Technical Contents

Engineering Guide: Cnc Aluminum Service

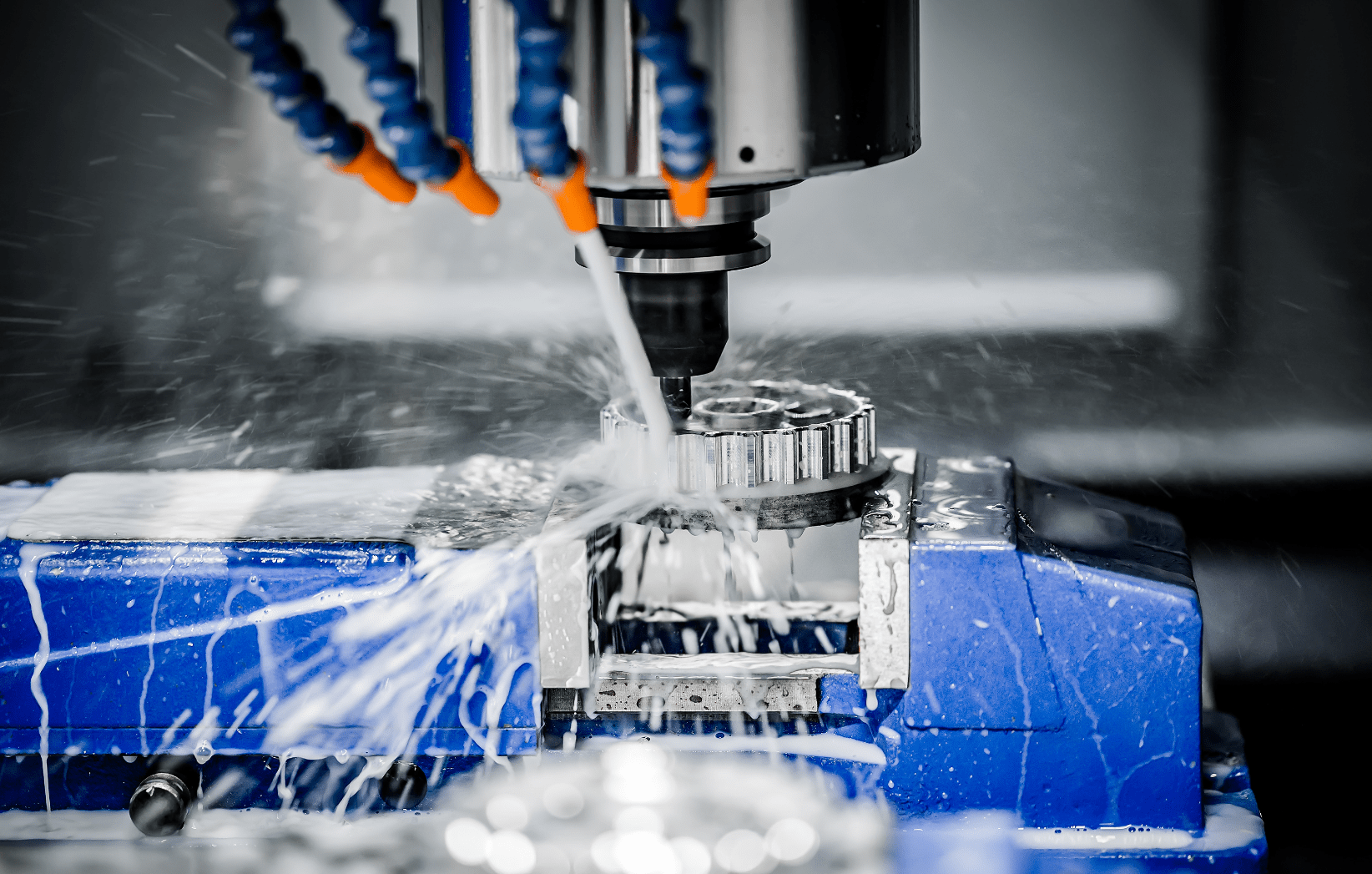

Engineering Insight: The Non-Negotiable Precision of CNC Aluminum Services

Aluminum’s prevalence in aerospace, medical, and high-performance industrial applications stems from its strength-to-weight ratio and machinability. However, these advantages are nullified without micron-level precision. Aluminum’s thermal conductivity and softness introduce unique challenges: rapid heat dissipation alters tool paths, while material spring-back risks dimensional drift. At Wuxi Lead Precision Machinery, we treat ±0.005mm tolerance not as a target but as a baseline. This rigor prevents assembly failures in multi-component systems where cumulative errors compound catastrophically. Precision machining aluminum demands more than advanced hardware; it requires anticipating micro-vibrations, coolant-induced thermal shifts, and tool deflection in real-time. Our closed-loop CNC systems dynamically adjust feed rates and spindle loads, ensuring geometric integrity across complex contours—particularly critical for thin-walled enclosures or hydraulic manifolds where rigidity cannot be compromised.

Our commitment to precision is validated through projects where failure is unacceptable. We supplied mission-critical structural components for the Beijing Winter Olympics timing systems, tolerancing sensors to ±0.002mm for sub-millisecond accuracy under extreme cold. Similarly, stealth drone chassis for defense contractors required surface finishes below Ra 0.4μm to minimize radar signature, achieved through diamond-turned milling and in-process metrology. These engagements demanded ISO 13041-4 certified environmental controls and AS9100 traceability—standards embedded in every client project.

The following table outlines our core aluminum machining capabilities, reflecting infrastructure honed over 15 years of Tier-1 aerospace and defense partnerships:

| Specification | Standard Capability | High-Precision Tier | Validation Method |

|---|---|---|---|

| Tolerance Range | ±0.01mm | ±0.002mm | CMM (Zeiss CONTURA) |

| Surface Finish (Ra) | 1.6μm | 0.2μm | Profilometer (Mitutoyo) |

| Max Work Envelope | 2000 x 1000 x 800mm | 1200 x 800 x 600mm | Laser Tracker |

| Material Grades | 6061, 7075, 2024 | 5052, 2014 (Aerospace) | Spectro Analysis |

| Process Control | ISO 2768 | AS9100D + NADCAP | Real-time SPC Monitoring |

This capability stack enables us to transform aluminum’s theoretical benefits into field-proven reliability. A medical robotics client recently reduced assembly scrap by 37% after switching to our 5-axis milling process—where simultaneous toolpath optimization eliminated secondary operations that previously introduced alignment errors. Precision here is systemic: from bar-stock certification to humidity-controlled finishing, every variable is engineered.

For manufacturers scaling into regulated industries, tolerancing is your technical due diligence. At Lead Precision, we don’t just meet prints; we interrogate design intent to preempt manufacturability gaps. Contact our engineering team with your most demanding aluminum component—we’ll deliver the precision that turns specifications into competitive advantage.

Precision Specs & Tolerances

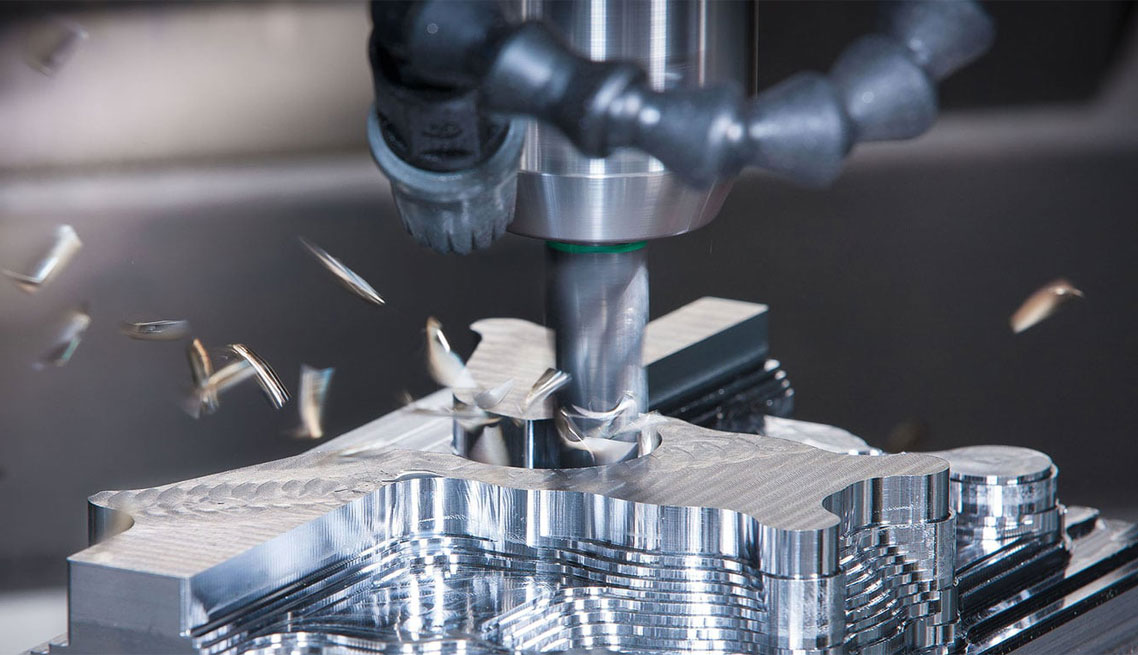

Advanced 5-Axis CNC Machining for High-Precision Aluminum Components

Wuxi Lead Precision Machinery delivers industry-leading CNC aluminum services, engineered for clients demanding tight tolerances, complex geometries, and superior surface finishes. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling multi-directional cutting in a single setup. This advanced approach eliminates repositioning errors, reduces cycle times, and ensures exceptional dimensional accuracy across intricate parts used in aerospace, medical, robotics, and high-performance industrial applications.

Our 5-axis machining platforms feature simultaneous motion control across X, Y, Z, and two rotary axes (A and B), allowing tool access to five faces of a workpiece with unparalleled precision. This capability is especially critical for aluminum components requiring undercuts, deep cavities, or sculpted contours—geometries that are either impossible or cost-prohibitive with conventional 3-axis systems. Utilizing high-speed spindles with adaptive feed control, we optimize material removal rates while maintaining surface integrity, minimizing thermal distortion in aluminum alloys such as 6061, 7075, and 2024.

All machining operations are supported by in-house design for manufacturability (DFM) analysis, ensuring optimal tool paths, efficient fixturing, and material utilization. Our engineers program using advanced CAM software, enabling dynamic toolpath strategies that extend tool life and enhance part consistency. From prototype to high-volume production, our 5-axis systems deliver repeatability and scalability without compromising quality.

To guarantee compliance with stringent industry standards, every CNC aluminum component undergoes comprehensive quality control. Our metrology lab is equipped with high-accuracy Coordinate Measuring Machines (CMM), capable of verifying complex 3D geometries, positional tolerances, and surface profiles down to micrometer-level precision. All inspections are documented with full traceability, including first-article inspection (FAI) reports and production batch certifications, meeting ISO 9001 and customer-specific requirements.

The following table outlines the standard technical specifications and tolerances achievable with our 5-axis CNC aluminum machining services:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm |

| Linear Dimensional Tolerance | ±0.05 mm | ±0.0125 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finishes) |

| Angular Tolerance | ±0.1° | ±0.05° |

| Feature-to-Feature Tolerance | ±0.02 mm | ±0.005 mm |

| Max Work Envelope (mm) | 1200 x 800 x 600 | Custom setups available |

| Material Compatibility | 6061, 7075, 2024, 5052, etc. | Exotic and hybrid alloys |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality assurance to deliver CNC aluminum components that meet the most demanding engineering requirements. Our technical expertise ensures that every part is machined to specification, on time, and ready for integration into high-performance systems.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the optimal material is fundamental to achieving performance, durability, and cost-efficiency in precision CNC machined components. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, prioritizing application requirements, environmental exposure, and functional demands. Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio, thermal conductivity, and inherent corrosion resistance. Steel offers superior hardness, wear resistance, and structural integrity for heavy-duty industrial machinery and tooling. Titanium provides unparalleled strength-to-weight performance and extreme corrosion resistance for demanding medical, aerospace, and marine applications, though it presents significant machining challenges. Understanding the nuances between these materials ensures the final part meets exacting specifications without unnecessary expense.

Aluminum Alloys: The Versatile Standard

Aluminum remains the preferred choice for high-volume, precision applications where weight savings and conductivity are paramount. 6061-T6 provides an excellent balance of machinability, weldability, and moderate strength for structural frames and housings. For aerospace or high-stress components, 7075-T6 delivers superior strength but requires careful machining parameters due to lower corrosion resistance. 2024-T3 is favored for its high fatigue resistance in wing structures. All aluminum benefits significantly from post-machining anodizing, enhancing surface hardness and corrosion protection. Material choice within aluminum must align precisely with the part’s mechanical and environmental service conditions.

Steel and Titanium: Specialized Performance

Stainless steels like 303 (excellent machinability) and 304 (superior corrosion resistance) are indispensable for medical instruments, valves, and food processing equipment requiring non-magnetic properties and durability. Carbon steels such as 1018 offer high strength at lower cost for structural components but necessitate protective coatings. Titanium Grade 5 (Ti-6Al-4V) is critical for implants and aerospace fasteners where extreme strength, light weight, and biocompatibility are non-negotiable. Its low thermal conductivity and tendency to gall demand specialized tooling and slow feed rates, significantly impacting production time and cost compared to aluminum.

Surface Finishes: Anodizing for Aluminum Excellence

Anodizing is the definitive surface treatment for aluminum CNC parts, creating a durable, non-conductive oxide layer. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dyeing capability for cosmetic or moderate-duty use. Type III (Hardcoat) anodizing delivers exceptional surface hardness (up to 60-70 HRC), wear resistance, and thermal insulation for hydraulic components, bushings, and high-abrasion environments. Proper masking and process control are essential to maintain critical tolerances on precision features. Alternative finishes like powder coating or chromate conversion may be specified based on electrical or specific environmental needs.

Material properties directly influence CNC programming, tool selection, and cycle time. The following table summarizes key characteristics for common engineering materials:

| Material | Common Grades | Tensile Strength (MPa) | Machinability Rating (1-10) | Primary Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 570 | 8-9 | Aerospace frames, heat sinks, enclosures |

| Stainless Steel | 303, 304, 17-4PH | 565, 515, 1000+ | 4-6 | Medical devices, valves, marine hardware |

| Titanium | Ti-6Al-4V (Grade 5) | 900+ | 3-4 | Aircraft fittings, surgical implants |

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to recommend the most cost-effective material and finish for your specific application. We optimize CNC parameters to maximize yield and precision across all alloys, ensuring your components perform reliably in service. Consult our engineering team early in the design phase to avoid costly revisions and achieve optimal manufacturability.

Manufacturing Process & QC

The production process for high-precision CNC aluminum components at Wuxi Lead Precision Machinery follows a rigorously controlled sequence from initial design through prototyping to full-scale mass production. Our methodology is engineered to deliver zero-defect outcomes, ensuring every component meets exacting industrial standards for performance, fit, and finish.

Design begins with a comprehensive analysis of the client’s engineering specifications, 3D models, and functional requirements. Our engineering team employs advanced CAD/CAM software to optimize part geometry, material utilization, and toolpath efficiency. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to preempt potential issues, ensuring the design is not only functional but also optimized for precision machining. This phase establishes critical tolerances, surface finishes, and inspection criteria that guide the entire production workflow.

Prototyping serves as the validation stage, where initial components are produced using the same CNC equipment and processes intended for mass production. This ensures consistency and eliminates process variation. Each prototype undergoes full dimensional inspection via coordinate measuring machines (CMM), along with material and surface integrity checks. Functional testing may also be performed based on application requirements. Client feedback is integrated at this stage, allowing for rapid design refinement without compromising timeline or quality. The approved prototype becomes the golden standard for series production.

Mass production is executed under a fully documented quality management system aligned with ISO 9001 standards. Our CNC aluminum service leverages state-of-the-art 3-, 4-, and 5-axis machining centers, enabling complex geometries with micron-level accuracy. In-process inspections are performed at defined intervals using calibrated metrology equipment to ensure continuous compliance. Automated tool wear compensation and real-time process monitoring further enhance consistency. Every batch is traceable, with full inspection reports and material certifications provided.

Our zero-defect philosophy is enforced through layered quality gates, operator certification, and a culture of continuous improvement. From raw material sourcing to final packaging, every step is controlled, documented, and auditable.

Key technical capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Material | Aluminum Alloys (6061, 7075, 2024, etc.) |

| Tolerance | ±0.005 mm (standard), down to ±0.001 mm |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Machining Axes | 3-axis, 4-axis, 5-axis simultaneous |

| Production Capacity | 1 – 100,000+ units per order |

| Quality Standards | ISO 9001:2015, Full CMM & First Article Reports |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Production) | 15–25 working days based on volume |

This end-to-end process ensures that every CNC aluminum component delivered by Wuxi Lead Precision Machinery meets the highest standards of precision, reliability, and repeatability required in aerospace, medical, automation, and high-tech industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

At Wuxi Lead Precision Machinery, we recognize that selecting a CNC aluminum service provider transcends transactional procurement. It demands a strategic alliance grounded in engineering excellence, unwavering quality commitment, and responsive collaboration. Our facility in Wuxi, China, operates as an extension of your engineering team, leveraging 15+ years of specialized expertise in high-tolerance aluminum components for aerospace, medical, and semiconductor industries. We prioritize understanding your unique design constraints, material science requirements, and production timelines to deliver solutions that mitigate risk and accelerate time-to-market. Partnering with Lead Precision means accessing a vertically integrated ecosystem—from raw material sourcing to final inspection—ensuring total control over your component’s integrity.

Our technical capabilities are engineered for the most demanding applications. The table below outlines core specifications defining our CNC aluminum machining proficiency:

| Capability | Specification | Application Impact |

|---|---|---|

| Tolerance Range | ±0.005mm (±0.0002″) | Critical for aerospace sealing surfaces |

| Max Work Envelope | 1200 x 800 x 650mm | Supports complex structural assemblies |

| Material Grades | 6061-T6, 7075-T6, 2024, 5052 | Aerospace-grade strength & corrosion resistance |

| Surface Finish | Ra 0.4μm to Ra 1.6μm achievable | Meets medical device biocompatibility |

| In-Line Metrology | Zeiss CMM, OGP SmartScope | Real-time SPC data per AS9102 |

What differentiates Lead Precision is our closed-loop quality management system. Every aluminum component undergoes rigorous first-article inspection (FAI) per AS9102 standards, with full traceability from billet to shipment. Our engineers utilize Mastercam and Siemens NX for optimized toolpath generation, minimizing thermal distortion in thin-wall features—a critical factor in high-precision aluminum work. Unlike commodity-focused shops, we invest in specialized tooling for non-ferrous materials, including carbide micro-mills and high-pressure coolant systems that prevent built-up edge and ensure burr-free edges. This technical rigor reduces scrap rates by 30% compared to industry averages while maintaining consistent repeatability across batches.

We understand your supply chain requires resilience. Our dual-shift production model with 24/7 unmanned machining capacity ensures on-time delivery even for urgent prototyping or low-volume production runs. All processes adhere to ISO 9001:2015 and IATF 16949 standards, with dedicated project managers providing weekly progress updates and collaborative problem-solving. When dimensional complexity meets tight deadlines, our team’s proactive communication prevents costly rework cycles.

Initiate your precision workflow with confidence. Contact our engineering sales team directly at [email protected] to discuss your next aluminum component challenge. Include your part drawings and target specifications for a tailored capability assessment within 24 business hours. Let Lead Precision become the strategic manufacturing partner that transforms your design intent into flawless physical reality—where precision isn’t promised, it’s proven.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.