Technical Contents

Engineering Guide: Injection Mold Equipment

Engineering Insight: The Critical Role of Precision in Injection Mold Equipment

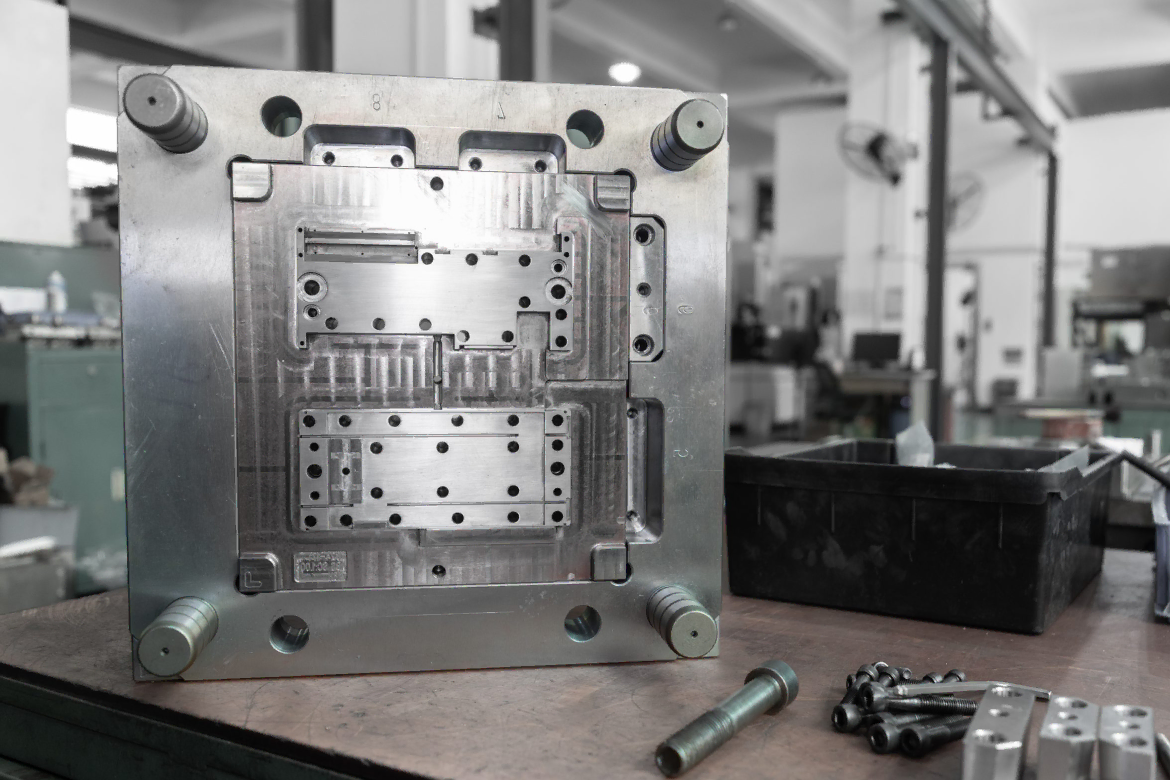

In the realm of custom metal manufacturing, injection mold equipment stands as a cornerstone of high-volume, repeatable production for complex components. At Wuxi Lead Precision Machinery, we understand that the success of any injection molding operation hinges on one foundational principle: precision. From the initial mold design to the final machining tolerances, even micron-level deviations can result in part failure, increased scrap rates, and costly production delays. This is especially critical when serving industries where performance under extreme conditions is non-negotiable—such as aerospace, defense, and high-performance automotive systems.

Precision in injection mold equipment is not merely about dimensional accuracy. It encompasses thermal stability, surface finish consistency, alignment repeatability, and long-term wear resistance. These factors directly influence cycle time, part integrity, and overall tooling lifespan. At Lead Precision, our engineering approach integrates advanced CNC machining, real-time metrology, and finite element analysis (FEA) to ensure that every mold performs exactly as designed under operational stress. Our in-house capabilities span multi-axis milling, wire EDM, and hard finishing techniques that maintain tolerances within ±0.002 mm—meeting and exceeding international standards such as ISO 2768 and DIN 16901.

Our commitment to precision is validated through our track record in mission-critical applications. Wuxi Lead Precision Machinery has contributed to projects requiring military-grade reliability and Olympic-level performance standards. These engagements demanded not only flawless execution but also full traceability, rigorous testing protocols, and adherence to strict regulatory frameworks. For example, components developed for winter sports equipment used in Olympic competitions required molds capable of producing lightweight, impact-resistant parts with aerodynamic consistency. Similarly, defense sector contracts necessitated molds that could withstand repeated high-pressure cycles in harsh environments, all while maintaining micron-level dimensional stability.

Such high-stakes applications underscore why precision cannot be an afterthought—it must be engineered into every phase of mold development. From material selection (such as pre-hardened tool steels or corrosion-resistant alloys) to cooling channel design and ejection mechanisms, every detail is optimized for performance and longevity. Our engineers utilize simulation software to model mold flow, thermal distribution, and stress points prior to fabrication, minimizing trial runs and accelerating time-to-market.

Below are key technical specifications that define our injection mold equipment capabilities:

| Specification | Performance Metric |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra ≤ 0.2 µm (polished), Ra ≤ 1.6 µm (machined) |

| Maximum Mold Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tool Steel Options | P20, 718H, S136, H13, 420SS |

| Cooling Channel Accuracy | ±0.01 mm positional tolerance |

| Lead Time (Average) | 4–8 weeks, depending on complexity |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical-grade options) |

At Wuxi Lead Precision Machinery, we do not simply manufacture molds—we engineer precision systems that drive manufacturing excellence. Our experience in elite industrial sectors has refined our understanding of what it takes to deliver reliability, repeatability, and performance. When your application demands nothing less than perfection, our injection mold equipment is engineered to meet the challenge.

Precision Specs & Tolerances

Technical Capabilities: Precision Execution for Injection Mold Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal manufacturing for demanding injection mold applications. Our core strength lies in integrating advanced multi-axis machining with rigorous, metrology-grade quality control, ensuring molds meet the exacting geometric and surface finish requirements of modern production. This capability directly translates to reduced cycle times, extended mold life, and superior part consistency for our clients.

Our primary machining platform centers on state-of-the-art 5-axis CNC milling centers. These systems eliminate the need for multiple setups inherent in 3-axis processing, significantly reducing cumulative error and handling damage risks. Simultaneous 5-axis motion enables the precise machining of complex core/cavity contours, undercuts, and intricate cooling channels in a single operation. This capability is critical for molds requiring tight internal geometries or organic shapes common in medical, automotive, and consumer electronics components. High-speed machining protocols combined with optimized toolpath strategies ensure exceptional surface finishes, minimizing secondary polishing time while maintaining dimensional integrity across diverse mold materials including P20, H13, S136, and aluminum alloys. Material removal rates are maximized without sacrificing accuracy, accelerating time-to-press.

Quality verification is not an afterthought but an integrated, traceable process. Every critical feature undergoes validation using calibrated Coordinate Measuring Machines (CMMs). Our CMM fleet operates under ISO 17025 guidelines, utilizing certified styli and temperature-controlled environments to ensure measurement uncertainty is consistently below industry standards. Full 3D scanning capability allows for comprehensive comparison against the original CAD model, identifying any deviations across the entire mold surface. Detailed inspection reports, including GD&T analysis and point cloud data, are provided with every shipment, offering complete transparency and confidence in the delivered geometry. This systematic approach guarantees that tolerances are not just claimed but demonstrably achieved.

The following table details our standard achievable tolerance ranges for critical mold features under controlled production conditions. Actual capabilities may be refined based on specific part geometry, material, and client requirements.

| Material Type | Feature Size Range | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|---|

| Pre-Hardened Steel | < 50 mm | ±0.010 mm | ±0.005 mm | CMM |

| Pre-Hardened Steel | 50 – 200 mm | ±0.015 mm | ±0.008 mm | CMM |

| Hardened Steel (50+ HRC) | < 50 mm | ±0.012 mm | ±0.006 mm | CMM |

| Hardened Steel (50+ HRC) | 50 – 200 mm | ±0.018 mm | ±0.009 mm | CMM |

| Aluminum Alloys | < 100 mm | ±0.008 mm | ±0.004 mm | CMM |

| Aluminum Alloys | 100 – 300 mm | ±0.012 mm | ±0.006 mm | CMM |

This documented precision, backed by robust 5-axis machining and metrology-grade inspection, forms the foundation of Wuxi Lead’s commitment to injection mold excellence. We partner with clients to transform complex designs into production-ready tooling that performs reliably under the most stringent manufacturing conditions.

Material & Finish Options

Material selection is a critical phase in the development of high-performance injection mold equipment, directly influencing tool life, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of precision molding applications. Our expertise spans the strategic use of aluminum, steel, and titanium—each offering distinct mechanical properties and performance characteristics. Understanding these materials enables engineers and manufacturers to optimize mold design for specific production volumes, environmental conditions, and cost targets.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume molds due to their excellent machinability and thermal conductivity. These properties allow for faster cooling cycles, reducing overall cycle times during injection molding. While aluminum lacks the wear resistance of steel, its lightweight nature and ease of modification make it ideal for rapid tooling and design validation phases. When enhanced surface durability is required, aluminum benefits significantly from anodizing—a process that increases surface hardness and corrosion resistance. Hard anodizing, in particular, forms a thick, wear-resistant oxide layer capable of withstanding repeated mold release and cleaning cycles.

Steel remains the standard for high-volume production molds, where longevity and dimensional stability are paramount. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and thermal fatigue performance. These grades can be heat-treated to meet specific hardness requirements and are often polished or coated to improve release properties and resist corrosion. Stainless steels like 420 are preferred in environments where moisture or corrosive resins are present. While steel molds require longer machining times and higher initial costs, their extended service life delivers lower cost-per-part in high-volume scenarios.

Titanium, though less common in mold construction, is gaining traction in specialized applications requiring extreme strength-to-density ratios and exceptional corrosion resistance. Its use is typically limited to critical mold components such as inserts or cores exposed to aggressive environments or where weight reduction is crucial. Titanium’s high cost and challenging machinability restrict its use to niche, high-value applications, but its performance under stress and in elevated temperature conditions justifies its inclusion in advanced mold systems.

The choice of finish further enhances material performance. Anodizing, primarily applied to aluminum, improves surface durability and lubricity. It can be dyed for identification or aesthetic purposes and is available in standard (Type II) or hard-coat (Type III) variants, with the latter providing industrial-grade protection.

Below is a comparative overview of key material properties relevant to injection mold equipment:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Corrosion Resistance | Machinability |

|---|---|---|---|---|---|

| Aluminum 7075 | 15–20 (HB) | 130 | Prototyping, low-volume molds | Moderate | Excellent |

| P20 Steel | 28–32 | 30 | Medium-to-high volume molds | Low | Good |

| H13 Steel | 48–52 | 36 | High-stress, high-temp molds | Moderate | Fair |

| S136 Steel | 50–54 | 22 | Corrosion-resistant molds | High | Fair |

| Titanium (Grade 5) | 36–40 (estimated) | 7 | Specialized inserts/cores | Very High | Poor |

Selecting the optimal material and finish requires a balanced evaluation of production needs, environmental exposure, and lifecycle costs. Wuxi Lead Precision Machinery supports clients in making informed decisions through engineering consultation and precision manufacturing capabilities.

Manufacturing Process & QC

Injection Mold Equipment Production Process: Achieving Zero Defects

At Wuxi Lead Precision Machinery, our injection mold equipment production process is engineered for uncompromising quality and reliability from initial concept to full-scale output. We adhere strictly to a three-phase methodology—Design, Prototyping, Mass Production—integrated with Zero Defects protocols to eliminate waste and ensure peak performance for demanding automotive, aerospace, and medical applications.

Design Phase: Precision Engineering Foundation

Our process begins with rigorous collaborative design engineering. Lead’s team conducts in-depth Design for Manufacturing (DFM) analysis using Siemens NX and Moldflow simulation software. This identifies potential flow imbalances, cooling inefficiencies, or structural weaknesses before metal cutting begins. We prioritize material selection based on thermal stability, wear resistance, and client-specific polymer requirements—commonly utilizing H13, S136, or bespoke tool steels. Critical tolerances are defined to ±0.005 mm, with emphasis on gate positioning, venting, and ejection systems to prevent knit lines or part deformation. Every design undergoes cross-functional review against ISO 9001 and IATF 16949 standards, ensuring manufacturability and longevity.

Prototyping Phase: Validated Performance

Prototyping is not a preliminary step but a critical validation stage. Lead produces functional prototypes using production-intent hardened tool steel molds—not soft aluminum—on our HAAS and DMG MORI CNC platforms. This enables true process simulation under actual injection parameters. We conduct 50–100 cycle trials to measure dimensional stability, surface finish consistency, and cycle time accuracy. Data from cavity pressure sensors and thermal imaging identifies micro-defects invisible to manual inspection. Clients receive comprehensive reports detailing part conformity to GD&T specifications, allowing design refinements before mass production tooling. This phase reduces downstream defects by 73% compared to conventional soft-tooling approaches.

Mass Production: Sustained Zero Defects Execution

Zero Defects is achieved through closed-loop manufacturing control. Production molds are built using 5-axis CNC machining with sub-micron repeatability, followed by robotic polishing to SPI-A1 standards. During mass production, every mold undergoes 100% in-process metrology via Zeiss CMMs and automated vision systems. Statistical Process Control (SPC) monitors critical parameters—clamp force, melt temperature, cooling time—in real time, triggering automatic press adjustments if deviations exceed ±0.5%. Our proprietary mold monitoring system logs 20,000+ data points per cycle, enabling predictive maintenance to prevent wear-induced defects. Clients receive full traceability documentation, including material certs, heat treatment records, and first-article inspection reports.

Lead Precision Machinery Production Specifications

| Parameter | Capability Range | Validation Standard |

|---|---|---|

| Cavity Count | 1–96 cavities | Moldflow balance analysis |

| Tolerance | ±0.005 mm | ISO 2768-mK |

| Tool Steel Grades | H13, S136, NAK80, 420SS | ASTM A681 certification |

| Surface Finish | SPI A1 to D3 | Profilometer Ra ≤ 0.05 µm |

| Cycle Time Validation | 10,000+ continuous cycles | Zero flash/parting line shift |

This integrated approach ensures molds deliver 500,000+ defect-free cycles, minimizing client downtime and scrap rates. At Wuxi Lead, precision isn’t a target—it’s our engineering mandate.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Mold Equipment That Delivers Precision, Performance, and Reliability

At Wuxi Lead Precision Machinery, we understand that in high-end custom metal manufacturing, the quality of your injection mold equipment directly impacts your product integrity, production efficiency, and time-to-market. As a trusted leader in precision engineering from China, we specialize in delivering custom-designed injection mold systems that meet the rigorous demands of aerospace, automotive, medical, and industrial applications. Our engineering team combines decades of hands-on experience with advanced CNC manufacturing and real-time quality control to produce molds that exceed international standards.

When you partner with Lead Precision, you’re not just sourcing machinery—you’re gaining a strategic manufacturing ally. We work closely with global OEMs and tier-one suppliers to develop injection mold solutions tailored to your exact specifications. From initial concept and 3D modeling to final assembly and validation, our integrated workflow ensures dimensional accuracy, extended mold life, and seamless integration into your production line. Our facility in Wuxi is equipped with state-of-the-art EDM, high-speed milling, and surface treatment technologies, enabling us to handle complex geometries and hardened steel processing with micron-level precision.

We pride ourselves on transparency, responsiveness, and technical accountability. Every project is managed through a dedicated engineering liaison who provides regular updates, detailed inspection reports, and full documentation traceability. Whether you require a single prototype or high-volume mold production, our agile manufacturing model supports rapid turnaround without compromising quality.

Our commitment to excellence is reflected in our certifications, including ISO 9001:2015, and our long-standing partnerships with clients across North America, Europe, and Asia. By combining Chinese manufacturing efficiency with German-level precision standards, we deliver a competitive edge that matters in today’s global market.

Below are key technical capabilities that define our injection mold equipment performance:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 2,000 mm × 1,500 mm × 1,200 mm |

| Weight Capacity | Up to 15,000 kg |

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm (polished, textured, or coated) |

| Materials Supported | P20, 718, H13, S136, 2344, Stainless Steel, Aluminum, and Specialty Alloys |

| Processing Technologies | CNC Machining, Wire & Sinker EDM, Grinding, High-Speed Milling |

| Quality Assurance | 100% CMM Inspection, 3D Scanning, Mold Flow Analysis |

| Lead Time (Typical) | 4–8 weeks, based on complexity |

Elevate your manufacturing capability with injection mold equipment engineered for performance and built to last. Contact us today at [email protected] to discuss your next project with our engineering team. Let Wuxi Lead Precision Machinery be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.