Technical Contents

Engineering Guide: Cnc Macchine

Engineering Insight Precision as the Non-Negotiable Foundation of Modern CNC Machining

Precision in CNC machining transcends basic dimensional accuracy; it defines the viability of components operating under extreme conditions, within complex assemblies, and across critical industries. At the micro-level, tolerances measured in microns directly impact functionality, safety, and longevity. Achieving true precision requires a holistic engineering approach integrating rigid machine construction, advanced thermal compensation systems, high-resolution feedback mechanisms, and meticulously controlled environmental factors. It is not merely about hitting a target dimension once, but about sustaining that accuracy repeatably across thousands of cycles, through material variations, and across extended production runs. Compromised precision leads to assembly failures, premature wear, catastrophic system malfunctions, and ultimately, significant financial and reputational damage for manufacturers and their end-users.

Wuxi Lead Precision Machinery has engineered its core competency around this uncompromising demand for precision. Our machine platforms are designed from the ground up with monolithic cast iron beds, linear roller guideways, and direct-drive spindles to minimize deflection and vibration. Integrated real-time thermal compensation systems continuously adjust for environmental fluctuations, while laser interferometer calibration ensures volumetric accuracy across the entire work envelope. This commitment is rigorously validated through our work on projects where failure is not an option. We have supplied precision-machined components for critical systems in classified military aerospace programs, where dimensional stability under high-G forces and extreme temperatures is paramount. Similarly, our parts formed integral elements within the structural and mechanical systems of venues constructed for the Olympic Games, demanding flawless fit and long-term reliability under immense public scrutiny and operational stress.

The tangible output of this engineering philosophy is reflected in the consistent performance metrics of our flagship production systems. The following specifications represent the baseline capabilities achievable on our LP-800 Series 5-Axis Milling Center under controlled conditions:

| Parameter | Specification | Industry Standard Comparison |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.001 mm | Typically ±0.005 mm |

| Repeatability (X/Y/Z) | ±0.0005 mm | Typically ±0.002 mm |

| Surface Finish (Ra) | ≤ 0.8 μm (Aluminum) | Typically ≤ 1.6 μm |

| Volumetric Compensation | Full 3D Grid | Often Basic Linear Only |

| Thermal Drift Compensation | Real-time, Multi-point | Typically Basic Offset |

This level of achievable precision is not accidental. It is the direct result of decades of focused R&D, stringent process control, and a deep understanding of the physics governing metal removal at the highest levels. For manufacturers targeting sectors like aerospace, defense, medical device production, or advanced optics, partnering with a machine builder proven in environments where Olympic success or national security hinges on micron-level accuracy is not just advantageous – it is essential. Wuxi Lead Precision Machinery delivers the engineered stability and verifiable performance required to transform demanding design specifications into flawless physical reality, ensuring your production success in the most exacting global markets. The investment in true precision machining capability is an investment in product integrity, operational reliability, and sustained competitive advantage.

Precision Specs & Tolerances

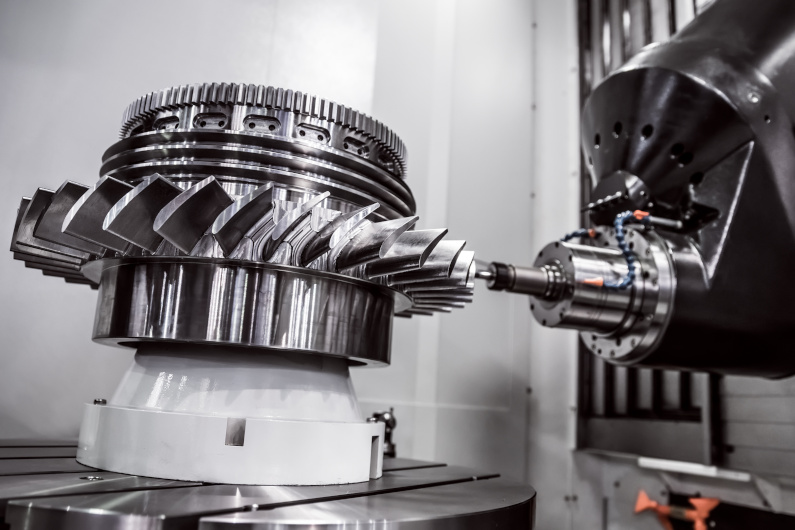

Wuxi Lead Precision Machinery delivers advanced 5-axis CNC machining capabilities designed for high-complexity, high-precision components across aerospace, medical, energy, and industrial automation sectors. Our technical foundation is built around state-of-the-art 5-axis CNC machining centers, enabling simultaneous multi-axis movement to produce intricate geometries with exceptional accuracy and surface finish. This technology allows for the complete machining of complex parts in a single setup, significantly reducing cycle times, minimizing human error, and improving part repeatability.

Our 5-axis systems are equipped with high-speed spindles, advanced tool management, and real-time monitoring systems that ensure optimal cutting conditions and tool life. These machines support a wide range of materials, including aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics, making them ideal for prototyping and low-to-medium volume production runs. The integration of CAD/CAM software ensures seamless translation from digital design to physical component, with full process simulation to prevent collisions and optimize toolpaths.

To maintain the highest level of quality, every component undergoes rigorous inspection using Coordinate Measuring Machines (CMM). Our CMM systems provide full 3D metrology with micron-level precision, verifying critical dimensions, geometric tolerances, and surface profiles. Data from CMM inspections is documented and traceable, supporting full compliance with ISO 9001 and AS9100 standards. This closed-loop quality control process ensures that all parts meet or exceed customer specifications.

We specialize in tight-tolerance machining where consistency and precision are non-negotiable. Our technical team combines deep manufacturing expertise with engineering insight to support Design for Manufacturability (DFM) feedback, ensuring optimal performance and cost-efficiency in every project.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Travel (X/Y/Z) | 1,200 / 600 / 500 mm (max) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (Standard) | ±0.025 mm |

| Linear Tolerance (Precision) | ±0.005 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (per ASME Y14.5) |

| Surface Roughness (Ra) | 0.4 – 3.2 µm (adjustable per requirement) |

| Max Workpiece Weight | 1,500 kg |

| Materials Supported | Aluminum, Steel, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Inspection Equipment | Zeiss & Mitutoyo CMM, Optical Comparators |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS |

Wuxi Lead Precision Machinery is committed to technical excellence, process transparency, and on-time delivery. Our 5-axis CNC and precision inspection capabilities position us as a trusted partner for mission-critical components in demanding industries.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting the optimal material is foundational to achieving performance, durability, and cost-efficiency in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering team leverages deep material science expertise to guide clients through this critical decision, balancing application demands with manufacturability. Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio, excellent thermal conductivity, and inherent corrosion resistance. These alloys machine efficiently, allowing for high feed rates and fine surface finishes, though 7075 requires more careful toolpath planning due to higher strength. Steel variants, especially 4140 and 303 stainless, are indispensable for high-strength, wear-resistant applications like hydraulic fittings, shafts, and medical instruments. 4140 offers superb toughness and hardenability, while 303 stainless provides essential corrosion resistance for demanding environments, though its sulfur content can impact chip control during machining. Titanium Grade 5 (Ti-6Al-4V) is the premium choice for extreme conditions in aerospace structural parts and biomedical implants, offering unparalleled strength-to-weight ratio and biocompatibility. However, its low thermal conductivity and chemical reactivity necessitate specialized tooling, rigid setups, and controlled cutting parameters to prevent work hardening and tool damage, significantly influencing production cost and lead time.

Surface finishing, particularly anodizing, is integral to enhancing aluminum component performance. Type II (Sulfuric Acid) anodizing provides a durable, decorative, and moderately corrosion-resistant oxide layer, available in various colors, suitable for enclosures and consumer hardware. For critical aerospace or military applications demanding maximum wear and corrosion resistance, Type III (Hardcoat) anodizing creates a significantly thicker, harder, and more abrasion-resistant surface. Our precision CNC processes are meticulously calibrated to ensure dimensional stability during anodizing, maintaining tight tolerances on critical features. Material choice directly impacts machining strategy, tool life, cycle time, and ultimately, part cost and quality. Partnering with Wuxi Lead ensures your selection aligns with both functional requirements and efficient, high-yield manufacturability on our state-of-the-art CNC systems.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (90) | Aerospace brackets, heat sinks, frames |

| Steel 4140 | 7.85 | 655 | Good (65) | Shafts, gears, high-strength tooling |

| Stainless 303 | 8.0 | 620 | Fair (50) | Valves, fasteners, surgical instruments |

| Titanium Ti-6Al-4V | 4.43 | 900 | Poor (20) | Aircraft landing gear, medical implants |

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every high-performance CNC machining project begins with precision engineering in the design phase. Our team of experienced mechanical engineers and CAD/CAM specialists collaborates closely with clients to translate conceptual requirements into detailed 3D models and technical drawings. Utilizing advanced software such as SolidWorks, AutoCAD, and Siemens NX, we ensure every geometric tolerance, surface finish, and material specification aligns with functional and regulatory standards. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to preemptively resolve structural weaknesses and production challenges. This rigorous digital validation ensures that the design is not only optimal for performance but also fully compatible with our CNC capabilities, minimizing downstream risks and setting the stage for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to the prototyping stage, a critical checkpoint in our zero-defect philosophy. Using high-accuracy 5-axis CNC machining centers and precision wire EDM equipment, we produce functional prototypes that mirror the final product in form, fit, and function. These prototypes undergo comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify dimensional accuracy within ±0.002 mm. In parallel, we conduct real-world performance tests including thermal cycling, load stress evaluation, and assembly compatibility checks. Client feedback is integrated at this stage, allowing for rapid iteration without impacting the production timeline. This iterative validation ensures that every design flaw or tolerance deviation is corrected before mass production begins, drastically reducing the risk of defects.

Mass Production: Consistency Through Automation and Control

With prototype approval, we transition seamlessly into mass production, where consistency, efficiency, and quality are enforced through automated workflows and real-time monitoring. Our production floor integrates CNC machines with centralized tool management systems and automated pallet changers to maintain uninterrupted operation. Each machining cycle follows a standardized process plan, with tool wear compensation and in-process gauging ensuring repeatability across thousands of parts. Statistical process control (SPC) is employed to monitor key variables such as spindle load, dimensional drift, and surface quality, enabling predictive adjustments before deviations occur. Every component undergoes 100% first-article inspection and batch sampling, with full traceability maintained via barcode tracking and digital quality records.

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | 0.2 – 3.2 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, PEEK, Brass |

| CNC Equipment | 3/4/5-Axis Machining Centers, CNC Lathes, Wire EDM |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP, FAI Compliant |

This end-to-end process—anchored in design rigor, validated through prototyping, and executed with precision in mass production—ensures Wuxi Lead delivers defect-free components at scale, meeting the exacting demands of aerospace, medical, and advanced industrial sectors.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engine for Advanced Manufacturing Success

In today’s competitive precision manufacturing landscape, component accuracy, repeatability, and throughput are non-negotiable. Wuxi Lead Precision Machinery delivers engineered CNC solutions that transform these demands into measurable production advantages. We do not merely supply machines; we integrate our expertise into your value chain, ensuring every spindle rotation, axis movement, and toolpath decision directly elevates your output quality and operational efficiency. Our machines are engineered for the most stringent aerospace, medical, and energy sector applications where tolerances exist in the single-micron range and failure is not an option.

The foundation of this partnership is our commitment to technical excellence, validated through rigorous ISO 9001:2015 and ISO 14001 certified processes. Below are core specifications defining our flagship 5-axis vertical machining centers, engineered for uncompromising performance:

| Parameter | Specification | Application Impact |

|---|---|---|

| Positioning Accuracy | ±0.002 mm (X, Y, Z axes) | Guarantees micron-level feature alignment |

| Repeatability | ±0.001 mm | Eliminates scrap from batch-to-batch drift |

| Work Envelope (X×Y×Z) | 1,200 × 800 × 750 mm | Accommodates complex, large-scale components |

| Spindle Speed | 24,000 RPM (HSK-A63 interface) | Enables high-speed finishing of hardened steels |

| Thermal Compensation | Full-axis real-time monitoring | Maintains dimensional stability over extended runs |

This technical rigor translates into tangible business outcomes: reduced secondary operations, minimized tooling costs, and accelerated time-to-market for your end products. Our engineering team collaborates with yours from initial feasibility studies through production ramp-up, providing application-specific programming support, fixture design validation, and on-site process optimization. We understand that machine capability alone is insufficient; true partnership requires proactive problem-solving and shared accountability for your production targets.

When you choose Wuxi Lead Precision Machinery, you gain a strategic ally invested in your long-term competitiveness. Our global service network ensures minimal downtime with localized technical support, while our continuous R&D pipeline keeps your operations ahead of evolving industry standards. We operate under a zero-defect culture, rigorously testing every machine against real-world production scenarios before shipment.

Initiate your transformation to precision manufacturing excellence today. Contact our engineering sales team directly at [email protected] to schedule a confidential consultation. Specify your component challenges, volume requirements, and target tolerances. We will respond within 24 business hours with a tailored capability analysis and ROI projection. Do not compromise on precision—partner with the engineering team that treats your specifications as our mandate. Let us demonstrate how Lead Precision becomes the cornerstone of your manufacturing advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.