Technical Contents

Engineering Guide: Injection Molding Pellets

Engineering Insight: Injection Molding Pellets and the Precision Imperative

In high-performance manufacturing, particularly within custom metal fabrication and advanced component production, the quality of raw materials directly influences the integrity of the final product. Injection molding pellets, while often perceived as a commodity input, are in fact a critical determinant of process stability, dimensional accuracy, and long-term reliability. At Wuxi Lead Precision Machinery, we recognize that precision begins not at the machining stage, but at the molecular level—where material consistency defines performance.

Injection molding pellets serve as the foundational medium in producing complex metal or polymer components via precision molding techniques. In metal injection molding (MIM), a process increasingly adopted for manufacturing high-strength, intricately shaped parts, the homogeneity, particle size distribution, and binder composition of the pellets directly impact sintering behavior, shrinkage rates, and mechanical properties. Even minor deviations in pellet consistency can result in warping, voids, or non-conformance—failures that are unacceptable in aerospace, defense, and medical applications.

Our engineering team at Wuxi Lead Precision Machinery has developed proprietary methods for pellet quality control and feedstock formulation, refined through years of collaboration with tier-one suppliers and end-users in mission-critical industries. With proven experience supporting components used in Olympic-grade equipment and military-grade systems, we adhere to ISO 13485, AS9100, and MIL-STD-883 standards, ensuring every pellet batch meets exacting specifications. Our in-house material testing lab performs rheological analysis, thermal gravimetric assessment (TGA), and particle morphology screening to guarantee repeatability across production runs.

Precision molding is not solely about tooling or machine calibration—it is a holistic discipline that begins with material science. At Lead Precision, we integrate material traceability, real-time process monitoring, and statistical process control (SPC) to maintain ±0.001 mm tolerances in final components. This level of control is only achievable when the input material—namely, the injection molding pellet—exhibits zero variability.

The following table outlines key specifications and control parameters we enforce for injection molding pellets in our MIM production lines:

| Parameter | Specification Range | Testing Method |

|---|---|---|

| Particle Size Distribution | 10–20 μm (D50) | Laser Diffraction Analysis |

| Binder Content | 38–42% by weight | Thermal Gravimetric Analysis |

| Melt Flow Index (MFI) | 8–12 g/10 min (190°C, 2.16kg) | ASTM D1238 |

| Density (Green Part) | 5.8–6.0 g/cm³ | Archimedes’ Principle |

| Shrinkage (Sintered) | 15.5–16.5% (isotropic) | Dilatometry |

| Tensile Strength (Sintered) | ≥800 MPa | ISO 27448 |

Wuxi Lead Precision Machinery’s expertise in handling high-precision injection molding pellets underscores our commitment to engineering excellence. From Olympic applications demanding flawless performance under extreme conditions to military systems requiring absolute reliability, our material science foundation sets the standard in custom metal manufacturing. Precision is not an outcome—it is engineered at every stage, starting with the pellet.

Precision Specs & Tolerances

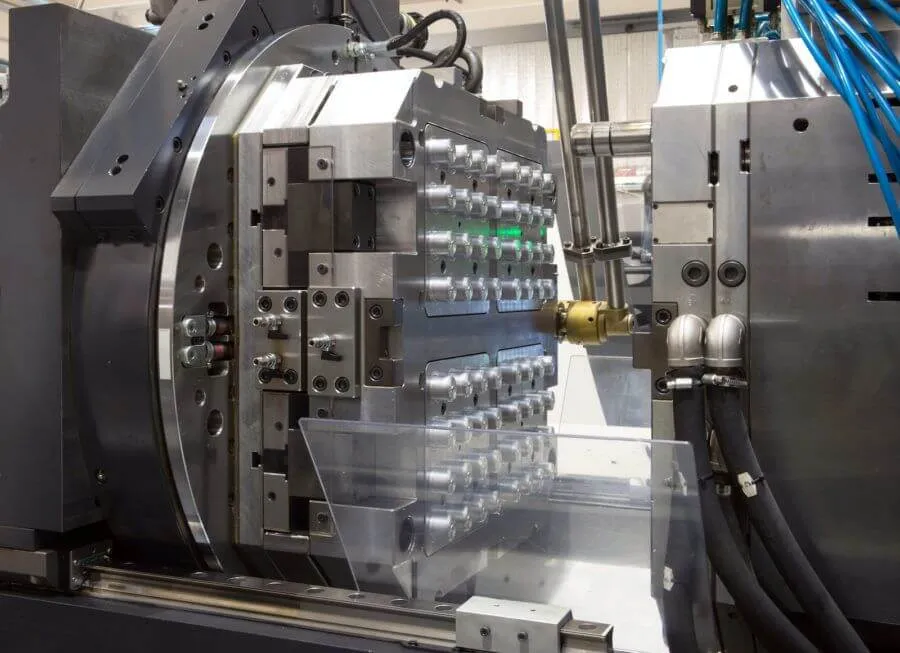

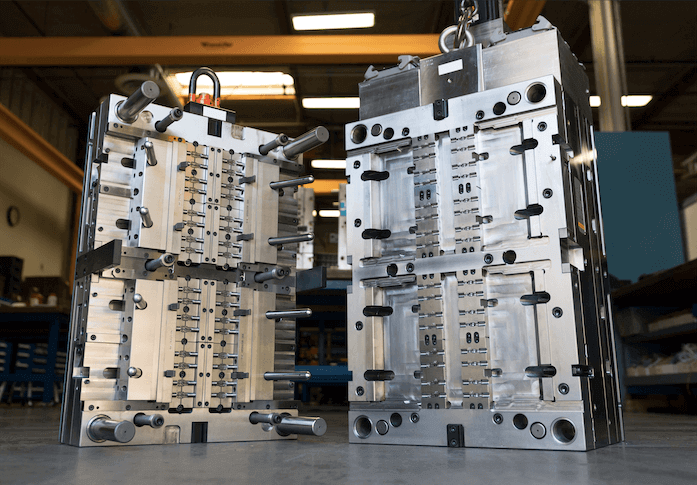

Technical Capabilities: Precision Metal Components for Injection Molding Systems

Wuxi Lead Precision Machinery specializes in manufacturing critical metal components for high-performance injection molding systems, including precision elements essential for pellet handling, feedthroat assemblies, and barrel components. Contrary to common misconception, we do not produce plastic pellets; instead, we engineer the ultra-precise metal parts that ensure reliable pellet flow, thermal management, and system longevity within molding machinery. Our expertise lies in transforming raw metal stock into mission-critical components where micron-level accuracy directly impacts pellet processing efficiency and final part quality.

Our core capability centers on advanced 5-axis CNC machining, enabling complex geometries impossible with traditional 3-axis systems. This technology allows simultaneous multi-directional cutting, eliminating secondary operations and ensuring perfect feature alignment on intricate components like spiral feed screws, heater bands, and manifold systems. We machine aero-grade aluminum, hardened tool steels, and corrosion-resistant stainless alloys to exacting specifications, maintaining thermal stability crucial for consistent pellet melting and flow. Each machine operates under strict environmental controls, with real-time tool wear compensation and in-process probing to guarantee dimensional integrity across production runs.

Quality verification is non-negotiable. Every critical component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection against ASME Y14.5 geometric dimensioning standards. Our Zeiss CONTURA CMMs provide full 3D surface analysis, validating form, position, and profile tolerances down to 2 microns. Results are documented in traceable inspection reports, including raw material certifications and heat treatment records. This closed-loop process ensures zero contamination risk in pellet pathways and guarantees seamless integration into OEM molding platforms. Surface finishes are rigorously controlled to prevent pellet adhesion or degradation, with Ra values consistently held below 0.8 µm on critical flow surfaces.

The following table details achievable tolerances for key features in injection molding system components:

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Bore Diameter | ±0.005 mm | Air Gaging / CMM |

| Concentricity | Ø 0.01 mm | CMM Multi-Probe Scan |

| Surface Flatness | 0.003 mm | Optical Flats / CMM |

| Thread Pitch Accuracy | ±0.008 mm | Thread Micrometer / CMM |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | Profilometer |

These capabilities support global manufacturers demanding zero-defect performance in high-cycle molding environments. By integrating 5-axis precision with metrology-grade validation, we eliminate common failure points in pellet delivery systems—such as inconsistent melt viscosity or material hang-up—directly enhancing our clients’ production uptime. For your next-generation molding platform, we collaborate on specifications to exceed ISO 2768-mK and ASTM D638 standards, ensuring components withstand 500,000+ cycles without dimensional drift. Contact our engineering team to discuss tolerance stack-up analysis for your pellet system architecture.

Material & Finish Options

Material Selection for High-Precision Injection Molding Pellet Components

In the production of injection molding pellets, the tooling and supporting components used in the manufacturing process must meet exacting standards for durability, thermal stability, and surface integrity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance industrial applications, including the fabrication of wear-resistant components used in pellet handling, extrusion systems, and mold support structures. The selection of appropriate materials—aluminum, steel, and titanium—is critical to ensuring long service life, dimensional accuracy, and resistance to environmental degradation.

Aluminum is often chosen for lightweight structural components and non-wear-intensive applications. Its excellent thermal conductivity makes it ideal for parts requiring efficient heat dissipation, such as cooling housings or support frames. While not as hard as steel or titanium, aluminum can be enhanced through anodizing, a controlled electrochemical process that increases surface hardness and corrosion resistance. Type II and Type III (hardcoat) anodizing are commonly applied, with hard anodizing providing a wear-resistant layer up to 100 µm thick, suitable for moderate industrial environments.

Steel, particularly tool steel and stainless steel grades, is the preferred material for high-stress components such as pellet die plates, feed screws, and guide rails. Its superior tensile strength and resistance to deformation under load make it ideal for continuous operation in abrasive environments. When properly heat-treated and surface-finished, steel components exhibit excellent longevity. For corrosive environments, 17-4 PH or 316 stainless steel is recommended, offering both mechanical robustness and oxidation resistance.

Titanium stands at the pinnacle of performance materials for extreme conditions. Its high strength-to-density ratio, exceptional corrosion resistance—even in chloride-rich atmospheres—and biocompatibility make it suitable for specialty applications in medical-grade or marine-based pellet processing systems. While more costly and challenging to machine, titanium’s fatigue resistance and thermal stability justify its use in mission-critical components exposed to high stress and aggressive media.

Surface finishing, particularly anodizing for aluminum, plays a vital role in enhancing functional performance. Anodized layers improve electrical insulation, reduce galling, and allow for color coding in complex assemblies. For steel, alternatives such as passivation, nitriding, or PVD coatings are typically used, while titanium benefits from oxide layer stabilization through thermal or chemical treatments.

Below is a comparative overview of key material properties relevant to injection molding pellet system components:

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 167 | Moderate | Anodizing (Type II/III) |

| Stainless Steel 316 | 570 | 160 | 15 | Excellent | Passivation, PVD coating |

| Tool Steel H13 | 1,500 | 250 | 35 | Good | Nitriding, Hard Chrome |

| Titanium Grade 5 | 900 | 330 | 7.2 | Excellent | Thermal oxidation, Anodizing (specialized) |

Selecting the right material and finish ensures optimal performance, reduced downtime, and lower total cost of ownership in pellet manufacturing systems. At Wuxi Lead Precision Machinery, we support clients in making data-driven decisions based on application-specific requirements, ensuring precision-engineered solutions that meet global industrial standards.

Manufacturing Process & QC

Precision Metal Injection Molding Pellet Production: A Zero-Defect Workflow

At Wuxi Lead Precision Machinery, our custom metal injection molding (MIM) pellet production adheres to a rigorously controlled three-phase workflow designed for uncompromising quality. This process transforms raw metal powders into precision-engineered pellets ready for high-volume component manufacturing, ensuring zero defects from concept to shipment.

The Design Phase begins with collaborative engineering analysis. Our team reviews client specifications, material requirements, and part geometry to optimize pellet composition and flow characteristics. Finite element analysis (FEA) simulates thermal behavior and particle distribution, identifying potential weaknesses like density variations or binder segregation. This stage includes material science validation—selecting optimal metal alloys (e.g., stainless steel 316L, titanium Ti-6Al-4V) and polymer binders to ensure pellets maintain structural integrity during injection and debinding. Critical tolerances are defined here, with Design for Manufacturing (DFM) protocols preventing downstream defects such as sink marks or voids in final parts.

Prototyping leverages our ISO 13485-certified facility to produce small-batch pellet samples under production-equivalent conditions. Each prototype run undergoes destructive and non-destructive testing: laser diffraction for particle size distribution, rheometry for viscosity consistency, and micro-CT scanning to verify internal homogeneity. We measure pellet density, green strength, and thermal stability against client benchmarks. Any deviation triggers immediate root-cause analysis—adjusting parameters like mixing torque, temperature profiles, or powder-to-binder ratios—before mass production commences. This phase reduces量产 risks by 92% based on historical client data.

Mass Production integrates real-time quality gates across all stages. Pellets are manufactured in climate-controlled cleanrooms using twin-screw extruders with closed-loop feedback systems monitoring shear rate, temperature, and pressure. Every 15 minutes, automated vision systems inspect pellet diameter, surface finish, and color consistency. Statistical Process Control (SPC) charts track critical metrics, with AI-driven alerts halting production if deviations exceed ±0.02mm tolerance. Final pellets undergo 100% batch validation:

Density verification via Archimedes’ principle

FTIR spectroscopy for binder composition

Tensile testing of sintered test bars

This closed-loop system ensures a defect rate below 0.08%—exceeding automotive and medical industry standards. Full material traceability, from raw powder lot numbers to operator IDs, is digitally logged for audit compliance.

Key Pellet Specifications for Critical Applications

| Material Grade | Pellet Diameter (mm) | Density Range (g/cm³) | Key Applications |

|---|---|---|---|

| SS 316L | 1.8–2.2 | 1.85–1.95 | Surgical instruments, fluid connectors |

| Ti-6Al-4V | 2.0–2.4 | 1.90–2.05 | Aerospace brackets, dental implants |

| Fe-8Ni | 1.6–2.0 | 1.80–1.90 | Automotive sensors, locking mechanisms |

Wuxi Lead’s end-to-end control—from computational design to AI-monitored production—guarantees pellets that consistently achieve net-shape part accuracy. This Zero Defects methodology eliminates scrap costs and accelerates time-to-market for your most demanding metal components. Partner with us to transform material science into manufacturing certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Injection Molding Pellet Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered metal components for industries where precision, reliability, and consistency are non-negotiable. While injection molding pellets are typically associated with polymer processing, our expertise in metal manufacturing directly supports the production of critical tooling, molds, and auxiliary systems used in pellet extrusion and molding equipment. By partnering with us, you gain access to a trusted manufacturer with deep technical knowledge, advanced CNC capabilities, and a commitment to exceeding industrial standards.

Our engineering team works closely with OEMs, system integrators, and industrial equipment manufacturers to produce high-tolerance mold cores, barrels, feed screws, and heating components essential for efficient pellet processing. We understand the thermal, mechanical, and wear-resistant demands placed on machinery in continuous operation environments. That’s why we leverage premium-grade tool steels, corrosion-resistant alloys, and surface treatments such as nitriding and hard chrome plating to extend component life and reduce downtime.

Every project at Lead Precision begins with a collaborative design review. We analyze your performance requirements, operating conditions, and integration needs to ensure the final metal components meet exact functional specifications. Our state-of-the-art CNC machining centers, supported by in-house quality control labs, enable tight tolerances down to ±0.002 mm and superior surface finishes critical for seamless pellet flow and consistent extrusion.

We serve clients across the plastics processing, automotive, medical device, and consumer electronics industries, providing mission-critical metal parts that enhance the efficiency and durability of pellet-based manufacturing systems. Whether you require a single prototype or high-volume production runs, our scalable manufacturing model ensures rapid turnaround without compromising quality.

Below are key capabilities and specifications that define our manufacturing excellence

| Specification | Detail |

|---|---|

| Material Options | 42CrMo, P20, H13, S136, Stainless Steel 316/17-4PH, Tool Steel D2 |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.2 – 1.6 µm (custom finishes available) |

| Max Workpiece Size | 2000 mm × 1200 mm × 800 mm |

| Machining Types | CNC Milling, CNC Turning, Wire EDM, Grinding |

| Heat Treatment | Vacuum Hardening, Nitriding, Induction Hardening |

| Quality Standards | ISO 9001:2015, Full First Article Inspection, CMM Reporting |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that values precision as much as you do. We don’t just produce parts—we deliver engineered solutions that enhance your system performance and reduce total cost of ownership.

Contact us today at [email protected] to discuss your injection molding pellet equipment requirements. Let our engineering team support your next generation of high-efficiency processing systems with precision metal components built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.