Technical Contents

Engineering Guide: High Precision Machining Services

Engineering Insight Precision as the Non-Negotiable Foundation

In high precision machining services the pursuit of dimensional accuracy transcends mere specification adherence it defines functional integrity reliability and ultimate product success. For critical components in aerospace defense medical technology and advanced industrial equipment microscopic deviations directly impact performance safety and lifecycle costs. Achieving true precision demands more than advanced machinery it requires an integrated engineering philosophy encompassing material science thermal stability vibration control metrology rigor and deep process understanding. At Wuxi Lead Precision Machinery we recognize that tolerances measured in microns are not abstract targets but essential prerequisites for systems where failure is not an option. Our engineering approach begins with comprehensive material analysis and thermal compensation modeling ensuring that every machining strategy accounts for real-world behavior under operational stress. This foundational commitment to precision engineering is why global leaders in demanding sectors consistently partner with us.

Our proven capability in mission-critical applications underscores this commitment. We have delivered components for Olympic venue structural systems where dimensional stability under extreme environmental loads was paramount. Similarly our work within stringent defense supply chains necessitates adherence to ITAR protocols and tolerances where absolute reliability is non-negotiable. These projects demand not only technical execution but also rigorous documentation traceability and process validation far exceeding standard industry practices. The experience gained from such high-stakes environments directly benefits every client by embedding military-grade discipline into our standard operating procedures. Precision machining at this level minimizes assembly scrap reduces field failures and extends operational longevity delivering significant total cost of ownership advantages.

The following table outlines core precision capabilities achievable across our certified manufacturing platforms:

| Process Type | Tolerance Range | Surface Finish (Ra) | Max Work Envelope (mm) | Key Applications |

|---|---|---|---|---|

| 5-Axis Milling | ±0.002 mm to ±0.005 mm | 0.4 μm to 1.6 μm | 1200 x 800 x 750 | Aerospace structural brackets |

| Precision Turning | ±0.0015 mm to ±0.003 mm | 0.2 μm to 0.8 μm | Ø420 x 1000 | Medical implant components |

| Micro-Machining | ±0.0005 mm to ±0.001 mm | 0.1 μm to 0.4 μm | 150 x 100 x 80 | Sensor housings optical mounts |

| Swiss-Type Machining | ±0.001 mm to ±0.0025 mm | 0.2 μm to 0.6 μm | Ø32 x 200 | Defense actuator parts |

True precision engineering is a continuous improvement cycle not a static achievement. At Wuxi Lead Precision Machinery our ISO 9001 and AS9100 certified processes integrate real-time in-process gauging predictive tool wear algorithms and multi-sensor CMM validation to maintain consistency across production runs. We collaborate with clients during the design phase to optimize manufacturability ensuring precision targets are achievable cost-effectively. When your application demands components that perform flawlessly under extreme conditions our engineering rigor and proven heritage in Olympic and defense projects provide the assurance that micron-level accuracy is consistently delivered. This is the standard we uphold for every partner.

Precision Specs & Tolerances

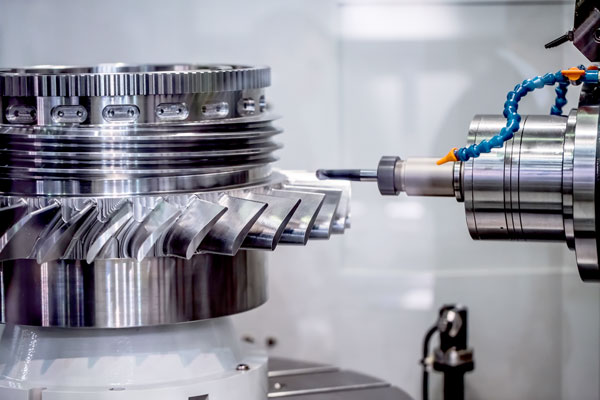

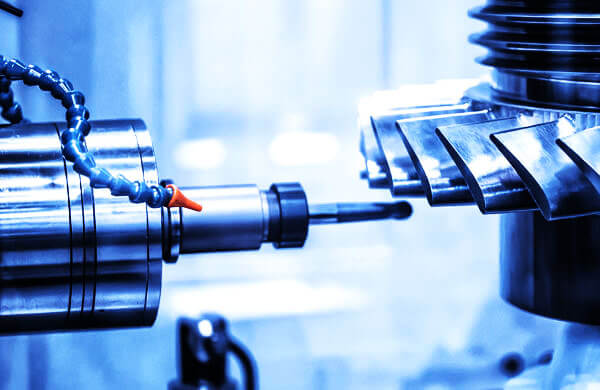

Wuxi Lead Precision Machinery delivers advanced high precision machining services tailored for complex, mission-critical components across aerospace, medical, energy, and industrial automation sectors. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of geometrically intricate parts with superior surface finish and dimensional accuracy. Our machining centers operate with simultaneous multi-axis motion, allowing for complex contours, deep cavities, and compound angles to be machined in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times compared to conventional 3-axis alternatives.

All machining operations are supported by high-rigidity spindles with thermal compensation and real-time tool monitoring systems, ensuring stability during extended production runs. We work with a wide range of engineering-grade metals, including titanium alloys, Inconel, stainless steel, aluminum alloys, and hardened tool steels. Our programming team utilizes industry-leading CAM software to optimize toolpaths, minimize cycle times, and maintain material integrity, particularly in thin-wall or high-precision features.

To guarantee conformance to the most demanding specifications, every critical component undergoes comprehensive quality verification using a Coordinate Measuring Machine (CMM). Our CMM inspection process is fully automated and aligned with ISO 10360 standards, providing traceable, high-resolution measurement data for first-article inspections, production sampling, and full batch validation. Dimensional reports include GD&T analysis, profile deviation mapping, and positional accuracy verification, ensuring full compliance with AS9100, ISO 13485, and other industry-specific quality requirements.

In addition to CMM, our quality lab is equipped with surface roughness testers, optical comparators, and hardness testing instruments to validate material and finish properties. All inspection data is digitally archived for full traceability, supporting audit readiness and long-term production consistency.

The following table outlines the standard precision tolerances we consistently achieve across our 5-axis CNC machining and inspection processes:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm | ±0.002 mm |

| Positional Tolerance | ±0.008 mm | ±0.003 mm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| True Position (GD&T) | 0.01 mm | 0.005 mm |

| Runout / Total Indicator Reading | 0.005 mm | 0.002 mm |

Our technical infrastructure is designed for scalability and repeatability, supporting low-volume prototyping through high-mix, medium-volume production. With a focus on precision, traceability, and engineering collaboration, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of performance and reliability in demanding operational environments.

Material & Finish Options

Material Selection for High-Precision Machined Components

Material choice fundamentally dictates the performance, manufacturability, and longevity of precision-machined components. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your application’s functional demands, environmental exposure, and stringent tolerance requirements. Selecting the optimal alloy and finish is not merely a specification checkbox; it is integral to achieving yield, reliability, and cost efficiency in high-mix, low-volume production.

Aluminum Alloys dominate aerospace, electronics, and prototyping due to their exceptional strength-to-weight ratio and machinability. Series 6061-T6 offers a versatile balance of weldability, corrosion resistance, and moderate strength, ideal for structural frames and housings. For higher strength demands, 7075-T6 provides aerospace-grade performance but requires careful thermal management during machining to prevent distortion. Aluminum’s high thermal conductivity aids heat dissipation during cutting but necessitates precise toolpath strategies to counter its relatively high thermal expansion coefficient, ensuring micron-level tolerances are maintained.

Steel Alloys are selected when ultimate strength, wear resistance, or high-temperature stability are paramount. Low-carbon 1018 steel is cost-effective for non-critical fixtures, while 4140 and 4340 chrome-moly steels deliver superior toughness and hardenability for demanding applications like shafts and landing gear components. Tool steels such as A2 or D2 are essential for molds and dies requiring extreme edge retention. Machining hardened steels demands rigid setups and specialized tooling to manage work hardening and achieve surface finishes below Ra 0.8 µm consistently.

Titanium Alloys, particularly Ti-6Al-4V, are critical in medical implants and aerospace where biocompatibility, strength-to-weight, and corrosion resistance are non-negotiable. However, titanium presents significant machining challenges: low thermal conductivity causes heat concentration at the tool tip, accelerating wear, and its tendency to gall requires strict control of cutting parameters and coolant application. Our CNC processes utilize high-pressure coolant systems and optimized spindle speeds to mitigate these issues, ensuring dimensional stability and surface integrity.

Anodizing Finishes enhance aluminum components by providing wear resistance, electrical insulation, and corrosion protection without significantly altering critical dimensions. Type II (Sulfuric Acid) anodizing offers a standard decorative and protective layer, while Type III (Hardcoat) anodizing delivers superior abrasion resistance for high-wear applications. Crucially, our finishing protocols account for the anodizing layer’s growth (50% inward, 50% outward from the base metal), incorporating dimensional compensation into the machining process to maintain final tolerances.

Material properties directly influence machining strategy and final part performance. The table below summarizes key characteristics for common high-precision alloys:

| Material | Typical Alloy | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Key Machining Consideration |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | 167 | Manage thermal expansion; high chip flow |

| Aluminum | 7075-T6 | 2.8 | 572 | 130 | Avoid chatter; sensitive to heat buildup |

| Steel | 4140 (Annealed) | 7.85 | 655 | 42.6 | Control work hardening; rigid setup |

| Steel | 4340 (Hardened) | 7.85 | 1100+ | 36.0 | Requires carbide/titanium nitride tooling |

| Titanium | Ti-6Al-4V | 4.43 | 900 | 7.2 | Low speed/high pressure coolant; avoid galling |

Wuxi Lead Precision Machinery integrates deep material science expertise with advanced CNC capabilities. We collaborate from the design phase to select the optimal material-finish combination, ensuring your precision components meet functional requirements while maximizing manufacturability and yield. Let our engineers translate your specifications into flawless execution.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the manufacturing journey begins with meticulous design engineering. Every custom metal component is developed in close collaboration with the client, ensuring that functional requirements, material specifications, and geometric tolerances are fully aligned with end-use applications. Our engineering team utilizes advanced CAD/CAM software—such as SolidWorks, AutoCAD, and Siemens NX—to create 3D models and detailed technical drawings. These digital blueprints are rigorously reviewed through Design for Manufacturability (DFM) analysis, identifying potential production challenges before any material is cut. This proactive approach minimizes rework, reduces lead times, and ensures that every design is optimized for both performance and precision.

Prototyping: Validating Accuracy and Functionality

Once the design is finalized, we proceed to the prototyping phase—a critical step in our zero-defect philosophy. Using state-of-the-art CNC machining centers, we produce functional prototypes that mirror the final product in material, dimension, and finish. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify conformance to specifications. Dimensional accuracy is validated against ISO 2768-mK and GD&T standards, ensuring that even the most complex geometries meet exacting tolerances. Clients receive detailed inspection reports and physical samples for functional testing, enabling design validation and approval prior to mass production. This iterative process ensures that any discrepancies are resolved early, reducing risk and ensuring reliability at scale.

Mass Production: Precision, Consistency, Zero Defects

With prototype approval, we transition seamlessly into high-volume manufacturing. Our production floor is equipped with over 120 CNC machines, including multi-axis milling centers, turning centers, and Swiss-style lathes, enabling the production of intricate metal components in aluminum, stainless steel, titanium, and specialty alloys. Each production run is governed by standardized work instructions, tooling validation, and real-time process monitoring. We implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols to maintain consistency across batches. In-process inspections occur at critical stages, ensuring deviations are detected and corrected immediately.

Our quality management system is certified to ISO 9001:2015, and we adhere to a zero-defect mindset through full traceability, from raw material sourcing to final packaging. Every component is inspected post-machining, with final reports including dimensional data, material certifications, and surface finish analysis.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Maximum Part Size | 800 mm × 500 mm × 400 mm |

| Minimum Feature Size | 0.1 mm (micro-machining) |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Inconel, PEEK |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days (after prototype approval) |

Through integrated design, prototyping, and precision manufacturing, Wuxi Lead delivers custom metal components with uncompromising quality, engineered for performance and repeatable excellence.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

Selecting a precision machining partner transcends transactional procurement it demands a strategic alliance built on uncompromising quality, technical mastery, and responsive collaboration. At Wuxi Lead Precision Machinery, we engineer this partnership for global enterprises requiring mission-critical metal components. Our integrated approach ensures your most demanding specifications translate seamlessly from CAD model to certified physical part, mitigating supply chain risk while accelerating time-to-market. We operate beyond standard job shop parameters, functioning as an extension of your engineering team through proactive DFM consultation, rigorous process validation, and full material traceability. This commitment delivers measurable value: reduced scrap rates, predictable lead times, and components performing flawlessly in extreme operational environments.

Our technical capabilities are structured to meet aerospace, medical, and semiconductor industry benchmarks. The following specifications demonstrate our production envelope for complex geometries and tight-tolerance requirements:

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Tolerance Range | ±0.0001″ (2.5µm) to ±0.0005″ (12.7µm) | ISO 2768-mK, ASME Y14.5 |

| Materials Processed | Titanium (Gr 2,5), Inconel 718, Hastelloy C-276, 17-4PH, 440C, Aluminum 7075-T73 | AMS, ASTM, EN, JIS |

| Max Work Envelope | 850 x 500 x 450 mm (33.5″ x 19.7″ x 17.7″) | N/A |

| Surface Finish | Ra 0.1 µm to 1.6 µm (4µin to 63µin) | ISO 1302, ASME B46.1 |

| Certifications | ISO 9001:2015, IATF 16949, AS9100D | Mandatory for Tier 1 Supply |

These metrics represent our baseline operational capacity. True partnership emerges in how we deploy this infrastructure: through real-time dimensional reporting via cloud-based SPC dashboards, dedicated project engineers fluent in technical English, and zero-defect protocols validated by in-house CMM, optical comparators, and surface roughness testers. We eliminate guesswork by providing material certs, heat treat records, and first-article inspection reports with every shipment—ensuring full compliance for regulated sectors.

Initiate your precision manufacturing solution by contacting our engineering team directly. Email [email protected] with your project specifications, including material requirements, critical tolerances, and target volumes. Our response includes a feasibility assessment within 24 business hours, followed by a collaborative review of process planning and timeline optimization. For urgent RFQs, reference “URGENT” in the subject line to trigger expedited handling. We require no NDAs for initial technical discussions, enabling immediate progress assessment.

Wuxi Lead Precision Machinery operates at the convergence of Chinese manufacturing scale and German-engineered process discipline. Partner with us to transform precision challenges into competitive advantage—where every micron of tolerance delivers measurable ROI. Contact [email protected] today to begin your precision engineered partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.