Technical Contents

Engineering Guide: 3D Mold Maker

Engineering Insight Precision in 3D Mold Manufacturing

Achieving dimensional stability and surface perfection in complex 3D molds is non-negotiable for high-performance manufacturing. Minute deviations during the molding process translate directly into part failure, assembly issues, and accelerated tool wear. Precision engineering governs critical factors like thermal expansion management, cavity pressure distribution, and ejection dynamics. A variance of even 0.005mm can compromise the integrity of micro-features in aerospace components or medical devices, leading to costly scrap rates and production delays. The mold’s ability to consistently replicate intricate geometries across thousands of cycles hinges on the foundational accuracy achieved during its creation. This demands not only advanced multi-axis CNC capabilities but also deep material science understanding and rigorous process validation under simulated production conditions.

Our facility utilizes metrology-grade machining centers specifically calibrated for mold production. The table below outlines the core specifications enabling our precision standard.

| Parameter | Specification | Industry Standard | Verification Standard |

|---|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.005 mm | ISO 230-2 |

| Repeatability | ±0.001 mm | ±0.003 mm | ISO 230-2 |

| Max Work Envelope | 2000 x 1200 x 1000 mm | Varies | N/A |

| Spindle Speed Range | 20 – 30,000 RPM | Typically <20k RPM | Laser Tachometer |

| Material Compatibility | Hardened Steels (HRC 58+), Aluminum, Copper Alloys | Standard Steels | Material Certificates |

This level of machine capability is essential but insufficient alone. True precision mastery requires integrating machining science with real-world application knowledge. Our engineering team possesses proven experience delivering molds where failure is not an option. We engineered the core cavity inserts for the medal production molds used in the Beijing Winter Olympics, requiring absolute thermal stability across 200+ identical units to ensure flawless surface replication under high-volume casting. Similarly, we developed critical composite layup molds for a major defense contractor’s next-generation UAV program. These molds demanded micron-level accuracy across large envelopes to maintain aerodynamic tolerances in carbon fiber components operating under extreme stress. Both projects required zero-defect validation protocols exceeding standard aerospace specifications.

Wuxi Lead Precision Machinery applies this same uncompromising standard to every 3D mold project. We understand that your product’s performance and market reputation are intrinsically linked to the mold’s fidelity. Our process combines certified machine performance, material expertise honed through mission-critical applications, and rigorous in-process inspection. This ensures your molds deliver not just initial accuracy, but sustained precision throughout their operational lifecycle, maximizing yield and minimizing total cost of ownership. Partner with us for molds engineered where precision is the foundation, not an aspiration.

Precision Specs & Tolerances

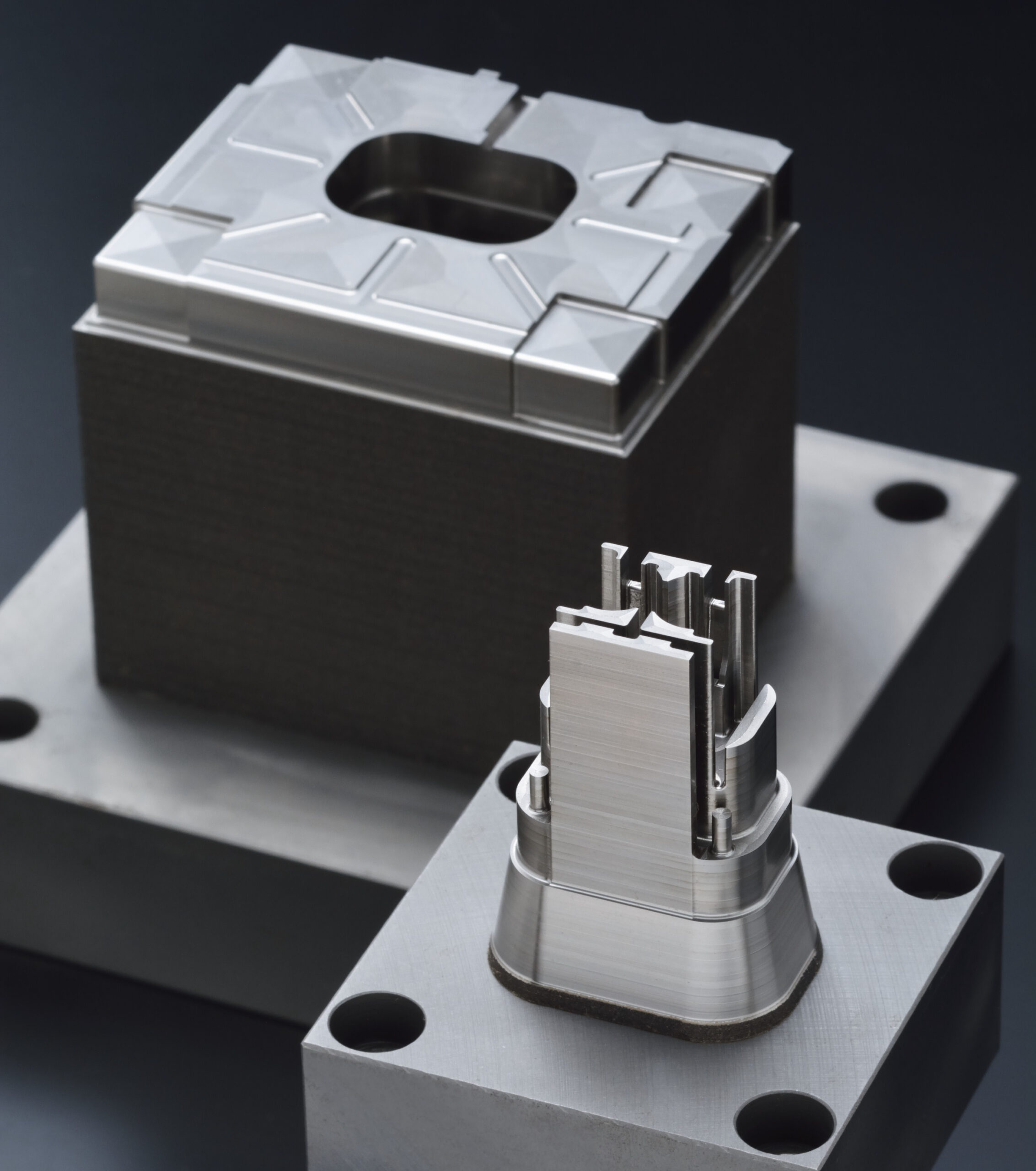

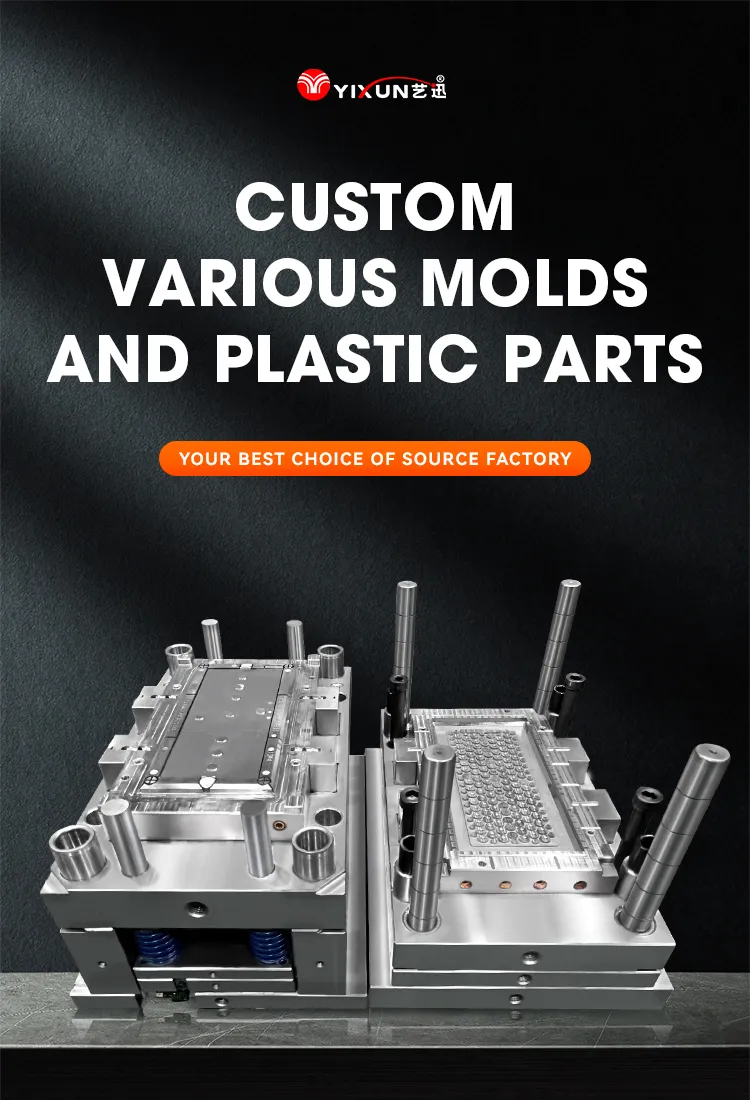

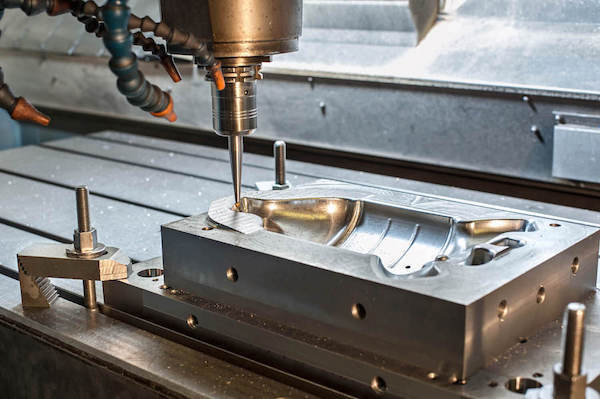

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-precision industries such as aerospace, medical, automotive, and industrial equipment. At the core of our production infrastructure is a fully integrated 5-axis CNC machining platform, enabling us to produce complex 3D mold geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across multiple planes, significantly reducing setup times and enabling single-operation completion of intricate components. This capability is essential for manufacturing molds with undercuts, compound angles, and organic contours commonly found in injection molds, die-casting tools, and composite forming dies.

Our machining centers are operated by certified CNC programmers and skilled technicians who utilize industry-leading CAD/CAM software to optimize toolpaths, minimize cycle times, and ensure material integrity. We support a wide range of metals, including hardened steels, aluminum alloys, titanium, and high-temperature superalloys, ensuring compatibility with diverse application requirements. In addition to machining, we offer comprehensive in-house finishing services, including polishing, texturing, and heat treatment coordination, to deliver molds that meet exact functional and aesthetic specifications.

Quality control is rigorously enforced throughout the production cycle. Every component undergoes systematic inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), ensuring dimensional compliance with design intent. Our CMM system provides full 3D metrology reporting with GD&T analysis, traceable to international standards (ISO 17025). This level of inspection guarantees that critical mold features—such as cavity symmetry, core alignment, and parting line precision—are maintained within tight tolerance bands. Additionally, first-article inspection reports (FAIR) and production batch certifications are available upon request to support customer quality documentation.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (per 100 mm) | ±0.010 mm |

| Angular Tolerance | ±0.02° |

| Surface Finish (as machined) | Ra 0.8 – 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| Materials Supported | Tool Steel, Stainless Steel, Aluminum, Titanium, Brass, Bronze, High-Temp Alloys |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Micrometers, Calipers |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade verification to deliver 3D mold solutions that are both technically advanced and consistently repeatable. Our technical capabilities are designed to support prototyping, bridge tooling, and full-scale production runs with equal precision.

Material & Finish Options

Material Selection for High-Performance 3D Mold Making

Material selection is a critical engineering decision directly impacting mold longevity, part quality, production efficiency, and total cost of ownership in precision 3D mold manufacturing. At Wuxi Lead Precision Machinery, our engineers prioritize matching material properties to the specific demands of the molding process, resin type, production volume, and required surface finish. Aluminum, tool steel, and titanium each offer distinct advantages; understanding their characteristics ensures optimal mold performance.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and low-to-medium volume production due to exceptional thermal conductivity and machinability. This allows for faster cycle times and easier cooling channel integration. While softer than steel, high-grade aluminum provides sufficient hardness for many applications and is significantly lighter, reducing handling strain. It is ideal for prototypes, bridge tooling, and molds running engineering plastics where wear resistance is less critical than speed.

Tool steels, especially pre-hardened grades like P20 and H13, are the standard for high-volume production molds. Their superior hardness, wear resistance, and ability to withstand high injection pressures and abrasive fillers ensure extended mold life, often exceeding hundreds of thousands of cycles. H13, with its excellent hot hardness and thermal fatigue resistance, is preferred for molds processing high-temperature resins like PEEK or LCP. The higher initial cost is justified by longevity in demanding applications.

Titanium alloys (e.g., Ti-6Al-4V) serve specialized niches where extreme corrosion resistance against highly aggressive chemicals or exceptional strength-to-weight ratio is paramount, such as in specific medical or aerospace molding. While significantly more expensive and challenging to machine, titanium’s inertness prevents contamination and ensures part purity in critical applications, justifying its use despite higher costs.

The following table summarizes key comparative properties:

| Material | Thermal Conductivity (W/m·K) | Typical Hardness (HRC) | Density (g/cm³) | Corrosion Resistance | Primary Application Focus |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 130 | 15-20 | 2.81 | Moderate | Prototypes, Bridge Tooling, Low/Med Volume |

| Tool Steel P20 | 28-36 | 28-32 | 7.85 | Good | Medium/High Volume Production |

| Tool Steel H13 | 24-30 | 48-52 | 7.76 | Very Good | High Temp Resins, High Volume |

| Titanium Ti-6Al-4V | 7.2 | 33-38 | 4.43 | Excellent | Extreme Corrosion, Critical Purity |

Surface finishing, particularly anodizing, is essential for aluminum molds. Type II (Sulfuric Acid) anodizing provides a standard decorative and moderately wear-resistant layer (5-25μm). For demanding aluminum molds requiring enhanced surface hardness, abrasion resistance, and dimensional stability, Type III (Hardcoat) anodizing is critical. This process creates a dense, thick oxide layer (25-50μm) with hardness approaching 60-70 HRC, significantly extending mold life in abrasive resin applications and improving release characteristics. Proper masking of critical sealing surfaces and ejector pins during anodizing is mandatory to maintain precision.

Selecting the right base material combined with the appropriate finish is not merely a cost exercise; it is an investment in production stability and part quality. Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients to analyze application requirements and recommend the optimal material and surface treatment solution, ensuring maximum return on your mold investment. Consult our specialists for a tailored assessment.

Manufacturing Process & QC

From Concept to Precision: The 3D Mold Maker Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer excellence into every stage of the 3D mold manufacturing process. Our end-to-end workflow—spanning design, prototyping, and mass production—is built on a foundation of precision, advanced technology, and a zero-defect philosophy. This ensures that every custom metal component we produce meets the most exacting industrial standards.

The process begins with design integration, where our engineering team collaborates closely with clients to translate conceptual models into manufacturable, high-precision 3D mold designs. Utilizing advanced CAD/CAM software and simulation tools, we perform comprehensive design for manufacturability (DFM) analysis. This step identifies potential structural, thermal, or dimensional challenges early, optimizing tool paths, material selection, and cooling channel layouts to ensure long-term mold performance and part consistency.

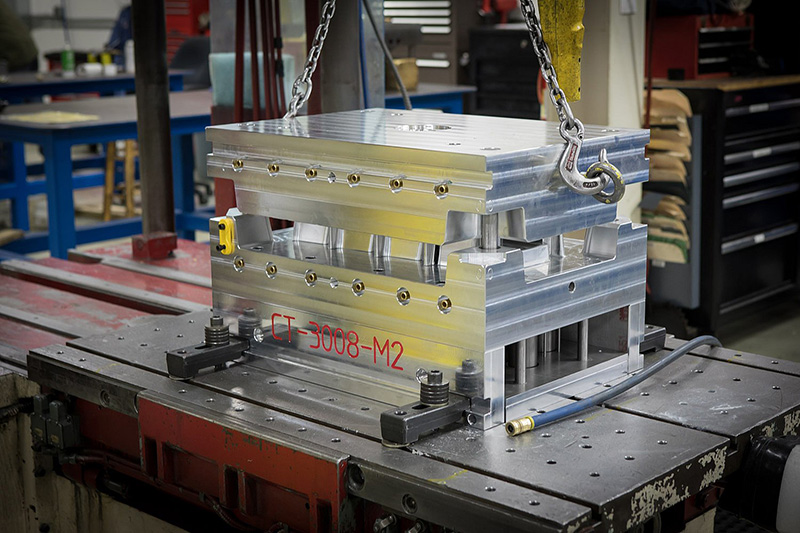

Once the design is validated, we move to precision prototyping. Our in-house CNC machining centers, equipped with 5-axis milling, high-speed cutting, and wire EDM capabilities, produce functional prototypes with micron-level accuracy. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional conformity and surface integrity. This phase is critical for validating mold functionality, ejection mechanisms, and part quality before committing to full-scale production. Any deviations are corrected in real time, ensuring a flawless transition to the next stage.

Mass production is executed on our automated, high-efficiency manufacturing lines. Each mold is machined from premium-grade tool steel or aluminum alloys, depending on production volume and application requirements. Our production cells integrate real-time monitoring systems that track temperature, tool wear, and cycle times, enabling predictive maintenance and immediate anomaly detection. Every component passes through a multi-stage quality gate, including visual inspection, hardness testing, and surface finish analysis, ensuring 100% compliance with specifications.

Our zero-defect mandate is enforced through a closed-loop quality management system compliant with ISO 9001:2015. Process data is continuously logged and analyzed to identify trends and prevent recurrence of any non-conformities. This proactive approach minimizes waste, reduces lead times, and guarantees repeatability across production runs.

Wuxi Lead Precision Machinery combines engineering expertise with cutting-edge automation to deliver 3D molds that perform reliably under the most demanding industrial conditions. Our process is not just about manufacturing—it’s about perfecting precision at every step.

| Specification | Detail |

|---|---|

| Material Options | P20, 718, NAK80, S136, H13, Aluminum 7075, Stainless Steel |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.1 – 1.6 μm (polished, textured, or as-machined) |

| Max Mold Size | 1200 × 800 × 700 mm |

| Machining Capabilities | 5-axis CNC, Wire EDM, High-Speed Milling, Grinding |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, 3D Scanning, First Article Inspection (FAI) |

| Lead Time (Prototype) | 10–15 days |

| Lead Time (Production Mold) | 25–40 days, depending on complexity |

Why Choose Wuxi Lead Precision

Elevate Your Mold Manufacturing Through Precision Partnership

In the demanding realm of high-precision 3D mold making, component accuracy and material integrity are non-negotiable. Tolerances measured in microns directly impact final part quality, production cycle times, and your bottom line. Partnering with a manufacturer possessing deep technical expertise and unwavering process control is not merely an option—it is a strategic imperative for achieving market leadership. Wuxi Lead Precision Machinery exists to be that indispensable partner for discerning global manufacturers.

We understand the critical pressures you face: complex geometries requiring multi-axis machining, stringent surface finish requirements, demanding material specifications, and relentless pressure on lead times. Our engineering-driven approach begins with a thorough analysis of your mold design intent and functional requirements. We translate these into optimized CNC machining strategies utilizing our advanced equipment suite, ensuring every cavity, core, and intricate detail meets or exceeds your exacting standards. This collaborative process minimizes iterations and accelerates time-to-market.

Our technical capabilities are engineered for the highest echelons of mold production. The core of our precision lies in our controlled environment and rigorously maintained machinery. The following specifications represent our standard production capability for critical mold components:

| Specification Category | Performance Level |

|---|---|

| Positioning Accuracy (All Machines) | ±0.002 mm |

| Repeatability (All Machines) | ±0.001 mm |

| Typical Surface Finish (Mold Cavities) | Ra 0.2 µm – Ra 0.8 µm |

| Core Materials Processed | P20, 718H, S136, H13, Maraging Steel, Aluminum Alloys |

| Maximum Work Envelope (5-Axis Milling) | 1200 x 800 x 750 mm |

Beyond raw machine capability, our integrated quality management system provides the consistency you require. Every stage, from raw material certification through final inspection using calibrated CMMs and optical comparators, is documented and traceable. We implement rigorous in-process checks specifically designed for the thermal stability and wear characteristics critical to long-life molds. This systematic approach eliminates costly surprises and ensures your molds perform reliably from the first shot.

Choosing Wuxi Lead Precision Machinery means selecting a partner committed to your success through engineering excellence, not just component supply. We invest in the technology, talent, and processes necessary to solve your most challenging mold manufacturing problems. Our goal is to become a seamless extension of your engineering team, providing the precision foundation upon which your success is built.

Initiate a conversation that transforms your mold manufacturing capability. Contact our engineering sales team directly at [email protected]. Provide your specific project requirements or technical challenge, and we will respond within 24 business hours with a detailed capability assessment and actionable next steps. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.