduce lead times and minimize costs without compromising quality. Our agile production floor allows for quick changeovers and responsive scaling, ensuring your project stays on schedule, every time.

Below are the core technical specifications of our CNC 3-axis machining platform:

| Specification | Detail |

|---|---|

| Axis Configuration | X, Y, Z linear axes with high-precision ball screws |

| Spindle Speed | Up to 12,000 RPM (optional high-speed spindles available) |

| Table Size | 800 mm × 500 mm (custom work envelope options) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Control System | Fanuc, Siemens, or Mitsubishi (client-selectable) |

| Rapid Traverse Rate | 36 m/min (X/Y/Z) |

| Tool Magazine Capacity | 24–30 tools (automatic tool changer) |

| Coolant System | High-pressure through-spindle cooling (optional) |

| Supported Materials | Aluminum alloys, steel, stainless steel, titanium, brass, plastics (PEEK, Delrin, etc.) |

At Lead Precision, we measure success not by the volume of parts produced, but by the value we deliver to your business. Our commitment to transparency, technical excellence, and on-time delivery has made us a trusted partner for global OEMs and Tier-1 suppliers.

Ready to enhance your manufacturing precision and efficiency? Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your strategic partner in precision CNC 3-axis machining.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.