Technical Contents

Engineering Guide: Sheet Metal Countersink

Engineering Insight: Precision Countersinking in Critical Sheet Metal Fabrication

Countersinking in sheet metal components is far more than a simple finishing operation; it is a critical engineering step demanding exacting control to ensure structural integrity, assembly reliability, and long-term performance. An improperly formed countersink induces stress concentrations at the hole edge, compromises fastener clamping force, and can lead to premature fatigue failure or assembly misalignment. In high-stakes applications where failure is not an option, the geometric precision of the countersink – its angle, depth, diameter, and surface finish – directly impacts the safety and functionality of the final product. Tolerances often fall within ±0.05mm for depth and diameter, with angular accuracy critical to match the specific fastener head profile. Variations beyond these limits cause point loading, galling, or incomplete seating, undermining the joint’s designed strength and vibration resistance. Achieving this level of consistency requires sophisticated CNC machining centers with rigid spindles, high-precision tooling, and real-time process monitoring, moving beyond basic drill presses to engineered manufacturing solutions.

Material behavior significantly influences the countersinking process. Thin-gauge aluminum alloys demand different feed rates and speeds compared to hardened stainless steel or titanium to prevent burring, tearing, or work hardening at the countersink lip. The chosen tool geometry – whether a single-angle, multi-flute, or specialized form tool – must be optimized for the specific material’s machinability and the required finish. Surface roughness (Ra) is equally vital; a poor finish creates initiation points for cracks under cyclic loading. Process validation through rigorous in-process inspection using optical comparators or coordinate measuring machines (CMMs) is non-negotiable for mission-critical parts. This level of scrutiny ensures every countersink meets the stringent demands of aerospace, defense, and advanced industrial equipment.

Wuxi Lead Precision Machinery applies this uncompromising precision standard daily. Our CNC fabrication cells, operating under ISO 9001 and AS9100 frameworks, consistently deliver countersinks meeting aerospace and military specifications. This capability was rigorously proven during our production of structural components for Olympic venue infrastructure, where dimensional accuracy directly impacted seismic safety margins. Similarly, our work for defense contractors supplying avionics housings and armored vehicle subsystems demands countersink tolerances that ensure flawless integration under extreme operational stresses. We understand that the seemingly minor detail of a countersink is often the linchpin of a larger, high-reliability assembly.

The following table outlines key precision countersink specifications achievable within our controlled manufacturing environment:

| Parameter | Standard Tolerance | Aerospace/Military Tolerance | Critical Material Consideration |

|---|---|---|---|

| Countersink Angle | ±1° | ±0.5° | Material springback affects final angle; compensated in toolpath |

| Depth | ±0.10 mm | ±0.05 mm | Critical for fastener head flushness; measured via CMM |

| Diameter (Top) | ±0.15 mm | ±0.08 mm | Must match fastener head spec; affects load distribution |

| Surface Roughness (Ra) | ≤ 1.6 µm | ≤ 0.8 µm | Minimizes stress risers; vital for fatigue-critical parts |

| Concentricity | ≤ 0.10 mm | ≤ 0.05 mm | Ensures uniform seating; verified optically |

Precision countersinking is an engineering discipline, not merely a machining step. At Wuxi Lead Precision Machinery, decades of experience in the most demanding sectors inform our approach, guaranteeing that every countersink we produce contributes to the ultimate reliability and performance of your critical sheet metal assemblies. We partner with engineers to solve the hidden challenges at the intersection of fastener and component.

Precision Specs & Tolerances

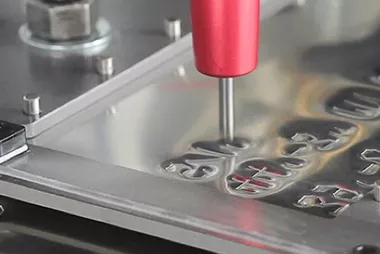

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication capabilities with a specialized focus on precision countersinking operations. Our technical expertise is built around high-performance 5-axis CNC machining centers, enabling us to execute complex countersink profiles with exceptional accuracy and repeatability. These multi-axis systems provide full rotational and linear control, allowing for angled, deep, and compound countersink features that are difficult or impossible to achieve with conventional 3-axis equipment. This level of sophistication ensures optimal tool approach angles, minimized tool deflection, and superior surface finish on a wide range of sheet metal materials, including aluminum alloys, stainless steel, titanium, and high-strength carbon steels.

Our 5-axis CNC platform supports simultaneous machining operations, reducing setup cycles and maintaining tight geometric relationships across multiple features. This is particularly critical in aerospace, defense, and high-end industrial applications where countersink angles must align precisely with fastener specifications and assembly requirements. We program all countersink operations using advanced CAM software, enabling precise toolpath optimization, collision detection, and material removal simulation. This digital-first approach ensures process reliability and minimizes production risk, especially for low-volume, high-mix components requiring stringent compliance.

Quality assurance is integral to our countersink manufacturing process. Every critical dimension is verified through comprehensive CMM (Coordinate Measuring Machine) inspection, providing full traceability and compliance with AS9100 and ISO 9001 standards. Our CMM systems are calibrated to international standards and capable of measuring angular accuracy, depth, diameter, and positional tolerances to micron-level precision. Inspection reports are generated for each batch, including first-article inspection (FAI) documentation upon request, ensuring full transparency and audit readiness for our clients.

We support a wide range of countersink types, including standard 82°, 100°, and 120° configurations, as well as custom angles and stepped profiles. Our tooling library includes solid carbide and coated drills, pilot-guided countersinks, and specialty tools for thin-gauge and high-hardness materials. All operations are performed under strict environmental and process controls to maintain dimensional stability and part consistency across production runs.

Below are the standard technical specifications and tolerances achievable in our sheet metal countersink operations:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Countersink Diameter | ±0.05 mm | ±0.02 mm |

| Countersink Depth | ±0.05 mm | ±0.03 mm |

| Included Angle Tolerance | ±1° | ±0.5° |

| Positional Tolerance (XY) | ±0.05 mm | ±0.02 mm |

| Edge Distance Tolerance | ±0.10 mm | ±0.05 mm |

| Surface Roughness (Ra) | ≤3.2 µm | ≤1.6 µm |

| Material Thickness Range | 0.5 mm – 6.0 mm | 0.5 mm – 6.0 mm |

| Minimum Feature Spacing | 2.5 x material thickness | 2.0 x material thickness |

Our technical team collaborates closely with design and engineering partners to optimize countersink specifications for manufacturability, performance, and cost-efficiency. Through the integration of 5-axis CNC technology and rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures every countersink feature meets the highest standards of precision and reliability in modern sheet metal fabrication.

Material & Finish Options

Material Selection for Precision Sheet Metal Countersinks

Selecting appropriate materials and finishes is critical for countersink performance in high-tolerance sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties that directly impact countersink integrity, tool life, and final assembly reliability. Aluminum, steel, and titanium each present distinct advantages and challenges in countersinking operations, requiring tailored machining strategies to avoid burring, deformation, or premature tool failure.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace and electronics enclosures due to their lightweight nature and machinability. However, their softness increases galling and chip adhesion risks during countersinking. We recommend sharp carbide tools with polished flutes and moderate feed rates to prevent material smearing. Anodizing is essential for corrosion resistance but must be applied post-countersinking; pre-anodized aluminum causes accelerated tool wear and inconsistent chamfer geometry. Type II (sulfuric acid) anodizing is standard, while Type III (hard coat) requires tighter countersink angle tolerances to accommodate thicker oxide layers.

Carbon steel (e.g., AISI 1018) offers high strength at low cost but demands aggressive corrosion protection. Countersinking generates heat-sensitive work-hardening, necessitating coolant use and reduced spindle speeds. Stainless steel variants like 304 and 316 improve corrosion resistance but double tool wear rates versus carbon steel. Passivation or electropolishing post-machining is non-negotiable for critical applications. Titanium alloys (Grade 5 Ti-6Al-4V) excel in extreme environments but require specialized low-RPM countersinking with rigid setups to manage heat buildup and springback. Their reactivity mandates dedicated tooling to avoid contamination.

Anodizing remains exclusive to aluminum and must align with countersink functional requirements. The porous oxide layer enhances paint adhesion but reduces fatigue strength; we advise chamfer depth verification after anodizing to ensure fastener clearance. For steel and titanium, alternatives like zinc-nickel plating or PVD coatings serve similar protective roles but do not replicate anodizing’s dimensional stability.

Material performance metrics guide optimal countersink programming. Key specifications include:

| Material | Common Alloys | Optimal Countersink Speed (SFM) | Tool Wear Consideration | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 100–150 | High risk of built-up edge | Type II/III post-process |

| Carbon Steel | AISI 1018, 1020 | 40–60 | Moderate wear; coolant critical | Not applicable |

| Stainless Steel | AISI 304, 316 | 30–50 | High wear; low feed rates | Not applicable |

| Titanium | Grade 5 (Ti-6Al-4V) | 20–30 | Extreme heat sensitivity | Not applicable |

Material choice must balance project-specific needs: aluminum for weight-sensitive assemblies requiring anodizing, steel for structural durability with plating, or titanium for mission-critical corrosion resistance. At Wuxi Lead, our CNC engineers validate material-countersink interactions through empirical testing, ensuring zero-defect hole preparation. Partner with us to optimize your material and finish strategy for flawless fastening integrity. Consult our technical team for application-specific tooling and process parameters.

Manufacturing Process & QC

Sheet Metal Countersink: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, the production of precision sheet metal countersinks follows a rigorously controlled workflow that ensures dimensional accuracy, material integrity, and long-term performance. Our process is structured into three core phases: Design, Prototyping, and Mass Production—each engineered to eliminate defects before they occur.

The Design phase begins with detailed collaboration between our engineering team and the client. Using advanced CAD software, we model the countersink geometry to match fastener specifications, sheet thickness, and material type. Critical parameters such as countersink angle (typically 82°, 90°, or 100°), diameter, depth, and edge distance are precisely calculated. Finite Element Analysis (FEA) may be applied to simulate stress distribution and ensure structural reliability under load. Design for Manufacturability (DFM) reviews are conducted to optimize tooling paths, reduce cycle time, and prevent common issues such as burring or material deformation.

Once the design is validated, we proceed to Prototyping. A limited batch of components is produced using the same CNC turret presses, punch presses, or CNC machining centers intended for full-scale production. This ensures process consistency and enables real-world testing of form, fit, and function. Prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and optical comparators. Any deviation from tolerances triggers immediate process correction. Client feedback is incorporated at this stage, ensuring alignment with application requirements before scaling.

Mass Production is executed under a Zero-Defect Manufacturing (ZDM) framework. Our ISO 9001-certified facility employs statistical process control (SPC) to monitor critical dimensions in real time. Automated in-process inspections flag anomalies instantly, halting production until root causes are resolved. Tool wear is tracked and managed through scheduled maintenance and replacement protocols. Every batch is traceable, with full documentation of material certifications, inspection reports, and process parameters.

Our commitment to quality extends beyond conformance. We integrate continuous improvement methodologies such as Six Sigma and 5S to refine efficiency and reduce variability. This disciplined approach ensures that every countersink produced meets the highest standards of precision and reliability.

Typical Countersink Specifications at Wuxi Lead Precision Machinery

| Parameter | Standard Range | Tolerance | Applicable Materials |

|---|---|---|---|

| Countersink Angle | 82°, 90°, 100° | ±1° | Mild Steel, Stainless Steel, Aluminum, Galvanized Sheet |

| Diameter (Top) | 4.0 mm – 12.0 mm | ±0.1 mm | Thickness: 0.8 mm – 6.0 mm |

| Depth | 0.5 mm – 3.0 mm | ±0.05 mm | |

| Edge Distance | ≥ 2× hole diameter | ±0.2 mm | |

| Surface Finish | Smooth, burr-free (Ra ≤ 3.2 µm) | Per ISO 1302 |

Through integrated design validation, precision prototyping, and defect-prevention systems, Wuxi Lead Precision Machinery delivers sheet metal countersinks that perform flawlessly in aerospace, automotive, and industrial equipment applications.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Assembly with Precision Countersinking

In high-performance sheet metal fabrication, the integrity of every fastened joint begins with a precisely executed countersink. Imperfect countersinks lead to compromised torque values, fastener pull-through, and costly field failures – risks no discerning manufacturer can afford. At Wuxi Lead Precision Machinery, we engineer countersinking not as a routine step, but as a critical quality control point within your assembly process. Our advanced CNC turret presses and dedicated forming stations deliver geometric consistency that ensures optimal fastener seating and structural reliability, directly impacting your product’s longevity and performance in demanding applications.

Our technical expertise spans complex geometries and challenging materials, from thin-gauge aluminum enclosures to hardened steel structural components. We implement rigorous in-process metrology, utilizing optical comparators and CMM verification to maintain angular accuracy and depth control far exceeding standard industry tolerances. This systematic approach eliminates the common pitfalls of inconsistent chamfer depth, uneven edge breakout, or material deformation that plague lesser processes. Partnering with Lead Precision means integrating a countersink solution validated for seamless compatibility with your specified fasteners and assembly protocols, significantly reducing rework and warranty claims downstream.

The following specifications represent our standard high-precision countersinking capability, achievable across diverse production volumes. We tailor parameters to your exact engineering drawings and material certifications:

| Parameter | Specification Range | Standard Tolerance | Notes |

|---|---|---|---|

| Angle Range | 60°, 82°, 90°, 100°, 120° | ±0.1° | Custom angles available |

| Depth Tolerance | As per drawing | ±0.05 mm | Verified per hole |

| Material Range | Aluminum to Hardened Steel | Up to 45 HRC | Includes stainless, titanium |

| Max Sheet Thickness | 6.0 mm | N/A | Varies by material hardness |

| Surface Finish | Deburred, Burr-Free | ISO 2768-mK | Critical for paint adhesion |

This level of control is non-negotiable for aerospace, medical device, and premium electronics manufacturing – sectors where Lead Precision is a trusted partner. We understand that your reputation hinges on flawless component integration. Our engineering team collaborates directly with your design and production staff to optimize countersink placement, size, and process parameters during the quoting phase, preventing costly design-for-manufacturing issues before metal is cut.

Do not let substandard countersinking undermine your product quality. Contact our precision engineering team today to discuss your specific requirements. Send your detailed drawings and volume needs to [email protected]. We will provide a comprehensive process capability analysis and a competitive quotation within 24 business hours. Request a countersink process audit for your current components – discover how Lead Precision’s technical execution translates to measurable reductions in assembly time and field failures. Partner with certainty; partner with precision engineered. Contact [email protected] now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.