Technical Contents

Engineering Guide: Precision Cnc Metal Machining

Engineering Insight: The Critical Role of Precision in CNC Metal Machining

In high-performance industries such as aerospace, defense, medical technology, and advanced automation, the demand for absolute precision in metal components is non-negotiable. Precision CNC metal machining is not merely a manufacturing process—it is an engineering discipline where tolerances measured in microns determine the success or failure of mission-critical systems. At Wuxi Lead Precision Machinery, we understand that precision is more than accuracy; it is consistency, repeatability, and the ability to meet exacting specifications under rigorous quality control.

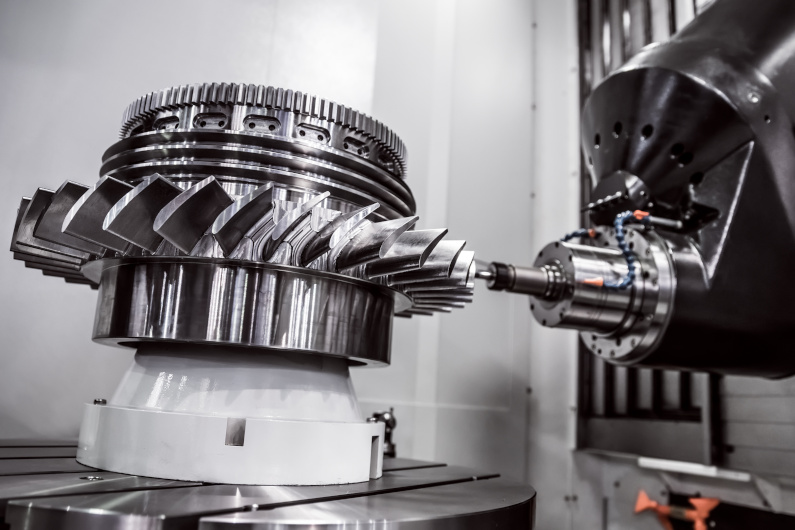

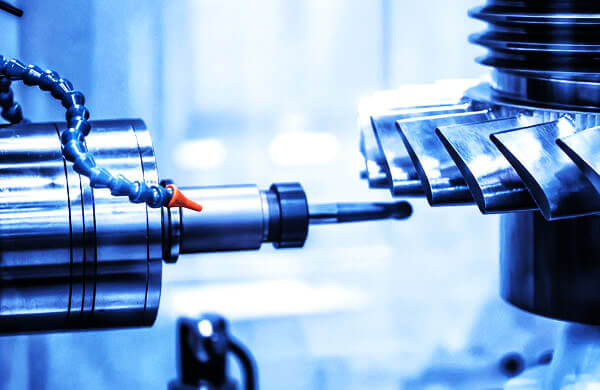

The foundation of precision lies in the integration of advanced CNC equipment, expert programming, and meticulous material handling. Modern multi-axis machining centers, combined with high-resolution probing systems and thermal compensation technology, enable sub-micron-level control over dimensional accuracy. However, equipment alone is insufficient. True precision emerges from decades of engineering refinement, process optimization, and a culture of quality that permeates every stage of production.

Wuxi Lead Precision Machinery has built its reputation on delivering components where failure is not an option. Our involvement in projects tied to Olympic-standard equipment and military-grade applications underscores our capability to meet the most stringent requirements. These programs demand not only tight tolerances but also full traceability, rigorous inspection protocols, and compliance with international standards such as ISO 9001 and AS9100. Our team’s experience in these elite domains directly translates into superior outcomes for all clients, regardless of industry.

Precision machining at this level requires a holistic approach. Material selection, toolpath optimization, fixturing design, and real-time in-process inspection all contribute to the final part quality. Even minor deviations in surface finish or geometric alignment can compromise performance in high-stress environments. This is why we invest heavily in metrology—utilizing coordinate measuring machines (CMM), optical comparators, and laser scanning to validate every critical dimension.

Our commitment to precision is reflected in the performance of the components we produce—components that operate in satellites, surgical robotics, and next-generation defense systems. When industries push the boundaries of what is technically possible, they rely on partners who can deliver with unwavering accuracy and reliability.

Typical Precision CNC Machining Capabilities at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Surface Roughness (Ra) | 0.4–1.6 μm (adjustable to 0.1 μm) |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Tolerance Range | IT6 to IT7 (ISO 286-1) |

| Materials Processed | Aluminum alloys, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Machining Processes | 3-axis, 4-axis, 5-axis Milling, Turning, Mill-Turn, Swiss Machining |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a proven standard, validated through performance in the world’s most demanding applications.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery: Advanced Technical Capabilities in Precision CNC Metal Machining

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding metal components across aerospace, medical, and high-tech industrial sectors. Our core technical capabilities are engineered to transform complex designs into reality with exceptional accuracy and repeatability, directly addressing the stringent requirements of modern high-performance applications. Central to this capability is our strategic investment in state-of-the-art multi-axis machining technology and rigorous, integrated quality control systems.

Our production floor is anchored by a comprehensive fleet of advanced 5-axis CNC machining centers from industry-leading manufacturers. These machines are not merely capable of simultaneous 5-axis motion; they are meticulously maintained and operated by our highly skilled technicians to exploit the full potential of complex contouring, deep cavity machining, and single-setup part completion. This eliminates cumulative errors inherent in multiple setups, significantly improving geometric accuracy and surface finish while reducing overall production lead times. We routinely machine challenging materials including titanium alloys, Inconel, hardened steels, and complex aluminum alloys to exacting specifications. The integration of high-precision spindles, thermal compensation systems, and robust machine structures ensures dimensional stability critical for mission-critical components.

Quality is not a final checkpoint at Wuxi Lead; it is an intrinsic, continuous process embedded within every manufacturing stage. Our dedicated metrology laboratory houses multiple calibrated Coordinate Measuring Machines (CMMs), including high-accuracy bridge and gantry types equipped with advanced tactile and optical probing systems. Every critical feature undergoes comprehensive inspection against the original CAD model and detailed GD&T callouts. Our certified metrologists perform full first-article inspections (FAI) per AS9102 standards where required and implement robust statistical process control (SPC) during production runs. This systematic approach, utilizing calibrated equipment traceable to national standards, guarantees that every component shipped meets or exceeds the specified tolerances and functional requirements, providing absolute confidence in part performance and interchangeability.

The following table details the precision tolerances consistently achievable across our production processes under controlled conditions. These capabilities represent our standard operating envelope for critical features on production parts.

| Feature | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Dimension (mm) | ±0.010 | ±0.005 |

| Linear Dimension (inch) | ±0.0004 | ±0.0002 |

| Geometric Tolerance (Flatness, Roundness) | 0.010 mm | 0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angular Tolerance | ±0.02° | ±0.01° |

This documented precision, combined with our 5-axis machining proficiency and rigorous CMM-based quality assurance, forms the bedrock of Wuxi Lead’s value proposition. We translate complex engineering intent into physically perfect metal components, ensuring optimal fit, function, and reliability within your final assembly, ultimately reducing your total cost of ownership through minimized scrap and assembly time. Partner with us for machining where precision is non-negotiable.

Material & Finish Options

Material Selection in Precision CNC Metal Machining

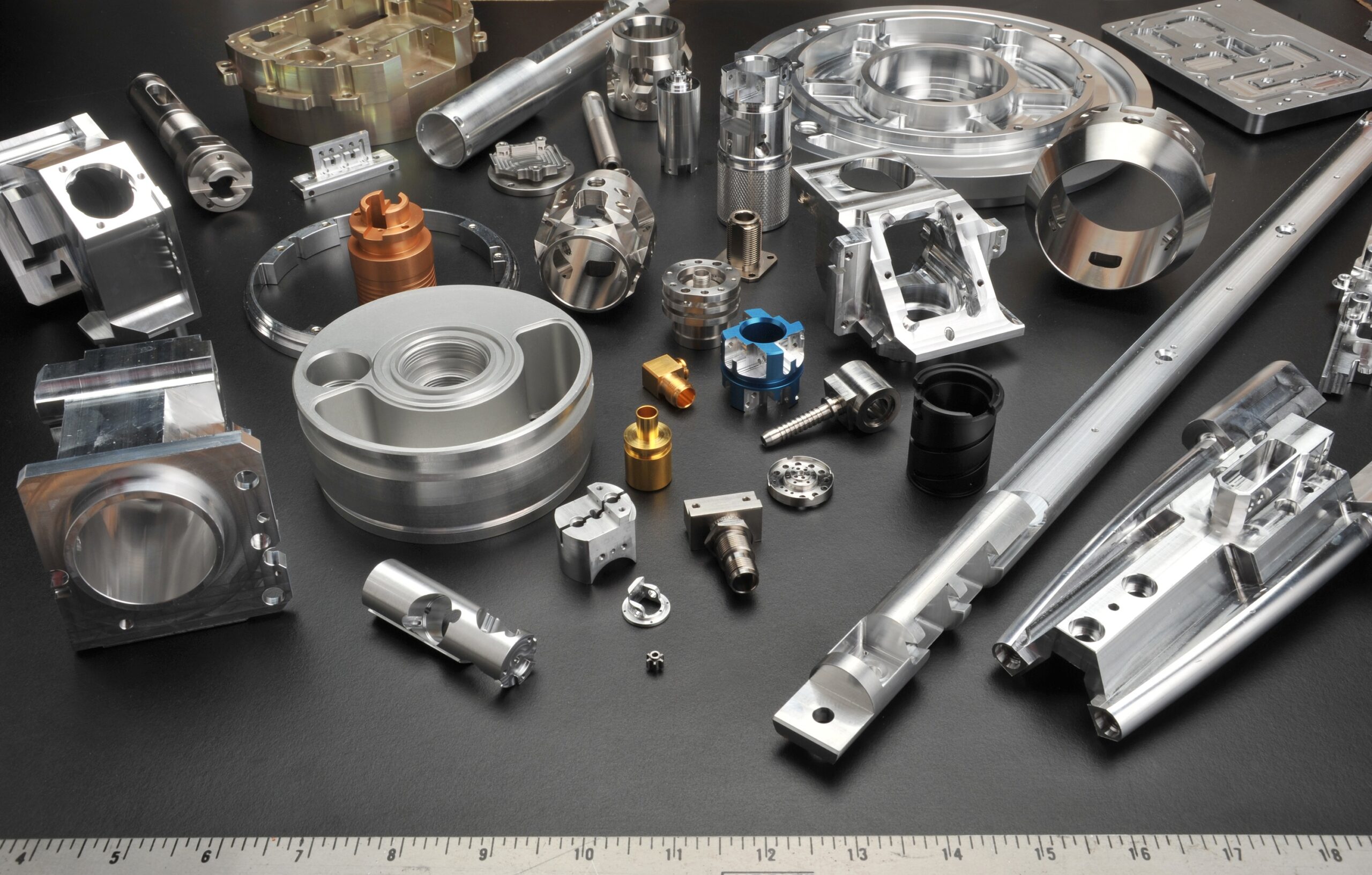

Selecting the appropriate material is a foundational decision in precision CNC metal machining, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we prioritize material compatibility with application requirements, ensuring optimal results across aerospace, medical, automotive, and industrial sectors. Among the most widely used materials in high-precision machining are aluminum, steel, and titanium—each offering distinct mechanical properties and machining characteristics.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Grade 6061-T6 is particularly favored in structural and prototype applications due to its weldability and machinability. It is ideal for components requiring lightweight construction without sacrificing rigidity, such as enclosures, heat sinks, and drone frames. However, aluminum’s softness compared to steel demands precise toolpath strategies to maintain dimensional accuracy and surface finish.

Steel, particularly in alloy forms like 4140 and 1018, offers superior strength, wear resistance, and dimensional stability. These properties make steel the preferred choice for high-load mechanical parts, tooling, and structural components. While more challenging to machine than aluminum due to higher cutting forces and tool wear, modern CNC techniques and tooling allow for tight tolerances and smooth finishes. Stainless steel grades such as 304 and 316 add excellent corrosion resistance, making them suitable for medical devices and marine environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and resistance to extreme temperatures and corrosion. It is extensively used in aerospace and medical implant applications where reliability under stress and biocompatibility are critical. However, titanium’s low thermal conductivity and high reactivity with cutting tools require specialized machining parameters, including lower cutting speeds and rigid setups, to prevent work hardening and tool degradation.

Surface finishing further enhances material performance. Anodizing, particularly for aluminum, improves surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) provides a thicker, engineered layer suitable for high-wear environments. Anodized layers are electrically insulating and can be dyed for identification, offering both functional and aesthetic benefits.

Understanding the interplay between material properties and machining processes ensures reliable, high-performance components. At Wuxi Lead Precision Machinery, we combine advanced CNC capabilities with material science expertise to deliver precision-machined parts tailored to your operational demands.

Material Comparison Table

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Machinability Notes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, electronics, automotive | High machinability; requires chip control |

| Steel | 1018, 4140, 304 | 440–1000 | 7.8–8.0 | Tooling, structural, medical devices | Moderate to difficult; high tool wear |

| Titanium | Ti-6Al-4V (Gr 5) | 950–1000 | 4.4 | Aerospace, implants, defense | Challenging; low thermal conductivity |

Manufacturing Process & QC

Integrated Precision Workflow: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our precision CNC metal machining process is engineered for uncompromising quality and seamless scalability, delivering true zero-defect outcomes for demanding aerospace, medical, and automotive applications. We eliminate traditional handoffs through a vertically integrated workflow, ensuring dimensional integrity and material performance from initial concept to high-volume fulfillment. This closed-loop system is the cornerstone of our commitment to total client success.

Design Validation Phase

Engineering collaboration begins with rigorous DFMA analysis. Our team scrutinizes CAD models for manufacturability, optimizing toolpaths while ensuring adherence to critical GD&T callouts and material-specific thermal compensation requirements. Finite element analysis validates structural integrity under operational loads, preventing costly revisions. Approved designs feed directly into our CAM suite, where multi-axis simulation identifies potential collisions and verifies micron-level accuracy before any metal is cut. This phase establishes the immutable quality baseline for all subsequent stages.

Precision Prototyping Phase

Prototypes are machined on the same production-grade Haas and DMG MORI platforms used for volume runs, eliminating process variation. Each component undergoes 100% first-article inspection against the validated design using thermal-stable granite CMMs and optical comparators. Material certifications, surface roughness measurements (Ra 0.2µm to 1.6µm), and hardness verification are documented per AS9100 and ISO 13485 standards. Client sign-off on prototype performance data is mandatory before progression, ensuring functional requirements are met with zero assumptions.

Zero-Defect Mass Production Phase

Volume manufacturing executes under our proprietary SmartTrack™ quality management system. Every work cell implements real-time SPC monitoring with sub-micron resolution probes, automatically adjusting for tool wear and thermal drift. In-process inspections occur at statistically determined intervals, while final verification includes full FAI documentation and batch traceability to raw material heat numbers. Our zero-defect mandate is enforced through automated gaging stations that reject non-conforming parts before they leave the machine envelope, guaranteeing 100% compliance with your specifications.

Key production capabilities enabling this workflow include:

| Parameter | Capability | Equipment/Control Method |

|---|---|---|

| Tolerance Range | ±0.0001″ (2.5µm) to ±0.001″ (25µm) | Laser interferometer calibrated CMMs |

| Materials | Titanium, Inconel, 17-4PH, Aluminum | Material-specific coolant & tooling |

| Max Work Envelope | 1200 x 800 x 600 mm | 5-axis vertical machining centers |

| Surface Finish | Ra 0.1µm to 3.2µm | Polycrystalline diamond tooling |

| Process Capability | Cpk ≥ 1.67 standard | Real-time SPC with p-chart monitoring |

This integrated approach transforms precision machining from a transactional service into a strategic partnership. By enforcing design continuity, validating performance through production-intent prototyping, and embedding quality into every machining cycle, Wuxi Lead delivers components that install flawlessly and perform reliably—eliminating scrap, rework, and production line disruptions for our global clients. Your zero-defect requirement is not our target; it is our operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Metal Machining

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, precision is not an option—it is a requirement. As a globally recognized leader in precision CNC metal machining, we invite forward-thinking manufacturers, engineering firms, and OEMs to partner with us for mission-critical components that meet the most rigorous standards. Whether your application is in aerospace, medical devices, automotive R&D, or advanced industrial automation, our expertise ensures your designs are translated into flawless, repeatable metal parts.

Our advanced manufacturing ecosystem combines state-of-the-art CNC machining centers with a culture of engineering excellence. We operate under strict ISO 9001:2015 quality management protocols, ensuring every component is machined to micron-level tolerances with full traceability. Our team of seasoned CNC engineers collaborates directly with your design and production staff, offering DFM (Design for Manufacturability) feedback, rapid prototyping, and scalable production runs—all tailored to your project timeline and quality expectations.

We specialize in machining complex geometries from a broad spectrum of metals, including aluminum alloys, stainless steel, titanium, Inconel, and specialty brass and copper alloys. Our 3-, 4-, and 5-axis CNC milling and turning capabilities allow us to produce intricate components with minimal setup, reducing lead times and enhancing dimensional consistency. From first-article inspection reports to full batch certifications, we deliver transparency and reliability at every stage.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to your success. We support global clients with seamless logistics, real-time project tracking, and responsive technical communication in English and Mandarin, ensuring clarity and efficiency across time zones.

Explore how our precision CNC machining services can elevate your manufacturing outcomes. Let us handle the complexity so you can focus on innovation.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide a detailed quote, technical consultation, or material recommendation—within 24 hours.

| Specification | Detail |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling; CNC Turning; Multi-Task Machining |

| Tolerances | As tight as ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel 718, Brass, Copper, Tool Steels |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), Custom setups available |

| Surface Finishes | As-machined, Anodizing (Type II, Type III), Plating, Passivation, Polishing, Powder Coating |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI), PPAP, SPC |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

| Certifications | ISO 9001:2015, RoHS Compliant, ITAR Registered (upon request) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.