Technical Contents

Engineering Guide: Design Molds

Engineering Insight: Precision as the Foundation of Mold Design

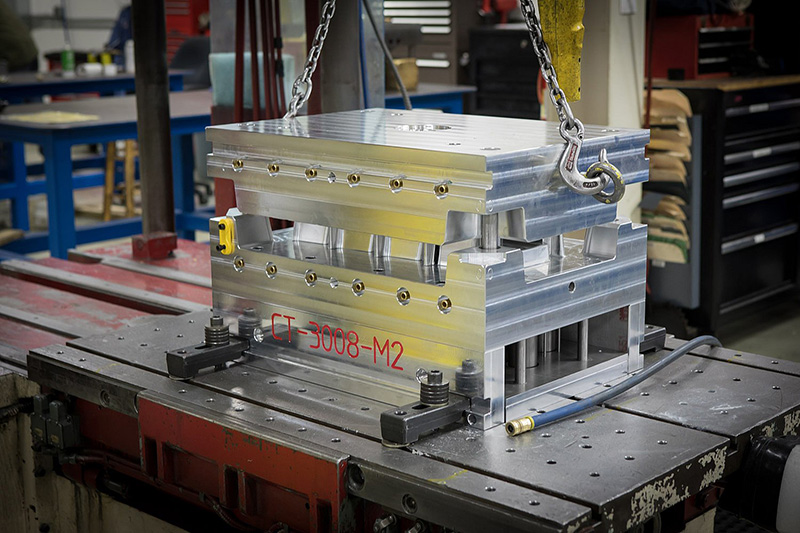

In custom metal manufacturing, mold design transcends mere geometry—it is the critical determinant of part integrity, production efficiency, and long-term cost control. Sub-micron tolerances are not theoretical ideals; they directly govern material flow, thermal distribution, and structural consistency during high-pressure forming. A deviation of 0.005mm in cavity alignment can propagate into warpage, flash, or dimensional drift across thousands of cycles, rendering entire production runs non-compliant for aerospace or medical applications. At Wuxi Lead Precision Machinery, we treat mold precision as non-negotiable engineering physics, not incremental refinement. Our approach integrates finite element analysis (FEA) with real-world thermal validation to preempt stress concentrations and wear patterns before steel is cut.

The cost of imprecise mold design extends far beyond scrap rates. Inefficient cooling channels increase cycle times by 15–30%, while poor venting induces porosity that compromises fatigue resistance in load-bearing components. For clients in defense or elite sports—where we engineered molds for Olympic bobsled track components and military-grade hydraulic housings—such flaws are mission-critical failures. These projects demanded tolerances held to ±0.002mm under 1500-ton clamping forces, validated through 500+ hour stress simulations. Our experience proves that precision mold design is the ultimate cost-saver: optimizing tool life, reducing secondary operations, and ensuring first-article compliance for zero-defect supply chains.

Wuxi Lead Precision Machinery leverages 18 years of Tier-1 manufacturing rigor to transform design intent into production reality. Our in-house metrology lab, certified to ISO 17025, validates every mold against AS9100 and MIL-STD-883 standards. Below are core specifications achievable through our integrated design-to-manufacturing workflow.

| Parameter | Specification | Application Impact |

|---|---|---|

| Geometric Tolerance | ±0.001mm to ±0.005mm | Ensures fit/function in multi-part assemblies |

| Surface Finish (Cavity) | Ra 0.05µm to Ra 0.2µm | Eliminates post-machining for optical/aerospace parts |

| Thermal Uniformity | ΔT ≤ 2°C across cavity | Prevents sink marks in thick-walled structural components |

| Tool Steel Hardness | 52–58 HRC (pre-hardened) | Extends mold life beyond 500,000 cycles in aluminum die-casting |

| Cooling Channel Accuracy | ±0.01mm positional | Reduces cycle time by 22% versus industry average |

Precision mold design is where engineering ambition meets manufacturing reality. At Wuxi Lead, we do not merely meet specifications—we engineer molds that become force multipliers for your production system. When your application demands zero-compromise performance, from satellite components to next-generation EV powertrains, our Olympic-proven methodology ensures your design intent is flawlessly replicated at scale. Demand molds built for physics, not just paperwork. Partner with precision.

Precision Specs & Tolerances

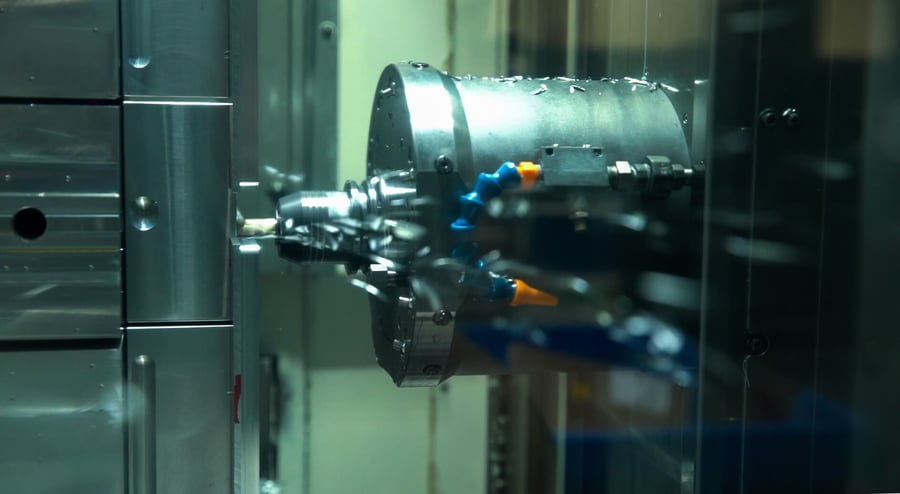

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance mold design and production. Our technical capabilities are engineered to meet the stringent demands of industries such as automotive, aerospace, medical, and consumer electronics, where precision, repeatability, and material integrity are critical. At the core of our machining operations is a fleet of state-of-the-art 5-axis CNC machining centers, enabling complex geometries, tight tolerances, and superior surface finishes on a wide range of mold components.

Our 5-axis CNC systems provide simultaneous multi-directional cutting, allowing for the efficient production of intricate mold cavities, cores, and inserts with minimal setup changes. This capability significantly reduces lead times while enhancing dimensional accuracy and part consistency. Whether working with hardened steels, aluminum alloys, or specialty tool steels, our machines maintain stability and precision across extended production runs. Advanced toolpath strategies and high-speed machining techniques ensure optimal material removal rates without compromising surface quality—essential for molds requiring fine textures or optical finishes.

Quality control is integrated at every stage of the manufacturing process. All critical components undergo comprehensive inspection using our Coordinate Measuring Machine (CMM) system, which provides full 3D metrology validation. This allows us to verify geometric dimensions, positional tolerances, and surface profiles with micron-level accuracy. Data from CMM reports are traceable and provided with each shipment, ensuring full transparency and compliance with international quality standards such as ISO 9001.

To support precision mold design, we maintain strict control over dimensional tolerances across all production phases. The table below outlines our standard and achievable tolerance ranges, reflecting our commitment to delivering components that meet or exceed customer specifications.

| Feature | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | For features up to 300 mm |

| Hole Diameter | +0.015 / -0.005 mm | +0.010 / -0.005 mm | Reamed or precision bored |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Measured via CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | As machined; polishable to <0.1 µm |

| Angular Tolerance | ±0.05° | ±0.02° | Between features |

Our technical team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize mold geometry, material selection, and machining strategy. This proactive approach minimizes risk, improves tool life, and ensures seamless integration into the customer’s production environment. With advanced equipment, rigorous quality assurance, and deep expertise in mold-making, Wuxi Lead Precision Machinery stands as a trusted partner for high-end custom metal manufacturing in global industrial markets.

Material & Finish Options

Material Selection for High-Performance Mold Manufacturing

Selecting the optimal material for mold construction is critical to balancing performance, longevity, and cost efficiency in precision manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your production volume, part complexity, and surface finish requirements. Aluminum excels in rapid prototyping and low-volume runs due to its exceptional machinability and thermal conductivity, enabling faster cycle times. However, its lower hardness limits durability for high-volume production. Steel remains the industry standard for high-cavitation molds, offering superior wear resistance and structural stability under prolonged thermal cycling. Titanium, while less common due to cost and machining complexity, provides unmatched strength-to-weight ratio and corrosion resistance for specialized aerospace or medical applications where weight reduction is paramount.

The following table summarizes key material specifications for mold applications:

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Cost Factor | Best For Applications |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | Low | Prototypes, low-volume runs |

| P20 Tool Steel | 280–320 | 28 | Medium | Medium/high-volume production |

| H13 Steel | 200–250 | 27 | High | High-heat, high-wear cavities |

| Titanium Gr5 | 330 | 7.2 | Very High | Weight-sensitive inserts |

Surface finish selection directly impacts part release, aesthetic quality, and mold maintenance intervals. Anodizing is a premier electrochemical process for aluminum molds, enhancing surface hardness and corrosion resistance while enabling precise color coding. Type II (sulfuric acid) anodizing yields functional coatings of 5–25μm thickness, suitable for general-purpose molds requiring moderate wear resistance. For demanding applications, Type III (hard coat) anodizing achieves 25–50μm coatings with surface hardness exceeding 60 HRC, drastically extending mold life in abrasive polymer environments. Crucially, anodizing must be applied post-machining and polishing to preserve dimensional accuracy; improper sealing can lead to premature coating failure in humid conditions.

Wuxi Lead Precision Machinery leverages decades of CNC expertise to match material and finish specifications to your exact production demands. We conduct rigorous thermal and stress simulations during the design phase to prevent premature wear or deformation. Contact our engineering team to discuss how material science integration can optimize your mold’s total lifecycle cost without compromising precision.

Senior CNC Engineer & Sales Director, Wuxi Lead Precision Machinery

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, repeatability, and zero-defect performance. We specialize in high-end mold design and production, serving global industries where reliability and dimensional accuracy are non-negotiable. Our end-to-end workflow integrates advanced engineering with rigorous quality control, ensuring every product meets the most demanding specifications.

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D models and technical drawings. Utilizing industry-leading CAD/CAM software, we optimize mold geometry for manufacturability, thermal efficiency, and structural integrity. Finite element analysis (FEA) is applied to simulate stress, deformation, and cooling behavior, minimizing risks before physical production begins. All designs undergo internal design reviews and client approval, ensuring alignment with functional and production goals.

Next, we move to Prototyping, a critical phase for validating design performance. Using CNC machining, wire EDM, and surface grinding, we fabricate prototype molds from tool-grade steels or aluminum, depending on test requirements. These prototypes are used to produce initial sample parts, which are subjected to comprehensive metrological inspection using coordinate measuring machines (CMM) and 3D scanning. We evaluate part dimensions, surface finish, and consistency across multiple cycles. Any deviations trigger immediate design or process adjustments. This iterative validation ensures the mold performs flawlessly under real production conditions.

Once the prototype is approved, we transition to Mass Production, executed in our ISO 9001-certified facility. Our production lines are equipped with high-speed CNC centers, automated tool changers, and real-time monitoring systems to maintain micron-level accuracy. Each mold undergoes strict in-process inspections, with documented checks at key stages: rough machining, semi-finishing, hardening, finishing, and assembly. We employ statistical process control (SPC) to detect trends and correct deviations before they affect output. Every finished mold is tested for moldability, ejection performance, and cycle time stability.

Our zero-defect philosophy is enforced through full traceability, documented process parameters, and final 100% inspection before shipment. All materials, heat treatments, and machining logs are archived for complete audit readiness.

Below are key technical specifications for our standard production capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | 0.1 – 0.8 µm (finish pass) |

| Maximum Workpiece Size | 1200 × 800 × 600 mm |

| Materials Supported | P20, 718, H13, S136, 420, Stainless Steel |

| Heat Treatment | Up to 52 HRC, controlled quenching |

| Lead Time (Prototype) | 15–25 days (based on complexity) |

| Lead Time (Mass Production) | 30–45 days (including validation) |

From design to full-scale production, Wuxi Lead Precision Machinery ensures every mold exceeds performance expectations—delivering precision, durability, and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Mold Design Execution

Designing high-performance molds demands more than theoretical expertise; it requires manufacturing partners who translate complex geometries into flawless physical components under stringent tolerances. At Wuxi Lead Precision Machinery, we bridge this gap through engineer-to-engineer collaboration, ensuring your mold designs achieve first-article success without costly iterations. Our integrated approach combines advanced CNC machining, material science proficiency, and proactive design validation to eliminate hidden risks before metal meets toolpath.

Unlike conventional suppliers, we engage during your conceptual phase to identify manufacturability constraints early—addressing thermal dynamics, ejection forces, and surface finish requirements that impact production longevity. This preemptive engineering reduces time-to-market by up to 30% while safeguarding against premature wear or dimensional drift in high-cycle applications. Our facility operates under ISO 9001 and IATF 16949 frameworks, with dedicated cells for mold-specific materials including P20, H13, S136, and beryllium-copper alloys.

Technical Capabilities for Mold Manufacturing

| Specification | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Tolerance Control | ±0.002 mm (linear) / ±0.001° (angular) | ±0.01 mm |

| Surface Finish | Ra 0.05 µm (mirror polishing) | Ra 0.8 µm |

| Max Work Envelope | 1,200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Lead Time (Prototype) | 12–18 days | 25–35 days |

| Material Hardness Range | Up to 60 HRC (post-heat treatment) | 52 HRC |

We recognize that mold integrity hinges on invisible factors: residual stress distribution, micro-porosity management, and thermal equilibrium during cooling. Our engineers deploy finite element analysis (FEA) simulations to model these variables, providing data-driven recommendations for core/cavity venting, cooling channel placement, and parting line optimization. This technical rigor prevents common failures like sink marks, warpage, or flash—issues that cascade into scrap rates exceeding 15% with less rigorous partners.

Confidentiality remains non-negotiable. All projects utilize encrypted digital workflows with NDA-backed IP protection, while our bilingual engineering team ensures zero miscommunication through shared CAD/CAM platforms and real-time progress dashboards. No overseas time zone delays, no translation errors—just synchronized development from your 3D model to production-ready mold.

Your next mold design deserves a partner invested in your operational continuity, not just order fulfillment. Contact our engineering team directly to initiate a technical feasibility review. Email [email protected] with your design files and production targets. We will respond within 4 business hours with a preliminary assessment of critical tolerances, material suitability, and risk-mitigation strategies—no obligation, pure engineering value. Let Lead Precision become the silent guardian of your mold performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.