Technical Contents

Engineering Guide: Injection Molding Threaded Inserts

Engineering Insight: Precision Imperatives in Injection Molding Threaded Inserts

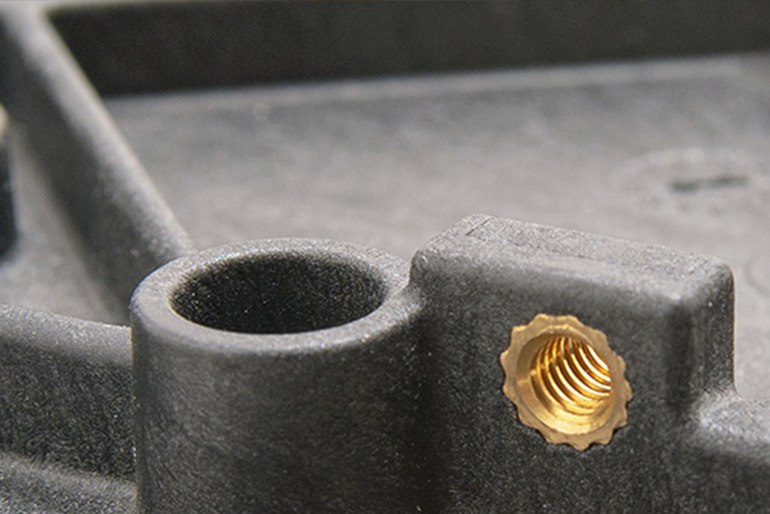

Threaded inserts represent a critical junction point within injection molded components, where the structural integrity and functional reliability of the final assembly are decisively determined. In high-performance applications spanning aerospace, defense, and advanced medical devices, the margin for error is effectively zero. Inadequate precision in insert geometry, particularly thread form, pitch, and concentricity, directly translates to catastrophic thread stripping, torque inconsistency, or premature joint failure under cyclic loading. The thermal expansion differential between the metal insert and the surrounding polymer matrix further compounds these risks; even minor dimensional deviations can induce significant internal stresses during the molding cycle or in service, leading to housing cracking or insert pull-out. Achieving consistent, high-integrity assemblies demands inserts manufactured to tolerances far exceeding standard commercial practices, where microns define success or failure.

At Wuxi Lead Precision Machinery, we engineer threaded inserts to meet the uncompromising standards demanded by mission-critical sectors. Our deep expertise stems from direct involvement in projects requiring absolute reliability, including components for Olympic venue infrastructure where structural safety under extreme environmental loads was non-negotiable, and precision subsystems for military applications where failure is not an option. This experience ingrained a fundamental principle: precision is not merely a specification, but the bedrock of functional performance. We leverage advanced multi-axis Swiss turning and precision grinding capabilities, coupled with rigorous in-process metrology using high-resolution CMMs and optical comparators, to control critical dimensions at the micron level. Material selection and proprietary surface treatments are equally vital, ensuring optimal adhesion to the polymer melt while resisting corrosion and galling during installation and service life.

The following table outlines key dimensional and performance parameters where precision directly impacts insert functionality within the injection molding process and final assembly:

| Parameter | Standard Commercial Tolerance | Wuxi Lead Precision Capability | Critical Impact |

|---|---|---|---|

| Thread Pitch Diameter | ±0.05 mm | ±0.015 mm | Ensures consistent thread engagement, prevents stripping |

| Concentricity (OD to Thread) | 0.10 mm | ≤ 0.005 mm | Eliminates uneven polymer flow, prevents housing stress cracks |

| Insertion Force Consistency | ±15% | ±5% | Guarantees reliable automated assembly, avoids component damage |

| Thread Form Accuracy | ISO 2768-mK | ISO 2768-k | Maximizes load-bearing capacity, ensures torque-tension correlation |

| Surface Roughness (Ra) | 1.6 µm | ≤ 0.4 µm | Optimizes polymer adhesion, minimizes stress concentration |

This level of dimensional control and process mastery is non-negotiable for applications where safety, longevity, and performance are paramount. Wuxi Lead Precision Machinery applies this disciplined engineering approach to every custom threaded insert project, transforming a seemingly simple component into a guaranteed, high-reliability interface within your most demanding injection molded assemblies. Precision isn’t just our standard; it’s the foundation of your product’s success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-performance injection molding threaded inserts, engineered to meet the exacting standards of aerospace, medical, automotive, and industrial applications. Our technical capabilities are built around precision, repeatability, and material integrity, ensuring every component performs under demanding operational conditions. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, which enable complex geometries, tight tolerances, and superior surface finishes that are unattainable with conventional 3-axis systems.

The integration of 5-axis technology allows for simultaneous multi-directional cutting, reducing setup cycles and enhancing dimensional accuracy. This capability is particularly critical when producing threaded inserts with asymmetrical features, undercuts, or integrated alignment structures. By maintaining a single workholding setup throughout the machining process, we minimize human error and thermal distortion, resulting in components with consistent concentricity and thread integrity. Our machines support a wide range of materials, including stainless steel (303, 304, 316), brass (C36000), titanium, and high-strength aluminum alloys, all commonly specified in threaded insert applications.

Quality control is embedded at every stage of production. Each batch undergoes rigorous inspection using a Zeiss DuraMax Coordinate Measuring Machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM protocols verify critical dimensions such as thread pitch, major and minor diameters, concentricity, and positional tolerances. Data from each inspection is documented and archived, providing full traceability for regulated industries. In addition to automated metrology, our quality engineers perform first-article inspections and in-process checks to preempt deviations before final assembly.

We specialize in custom threaded insert designs, from simple helical forms to multi-start threads and proprietary locking geometries. Our engineering team collaborates directly with clients to optimize part design for manufacturability, minimizing cycle time without sacrificing performance. All inserts are deburred, cleaned, and optionally passivated or coated based on environmental exposure requirements.

The following table outlines our standard machining capabilities and achievable tolerances for injection molding threaded inserts:

| Parameter | Capability |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Materials | Stainless Steel, Brass, Aluminum, Titanium, Alloy Steel |

| Insert Diameter Range | Ø2.0 mm to Ø50.0 mm |

| Length Range | 3.0 mm to 100.0 mm |

| Thread Standards | ISO, UN, NPT, M, Custom Profiles |

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm (machined) |

| Concentricity | ≤ 0.015 mm |

| Inspection Method | CMM (Zeiss DuraMax), Optical Comparators, Thread Gauges |

| Compliance Standards | ISO 9001:2015, RoHS, PPAP Level 3 |

Wuxi Lead Precision Machinery combines cutting-edge technology with disciplined quality management to deliver threaded inserts that ensure reliable mold integration and long-term performance in high-cycle injection environments.

Material & Finish Options

Material Selection for High-Performance Injection Molding Threaded Inserts

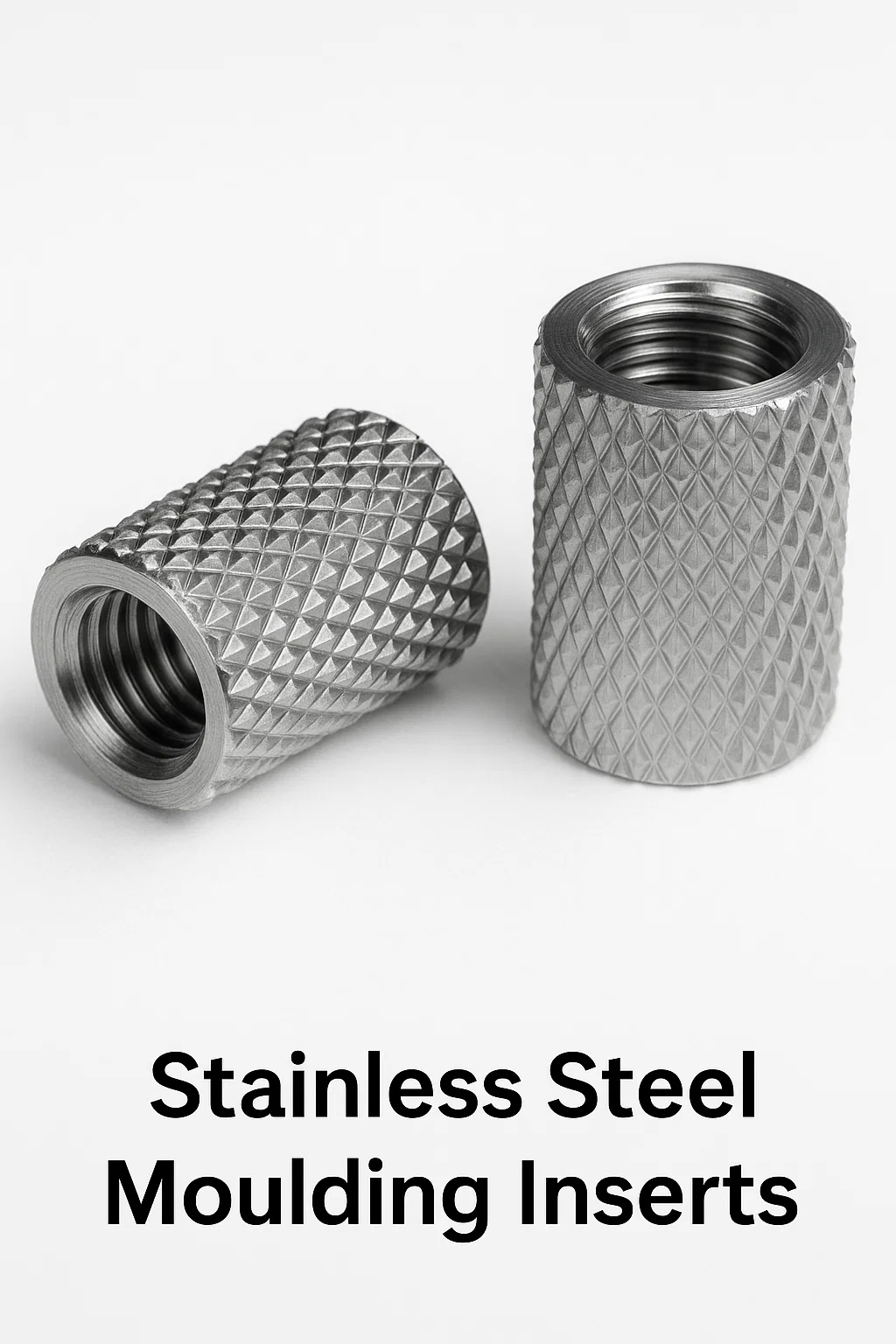

Selecting the optimal material for threaded inserts is critical for ensuring long-term structural integrity, assembly reliability, and cost-effectiveness within demanding injection molding applications. The insert must withstand significant insertion forces, thermal cycling during molding, sustained load in the final assembly, and potential exposure to corrosive environments. At Wuxi Lead Precision Machinery, our precision CNC machining processes are tailored to maximize the inherent properties of each substrate material, ensuring perfect thread geometry and dimensional stability. Aluminum, steel, and titanium represent the primary high-performance choices, each suited to specific operational requirements.

Aluminum alloys, particularly 6061-T6, offer an exceptional strength-to-weight ratio and excellent machinability, making them ideal for applications where weight reduction is paramount, such as in automotive or aerospace components. While inherently softer than steel or titanium, aluminum inserts gain significant surface hardness and corrosion resistance through anodizing. Steel inserts, commonly utilizing 303 or 304 stainless grades, provide superior tensile strength and wear resistance. They are the standard choice for high-load applications, general industrial equipment, and environments requiring robust corrosion resistance without the premium cost of titanium. Titanium alloy Ti-6Al-4V delivers the ultimate in strength-to-weight ratio and exceptional corrosion resistance across extreme temperatures and harsh chemical environments. It is the material of choice for critical aerospace, medical implant, and deep-sea applications where failure is not an option, despite its higher material and machining costs.

The comparative performance characteristics of these key materials are summarized below for rapid engineering reference.

| Material | Tensile Strength (MPa) | Hardness (HV) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | Moderate (Good with Anodizing) | Weight-sensitive assemblies, consumer electronics, automotive interiors |

| Steel 303/304 | 620-700 | 140-160 | High | Industrial machinery, automotive chassis, general hardware |

| Titanium Ti-6Al-4V | 900-950 | 330-360 | Exceptional | Aerospace components, medical implants, marine hardware |

Surface finishing, particularly for aluminum inserts, is non-negotiable for performance. Anodizing creates a hard, wear-resistant oxide layer that prevents galling during screw insertion and significantly enhances corrosion resistance. Type II (Sulfuric Acid) anodizing provides a standard protective and decorative finish. For threaded inserts subjected to severe wear or requiring maximum thread integrity, Type III (Hardcoat) anodizing is essential, producing a much thicker, denser, and harder ceramic-like layer. Our controlled anodizing processes at Wuxi Lead are meticulously calibrated to ensure uniform coating thickness without compromising critical thread dimensions or causing hydrogen embrittlement risks associated with some steel plating processes.

Material selection must be driven by the specific mechanical loads, environmental exposure, weight constraints, and lifecycle cost analysis of the end product. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and material science knowledge to guide clients toward the optimal insert solution, ensuring seamless integration into the injection molding process and reliable performance in the final assembly. Consult our engineering team to match your application demands with the precise material and finish specification.

Manufacturing Process & QC

Design Phase: Precision Engineering for Threaded Insert Integrity

At Wuxi Lead Precision Machinery, the production of injection molding threaded inserts begins with a rigorous design phase grounded in engineering precision and application-specific requirements. Our design engineers collaborate closely with clients to analyze load conditions, material compatibility, thermal cycling, and mating component geometry. Utilizing advanced CAD/CAM software, we model inserts to ensure optimal thread strength, wall thickness, and undercuts that facilitate secure anchoring within plastic substrates. Finite element analysis (FEA) is applied to simulate stress distribution and deformation under operational loads, minimizing the risk of thread stripping or insert pull-out. Every design is validated against international standards such as ISO 9001 and customer-specific quality benchmarks, ensuring compliance from the outset. Design for manufacturability (DFM) principles are embedded early to eliminate potential production flaws and reduce cycle time.

Prototyping: Functional Validation Before Scale-Up

Once the digital model is finalized, we proceed to low-volume prototyping using CNC machining and precision stamping techniques. This stage is critical for physical validation of form, fit, and function. Prototypes are subjected to a battery of tests including torque testing, pull-out force measurement, thermal aging, and dimensional inspection via coordinate measuring machines (CMM). We employ rapid iteration cycles—typically 3–5 prototype rounds—based on client feedback and test data to refine geometry and surface finish. All prototype data is documented and reviewed in cross-functional quality gates before approval for mass production. This phase ensures that design intent translates seamlessly into real-world performance, significantly reducing the risk of defects in final production.

Mass Production: Zero-Defect Manufacturing Execution

With prototype approval, production transitions to high-speed, automated manufacturing lines equipped with real-time monitoring systems. Our facility utilizes multi-slide stamping, cold forming, and CNC turning processes tailored to the insert’s geometry and material—commonly brass, stainless steel, or aluminum alloys. Each production batch is governed by Statistical Process Control (SPC), with in-line sensors detecting deviations in diameter, thread pitch, and insertion depth. 100% automated optical inspection (AOI) systems scan every insert for surface defects, ensuring zero non-conformities. Environmental controls maintain stable conditions for dimensional accuracy, while lot traceability is enforced through barcode tracking from raw material to final packaging. Final quality assurance includes destructive sampling per AQL 1.0 and certification of material test reports (MTRs).

Key Production Specifications

| Parameter | Specification Range |

|---|---|

| Insert Diameter | 2 mm – 25 mm |

| Thread Type | M, UNC, UNF, NPT, custom profiles |

| Material Options | Brass (C3604), SS304/316, Aluminum 6061 |

| Tolerance (±) | 0.02 mm (critical dimensions) |

| Surface Finish | Plain, Zinc Plated, Ni-Plated, PTFE Coated |

| Production Capacity | Up to 5 million units/month |

| Quality Standard | ISO 9001:2015, IATF 16949 (automotive) |

| Lead Time (Mass Production) | 15–25 days after sample approval |

This end-to-end process ensures that every threaded insert delivered by Wuxi Lead meets the highest standards of reliability, consistency, and performance in demanding injection molding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Threaded Insert Performance

Achieving flawless integration of threaded inserts within injection molded components demands more than standard manufacturing—it requires precision engineering, material science expertise, and rigorous process control. At Wuxi Lead Precision Machinery, we specialize in transforming this critical challenge into a competitive advantage for global OEMs and tiered suppliers. Our vertically integrated facility in Wuxi, China, operates under ISO 9001:2015 and IATF 16949 standards, ensuring every threaded insert meets aerospace, medical, and automotive durability requirements. We eliminate the risk of stripped threads, pull-out failures, or dimensional drift through proprietary ultrasonic insertion techniques and real-time cavity pressure monitoring during molding. This precision reduces scrap rates by up to 37% compared to conventional methods while extending tool life through optimized thermal management.

Our engineering team collaborates directly with your design staff during DFM analysis to select optimal insert geometries, materials, and placement strategies. Whether you require heat-staked brass inserts for high-torque applications or corrosion-resistant stainless steel variants for medical devices, we validate performance through ASTM F606 tensile testing and ISO 18265 thread engagement analysis. This proactive approach prevents costly redesigns and accelerates time-to-market without compromising structural integrity.

The following table details our core technical capabilities for injection molding threaded inserts:

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Material Options | Brass C36000, Stainless Steel 303/316, Aluminum 6061, Custom Alloys | ASTM B16, AMS 4640 |

| Thread Types | UNC, UNF, Metric, NPT, Custom Profiles | ISO 68-1, ASME B1.1 |

| Tolerance Range | ±0.025 mm (critical dimensions) | ISO 2768-mK, GD&T |

| Insertion Methods | Ultrasonic, Thermal, Mold-In | In-house validated protocols |

| Surface Treatments | Passivation, Anodizing, PTFE Coating | ASTM A967, MIL-A-8625 |

| Lead Time | 15-25 days (prototype to production) | JIT delivery support |

Choosing Wuxi Lead Precision Machinery means partnering with a manufacturer that owns its entire production ecosystem. We control every variable—from raw material sourcing through CNC turning, threading, and final assembly—within a single climate-controlled facility. This eliminates third-party quality variances and ensures batch-to-batch consistency your end products demand. Our engineers utilize Siemens NX simulation software to model insert behavior under thermal cycling and mechanical stress, providing you with data-driven validation before tooling commences.

Do not let substandard threaded inserts compromise your product’s reliability or brand reputation. Contact our engineering team today to discuss your specific application requirements. We will provide a detailed DFM report and competitive quotation within 48 hours of receiving your specifications. Schedule a no-obligation consultation by emailing [email protected]. Let Lead Precision become your strategic partner in achieving injection molding excellence—where precision isn’t promised, it’s proven.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.