Technical Contents

Engineering Guide: Fabrication Service

Engineering Insight Precision as the Non-Negotiable Core of Sheet Metal Fabrication

In high-stakes industrial manufacturing, precision within sheet metal fabrication transcends mere specification adherence; it is the absolute foundation of product integrity, performance, and longevity. Tolerances measured in hundredths of a millimeter directly dictate assembly success, structural reliability, functional efficacy, and ultimately, the safety and reputation of the end product. Compromised dimensional accuracy leads to cascading failures: misaligned components causing vibration and wear, compromised seals leading to system leaks, or structural weaknesses inviting catastrophic failure under load. For sectors like aerospace, defense, medical technology, and advanced energy, where Wuxi Lead Precision Machinery operates, the cost of imprecision is not merely financial waste but potential operational hazard and project derailment. Achieving true precision demands an integrated ecosystem far beyond advanced machinery alone.

It requires a deeply ingrained engineering culture prioritizing process control at every stage. This encompasses rigorous material certification and handling protocols to prevent warpage, sophisticated CAD/CAM programming optimizing toolpaths and minimizing thermal distortion, real-time in-process metrology for immediate correction, and stringent final inspection against 3D models using coordinate measuring machines (CMMs). Environmental controls within the manufacturing facility are equally critical, mitigating thermal expansion effects on both workpieces and measurement equipment. At Wuxi Lead Precision Machinery, this holistic approach is non-negotiable. Our facility operates under ISO 9001 and AS9100 standards, implementing statistical process control (SPC) to monitor critical parameters continuously, ensuring every bend, cut, and weld meets the exacting demands of our clients.

Our commitment to precision is validated through mission-critical projects. We provided complex, vibration-resistant structural components for timing systems at the Beijing Winter Olympics, where nanosecond accuracy was paramount. Similarly, we manufacture precision housings and chassis for advanced military communication and sensing equipment, where environmental resilience and exact dimensional conformity are essential for operational readiness in extreme conditions. These projects demanded tolerances and material properties exceeding standard industry norms, proving our capability where failure is not an option.

This relentless focus translates directly into client value: reduced assembly time and scrap rates, enhanced product performance and lifespan, and absolute confidence in supply chain reliability. Partnering with a fabricator possessing this depth of precision engineering expertise mitigates risk and accelerates time-to-market for sophisticated products.

Material Tolerance Capabilities at Wuxi Lead Precision Machinery

| Process | Typical Tolerance Range | Maximum Material Thickness | Key Equipment Examples | Secondary Processes Supported |

|---|---|---|---|---|

| Fiber Laser Cutting | ±0.02 mm to ±0.05 mm | Up to 25 mm (Steel) | Amada TruLaser 3030, Bystronic | Deburring, Marking |

| CNC Turret Punching | ±0.05 mm to ±0.10 mm | Up to 6.0 mm | Amada EM2510, TRUMPF TruPunch | Forming, Coining |

| CNC Press Brake Forming | ±0.1° to ±0.25° angle | Up to 12 mm | Amada HG-1003, TRUMPF TruBend | Hemming, Seaming |

| Robotic Welding | ±0.2 mm positional | Up to 10 mm | FANUC, KUKA systems | MIG, TIG, Spot Welding |

Precision sheet metal fabrication is an engineering discipline, not just a production step. Wuxi Lead Precision Machinery delivers the certified accuracy, process rigor, and proven project execution required for the most demanding global applications.

Precision Specs & Tolerances

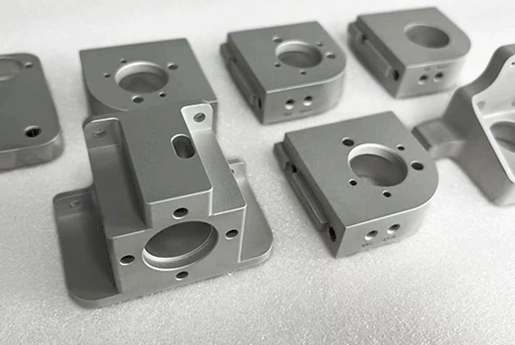

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication services engineered for high-precision industrial applications. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling complex geometries, tight tolerances, and superior surface finishes across a broad range of materials. These multi-axis systems allow simultaneous cutting from five different directions, minimizing setup changes and ensuring exceptional part accuracy. This level of machining flexibility is essential for producing intricate components used in aerospace, medical devices, automation, and high-end industrial equipment.

Our facility integrates 5-axis CNC technology with precision sheet metal processing including laser cutting, CNC punching, bending, and welding. This comprehensive approach ensures seamless transition from raw material to finished component, maintaining dimensional consistency throughout the fabrication process. Advanced programming and toolpath optimization software further enhance machining efficiency while reducing cycle times and material waste. All operations are conducted under strict environmental controls to maintain machine stability and repeatability.

Quality assurance is embedded into every stage of production. We utilize a calibrated Coordinate Measuring Machine (CMM) for first-article inspection and in-process quality verification. The CMM system provides full 3D measurement validation, ensuring compliance with engineering drawings and international standards such as ISO 2768 and ASME Y14.5. Our quality technicians are trained to interpret geometric dimensioning and tolerancing (GD&T), enabling precise verification of form, orientation, and location tolerances. All inspection reports are documented and archived for full traceability, supporting compliance with ISO 9001 quality management systems.

We maintain rigorous material control protocols, sourcing certified alloys and maintaining mill test certificates for traceability. Our production floor is organized to prevent cross-contamination and ensure clean handling of materials such as stainless steel, aluminum, carbon steel, and specialty alloys. In addition to CMM inspection, we employ surface roughness testers, micrometers, and optical comparators to validate critical features.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.025 mm |

| Linear Dimensional Tolerance | ±0.05 mm |

| Angular Tolerance | ±0.1° |

| Surface Roughness (Ra) | As low as 0.8 µm |

| Minimum Hole Diameter | 0.5 mm |

| Maximum Work Envelope (5-axis) | 800 x 600 x 500 mm |

| Material Thickness Range (Sheet Metal) | 0.5 – 12 mm |

| Repeatability (CMM Verified) | ±0.005 mm over 10 consecutive runs |

Our technical capabilities are designed to meet the demanding requirements of global OEMs and engineering firms. By combining 5-axis CNC precision with disciplined quality control and process traceability, Wuxi Lead Precision Machinery ensures consistent delivery of high-integrity fabricated components.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting optimal materials is foundational to achieving performance, durability, and cost efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and geometric complexity. Below we detail critical considerations for aluminum, steel, and titanium, alongside anodizing as a premier finish solution for aluminum components.

Aluminum alloys dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio and corrosion resistance. Grade 6061-T6 offers superior weldability and machinability for structural frames, while 5052-H32 excels in marine applications requiring high fatigue resistance. Aluminum’s low density reduces assembly weight without compromising rigidity, though its lower hardness necessitates careful toolpath planning during CNC bending to prevent micro-cracking.

Carbon steel remains indispensable for high-strength structural applications like industrial machinery frames and enclosures. ASTM A36 provides economical formability for non-critical parts, whereas cold-rolled 1008/1010 steel delivers tighter thickness tolerances (±0.05mm) for precision brackets. We emphasize that steel’s susceptibility to oxidation mandates post-fabrication finishing—such as powder coating or galvanization—to ensure longevity in humid or outdoor environments.

Titanium alloys (Grade 2, Grade 5) are reserved for extreme-condition applications including medical implants and aerospace hydraulic systems. Their unparalleled corrosion resistance in saline/chemical environments and biocompatibility justify higher costs, though titanium’s low thermal conductivity complicates laser cutting and requires specialized tooling to avoid work hardening. Fabrication demands stringent contamination control to prevent embrittlement.

Anodizing is the definitive surface treatment for aluminum, transforming the outer layer into a durable, non-conductive oxide. Type II (sulfuric acid) anodizing at 15–25µm thickness enhances wear resistance for consumer electronics housings, while Type III (hardcoat) at 50+µm suits hydraulic piston rods enduring abrasive contact. Critical to precision outcomes, our process maintains dimensional stability within ±0.0002″ tolerance—ensuring anodized parts meet tight assembly specifications without post-treatment rework.

Material Specifications Comparison

| Material | Common Grades | Thickness Range (mm) | Key Applications | Critical Fabrication Note |

|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 0.5 – 6.0 | Enclosures, brackets, heat sinks | Optimal bend radius = 1.5x material thickness |

| Carbon Steel | A36, 1008/1010 CR | 0.8 – 12.0 | Structural frames, chassis | Requires post-process corrosion protection |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 0.5 – 4.0 | Medical, aerospace components | Laser power must be reduced by 30% vs. steel |

Material choice directly impacts manufacturability, lifecycle cost, and end-product reliability. Wuxi Lead Precision Machinery leverages metallurgical expertise and ISO 9001-certified processes to guide your selection—ensuring your design intent transitions flawlessly from CAD model to certified component. Consult our engineering team to validate material suitability against your performance criteria and volume requirements.

Manufacturing Process & QC

Sheet Metal Fabrication Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, repeatability, and uncompromising quality. We follow a disciplined workflow that spans design validation, prototyping, and full-scale production—each phase integrated to ensure zero defects and seamless scalability for high-volume manufacturing.

The process begins with design analysis and DFM (Design for Manufacturability) optimization. Our engineering team collaborates closely with clients to review CAD models, assess material suitability, and identify potential manufacturability issues before production begins. This proactive approach minimizes rework, reduces lead times, and ensures that every design is optimized for precision fabrication. We support formats including STEP, DXF, and SolidWorks, enabling rapid integration into our production planning systems.

Once the design is finalized, we proceed to prototype development. Prototyping is a critical phase for validating form, fit, and function. Using advanced CNC punching, laser cutting, and bending equipment, we produce functional prototypes that mirror final production quality. Each prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and first-article inspection reports (FAIR) are provided upon request. This ensures that design intent is fully realized and any adjustments are implemented before scaling to mass production.

With prototype approval, we transition to high-efficiency mass production. Our automated production lines leverage state-of-the-art Amada and Trumpf machinery for consistent accuracy across thousands of parts. Processes including laser cutting, CNC punching, press braking, welding, and surface finishing are monitored in real time using SPC (Statistical Process Control) methodologies. Each stage is traceable, with batch records maintained for full production transparency.

Our commitment to zero defects is enforced through a multi-tiered quality assurance system. In-process inspections, final QA audits, and 100% visual checks are standard. Non-conforming parts are immediately quarantined, and root cause analysis is conducted to prevent recurrence. This closed-loop quality process ensures every component meets or exceeds international standards.

The table below outlines key capabilities and tolerances across our fabrication workflow:

| Process | Material Thickness Range | Tolerance (Typical) | Max Part Size | Key Equipment |

|---|---|---|---|---|

| Laser Cutting | 0.5 – 25 mm | ±0.1 mm | 3000 x 1500 mm | Trumpf TruLaser 3030 |

| CNC Punching | 0.8 – 6.0 mm | ±0.15 mm | 2500 x 1250 mm | Amada EMK 3610 |

| Press Brake Bending | 0.5 – 12 mm | ±0.2° / ±0.1 mm | 4000 mm length | Amada HG-1003 1000T |

| MIG/TIG Welding | 0.8 – 20 mm | Per ISO 13920 | Custom assemblies | Lincoln Electric Systems |

| Surface Finishing | All fabricated parts | Per customer spec | Up to 4000 mm | Powder coat, anodizing, plating |

From initial concept to final shipment, Wuxi Lead Precision Machinery delivers end-to-end control over the fabrication process—ensuring reliability, precision, and zero-defect performance for every client.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Sheet Metal Excellence

Selecting a sheet metal fabrication partner demands more than component production; it requires a strategic collaborator invested in your product’s success from prototype to volume delivery. At Wuxi Lead Precision Machinery, we engineer partnerships built on precision, reliability, and deep technical collaboration. Our ISO 9001-certified facility in Wuxi integrates German-engineered machinery with rigorous process control, ensuring every bracket, enclosure, and chassis meets exacting aerospace, medical, and industrial automation standards. We eliminate supply chain volatility through vertical integration—laser cutting, CNC bending, welding, and finishing occur under one roof, with full traceability from raw material to shipment. This cohesion reduces lead times by 30% versus fragmented supplier models while guaranteeing dimensional consistency critical for complex assemblies.

Our technical capabilities are engineered for mission-critical applications. The table below outlines core sheet metal specifications achievable across stainless steel, aluminum, and specialty alloys:

| Material Thickness | Primary Process | Typical Tolerance | Max Part Size |

|---|---|---|---|

| 0.5–6.0 mm | Fiber Laser Cutting | ±0.1 mm | 3000 x 1500 mm |

| 0.8–4.0 mm | CNC Press Brake | ±0.05° angle / ±0.1 mm | 3000 x 1500 mm |

| 1.0–3.0 mm | Robotic TIG Welding | ±0.2 mm gap | Custom per drawing |

| All Thicknesses | Precision Deburring & Finishing | Ra ≤ 0.8 µm | N/A |

Beyond specifications, we deliver engineering partnership. Our team engages early in your design phase, providing DFM feedback to optimize manufacturability without compromising performance. We identify material savings, simplify assembly sequences, and preempt production bottlenecks—turning blueprints into field-ready components. For regulated industries, our documentation package includes full material certifications, first-article inspection reports (FAIR), and PPAP Level 3 support, ensuring compliance from day one.

Wuxi Lead Precision Machinery operates as your extension, not just a vendor. With 15+ years serving global Tier 1 manufacturers, we understand that precision sheet metal is the backbone of product integrity. When tolerances are non-negotiable and deadlines are immovable, our facility becomes your competitive advantage.

Contact Us to Engineer Your Next Success

Initiate a technical consultation with our engineering team to discuss your project’s unique demands. Email [email protected] with your CAD files or specifications for a rapid feasibility assessment and precision-focused quotation. Let us demonstrate how strategic partnership in sheet metal fabrication drives your innovation forward—on time, to spec, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.