Technical Contents

Engineering Guide: Us Range Parts

Engineering Insight: The Critical Role of Precision in US Range Parts Manufacturing

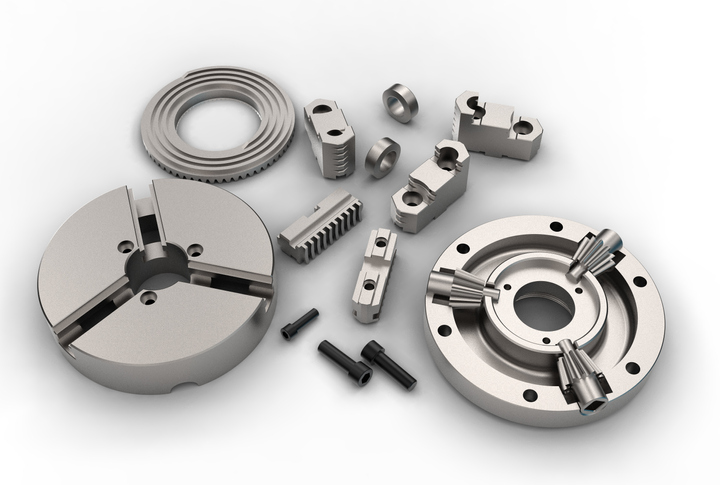

In the field of custom metal manufacturing, particularly for components designated under the US range parts specification, precision is not merely a performance metric—it is a foundational requirement. These parts, often engineered for integration into high-stakes mechanical systems such as aerospace actuators, defense-grade instrumentation, and advanced medical devices, demand tolerances that operate at the threshold of modern machining capability. At Wuxi Lead Precision Machinery, we understand that even a deviation of a few microns can compromise system integrity, leading to cascading failures in operational environments where reliability is non-negotiable.

Our experience in delivering precision-engineered US range parts stems from over a decade of collaboration with Tier-1 suppliers serving Olympic-standard equipment manufacturers and military defense contractors. These partnerships have instilled in our engineering team a rigorous approach to quality, traceability, and repeatability. Whether producing high-complexity housings for inertial navigation systems or miniature valve components for life-support equipment, our processes are calibrated to meet or exceed AS9100 and MIL-STD-810 standards.

The manufacturing of US range parts begins with material selection—typically aerospace-grade aluminum alloys, titanium, or corrosion-resistant stainless steels—followed by multi-axis CNC milling, turning, and grinding operations executed under controlled environmental conditions. Our facility employs real-time in-process metrology, including laser probing and coordinate measuring machines (CMM), ensuring dimensional accuracy throughout production runs. Surface finish, geometric tolerancing, and thermal stability are continuously monitored to maintain compliance with stringent technical drawings and inspection criteria.

Beyond equipment and process control, precision is sustained through engineering foresight. We engage in Design for Manufacturability (DFM) reviews at the outset, identifying potential stress points, assembly conflicts, or tolerance stack-ups before a single chip is removed. This proactive approach minimizes rework, accelerates time-to-market, and ensures that every component performs as intended in its final application.

Wuxi Lead Precision Machinery’s track record in high-reliability sectors underscores our capability to deliver US range parts that meet the most exacting expectations. From concept validation to batch production, our commitment is to precision as a standard, not an exception.

Typical Specifications for US Range Parts at Wuxi Lead Precision Machinery

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.001 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Material Options | 7075-T6, 6061-T6, 316L, Ti-6Al-4V | Custom alloys on request |

| Max Part Size (L×W×H) | 600 mm × 400 mm × 350 mm | Up to 800 mm with fixturing |

| Geometric Tolerance (GD&T) | Per ASME Y14.5 | Full inspection report |

| Production Volume | 1–5,000 units/month | Scalable with automation |

| Quality Certification | ISO 9001, IATF 16949 | AS9100, MIL-STD available |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers exceptional custom metal manufacturing solutions through advanced 5-axis CNC machining and rigorous quality control. Our core strength lies in producing intricate, high-integrity components for demanding sectors including aerospace, medical devices, and energy. The strategic deployment of state-of-the-art 5-axis CNC machining centers forms the foundation of our capability. These machines enable simultaneous multi-axis interpolation, allowing us to machine complex geometries—including deep cavities, undercuts, and organic contours—in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly enhancing part accuracy, surface finish, and overall structural integrity. The result is reduced lead times, minimized scrap rates, and the ability to meet the most sophisticated design requirements that challenge conventional 3-axis processes. We programm efficiently using industry-leading CAM software, optimizing toolpaths for material removal rates while ensuring tool life and dimensional stability across diverse production volumes.

Quality assurance is non-negotiable in high-performance applications. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMMs). Our metrology lab utilizes both bridge-type and portable CMM systems, operating under strict environmental controls to ensure measurement repeatability. Inspection routines are meticulously developed from customer CAD models and engineering drawings, covering geometric dimensioning and tolerancing (GD&T), critical form features, and surface specifications. Full first-article inspection reports (FAIRs) and comprehensive production batch certifications are standard deliverables, providing complete traceability and confidence in part conformance. This systematic approach, integrated within our ISO 9001-certified quality management system, ensures consistent output meeting the stringent requirements of regulated industries.

Our commitment to precision is quantifiable through achievable tolerance standards across common engineering materials. The table below reflects typical production capabilities under controlled processes; tighter tolerances are attainable for specific features and materials through specialized process qualification.

| Material Category | Standard Tolerance (mm) | Tight Tolerance Capability (mm) | Key Applications |

|---|---|---|---|

| Aluminum Alloys | ±0.010 | ±0.003 | Aerospace brackets, heat sinks, fluid components |

| Stainless Steel | ±0.012 | ±0.005 | Medical implants, surgical instruments, valve bodies |

| Titanium Alloys | ±0.015 | ±0.008 | Aircraft structural parts, biomedical fixtures |

| Engineering Plastics | ±0.025 | ±0.010 | Insulators, prototypes, non-metallic housings |

This precision, combined with our expertise in managing complex alloys and stringent surface finish requirements, positions Wuxi Lead as a trusted partner for mission-critical components. We translate engineering intent into flawless physical reality, ensuring your parts perform reliably in the most demanding operational environments. Partner with us to leverage manufacturing excellence that directly enhances your product’s performance and market success.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of precision components. At Wuxi Lead Precision Machinery, we specialize in delivering high-precision parts tailored to demanding industrial applications. Our expertise spans aluminum, steel, and titanium—three of the most widely used materials in advanced manufacturing. Each offers distinct mechanical properties, weight characteristics, and environmental resistance, making them suitable for specific use cases across aerospace, automotive, medical, and industrial automation sectors.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications where weight reduction is crucial without sacrificing structural integrity. Common alloys such as 6061-T6 and 7075-T6 are frequently used in drone frames, heat sinks, and lightweight structural components. Due to its high thermal and electrical conductivity, aluminum is also preferred in electronic enclosures and thermal management systems.

Steel, particularly stainless steel grades like 304 and 316, provides superior strength, wear resistance, and longevity. It performs exceptionally well in high-stress environments and maintains integrity under extreme temperatures and corrosive conditions. Stainless steel is widely used in medical instruments, food processing equipment, and industrial machinery where hygiene and durability are paramount. For applications requiring even greater hardness, we offer hardened tool steels processed to precise tolerances.

Titanium stands at the pinnacle of high-performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or acidic environments. Grade 5 (Ti-6Al-4V) is the most commonly used titanium alloy in aerospace and biomedical implants due to its biocompatibility and ability to withstand extreme operational conditions. While more challenging to machine, titanium’s long-term reliability justifies its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing, particularly for aluminum, increases surface hardness and corrosion resistance while allowing for color coding and improved aesthetics. Our Type II and Type III (hard coat) anodizing processes meet international standards, offering thicknesses from 15 to 50 µm depending on application requirements.

The following table summarizes key properties and applications of these materials:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 – 570 | 2.7 | Aerospace, electronics, automotive | Anodizing, bead blasting |

| Stainless Steel | 304, 316, 17-4PH | 505 – 1300 | 7.9 | Medical, food processing, machinery | Passivation, polishing |

| Titanium | Grade 2, Grade 5 | 345 – 1000 | 4.5 | Aerospace, biomedical, marine | Anodizing, sandblasting |

Selecting the optimal material and finish requires a thorough understanding of operational demands. At Wuxi Lead, we work closely with engineers and design teams to ensure every component meets exact functional and regulatory requirements. Our advanced CNC machining capabilities support complex geometries and tight tolerances across all three materials, ensuring consistent quality and performance in every part produced.

Manufacturing Process & QC

Production Process: Zero-Defect Manufacturing for US Range Parts

At Wuxi Lead Precision Machinery, our production process for US Range Parts is engineered for uncompromising quality and repeatability, adhering strictly to a zero-defect philosophy demanded by aerospace, medical, and high-tech industries. This disciplined approach spans three critical, interconnected phases: Design, Prototyping, and Mass Production. Each stage incorporates rigorous validation to eliminate errors before they reach the customer.

The Design Phase begins with deep collaboration. Our engineering team works directly with your specifications, utilizing advanced CAD/CAM software (Siemens NX, Mastercam) to create precise 3D models. Crucially, we conduct comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis. This proactive step identifies potential machining challenges, material constraints, or tolerance stack-up issues early. We validate geometric dimensioning and tolerancing (GD&T) against functional requirements and material properties, ensuring the design is not only optimal but inherently manufacturable to your exacting standards. This collaborative review prevents costly revisions later and establishes the foundation for defect prevention.

Prototyping Validation is where theoretical design meets physical reality. Using dedicated 5-axis CNC machining centers, we produce functional prototypes from your specified material. This is not merely a form check; it is a full process simulation. Every critical dimension, surface finish, and feature is verified against the CAD model using calibrated Coordinate Measuring Machines (CMM) and optical comparators. We rigorously test assembly fit, functional performance, and material behavior under simulated conditions. Any deviation triggers immediate root cause analysis and design or process adjustment. This phase is mandatory for validating the manufacturability roadmap and securing your approval before committing to production tooling.

Mass Production Execution leverages the validated process under stringent statistical process control (SPC). Our high-precision CNC fleet operates within tightly controlled environmental conditions. Real-time in-process monitoring tracks key parameters like tool wear, vibration, and thermal drift. Every critical dimension undergoes 100% in-process CMM verification at defined checkpoints, not just final inspection. Our proprietary LeadTrack SPC system analyzes data streams continuously, enabling predictive adjustments to maintain capability indices (Cp/Cpk > 1.67) well within your tolerance bands. Material traceability is absolute, from certified mill certificates through every machining stage. Final inspection includes full first-article inspection (FAI) reports per AS9102 and comprehensive batch certification, guaranteeing every US Range Part shipped meets zero-defect criteria.

Key Production Specifications for US Range Parts

| Parameter | Specification | Measurement Standard |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ISO 230-2 |

| Repeatability | ±0.001 mm | ISO 230-2 |

| Surface Finish Ra | As low as 0.2 µm (Ra) | ISO 4287 |

| Tolerance Range | ±0.005 mm standard; ±0.001 mm cap | ISO 2768 / Custom GD&T |

| Material Traceability | Full lot traceability to melt | Certified Mill Certificates |

This integrated process—grounded in proactive design validation, empirical prototyping, and data-driven mass production—ensures Wuxi Lead delivers US Range Parts with the reliability and precision your critical applications require. Our zero-defect commitment is not a goal; it is the measurable outcome of our engineered manufacturing system.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions that drive performance, reliability, and competitive advantage. As a trusted leader in high-precision custom metal manufacturing, we specialize in delivering mission-critical parts for industries where failure is not an option. From aerospace and medical devices to industrial automation and energy systems, our clients rely on us to turn complex designs into flawless reality.

Our US Range parts represent the pinnacle of engineering precision, material integrity, and process consistency. These components are built to meet the most stringent international standards while offering the flexibility to accommodate custom specifications. Whether you require small-batch prototypes or high-volume production runs, our advanced CNC machining centers, multi-axis milling capabilities, and automated inspection systems ensure every part exceeds expectations.

What sets us apart is not just our technology—it’s our partnership model. We work closely with engineering teams from the earliest stages of design to optimize manufacturability, reduce lead times, and control costs without compromising quality. Our engineers provide detailed feedback on DFM (Design for Manufacturability), material selection, and finishing options to ensure your project is not only feasible but optimized for long-term success.

We understand that in high-end manufacturing, every micron matters. That’s why every US Range part undergoes rigorous quality assurance protocols, including CMM inspections, surface roughness testing, and material certification. Our ISO 9001:2015 certification and adherence to AS9100 standards for aerospace components underscore our commitment to operational excellence.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic ally with deep technical expertise, scalable production capacity, and a relentless focus on precision. We are equipped to handle complex geometries, exotic alloys, and tight tolerance requirements that push the limits of conventional machining.

Below are key specifications that define the capabilities of our US Range parts:

| Specification | Detail |

|---|---|

| Material Options | Stainless Steel (303, 304, 316), Aluminum (6061, 7075), Titanium, Brass, Inconel, Tool Steels |

| Tolerance | Up to ±0.005 mm |

| Surface Finish | Ra 0.4 μm standard, down to Ra 0.1 μm with polishing |

| Max Part Size | 800 mm × 600 mm × 500 mm |

| Machining Processes | CNC Milling, CNC Turning, Wire EDM, Grinding, Boring |

| Secondary Operations | Heat Treatment, Anodizing, Passivation, Plating, Laser Marking |

| Quality Standards | ISO 9001:2015, AS9100, RoHS compliant, Full inspection reports provided |

Your next breakthrough component starts with the right manufacturing partner. Contact us today at [email protected] to discuss your project requirements, request a quote, or receive engineering support. Let Wuxi Lead Precision Machinery bring your vision to life—with precision, reliability, and performance built in.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.