Technical Contents

Engineering Guide: Ps Injection Molding

Engineering Insight: Precision Imperatives in PS Injection Molding

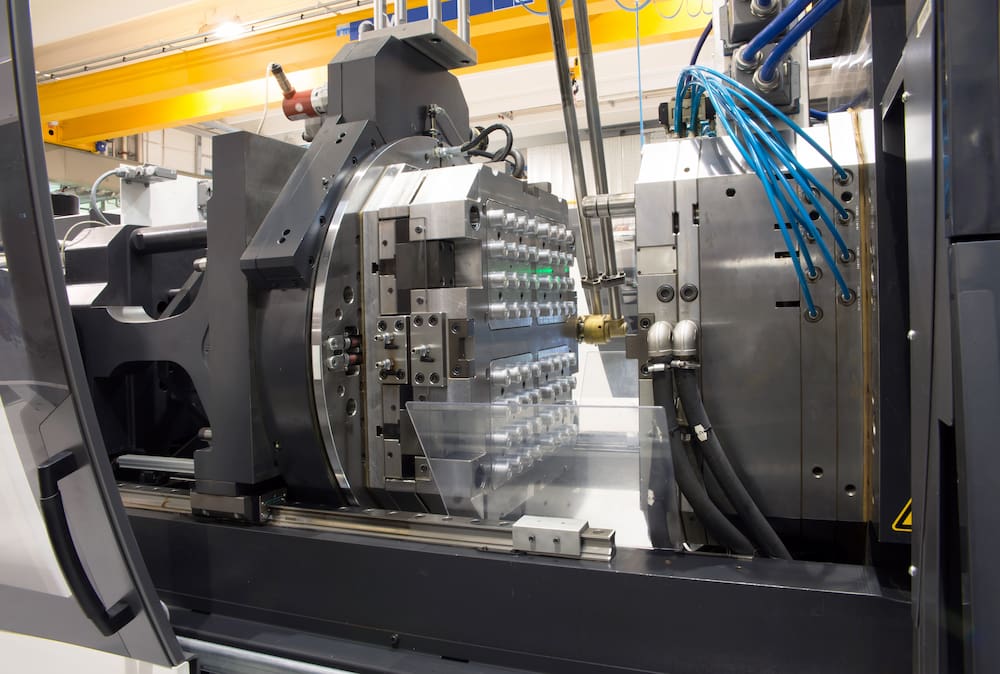

Polystyrene (PS) injection molding demands exceptional precision due to the material’s inherent sensitivity to thermal and mechanical variables. As a brittle thermoplastic with low impact resistance, PS requires exact control over melt temperature, injection pressure, and cooling rates to avoid defects like sink marks, warpage, or surface imperfections. Even minor deviations in mold geometry or process parameters can compromise part integrity, dimensional stability, and optical clarity—critical factors for applications ranging from medical housings to consumer electronics. At Wuxi Lead Precision Machinery, we recognize that precision begins long before the molding cycle starts; it originates in the metal tooling. Our custom molds, engineered to tolerances as tight as ±0.005mm, ensure consistent replication of complex geometries while mitigating material stress during ejection. This foundational accuracy directly translates to reduced scrap rates, minimized post-processing, and superior end-product performance.

Wuxi Lead’s expertise in high-stakes manufacturing environments underscores our capability in PS precision molding. Our engineering team has delivered mission-critical components for Olympic-grade equipment and military applications, where failure is not an option. These projects demanded adherence to AS9100 and MIL-STD-883 standards, requiring zero-defect output under extreme thermal cycling and structural loads. For instance, molds developed for aerospace instrumentation housings achieved 99.98% consistency across 500,000+ cycles—proof that our methodologies transcend standard industrial requirements. This rigor ensures PS components meet stringent regulatory and functional benchmarks, whether for sterile medical devices or automotive sensor assemblies.

The interplay between mold precision and process control defines PS molding success. Below are key parameters where micron-level accuracy is non-negotiable:

| Parameter | Critical Range | Impact on PS Quality |

|---|---|---|

| Melt Temperature | 200–280°C | Excessive heat causes yellowing; low temps induce brittleness |

| Injection Pressure | 70–150 MPa | Inconsistent pressure creates flow lines or voids |

| Cooling Rate | 15–40 seconds/cycle | Uneven cooling leads to warpage and residual stress |

| Mold Tolerance | ±0.005mm | Deviations exceed 0.01mm cause flash or fit failures |

Our proprietary mold design software integrates real-time process analytics with finite element analysis (FEA), predicting material behavior under PS-specific conditions. This allows preemptive correction of thermal gradients and pressure distribution—critical for maintaining clarity in transparent PS grades. Furthermore, our hardened P20 and H13 steel molds, surface-treated via nitriding, resist wear even during extended production runs of abrasive-filled PS compounds.

For B2B manufacturers, investing in precision-engineered tooling is not a cost but a strategic advantage. Wuxi Lead’s decade-long specialization in custom metal manufacturing for regulated industries ensures your PS components achieve optimal functionality, aesthetics, and compliance. Partner with our engineering team to transform material challenges into competitive differentiation. Contact us for a tolerance analysis specific to your PS application.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, energy, and industrial automation. Our expertise in precision machining is anchored in state-of-the-art 5-axis CNC technology, enabling us to produce complex geometries with superior accuracy, consistency, and efficiency. This multi-axis capability allows simultaneous cutting from five different angles, minimizing setup times and part handling while maximizing dimensional integrity across intricate components.

Our 5-axis CNC machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring optimal performance during extended production runs. These systems support a wide range of materials, including aluminum alloys, stainless steels, titanium, Inconel, and specialty alloys, catering to applications requiring both mechanical strength and thermal or corrosion resistance. Whether producing low-volume prototypes or high-volume production runs, our machining processes are designed for repeatability and compliance with international quality standards.

Quality control is integrated at every stage of production. All critical dimensions are verified using state-of-the-art Coordinate Measuring Machines (CMM), providing full traceability and comprehensive inspection reports. Our CMM systems operate with micron-level resolution, enabling precise validation of form, position, and surface characteristics in compliance with ISO 10360 standards. Additionally, first-article inspections, in-process checks, and final audits ensure that every component meets or exceeds customer specifications.

To support design and engineering collaboration, we offer detailed inspection documentation, including GD&T analysis, 3D scanning comparison reports, and SPC data upon request. This data-driven approach ensures transparency and facilitates rapid iteration during product development cycles.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and consistency.

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed or honed |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Per GD&T (ISO 1101) |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Measured via CMM |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Machined finish; polishing available |

| Angular Features | ±0.05° | ±0.02° | 5-axis simultaneous control |

These tolerances are achievable across a wide range of part sizes, from miniature components to large-scale structural elements, with full adaptability to customer-specific requirements. At Wuxi Lead Precision Machinery, our technical capabilities are not only defined by advanced equipment and rigorous inspection protocols but also by our engineering expertise in solving complex manufacturing challenges. We combine precision, quality, and responsiveness to deliver components that perform reliably in the most demanding environments.

Material & Finish Options

Material Selection for Precision PS Injection Molding Tooling

Material selection is a critical engineering decision directly impacting the performance, longevity, and cost-efficiency of PS injection molding tooling. At Wuxi Lead Precision Machinery, we prioritize matching the optimal metal substrate to your specific production volume, part geometry, polymer characteristics, and surface finish requirements. Understanding the distinct properties of Aluminum, Steel, and Titanium is fundamental to achieving superior mold performance and part quality.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are the preferred choice for rapid prototyping, low-to-medium volume production, and complex cores/cavities requiring efficient heat transfer. Their high thermal conductivity significantly reduces cycle times compared to steel, accelerating time-to-market. Aluminum’s machinability allows for intricate features and faster lead times, though its lower hardness necessitates protective surface treatments like hard anodizing for extended wear resistance in abrasive PS formulations. This balance of speed, thermal management, and cost makes aluminum ideal for initial production runs and technical validation.

For high-volume, long-life production molds demanding maximum durability and dimensional stability, tool steels are indispensable. Pre-hardened steels like P20 offer excellent machinability and good polishability for standard PS applications. For molds requiring exceptional wear resistance, corrosion resistance against additives, or the highest polish (critical for optical PS parts), hardened steels such as H13, S136, or 420 Stainless Steel are engineered solutions. These materials withstand millions of cycles but require precise heat treatment and grinding processes, which Wuxi Lead executes with stringent quality control to ensure mold longevity and consistent part replication.

Titanium alloys represent the pinnacle for highly specialized, extreme-condition molding. While significantly more expensive and challenging to machine, titanium offers an unparalleled strength-to-weight ratio, exceptional corrosion resistance against aggressive PS compounds or cleaning agents, and outstanding thermal stability. Its application is typically reserved for niche aerospace or medical components where weight reduction, absolute corrosion immunity, or extreme thermal cycling are non-negotiable factors, justifying the substantial investment.

Surface finishing, particularly anodizing, is integral to aluminum mold performance. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and a base for dyeing, suitable for many standard PS applications. For demanding production requiring superior abrasion resistance and extended mold life, hard anodizing (Type III) creates a much thicker, denser, and harder ceramic oxide layer. Wuxi Lead precisely controls anodizing thickness (typically 25-50µm for hard coat) and sealing processes to maximize wear protection while maintaining critical dimensional tolerances on mold surfaces.

The following table summarizes key comparative specifications for common mold materials:

| Material Property | Aluminum 7075-T6 | P20 Tool Steel | H13 Tool Steel | Titanium Grade 5 |

|---|---|---|---|---|

| Typical Hardness (HRC) | 150 HB (40 HV) | 28-32 | 48-52 | 36-41 |

| Thermal Conductivity (W/m·K) | 130 | 30 | 28 | 22 |

| Tensile Strength (MPa) | 570 | 1100 | 1650 | 900 |

| Relative Cost Factor | 1.0 | 1.8 | 2.5 | 8.0+ |

| Primary Application | Prototyping / Low-Medium Volume | Medium-High Volume Standard | High Volume / High Polish / Corrosive | Extreme Conditions / Weight Critical |

Selecting the right material and finish requires analyzing your specific PS molding parameters. Wuxi Lead Precision Machinery provides expert consultation to ensure your tooling investment delivers optimal performance, quality, and return. Contact our engineering team to discuss your project requirements in detail.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful PS injection molding project begins with a rigorous design phase. This stage integrates advanced CAD/CAM software with deep material science expertise to ensure that every component meets exact functional, aesthetic, and dimensional specifications. Our engineering team collaborates closely with clients to analyze part geometry, wall thickness, gate locations, and draft angles—critical factors in avoiding defects such as warping, sink marks, or flow lines. Finite Element Analysis (FEA) is employed to simulate mold filling, cooling, and ejection processes, enabling predictive optimization before any physical tooling begins. This digital-first approach ensures manufacturability, reduces cycle time, and aligns the design with both performance requirements and production scalability.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we transition into precision prototyping. Using high-speed CNC machining and EDM processes, we fabricate prototype molds from premium-grade tool steel, replicating production-grade conditions at a smaller scale. These molds are used to produce initial batches of PS (Polystyrene) parts under controlled parameters, allowing for comprehensive evaluation of form, fit, and function. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers to verify dimensional accuracy down to ±0.005 mm. Material behavior is assessed under real-world thermal and mechanical loads, ensuring long-term reliability. Client feedback is integrated at this stage, enabling rapid design iterations without impacting future mass production timelines. This phase is essential for risk mitigation, ensuring that only validated, defect-free designs move forward.

Mass Production: Precision at Scale with Zero Defects

With design and prototyping successfully completed, we initiate full-scale production using state-of-the-art electric and hybrid injection molding machines equipped with real-time monitoring systems. Our production lines operate under strict ISO 9001-certified protocols, with Statistical Process Control (SPC) continuously tracking critical parameters such as melt temperature, injection pressure, and cooling duration. Automated robotic arms handle part ejection and placement, minimizing human error and contamination. Each batch undergoes 100% visual inspection via machine vision systems and random sampling for destructive and non-destructive testing. Traceability is maintained through barcode tracking, linking each component to its specific mold cavity, machine settings, and inspection data.

Our commitment to zero defects is reinforced by preventive maintenance schedules, operator certification programs, and a closed-loop corrective action system that addresses deviations instantly. This disciplined progression from design through prototyping to mass production ensures consistent quality, on-time delivery, and full compliance with international standards.

| Parameter | Specification |

|---|---|

| Material | General Purpose & High-Impact Polystyrene (GPPS/HIPS) |

| Tolerance | ±0.005 mm to ±0.05 mm (based on part size) |

| Mold Steel | P20, 718, 2738, H13 (hardened & pre-hardened) |

| Machine Capacity | 50–1,200 tons clamping force |

| Surface Finish | SPI standards (A1 to C3), textured, polished, or matte |

| Production Rate | Up to 60 cycles per minute (depending on part complexity) |

| Quality Standards | ISO 9001, SPC, FAI, PPAP documentation available |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising PS Injection Molding Excellence

Achieving consistent, high-performance parts in polystyrene (PS) injection molding demands more than standard machinery. PS materials present unique challenges: precise thermal control to prevent degradation, exceptional surface finish requirements for optical clarity, and stringent dimensional stability for tight-tolerance applications. Generic solutions often fail under these demands, leading to costly scrap, production delays, and compromised part integrity. This is where Wuxi Lead Precision Machinery delivers transformative value.

As specialists in custom metal manufacturing for the global injection molding industry, we engineer solutions specifically for PS processing complexities. Our CNC-machined components—hot runner systems, precision molds, and critical machine elements—leverage aerospace-grade alloys and micron-level tolerances. This ensures optimal thermal management, eliminating flow imbalances and sink marks common in PS production. Our proprietary surface treatments further enhance release properties, critical for maintaining PS’s signature gloss without additives. The result is reduced cycle times, near-zero ejection defects, and compliance with medical, optical, and consumer safety standards.

Our technical partnership extends beyond component supply. We collaborate at the design phase, analyzing your PS formulation, part geometry, and production targets to optimize tooling and process parameters. This proactive engineering approach prevents downstream failures, saving weeks in trial runs and minimizing material waste. For high-volume PS applications—from diagnostic labware to LED lenses—our systems deliver unmatched repeatability, even under 24/7 operation.

Technical Capabilities for PS-Specific Manufacturing

| Feature | Specification Range | PS Application Impact |

|---|---|---|

| Clamping Force | 600–6000 Tons | Eliminates flash in thin-walled PS containers |

| Shot Weight Capacity | 50–32,000 g (PS) | Supports multi-cavity optical lens production |

| Max. Mold Size | 2000 × 2000 mm | Enables large-format display panels |

| Positioning Accuracy | ±0.005 mm | Ensures micron-level lens curvature precision |

| Thermal Stability | ±0.5°C (barrel/hot runner) | Prevents PS yellowing and viscosity swings |

Choosing Lead Precision means partnering with engineers who speak the language of polymer physics and precision metalcraft. We understand that PS isn’t just another resin—it requires a holistic system approach where every micron of tooling accuracy directly impacts your yield and product performance. Our CNC facilities in Wuxi operate under ISO 9001 and IATF 16949, with dedicated teams for rapid prototyping and full-scale production support.

Initiate your precision PS project with confidence. Contact our engineering team at [email protected] to schedule a technical consultation. Share your part specifications, material grade, and production goals—we’ll respond within 24 hours with a tailored capability assessment and process optimization roadmap. For multinational OEMs and tier-1 molders, this is the first step toward eliminating PS-specific production bottlenecks. Let Lead Precision’s 15 years of custom metal manufacturing expertise become your competitive advantage. Your next high-clarity, zero-defect PS component starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.