Technical Contents

Engineering Guide: Plastic Parts Incorporated

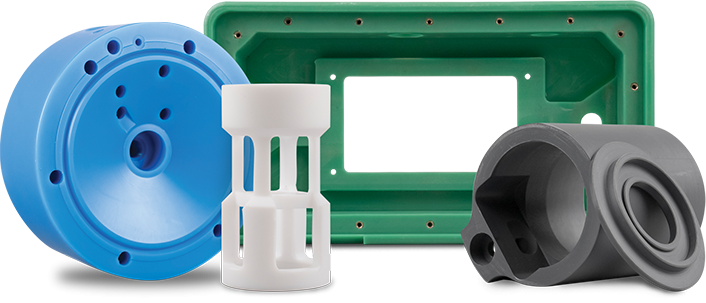

Engineering Insight Precision Metal Components for Plastic Parts Integration

In high-performance plastic part manufacturing, the precision of integrated metal components directly dictates final product integrity and functionality. Plastic materials exhibit inherent thermal expansion and contraction properties during molding and operational use. When metal inserts, cores, or structural elements lack micron-level accuracy, mismatched tolerances induce stress points, dimensional instability, and premature failure in the assembled unit. This is especially critical in sectors like medical devices, automotive sensors, and aerospace assemblies where plastic-metal interfaces must maintain hermetic seals, precise alignment under thermal cycling, or consistent electrical conductivity. Sub-micron deviations in metal part geometry propagate through the plastic matrix, compromising cycle life and performance reliability. The cost of failure extends beyond scrap rates; it includes field recalls, reputational damage, and redesign delays that disrupt supply chains.

Wuxi Lead Precision Machinery addresses this engineering imperative through specialized CNC machining processes honed over 15 years of producing mission-critical components. Our facility holds ISO 9001 and AS9100 certifications, with direct experience machining parts for Olympic Games infrastructure and Tier-1 military subcontractors. These projects demanded absolute adherence to tolerances below 0.001mm under extreme environmental conditions—requirements directly transferable to plastic parts manufacturers facing similar precision challenges. We implement in-process metrology using Zeiss CONTURA CMMs and laser interferometers, ensuring metal components maintain geometric conformity throughout production. This capability prevents common integration failures such as plastic warpage around inserts, inconsistent wall thickness in overmolded assemblies, or misaligned mating surfaces in multi-material housings.

Critical machining parameters for plastic-integration metal components include:

| Specification | Capability at Wuxi Lead | Impact on Plastic Part Performance |

|---|---|---|

| Positional Tolerance | ±0.0005 mm | Prevents flash lines and seal failures |

| Surface Roughness (Ra) | 0.05 µm | Ensures optimal adhesion for overmolding |

| Thermal Stability | <1.5 ppm/°C deviation | Minimizes stress during plastic cooling |

| Material Certification | Full traceability | Meets medical/aerospace compliance needs |

Our engineering team collaborates early in your design phase, conducting DFM analysis specifically for metal-plastic interfaces. We identify potential thermal mismatch risks, recommend optimal material pairings (e.g., beryllium copper cores for rapid heat dissipation in high-cycle molds), and validate toolpaths to eliminate micro-vibrations that affect surface finish. This proactive approach reduces prototyping iterations by up to 40% while guaranteeing that metal components perform as engineered within your plastic assembly. For plastic parts manufacturers, partnering with a precision metal supplier isn’t a procurement decision—it’s a strategic engineering investment in product resilience. Contact Wuxi Lead Precision Machinery to discuss tolerance stack-up analysis for your next integrated component project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the exacting demands of high-performance industries, including aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components from a wide range of metals, including aluminum alloys, stainless steel, titanium, and specialty engineering materials.

Our 5-axis CNC machining centers provide simultaneous multi-directional cutting, allowing for intricate geometries and superior surface finishes that are unattainable with traditional 3-axis systems. This capability significantly reduces the need for multiple setups, minimizing cumulative error and improving part consistency. With dynamic toolpath optimization and high-speed machining functionality, we achieve tight tolerances and fine detail across both prototype and volume production runs. Each machine is operated by certified CNC programmers and machinists who utilize industry-leading CAD/CAM software to ensure optimal tool engagement, material removal rates, and final part accuracy.

Quality assurance is embedded throughout the manufacturing process. All critical dimensions and geometric features are verified using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems. These high-precision metrology tools provide traceable, repeatable measurement data in full compliance with ISO 9001 standards. Our CMM inspection routines are developed in alignment with customer engineering drawings and GD&T requirements, ensuring that every component meets or exceeds specified tolerances. In addition to first-article inspection reports (FAIR), we offer in-process checks and final inspection documentation for complete quality traceability.

Our commitment to precision is reflected in the tolerances we consistently achieve across various feature types and materials. The following table outlines our standard and precision capability ranges:

| Feature Type | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm |

| Hole Diameter (mm) | ±0.03 mm | ±0.01 mm |

| Positional Tolerance | ±0.05 mm | ±0.02 mm |

| Flatness (per 100 mm) | 0.05 mm | 0.01 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Profile of Surface/Form | ±0.05 mm | ±0.02 mm |

These specifications are maintained through rigorous environmental controls, preventive maintenance schedules, and real-time process monitoring. Wuxi Lead Precision Machinery combines cutting-edge technology with disciplined engineering practices to deliver metal components that meet the highest standards of precision and reliability. Our technical team works closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, material selection, and production methodology—ensuring cost-effective, scalable, and high-quality outcomes.

Material & Finish Options

Strategic Material Selection for Mission-Critical Metal Components

Material choice fundamentally dictates the performance, longevity, and cost-efficiency of custom metal parts. At Wuxi Lead Precision Machinery, we advise clients to prioritize application demands over initial material cost. Consider operational stress, environmental exposure, weight constraints, and lifecycle requirements. Aluminum excels in lightweight structural applications where corrosion resistance and thermal conductivity are paramount. Steel variants offer unmatched strength and wear resistance for high-load scenarios, though weight and corrosion susceptibility require mitigation. Titanium delivers the ultimate strength-to-weight ratio and extreme corrosion resistance for aerospace or medical implants, justifying its premium cost in critical systems. Selecting incorrectly leads to premature failure, costly redesigns, or over-engineering. Partner with our engineering team early to model stress points and environmental factors, ensuring optimal material alignment with your functional and economic goals.

Key Material Properties for Precision Machining

| Material Family | Common Grades | Tensile Strength (MPa) | Yield Strength (MPa) | Key Advantages | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310-572 | 276-503 | Lightweight, excellent machinability, high thermal/electrical conductivity | Aerospace frames, automotive brackets, heat sinks |

| Steel | 4140, 304/316 SS | 655-1000 | 415-760 | High strength, wear resistance, cost-effective (carbon); superior corrosion resistance (stainless) | Shafts, tooling, hydraulic components, marine hardware |

| Titanium | Ti-6Al-4V (Grade 5) | 900-950 | 830 | Exceptional strength-to-weight ratio, biocompatibility, extreme corrosion resistance | Aircraft engine parts, medical implants, chemical processing |

Optimizing Surface Finishes: Anodizing Explained

Anodizing is the dominant surface treatment for aluminum components, enhancing durability and functionality beyond aesthetics. The electrochemical process grows a controlled oxide layer integral to the substrate, significantly improving corrosion and abrasion resistance. Type II (sulfuric acid) anodizing is standard for general industrial use, offering dye compatibility for identification. For extreme wear environments, Type III (hard anodizing) creates a thicker, harder ceramic-like surface (60-70 HRc) ideal for hydraulic pistons or firearm components. Crucially, anodizing affects dimensional tolerances; the oxide layer grows 50% inward and 50% outward from the original surface. Critical mating surfaces require precise pre-machining allowances—typically 0.001-0.002 inches per side—based on specified coating thickness. We rigorously control bath chemistry, temperature, and voltage to ensure uniform thickness and adhesion, preventing common failures like peeling or reduced fatigue strength. Always specify required thickness (e.g., 25µm for Type III) and sealing method (hot water, nickel acetate) during quotation to avoid rework.

Material and finish decisions directly impact manufacturability and total cost of ownership. Wuxi Lead’s integrated engineering review identifies optimal combinations before cutting metal, minimizing waste and accelerating time-to-market for your precision assemblies.

Manufacturing Process & QC

The journey from concept to flawless metal component at Wuxi Lead Precision Machinery follows a rigorously controlled process designed to ensure zero defects and uncompromising quality. Every custom metal part we produce begins with engineering-grade design collaboration. Our team works closely with clients to analyze technical drawings, material specifications, and functional requirements. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize geometry, tolerances, and manufacturability to prevent downstream inconsistencies. This foundational phase ensures that design intent aligns with production capability, reducing risk and accelerating time to market.

Once the design is finalized, we transition into precision prototyping. Prototypes are manufactured using the same high-accuracy CNC machining, stamping, or sheet metal fabrication processes intended for mass production. This ensures that the prototype is not just a model, but a fully functional representation of the final part. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to validate dimensional accuracy, material integrity, and performance under real-world conditions. Feedback from this stage is systematically integrated, and design or process adjustments are made before approval for full-scale production.

Mass production at Wuxi Lead is executed under a zero-defect framework. Our ISO 9001-certified production floor integrates automated process controls, real-time monitoring, and statistical process control (SPC) to maintain consistency across every batch. Each operation—from raw material sourcing to final finishing—is documented and traceable. In-process inspections occur at critical control points, ensuring deviations are detected and corrected immediately. We employ a closed-loop corrective action (CLCA) system that feeds quality data back into the production loop, minimizing variation and eliminating recurrence of potential issues.

Our commitment to perfection is reflected in the precision and reliability of every component we deliver. By aligning advanced technology with disciplined process management, Wuxi Lead ensures that high-volume output does not compromise quality. Clients receive parts that meet exact specifications, batch after batch, with full documentation and certification.

Below is an overview of our standard production capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Materials Supported | Aluminum, Stainless Steel, Brass, Copper, Carbon Steel, Alloy Steel |

| Max Workpiece Size | 1200 x 800 x 600 mm (CNC Machining) |

| Production Capacity | Up to 500,000 units/month (depending on part complexity) |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive ready) |

| Inspection Equipment | CMM, Optical Comparator, Hardness Tester, Roughness Tester, 3D Scanner |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 20–35 days (varies by order volume) |

This structured, technology-driven approach enables Wuxi Lead Precision Machinery to deliver custom metal components with the consistency and precision required by high-end industries including automotive, medical, and advanced automation.

Why Choose Wuxi Lead Precision

Elevate Your Precision Metal Manufacturing Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical custom metal components. We transcend conventional contract manufacturing by integrating deep CNC engineering expertise with rigorous quality systems, specifically designed for demanding sectors like aerospace, medical devices, and advanced automation. Our facility in Wuxi, China, operates under stringent international standards, utilizing advanced multi-axis machining centers, Swiss-type lathes, and high-precision grinding equipment. This infrastructure, combined with our team’s decades of hands-on CNC programming and process optimization experience, ensures we consistently deliver complex geometries with exceptional surface finishes and unparalleled dimensional stability. Partnering with Lead Precision means gaining a true engineering extension of your own team, focused on solving your most challenging manufacturing problems from prototype through high-volume production.

Your success hinges on predictable quality and on-time delivery, especially for components where failure is not an option. We mitigate your supply chain risk through proactive engineering collaboration. Our process begins with a thorough review of your design for manufacturability (DFM), identifying potential issues early to prevent costly delays or rework. We implement robust first-article inspection (FAI) protocols per AS9102 and maintain full traceability of materials and processes. Our quality management system, certified to ISO 9001:2015 and AS9100D, is not merely a compliance checkbox; it is embedded into every machining cycle and inspection procedure. This systematic approach guarantees that every part shipped meets your exact specifications, batch after batch, providing the reliability your end products demand and protecting your brand reputation.

The complexity of modern metal fabrication requires a partner who speaks the language of precision engineering fluently. Lead Precision offers the technical depth and operational discipline to handle your most sophisticated projects, from titanium aerospace brackets requiring micron-level tolerances to intricate stainless steel medical implants. We understand the criticality of material properties, thermal management during machining, and secondary process integration. Our commitment is to become your most trusted offshore manufacturing resource, delivering not just parts, but engineered solutions that enhance your product performance and accelerate your time-to-market.

Core Manufacturing Capabilities & Specifications

| Capability | Specification | Relevance to Your Project |

|---|---|---|

| Dimensional Tolerance | ±0.0002 inches (5 microns) | Essential for high-precision assemblies and sealing surfaces |

| Material Expertise | Titanium, Inconel, Stainless Steels (300/400 series), Aluminum Alloys, Brass | Supports demanding applications in aerospace, medical, energy |

| Maximum Part Size | Ø12 inches x 24 inches length | Accommodates a wide range of complex component geometries |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Critical for fatigue life, sealing, and biocompatibility |

| Quality Certifications | ISO 9001:2015, AS9100D | Ensures rigorous process control and traceability |

Initiate a partnership defined by engineering excellence and unwavering reliability. Contact our engineering team directly to discuss your specific project requirements and receive a detailed capability assessment. Email [email protected] with your engineering package, including drawings and material specifications. Our senior CNC engineers will respond within one business day to outline a precise, actionable manufacturing strategy tailored to your needs. Let Wuxi Lead Precision Machinery become the cornerstone of your high-integrity metal component supply chain.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.