Technical Contents

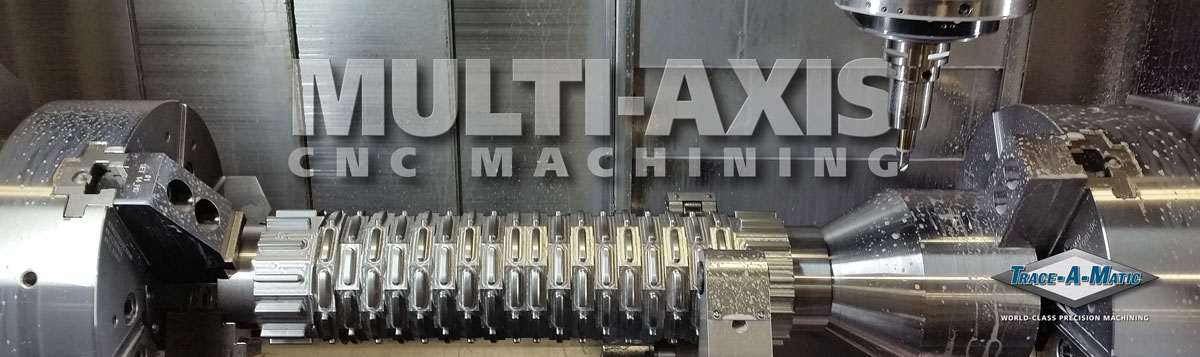

Engineering Guide: Multi Axis Milling

Engineering Insight: The Critical Role of Precision in Multi-Axis Milling

In the realm of advanced CNC machining, multi-axis milling stands as a cornerstone of modern manufacturing, enabling the production of highly complex geometries with unparalleled accuracy. Unlike conventional 3-axis systems, multi-axis milling integrates additional rotational axes—typically 4 or 5—allowing the cutting tool to approach the workpiece from virtually any direction. This capability is not merely a matter of convenience; it is a fundamental requirement for industries where precision, repeatability, and surface integrity are non-negotiable.

At Wuxi Lead Precision Machinery, we recognize that precision in multi-axis milling is not achieved through machinery alone—it is the result of integrated engineering excellence. Our systems are engineered with high-rigidity cast iron bases, advanced linear guideways, and direct-drive rotary tables to minimize deflection and thermal drift. These design elements ensure sub-micron level positioning accuracy and consistent performance across extended production runs. Furthermore, our use of high-resolution encoders and real-time error compensation algorithms allows for continuous adjustment during machining, maintaining tolerances down to ±0.002 mm.

Precision is not just a technical specification—it is a commitment to performance under real-world conditions. This commitment has been rigorously tested through our involvement in mission-critical projects, including components for Olympic-standard sporting equipment and precision subsystems for defense applications. These programs demand not only geometric accuracy but also material integrity, fatigue resistance, and long-term reliability. Our multi-axis platforms have consistently met these challenges, delivering parts that perform flawlessly in high-stress environments.

The complexity of multi-axis operations also necessitates sophisticated control systems and expert programming. At Lead Precision, our engineering team employs advanced CAM software with kinematic simulation to optimize toolpaths, reduce cycle times, and prevent collisions. This digital-first approach ensures that every motion is calculated for maximum efficiency and minimal error, translating directly into higher part quality and reduced scrap rates.

We understand that in sectors such as aerospace, medical device manufacturing, and high-performance automotive, the cost of failure is immense. A single micron of deviation can compromise the functionality of an entire assembly. This is why our multi-axis milling centers are built not only to meet international standards but to exceed them—validated through rigorous in-house testing and third-party certification.

Below is a representative specification table for one of our flagship 5-axis vertical machining centers, reflecting the precision engineering that defines our product line.

| Specification | Value |

|---|---|

| Axis Configuration | 5-Axis (X, Y, Z, A, C) |

| Spindle Speed | 24,000 rpm (HSK-A63) |

| Positioning Accuracy (X/Y/Z) | ±0.002 mm |

| Repeatability (X/Y/Z) | ±0.001 mm |

| Table Size | 600 mm × 600 mm |

| Maximum Workpiece Weight | 800 kg |

| Control System | Fanuc 31i-B5 with 5-axis interpolation |

| Tool Magazine Capacity | 30T (optional up to 60T) |

| Rapid Traverse (X/Y/Z) | 60 / 60 / 50 m/min |

At Wuxi Lead Precision Machinery, our legacy in delivering precision-engineered multi-axis solutions is backed by proven performance in the most demanding applications. We continue to push the boundaries of what is possible, ensuring our clients achieve excellence in every component they produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Multi-Axis Milling at Wuxi Lead

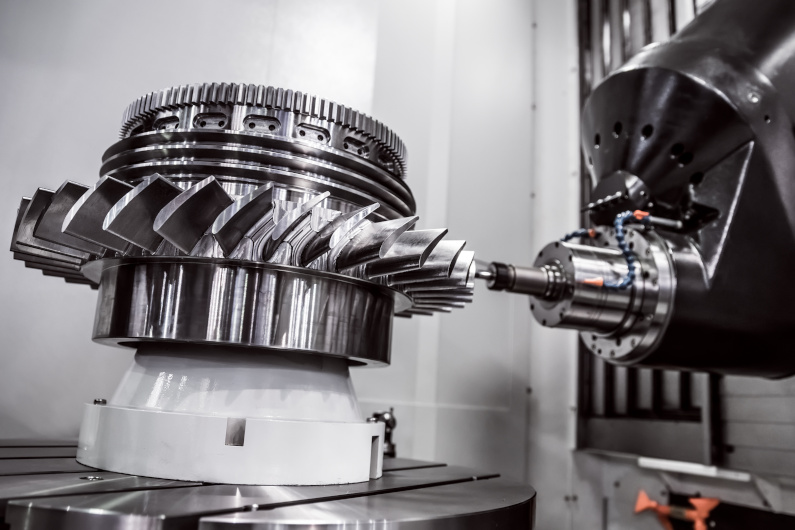

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding multi-axis machining applications. Our core strength lies in advanced 5-axis CNC milling technology, enabling the production of complex geometries with exceptional accuracy and surface finish, directly from solid stock. This capability eliminates secondary operations, reduces fixturing errors, and significantly shortens lead times for intricate components essential to aerospace, medical device, and energy sectors. We operate a modern fleet of high-rigidity 5-axis machining centers from industry leaders including DMG MORI and MAZAK, featuring integrated high-speed spindles, robust rotary tables, and sophisticated thermal compensation systems. These machines provide the dynamic stability and micron-level positioning accuracy required for machining challenging materials like titanium alloys, Inconel, and high-strength aluminum to exacting specifications.

Our technical approach centers on simultaneous 5-axis machining, where all rotary and linear axes move concurrently during cutting. This allows optimal tool engagement, access to deep cavities and undercuts, and the ability to machine complex organic shapes in a single setup. This methodology is critical for achieving the geometric tolerances and surface integrity demanded by turbine blades, orthopedic implants, and fluid manifold systems. Material utilization is maximized, and critical datum relationships are maintained inherently within the machining process, eliminating cumulative errors from multiple setups. Every machine undergoes rigorous daily calibration and preventative maintenance protocols to ensure consistent performance.

Quality assurance is intrinsically linked to our machining capability. Comprehensive inspection is performed using state-of-the-art Coordinate Measuring Machines (CMMs) from Zeiss and Hexagon, programmed to verify complex GD&T callouts and freeform surfaces against the original CAD model. This metrology-driven process ensures dimensional conformance before parts leave our facility. Our quality engineers utilize advanced analysis software to generate detailed inspection reports, providing full traceability and validation of critical features for every production run. This commitment to measurement integrity guarantees that components meet the stringent requirements of safety-critical applications.

The following table details our standard and achievable tolerance capabilities across common material types, reflecting the precision inherent in our multi-axis milling and inspection processes. Specific project requirements often drive us to exceed these standards.

| Feature | Standard Capability | High-Precision Capability | Typical Material Application |

|---|---|---|---|

| Linear Dimension (mm) | ±0.010 | ±0.005 | Aluminum, Steel, Titanium |

| Geometric Tolerance (GD&T) | ±0.015 | ±0.008 | All Critical Components |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Functional & Cosmetic Surfaces |

| Hole Position Accuracy | ±0.012 | ±0.006 | Precision Assemblies |

Wuxi Lead’s integrated capability—combining cutting-edge 5-axis hardware, deep process expertise, and rigorous CMM validation—ensures components are manufactured right the first time. We translate complex engineering designs into physically perfect parts, meeting the highest standards of precision manufacturing for global industries where failure is not an option. Partner with us for zero-defect delivery of your most challenging multi-axis milling requirements.

Material & Finish Options

Material Selection for Multi-Axis Milling in Precision CNC Machining

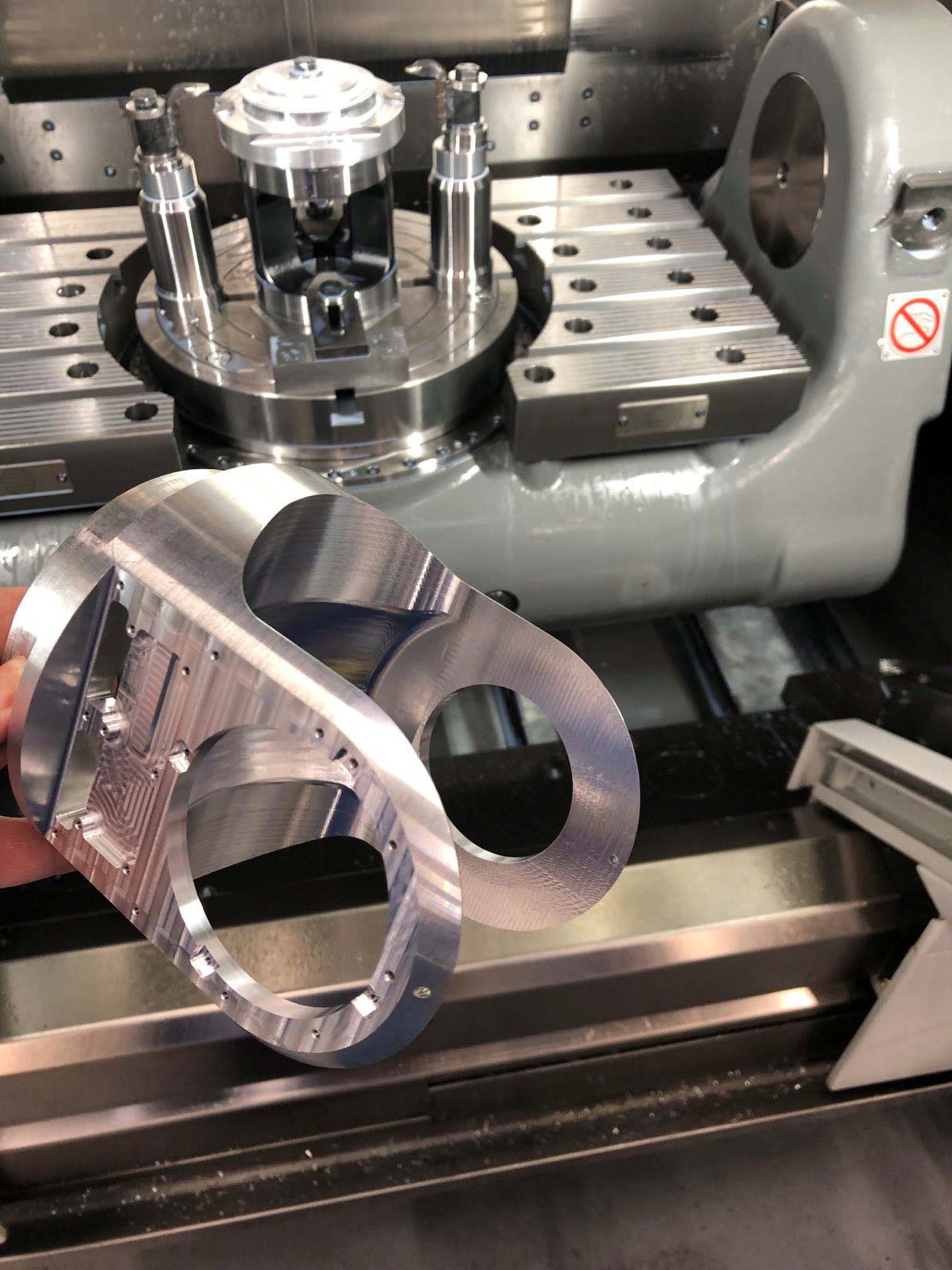

Selecting the appropriate material is critical in multi-axis milling, where complex geometries and tight tolerances demand optimal machinability, strength, and surface finish. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC machining for industries such as aerospace, medical, and automotive, where material performance directly impacts component reliability. Among the most widely used materials in our operations are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum is a preferred choice for lightweight, high-strength components requiring excellent thermal and electrical conductivity. Its low density and favorable strength-to-weight ratio make it ideal for aerospace enclosures, heat sinks, and structural parts. Aluminum alloys such as 6061 and 7075 are particularly well-suited for multi-axis milling due to their excellent machinability and dimensional stability. Post-machining, aluminum components often undergo anodizing to enhance surface hardness, corrosion resistance, and aesthetic quality. Type II (sulfuric acid) and Type III (hardcoat) anodizing are common finishes, with the latter providing superior wear resistance for demanding environments.

Steel, particularly alloy and stainless grades, is selected when high strength, durability, and resistance to wear and temperature are required. Materials like 4140 alloy steel and 304/316 stainless steel are frequently machined using multi-axis systems for applications in tooling, medical instruments, and industrial machinery. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, advanced toolpath strategies and high-torque spindles on our 5-axis platforms ensure precision and efficiency. Post-processing options such as passivation for stainless steel or nitriding for alloy steel further enhance performance characteristics.

Titanium, specifically Grade 5 (Ti-6Al-4V), is used in mission-critical applications where extreme strength-to-density ratios and corrosion resistance are paramount. Common in aerospace and medical implant manufacturing, titanium poses unique challenges in multi-axis milling, including low thermal conductivity and high chemical reactivity, which necessitate specialized cutting tools, reduced feed rates, and rigorous temperature control. Despite these challenges, the precision of our CNC systems ensures consistent results with minimal distortion.

Below is a comparative overview of key material properties relevant to multi-axis machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Excellent | Anodizing, Bead Blast | Aerospace, Enclosures, Heat Sinks |

| Steel 4140 | 655 | 7.85 | Good | Nitriding, Passivation | Tooling, Shafts, Industrial Parts |

| Steel 304 | 505 | 8.0 | Moderate | Electropolishing, Passivation | Medical, Food Processing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Fair | Anodizing, Laser Etching | Aircraft, Implants, Racing Components |

Understanding material behavior under high-speed, multi-directional cutting is essential for maximizing tool life and part accuracy. At Wuxi Lead Precision Machinery, we combine material science expertise with advanced 5-axis CNC technology to deliver components that meet the highest standards of precision and performance.

Manufacturing Process & QC

Multi-Axis Milling Production Process: Achieving Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our multi-axis milling production process is engineered for uncompromising precision and repeatability. We integrate advanced CNC technology with rigorous quality protocols across three critical phases to deliver components meeting aerospace, medical, and energy sector tolerances. This systematic approach ensures Zero Defects are not aspirational but operational reality.

The Design Phase begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team reviews CAD models to optimize toolpaths, minimize setups, and identify potential stress points. Finite Element Analysis (FEA) simulates material behavior under cutting forces, while CAM software validates 5-axis simultaneous interpolation strategies. This preemptive refinement eliminates geometric conflicts and ensures manufacturability before metal is cut, reducing downstream rework risk by up to 70%.

Prototyping transitions virtual designs into physical validation. Using HAAS and DMG MORI 5-axis platforms, we produce initial units under full production parameters. Each prototype undergoes metrology-grade inspection via Zeiss CONTURA CMMs, verifying critical dimensions against GD&T callouts. Surface roughness, dimensional stability, and feature alignment are cross-checked against simulation data. Client feedback is incorporated here, with iterative adjustments made to tooling and feeds/speeds—never to the design intent. This phase confirms process capability (CpK ≥ 1.67) before committing to volume.

Mass Production executes with embedded quality controls. Our smart factory environment utilizes in-process probing for real-time tool wear compensation and thermal drift correction. Every 10th part undergoes automated optical inspection, while Statistical Process Control (SPC) monitors key characteristics like bore concentricity and profile tolerances. Final inspection includes 100% first-article reporting and batch-level material certification. Traceability is maintained via laser-etched part IDs linked to machine logs, coolant analysis, and operator records—ensuring full auditability for critical applications.

Our multi-axis capabilities are defined by machine specifications engineered for zero-defect output:

| Parameter | Specification | Application Impact |

|---|---|---|

| Axis Configuration | 5-axis simultaneous | Eliminates secondary setups for complex geometries |

| Positioning Accuracy | ±0.002 mm | Ensures micron-level repeatability |

| Surface Finish | Ra 0.4 µm (typical) | Meets stringent aerospace sealing requirements |

| Max Work Envelope | 1,200 x 800 x 750 mm | Accommodates large structural components |

| In-Process Metrology | On-machine probing | Corrects thermal drift without manual intervention |

Zero Defects is sustained through this closed-loop methodology: design validation prevents errors, prototyping proves process robustness, and production leverages automation for consistency. At Wuxi Lead, we do not inspect quality in—we engineer it into every phase. This is how we deliver mission-critical components where failure is not an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Multi-Axis Milling Solutions

At Wuxi Lead Precision Machinery, we understand that in high-end manufacturing, precision, efficiency, and reliability are not just goals—they are requirements. As global industries push the boundaries of complexity in aerospace, medical device production, energy systems, and advanced automotive engineering, the demand for superior multi-axis milling capabilities has never been greater. That’s where we come in.

Lead Precision is a trusted name in CNC machining, specializing in high-precision multi-axis milling technologies that deliver unmatched accuracy, surface finish, and throughput. Our engineering team combines decades of experience with cutting-edge equipment to support clients in transforming complex designs into high-integrity components. Whether you are producing turbine blades, orthopedic implants, or intricate mold tooling, our solutions are engineered to meet the most stringent specifications.

When you partner with Lead Precision, you gain more than a supplier—you gain a strategic collaborator. We offer end-to-end support from initial design consultation and process optimization to full-scale production and quality assurance. Our facility in Wuxi, China, operates under strict ISO 9001 standards, ensuring every component meets international quality benchmarks. With advanced 5-axis CNC machines, high-speed spindles, and real-time in-process inspection systems, we maintain tolerances down to ±0.002 mm, even on the most geometrically complex parts.

Our commitment to innovation is reflected in our continuous investment in automation, tooling technology, and skilled personnel. We specialize in hard milling, deep cavity machining, and thin-wall component fabrication—applications where stability and precision are non-negotiable. By leveraging adaptive toolpaths, high-dynamic machining strategies, and rigorous thermal compensation, we minimize cycle times while maximizing part consistency.

Below are the core specifications of our multi-axis milling capabilities:

| Specification | Detail |

|---|---|

| Axis Configuration | 4-axis and 5-axis simultaneous milling |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, tool steels, engineering plastics |

| Surface Finish | As low as Ra 0.2 µm |

| CNC Control Systems | Siemens, Heidenhain, Fanuc |

We serve OEMs and Tier-1 suppliers worldwide, providing scalable production solutions that adapt to your volume and quality needs. Our team speaks your language—technically and commercially—ensuring seamless collaboration across time zones and industries.

For manufacturers seeking a competitive edge through precision engineering, the next step is clear. Contact us today to discuss your multi-axis milling requirements. Let Lead Precision become your trusted partner in advanced manufacturing.

Email us at [email protected] to start the conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.