Technical Contents

Engineering Guide: 3D Figure Printing Service

Engineering Insight: 3D Figure Printing Service – Where Precision Defines Performance

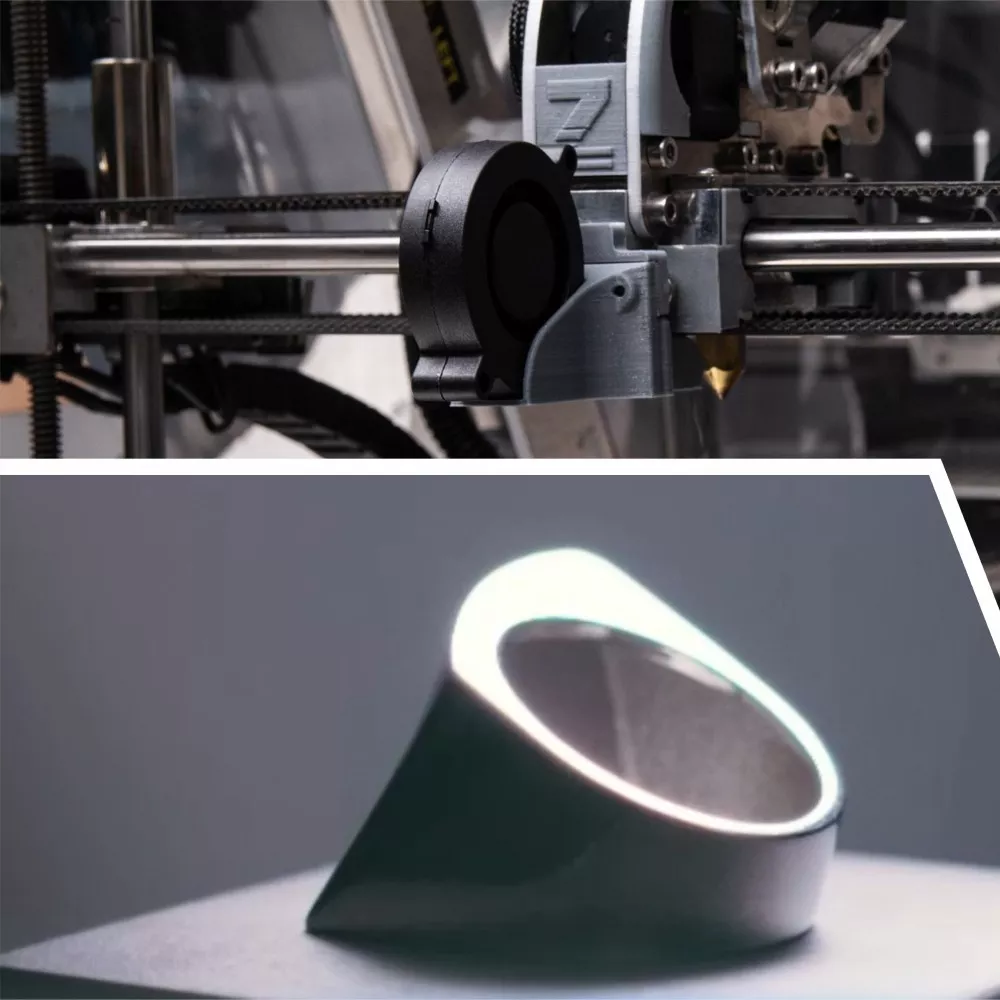

In the realm of custom metal manufacturing, 3D figure printing services are redefining what is possible in design complexity, geometric freedom, and functional integration. However, the true measure of a high-performance 3D printing solution lies not in its ability to produce intricate shapes, but in its capacity to maintain micron-level precision across every layer, every contour, and every critical dimension. At Wuxi Lead Precision Machinery, we understand that in industries such as aerospace, defense, and high-end industrial equipment, tolerances are not merely specifications—they are non-negotiable requirements that determine operational reliability, safety, and longevity.

Our approach to 3D figure printing is rooted in engineering rigor. Unlike conventional additive processes that prioritize speed over accuracy, we deploy a closed-loop manufacturing system that integrates real-time monitoring, thermal compensation algorithms, and post-process metrology to ensure dimensional consistency. This level of control is essential when producing mission-critical components such as turbine blades, sensor housings, or articulating mechanisms for military robotics—applications where a deviation of even 10 microns can compromise system integrity.

Wuxi Lead’s expertise in precision additive manufacturing has been validated through participation in high-profile national projects, including components developed for Olympic-grade athletic equipment and subsystems integrated into defense-grade unmanned platforms. These applications demanded not only aesthetic fidelity but mechanical repeatability under extreme stress and environmental exposure. Our ability to deliver on these challenges stems from our vertically integrated production environment, where material science, laser dynamics, and CNC post-machining converge under one quality-controlled workflow.

We utilize state-of-the-art metal additive systems capable of processing high-performance alloys such as Inconel 718, Ti-6Al-4V, and maraging steel, with layer resolutions down to 20 microns and build volumes accommodating parts up to 500 x 500 x 400 mm. Each print undergoes full geometric verification via coordinate measuring machines (CMM) and, when required, computed tomography (CT) scanning to validate internal integrity. This end-to-end traceability ensures compliance with AS9100 and ISO 13485 standards—critical for clients in regulated sectors.

The future of 3D figure printing in metal is not just about innovation in design, but in the disciplined execution of precision engineering. At Wuxi Lead Precision Machinery, we bring over a decade of advanced manufacturing experience to every project, ensuring that your 3D-printed components perform exactly as intended—on the battlefield, in the stratosphere, or on the world stage.

| Specification | Detail |

|---|---|

| Material Options | Stainless Steel 316L, Inconel 718, Ti-6Al-4V, Aluminum AlSi10Mg, Maraging Steel |

| Layer Thickness | 20–50 microns |

| Build Volume | Up to 500 x 500 x 400 mm |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 8–12 µm |

| Post-Processing | CNC Machining, Heat Treatment, HIP, Polishing, CMM Inspection |

| Quality Standards | ISO 9001, AS9100, ISO 13485 |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Complex Geometries

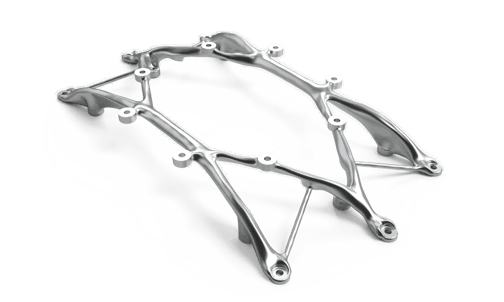

Wuxi Lead Precision Machinery delivers mission-critical metal components through advanced subtractive manufacturing, distinct from additive 3D printing. Our core strength lies in high-precision CNC machining of complex 3D geometries, particularly for demanding sectors including aerospace, medical devices, and energy. We specialize in transforming intricate digital models into certified metal parts using state-of-the-art 5-axis CNC technology, ensuring geometric accuracy unattainable through conventional methods. This capability is essential for producing organic shapes, undercuts, and integrated features common in high-performance 3D figure applications requiring metal’s strength and thermal properties.

Our facility operates 12 Haas and DMG MORI 5-axis vertical machining centers, each equipped with high-resolution probing systems and thermal compensation. These machines enable single-setup machining of complex contours, reducing cumulative error and secondary operations. We routinely machine challenging materials including titanium alloys (Ti-6Al-4V), Inconel 718, aluminum 7075-T6, and hardened tool steels up to 62 HRC. Advanced CAM programming with Siemens NX and Mastercam ensures optimal toolpath strategies for surface integrity and feature precision, critical for aesthetic and functional 3D figures.

Quality assurance is embedded at every process stage. All critical dimensions undergo 100% verification using Zeiss CONTURA and Hexagon GLOBAL S 121510 Coordinate Measuring Machines (CMM). Our CMM inspection routines follow ASME Y14.5-2018 GD&T standards, with full traceability to NIST-certified artifacts. First-article inspections include full 3D scan comparison against nominal CAD data using GOM ATOS systems, detecting deviations as small as 5 microns. Every shipment includes comprehensive dimensional reports, material certifications, and heat-treatment documentation.

The following table details achievable tolerances for critical features:

| Feature Type | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Geometric Features | ±0.015 mm | ±0.008 mm | CMM / Optical Scan |

| Hole Position | ±0.008 mm | ±0.003 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Angular Features | ±0.005° | ±0.002° | CMM |

These capabilities are validated through our ISO 9001:2015 and AS9100D certified quality management system. We maintain environmental controls in machining and inspection zones (20±1°C), critical for micron-level consistency. Our engineering team collaborates with clients during design for manufacturability (DFM) reviews to optimize part geometry for precision machining, minimizing cost while ensuring tolerance compliance. This integrated approach—combining 5-axis flexibility, rigorous metrology, and material expertise—makes Wuxi Lead the trusted partner for 3D figure applications where metal performance is non-negotiable. From prototyping to serial production, we deliver certified precision for your most complex metal components.

Material & Finish Options

Material Selection for High-Precision 3D Figure Printing in Metal

When producing custom metal 3D figures for industrial, aerospace, or luxury applications, material selection is a critical decision that directly impacts performance, durability, and aesthetics. At Wuxi Lead Precision Machinery, we specialize in advanced metal additive manufacturing, offering expert guidance in choosing the optimal combination of base materials and surface finishes. The most commonly used metals in our 3D figure printing service are aluminum, steel, and titanium—each with distinct mechanical properties and application advantages.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight components requiring good thermal conductivity and moderate strength. This material is ideal for prototyping, architectural models, and consumer product figures where weight reduction is essential. Aluminum’s natural corrosion resistance and ability to accept a range of surface treatments make it a versatile choice. However, it is less suitable for high-stress or high-temperature environments compared to steel or titanium.

Stainless steel, especially 316L and 17-4 PH grades, delivers superior strength, hardness, and resistance to corrosion. These properties make steel the preferred option for functional figures exposed to harsh environments or requiring long-term structural integrity. 316L offers excellent marine and chemical resistance, while 17-4 PH can be heat-treated to achieve high yield strength, making it suitable for precision-engineered industrial or defense-related figures.

Titanium, specifically Grade 5 (Ti-6Al-4V), provides the best strength-to-density ratio among the three materials and exhibits outstanding biocompatibility and corrosion resistance. It is commonly used in aerospace, medical, and high-performance automotive sectors. While more expensive and challenging to process, titanium’s durability under extreme conditions justifies its use in mission-critical or high-value display and functional figures.

Post-processing surface finishes further enhance both appearance and performance. Anodizing is a widely used electrochemical process, particularly for aluminum parts. It increases surface hardness, improves wear resistance, and allows for color customization through dye integration. Hard anodizing (Type III) can produce coatings up to 50–100 µm thick, suitable for demanding applications. While anodizing is specific to aluminum, steel and titanium benefit from alternatives such as passivation, polishing, or PVD coatings.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications | Suitable Finishes |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–500 | 250–300 | Prototypes, consumer models | Anodizing, polishing, painting |

| 316L Stainless Steel | 8.0 | 550–650 | 290–350 | Marine, medical, industrial | Passivation, electropolishing |

| 17-4 PH Steel | 7.8 | 900–1300 | 750–1100 | Aerospace, defense | HVOF, nitriding, plating |

| Ti-6Al-4V | 4.43 | 900–1000 | 830–880 | Aerospace, medical implants | Anodizing (Ti), laser texturing |

Selecting the right material and finish requires a clear understanding of the figure’s intended use, environmental exposure, and aesthetic goals. Our engineering team at Wuxi Lead Precision Machinery works closely with clients to ensure every 3D-printed metal figure meets exacting standards in both form and function.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Fulfillment

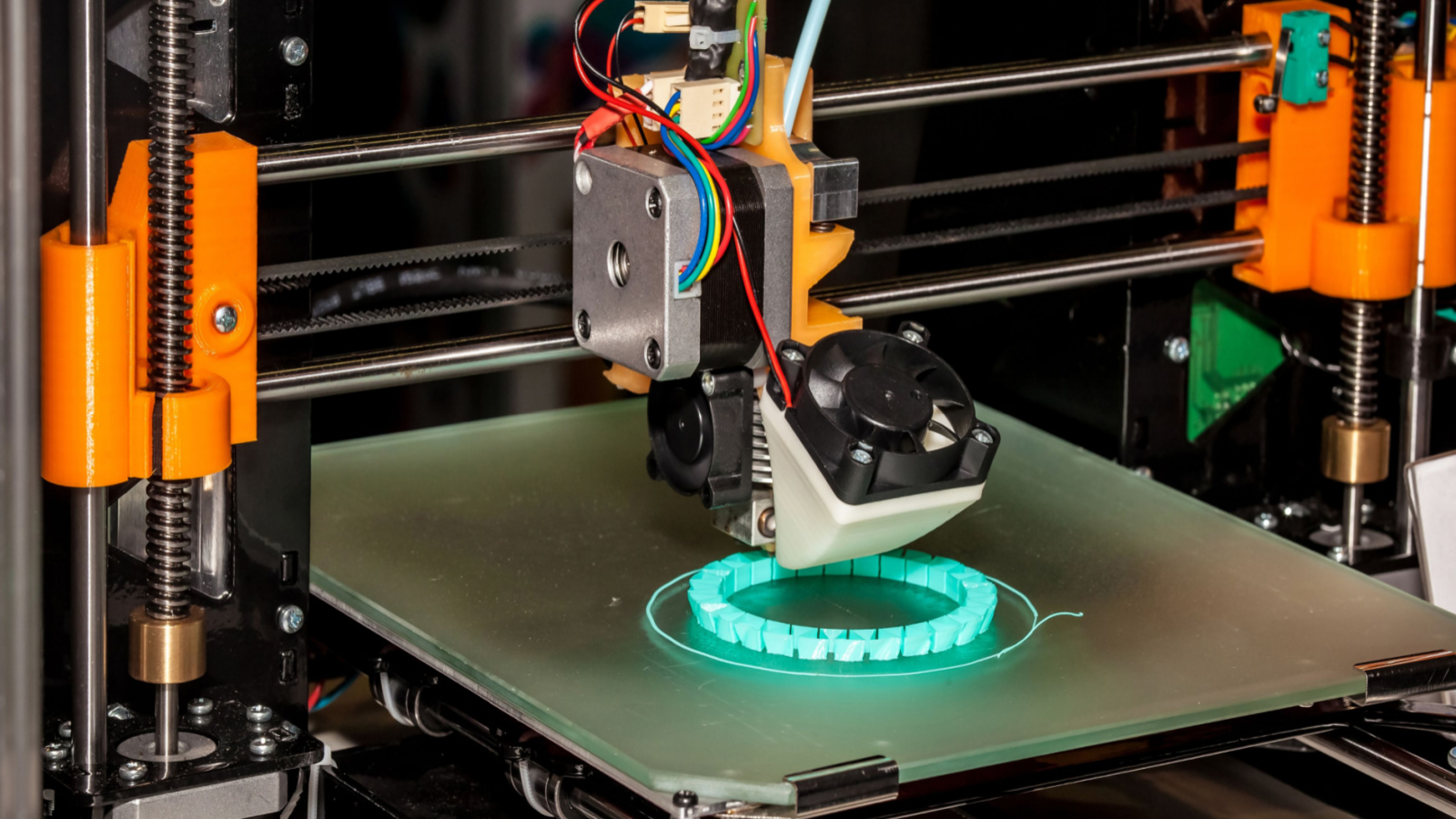

Wuxi Lead Precision Machinery delivers exceptional custom metal components, including intricate parts for high-fidelity 3D figures, through a rigorously controlled production methodology. While distinct from polymer-based 3D printing, our precision metal manufacturing process ensures the dimensional accuracy, surface finish, and material integrity demanded by premium figure applications. We achieve this through an integrated three-stage workflow designed for absolute quality: Design Validation, Precision Prototyping, and Zero-Defect Mass Production.

The process begins with meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients to review 3D CAD models, identifying potential geometric challenges, optimizing wall thicknesses, and selecting the optimal aerospace-grade aluminum, stainless steel, or brass alloy. Critical features like undercuts, thin walls, and fine surface textures are evaluated against our machining capabilities to prevent future defects. Material certification and traceability are confirmed at this stage, ensuring compliance with stringent industry standards. This proactive engineering phase eliminates 90% of potential production issues before metal is cut.

Prototyping is not merely a sample step; it is a critical validation checkpoint. Utilizing our advanced 5-axis CNC machining centers, we produce functional prototypes matching the exact material and tolerances of the final product. Every prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 standards. Critical dimensions, surface roughness (Ra values), and geometric tolerances are verified using calibrated CMMs and optical comparators. Client feedback on the physical prototype is incorporated, and the process parameters are fine-tuned. This stage confirms the design’s manufacturability and establishes the definitive quality baseline for production.

Mass production leverages the validated process under our Zero-Defect Manufacturing System. Each component is machined under strict environmental controls with real-time in-process inspections at defined intervals. Statistical Process Control (SPC) monitors key parameters like tool wear and dimensional drift, triggering automatic adjustments before deviations occur. Every finished part undergoes 100% critical dimension verification and final surface inspection against the approved prototype. Full material traceability and batch documentation are maintained, meeting ISO 9001:2015 and client-specific quality management requirements. This closed-loop system ensures consistent output where defects are statistically improbable, not merely minimized.

Our capability to deliver complex, high-precision metal parts for demanding applications is defined by measurable performance standards:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.2 µm to 3.2 µm | ISO 1302 |

| Material Options | Aluminum 6061/7075, Stainless Steel 303/304/316, Brass C360 | ASTM/EN Material Certificates |

| Typical Production Volume | 1 to 10,000+ parts | Per Client Schedule |

| Quality Certification | ISO 9001:2015, Full FAI Reports, Material Traceability | AS9102, PPAP Level 3 |

This integrated approach—grounded in engineering collaboration, validated through precision prototyping, and executed via statistically controlled mass production—guarantees that every metal component shipped from Wuxi Lead meets the uncompromising quality expectations of high-end figure manufacturing and beyond. Zero defects is our operational mandate, not an aspiration.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal 3D Figure Printing

At Wuxi Lead Precision Machinery, we redefine what’s possible in custom metal manufacturing through advanced 3D figure printing services. As a trusted leader in precision engineering and additive manufacturing, we specialize in transforming intricate designs into high-performance metal components for aerospace, medical, automotive, and industrial applications. Our state-of-the-art facilities in Wuxi, China, are equipped with next-generation metal 3D printing systems, enabling us to deliver complex geometries with micron-level accuracy and superior mechanical properties. When you partner with us, you gain more than a supplier — you gain a strategic manufacturing ally committed to innovation, quality, and on-time delivery.

Our team of senior CNC engineers and additive manufacturing experts collaborates closely with clients from concept to completion. Whether you require a single prototype or high-volume production runs, we apply rigorous process controls, material science expertise, and post-processing capabilities such as heat treatment, CNC machining, and surface finishing to ensure every component meets exacting standards. We work with a wide range of high-performance alloys, including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel 718, and aluminum (AlSi10Mg), tailored to your application’s thermal, structural, and environmental demands.

We understand that in high-end manufacturing, specifications are non-negotiable. Below are the key technical capabilities of our metal 3D printing service:

| Parameter | Specification |

|---|---|

| Printing Technology | Selective Laser Melting (SLM) |

| Build Envelope | Up to 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 μm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10 – 15 μm |

| Common Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 718, AlSi10Mg |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001:2015, Full Material Certification, First Article Inspection (FAI) Reports |

Every project undergoes comprehensive in-process monitoring and final inspection using coordinate measuring machines (CMM) and industrial CT scanning to verify internal integrity and dimensional compliance. Our digital workflow ensures full traceability, from raw material batch numbers to final packaging, giving you confidence at every stage.

We don’t just manufacture parts — we solve engineering challenges. Whether you’re developing lightweight aerospace components, biocompatible medical implants, or durable tooling, our team is ready to support your vision with scalable, cost-effective, and precision-driven solutions.

Contact us today to discuss your next project. Send your design files and requirements to [email protected] and receive a technical review and quotation within 24 hours. Let Wuxi Lead Precision Machinery be your partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.