Technical Contents

Engineering Guide: Plastic Injection Molding Usa

Engineering Insight: The Critical Role of Precision in Plastic Injection Molding – A Global Perspective

In the highly competitive landscape of custom metal manufacturing for plastic injection molding, precision is not merely a performance metric—it is the foundation of reliability, repeatability, and long-term cost efficiency. As demand grows for high-performance molds in industries ranging from automotive to medical devices, the need for micron-level accuracy in mold base production has never been more critical. This is especially true in the United States, where manufacturers serving aerospace, defense, and consumer electronics sectors demand tooling that consistently delivers flawless part replication over millions of cycles.

At Wuxi Lead Precision Machinery, we understand that precision begins at the engineering level. Our expertise in manufacturing custom mold bases for plastic injection molding is rooted in over two decades of advancing tolerances to meet the most stringent global standards. Our experience extends to supplying components for mission-critical applications, including systems used in Olympic-grade sporting equipment and military-grade defense systems—environments where failure is not an option. These projects demand not only exacting dimensional accuracy but also superior material integrity, thermal stability, and long-term wear resistance.

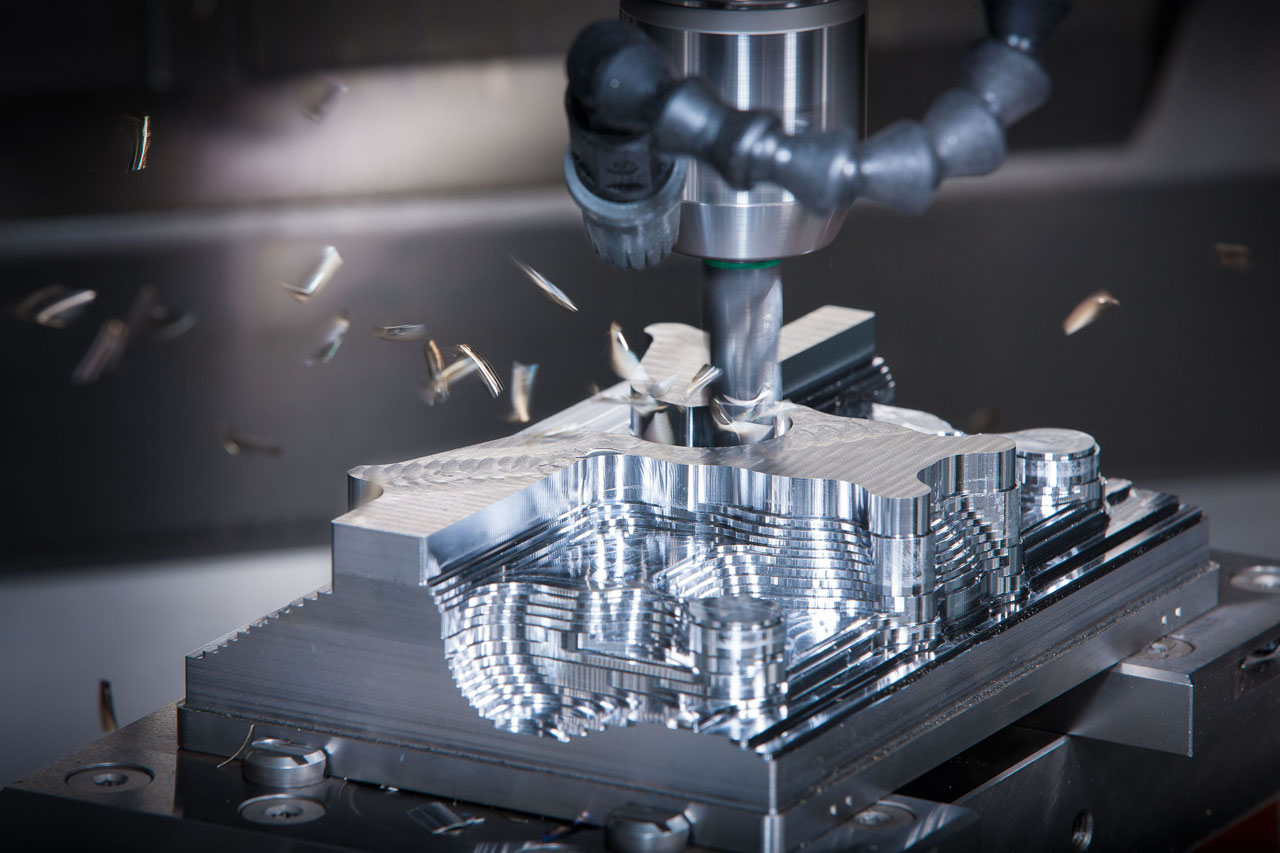

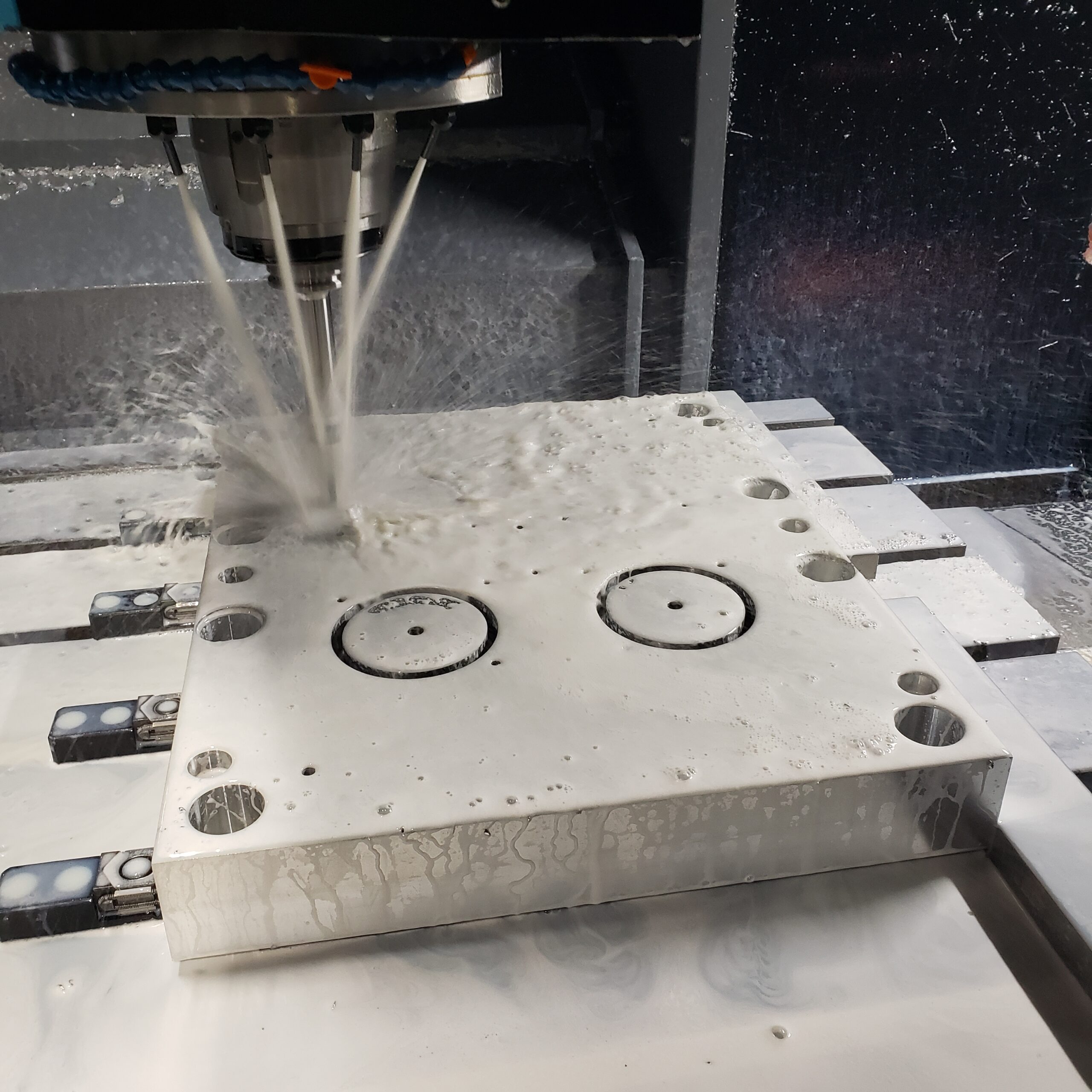

The success of any plastic injection molding operation hinges on the quality of the mold base. Even minor deviations in parallelism, flatness, or bore alignment can lead to part defects, increased cycle times, and premature tool wear. At Lead Precision, every mold base is machined using state-of-the-art CNC equipment calibrated to maintain tolerances within ±0.002 mm. This level of control ensures perfect alignment between cavity and core plates, precise ejector pin movement, and consistent cooling channel placement—factors that directly influence part quality and production uptime.

Our manufacturing process integrates advanced metrology systems, including coordinate measuring machines (CMM) and laser interferometry, to validate geometrical accuracy at every stage. Materials are selected based on application-specific requirements, with options ranging from pre-hardened P20 and H13 tool steels to high-corrosion-resistant stainless variants. All components undergo rigorous heat treatment and stress-relieving procedures to eliminate internal deformation risks.

Below is a summary of our standard precision specifications for custom mold bases, reflecting the capabilities that have made Lead Precision a trusted partner in high-end manufacturing:

| Specification | Standard Tolerance | High-Precision Option |

|---|---|---|

| Flatness | ±0.01 mm per 100 mm | ±0.005 mm per 100 mm |

| Parallelism | ±0.01 mm | ±0.005 mm |

| Perpendicularity | ±0.01 mm | ±0.008 mm |

| Bore Diameter Tolerance | H7 | H6 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Dimensional Accuracy | ±0.02 mm | ±0.002 mm |

These specifications are not theoretical benchmarks—they are consistently achieved across production batches, ensuring that our clients in the USA and beyond receive mold bases engineered for zero compromise. Whether supporting high-volume consumer production or low-volume, high-mix defense applications, Wuxi Lead Precision Machinery delivers the precision that advanced plastic injection molding demands.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Molding Excellence

Wuxi Lead Precision Machinery delivers mission-critical metal components for plastic injection molding applications across the USA, where dimensional accuracy directly impacts mold longevity, part consistency, and production efficiency. Our facility integrates advanced manufacturing technologies with rigorous quality control protocols to meet the exacting demands of high-volume, tight-tolerance tooling and components. This capability ensures your molds perform reliably under extreme cyclic stresses, minimizing downtime and scrap rates in your production environment.

Our core strength lies in multi-axis precision machining. We deploy state-of-the-art 5-axis CNC milling and turning centers, enabling complex geometries in a single setup. This eliminates cumulative errors inherent in multi-operation workflows, critical for intricate mold cores, cavities, slides, and lifters. The simultaneous 5-axis motion achieves undercuts, organic contours, and micro-features impossible with 3-axis systems, while maintaining thermal stability for micron-level repeatability. Materials processed include hardened tool steels (H13, S7, P20), stainless alloys, and aluminum, all machined to exacting surface finishes that reduce wear and improve part ejection.

Quality assurance is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), certified to ISO 10360-2 standards. Our CMM protocols validate critical dimensions, geometric tolerances (GD&T), and surface profiles against your CAD models, generating full inspection reports traceable to NIST standards. This data-driven verification ensures conformity before shipment, eliminating costly rework or mold trials delays at your facility. Statistical process control (SPC) monitors machining performance in real-time, enabling proactive adjustments to maintain output consistency across large production runs.

Tolerance achievement is foundational to mold performance. The following table reflects our standard and enhanced capabilities for machined components:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Standard |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.002 mm (±0.00008″) | ISO 2768-mK |

| Geometric (GD&T) | ±0.015 mm (±0.0006″) | ±0.003 mm (±0.00012″) | ASME Y14.5-2018 |

| Surface Roughness | Ra 0.8 µm (32 µin) | Ra 0.2 µm (8 µin) | ISO 1302 |

| Hole Position | ±0.012 mm (±0.0005″) | ±0.0025 mm (±0.0001″) | ISO 1101 |

These specifications are consistently achieved across production batches, validated by our CMM infrastructure. We specialize in components requiring micron-level precision for hot runner systems, valve gates, and micro-molding inserts—where deviations of even 0.005 mm compromise part integrity. Our engineering team collaborates pre-production to optimize manufacturability, ensuring tolerances are both achievable and cost-effective for your application.

For US injection molders, partnering with Wuxi Lead means accessing Chinese manufacturing scale without compromising on precision or accountability. We bridge the distance with documented quality, responsive engineering support, and parts that perform flawlessly from the first shot. This is precision engineering that travels—guaranteed.

Material & Finish Options

Material Selection in Custom Metal Manufacturing for Plastic Injection Molding Applications

Selecting the appropriate material is critical when designing and manufacturing precision components for plastic injection molding systems. The performance, durability, and cost-efficiency of mold components depend heavily on the base metal and surface treatment used. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using high-grade aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is widely used for prototype molds and low-volume production due to its excellent machinability and thermal conductivity. It allows for rapid cooling cycles, reducing overall cycle time during testing phases. While not as wear-resistant as steel, modern aluminum alloys such as 7075-T6 provide sufficient strength for many injection molding applications. Aluminum is also significantly lighter than steel, simplifying mold handling and reducing wear on molding machines.

Steel remains the standard for high-volume production molds. Tool steels like P20, H13, and S136 offer superior hardness, wear resistance, and longevity under repeated thermal cycling. These materials maintain dimensional stability over thousands of cycles, making them ideal for complex, high-precision parts. Stainless variants such as 420SS are preferred in corrosive environments or when molding materials like PVC that release acidic byproducts during processing.

Titanium is employed in specialized applications where extreme strength-to-density ratio and corrosion resistance are paramount. Though more expensive and challenging to machine, titanium components are used in critical mold elements such as ejector pins or inserts exposed to aggressive chemicals or high stress. Its biocompatibility also makes it suitable for medical-grade molding applications.

Surface finishing plays an equally vital role in mold performance. Anodizing, particularly hard anodizing, enhances aluminum’s surface hardness and wear resistance, extending mold life significantly. The process creates a durable, corrosion-resistant oxide layer that can withstand repeated contact with molten polymers. Decorative anodizing also allows for improved aesthetics and color coding of mold components. For steel, alternatives like nitriding or chrome plating are more common, but anodizing aluminum remains a cost-effective and high-performance solution.

Below is a comparative overview of key material properties relevant to plastic injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 570 | 15–20 (HB) | 130 | Moderate | Prototyping, low-volume production |

| P20 Steel | 900–1100 | 28–32 | 30 | Low | Medium to high-volume molds |

| H13 Steel | 1400–1600 | 48–52 | 28 | Moderate | Hot-runner systems, high-temp molds |

| Titanium Grade 5 | 900–1000 | 36–40 | 7 | Excellent | High-stress inserts, corrosive environments |

Choosing the right material and finish ensures optimal mold performance, longevity, and return on investment. Wuxi Lead Precision Machinery supports global clients with advanced material selection guidance and precision manufacturing tailored to U.S. and international standards.

Manufacturing Process & QC

Process Excellence: From Concept to Zero-Defect Production

Achieving flawless plastic injection molded components for the demanding US market requires a rigorously controlled, end-to-end process. At Wuxi Lead Precision Machinery, we integrate advanced engineering with disciplined manufacturing protocols, ensuring every part meets exacting specifications from initial concept through high-volume delivery. Our Zero Defects philosophy is not aspirational; it is systematically engineered into each phase.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with US clients during the conceptual stage, leveraging 3D CAD modeling and sophisticated mold flow simulation software. This critical step identifies potential weaknesses—such as sink marks, weld lines, or warpage—before tooling begins. We optimize gate locations, cooling channel layouts, and material selection to ensure cavity fill balance and thermal uniformity, directly preventing common defect origins. This proactive analysis reduces costly revisions and establishes the blueprint for consistent quality.

Prototyping transitions theory into tangible validation. Utilizing high-precision CNC-machined aluminum or soft steel molds, we produce functional prototypes mirroring final production intent. Each prototype undergoes rigorous dimensional inspection against the CAD model using coordinate measuring machines (CMM) and critical functional testing. Statistical Process Control (SPC) methodologies are applied immediately, analyzing initial process capability (Cp/Cpk) and establishing baseline parameters. This iterative phase, often involving 2-3 design validation cycles, confirms part functionality, assembly fit, and process stability, eliminating unforeseen issues prior to hard tooling investment.

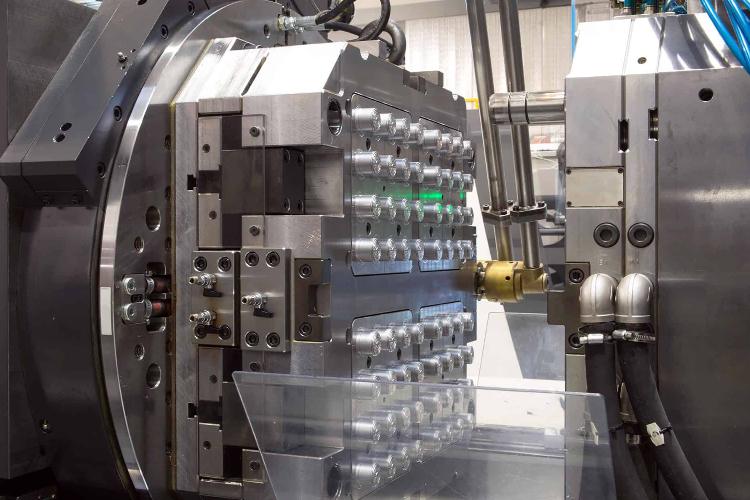

Mass Production executes the validated process with unwavering precision. Our state-of-the-art facilities deploy fully automated, electric injection molding presses equipped with real-time cavity pressure sensors and temperature monitoring. Every cycle is governed by tightly controlled parameters derived from prototyping, with automated vision systems performing 100% in-line dimensional checks on critical features. Statistical process control charts are monitored continuously, triggering immediate corrective action if trends approach specification limits. Material handling follows strict moisture control protocols, and preventive maintenance schedules ensure machine stability. Crucially, final inspection employs AQL 0.65 sampling against comprehensive first-article inspection reports (FAIR), with full traceability from raw material lot to finished part. This closed-loop system, combining automation, real-time data analytics, and human expertise, guarantees sustained Zero Defects output meeting US automotive, medical, and industrial standards.

Critical Process Control Specifications

| Process Stage | Key Parameter | Target Specification | Verification Method | Frequency |

|---|---|---|---|---|

| Design Validation | Mold Flow Balance | ±3% Fill Time per Cavity | Simulation Analysis Report | Per Design Iteration |

| Prototyping | Dimensional Tolerance | ±0.025 mm (Critical) | CMM Measurement | Per Prototype Batch |

| Mass Production | Process Capability (Cpk) | ≥1.67 | SPC Control Charts | Real-Time Monitoring |

| Mass Production | Dimensional Inspection | 100% Critical Features | Automated Vision System | Every Part |

| Final Quality Gate | AQL Level | 0.65 (Major Defects) | FAIR & Final Inspection Report | Per Shipment Lot |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Plastic Injection Molding Applications

When your plastic injection molding operations in the USA demand precision-engineered metal components, partnering with Wuxi Lead Precision Machinery ensures access to advanced manufacturing capabilities, rigorous quality control, and scalable production solutions. Specializing in custom metal manufacturing for the injection molding industry, we deliver high-performance molds, mold bases, and critical tooling components that meet the exacting standards of North American manufacturers.

Our facility in Wuxi, China, combines decades of engineering experience with state-of-the-art CNC machining, EDM, and surface treatment technologies. Every component we produce is built to enhance mold longevity, improve cycle times, and ensure consistent part quality—critical factors for high-volume plastic injection molding operations. Whether you require complex cavity and core inserts, ejector systems, or fully assembled mold packages, our team works directly with your engineering staff to translate designs into durable, high-tolerance metal solutions.

We understand that reliability and repeatability are non-negotiable in the injection molding sector. That’s why all our manufacturing processes adhere to international quality standards, including ISO 9001:2015, and undergo multi-stage inspection protocols using coordinate measuring machines (CMM) and 3D scanning. Our materials sourcing is equally stringent, with full traceability for tool steels such as P20, 718H, H13, S136, and other high-grade alloys suited for demanding molding environments.

Below are the key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining Centers | 3-axis, 4-axis, and 5-axis simultaneous milling |

| Maximum Work Envelope | 2000 mm × 1200 mm × 1000 mm |

| Tolerance Capability | ±0.002 mm |

| Surface Finish | As fine as Ra 0.05 µm (polished) |

| EDM Capabilities | Sinker and wire EDM with ±0.001 mm accuracy |

| Tool Steels | P20, 718H, H13, S136, NAK80, 1.2344, 1.2379 |

| Heat Treatment | Vacuum hardening, nitriding, and stress relieving |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP |

| Lead Times | 15–25 days for standard mold components, based on complexity |

| Surface Treatments | Nitriding, chrome plating, PVD coating, texturing |

Our clients across the automotive, medical, and consumer electronics sectors rely on us not just as a supplier, but as a strategic manufacturing partner. We offer DFM support, rapid prototyping, and full documentation packages to streamline your product development cycle and reduce time to market.

For U.S.-based companies seeking a trusted offshore partner with uncompromising precision and responsive communication, Wuxi Lead Precision Machinery delivers. We bridge the gap between Chinese manufacturing efficiency and American engineering standards.

Contact us today at [email protected] to discuss your next project. Let Lead Precision become the foundation of your high-performance injection molding success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.