Technical Contents

Engineering Guide: Finish Molding

Engineering Insight: The Critical Role of Precision in Finish Molding

In high-integrity metal manufacturing, finish molding transcends basic shaping; it defines the final geometric accuracy, surface integrity, and functional performance of critical components. Precision at this stage is non-negotiable. A deviation of mere microns can cascade into catastrophic field failures, accelerated wear, compromised sealing, or assembly rejection in aerospace actuators, medical implants, or defense systems. The finish molding process must consistently achieve target dimensions, surface finishes, and material properties within extremely tight tolerances, directly impacting product lifespan, safety, and operational reliability. Compromising on this final precision step negates the value of upstream processes and introduces unacceptable risk into the end application.

Achieving such micron-level consistency demands more than advanced machinery; it requires integrated process mastery. At Wuxi Lead Precision Machinery, we engineer finish molding solutions where thermal stability, tooling dynamics, real-time metrology, and material science converge. Our proprietary process control algorithms actively compensate for micro-thermal drift during extended cycles, while multi-axis synchronized tool paths eliminate handoff errors between operations. Crucially, every component undergoes in-process verification using calibrated CMMs and surface profilers before final release, ensuring specifications are met, not merely assumed. This closed-loop precision system is why we are trusted for applications where failure is impossible.

Our capability is validated through the most demanding real-world benchmarks. We supplied mission-critical titanium structural components for the Beijing 2022 Winter Olympic infrastructure, where sub-10µm tolerances ensured flawless integration under extreme cold stress. Similarly, we produce classified military components requiring ITAR-controlled precision molding, where dimensional repeatability directly impacts national security systems. These projects demand not just equipment, but deep process understanding forged over 15 years of solving the industry’s toughest molding challenges.

The table below outlines the precision envelope achievable with our certified finish molding systems for critical applications:

| Specification Parameter | Typical Capability Range | Measurement Standard | Application Relevance |

|---|---|---|---|

| Dimensional Tolerance (mm) | ±0.002 to ±0.005 | ISO 2768-mK | Aerospace bearing seats, hydraulic valves |

| Surface Roughness (Ra, µm) | 0.1 to 0.4 | ISO 4287 | Medical implant interfaces, optical mounts |

| Geometric Deviation (µm) | < 3.0 (per 100mm) | ASME Y14.5 GD&T | Satellite deployment mechanisms |

| Material Removal Consistency | ±1.5µm (layer) | In-process laser scan | Turbine blade airfoils, compressor disks |

| Batch Repeatability (CpK) | ≥ 1.67 | Statistical Process Ctrl | High-volume defense subsystems |

Precision finish molding is the final, decisive gatekeeper for component performance. It transforms near-net shapes into guaranteed-fit, high-reliability assets. Wuxi Lead Precision Machinery delivers this assurance through engineered process control, not just machine capability, proven in applications where global events and national security depend on zero-defect execution. Partner with us to convert your most challenging molding requirements into certified, mission-ready components.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Precision Finish Molding Components

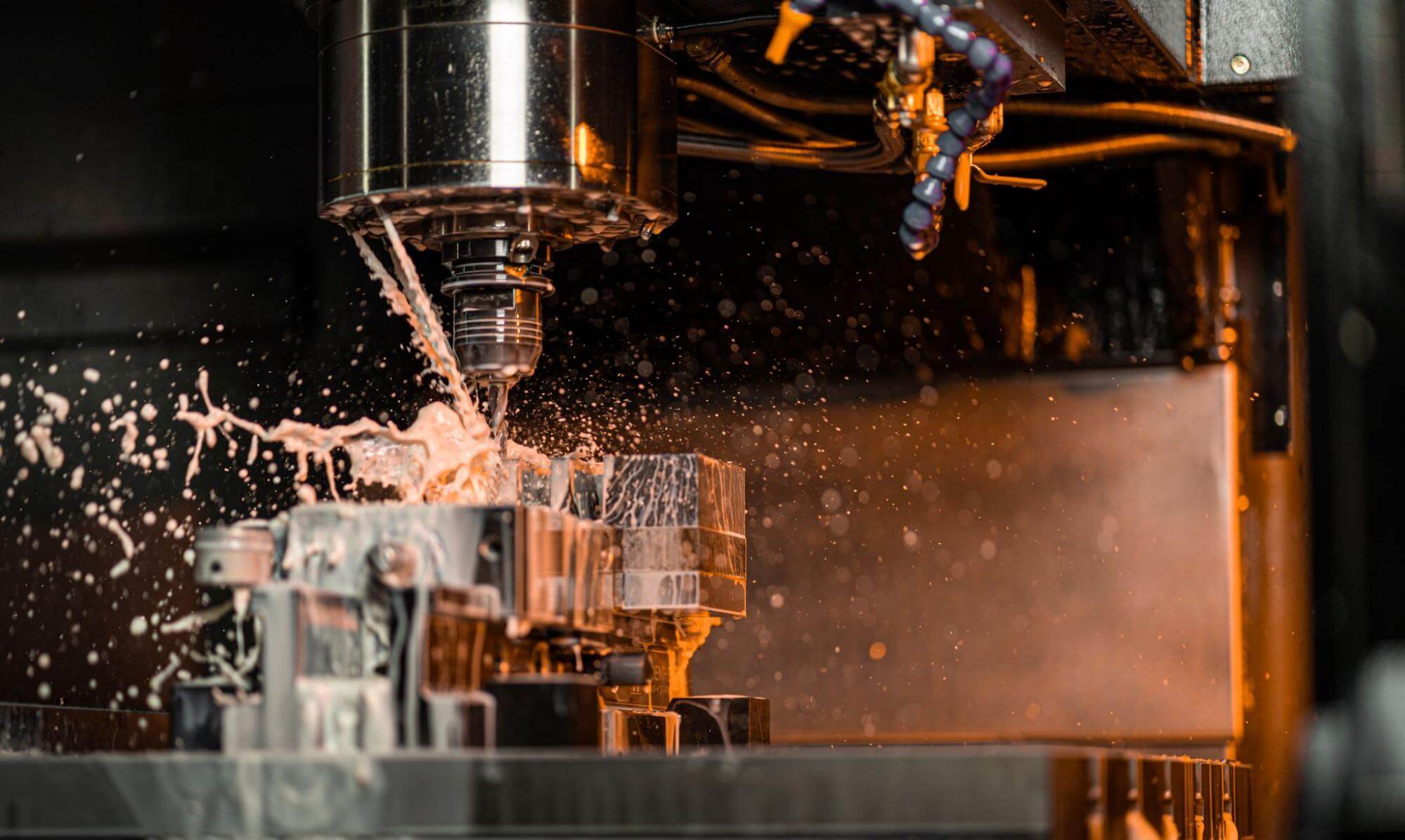

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of high-performance finish molding applications in custom metal manufacturing. Central to our precision workflow is our fleet of state-of-the-art 5-axis CNC machining centers, which enable the production of complex geometries with exceptional surface finish and dimensional accuracy. These systems allow simultaneous multi-axis movement, reducing setup times and eliminating cumulative tolerances associated with repositioning. This capability is critical when manufacturing intricate mold components, inserts, and cavities that require seamless contours, tight radii, and superior surface integrity.

Our 5-axis platforms are equipped with high-speed spindles, thermal compensation systems, and rigid tooling interfaces to maintain stability during prolonged precision cuts. This ensures consistent part quality across both prototyping and high-volume production runs. Materials commonly processed include hardened tool steels, stainless alloys, aluminum, and high-temperature superalloys—each selected based on the functional requirements of the final molding application.

To guarantee compliance with international quality standards, every component undergoes rigorous post-machining inspection using a Coordinate Measuring Machine (CMM). Our Zeiss and Hexagon CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and surface profiles. Data from each inspection is documented in a full traceability report, supporting industries where certification and repeatability are mandatory, such as automotive, aerospace, and medical device manufacturing.

We integrate CAD/CAM-driven programming with real-time toolpath simulation to optimize machining strategies and prevent collisions, ensuring first-time-right outcomes. Our engineers work closely with clients during the design-for-manufacturability phase to identify potential challenges and recommend adjustments that enhance mold performance and longevity.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled production conditions:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.010 mm | ±0.005 mm | Up to 300 mm length |

| Geometric Tolerance (GD&T) | ±0.015 mm (True Position) | ±0.008 mm | Includes flatness, perpendicularity |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Achieved with fine finishing passes |

| Angular Tolerance | ±0.05° | ±0.02° | Across multi-face interfaces |

| Feature Repeatability | ±0.008 mm | ±0.003 mm | Verified over 30-part batch |

These specifications reflect our commitment to delivering mold components that meet the highest standards of precision and reliability. By combining advanced 5-axis CNC technology with comprehensive CMM-based quality control, Wuxi Lead Precision Machinery ensures every finished part supports optimal molding performance, reduced cycle times, and extended tool life. Our technical team remains available to consult on custom tolerance requirements and material-specific processing strategies.

Material & Finish Options

Material Selection for Precision Finish Molding: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal base material and complementary finish is foundational to achieving performance, durability, and cost-efficiency in precision molded metal components. At Wuxi Lead Precision Machinery, our engineering team rigorously evaluates material-finish synergy to ensure your final part meets stringent functional and aesthetic requirements within the demanding context of high-volume manufacturing. This selection directly impacts mold design complexity, production yield, and long-term component reliability in critical applications across aerospace, medical, and industrial automation sectors.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the predominant choice for anodized finish molding due to their excellent machinability, favorable strength-to-weight ratio, and superior anodizing response. The anodizing process electrochemically converts the aluminum surface into a durable, corrosion-resistant aluminum oxide layer. This porous layer can be dyed for color coding or aesthetic purposes and subsequently sealed for maximum environmental resistance. Aluminum’s thermal conductivity also aids in efficient mold cooling cycles. While cost-effective for high-volume production, material grade must be specified precisely; 7075 offers higher strength but slightly reduced anodizing uniformity compared to 6061.

Carbon and alloy steels (e.g., 4140, 1045) provide exceptional strength, wear resistance, and dimensional stability under high loads and temperatures, making them suitable for structural or high-wear molding applications. However, steel is incompatible with standard anodizing. Alternative surface treatments like hard chrome plating, nitriding, or specialized powder coating are required for corrosion and wear resistance. These processes add cost and cycle time but are necessary where aluminum’s strength limits are exceeded. Steel selection must account for machinability during mold creation and potential post-mold heat treatment requirements.

Titanium alloys (primarily Grade 5, Ti-6Al-4V) offer an unparalleled strength-to-weight ratio and exceptional corrosion resistance, especially in harsh chemical or marine environments. While titanium can undergo a form of anodizing primarily for color identification (decorative or marking purposes), it does not produce the thick, hard, wear-resistant oxide layer achievable with aluminum. The primary value of titanium molding lies in its inherent material properties; surface finishing often focuses on precision machining, grit blasting, or specialized passivation rather than functional anodizing. Its high cost and challenging machinability necessitate careful evaluation against performance requirements.

The interplay between base material properties and the chosen finish dictates final part performance. The following table summarizes critical considerations for anodizing compatibility and key characteristics:

| Material | Primary Anodizing Purpose | Typical Hardness (Vickers) | Key Advantages for Molding | Key Limitations for Finish Molding |

|---|---|---|---|---|

| Aluminum 6061 | Functional & Decorative | 300-500 (Anodized) | Excellent anodizing response, Good machinability, Light weight, Cost-effective | Lower strength vs. steel/titanium, Color consistency challenges on complex geometries |

| Steel (4140) | Not Applicable | 200-250 (Base) | High strength & wear resistance, Dimensional stability at high temp | Requires non-anodizing finishes (e.g., chrome), Heavier, Slower machining |

| Titanium Gr5 | Decorative/Color Only | 350-400 (Base) | Exceptional strength-to-weight, Superior corrosion resistance | Very high material cost, Difficult machining, Anodizing not wear-resistant |

Material selection is not merely a technical specification; it is a strategic decision impacting total project cost, lead time, and field performance. Wuxi Lead Precision Machinery leverages decades of China-based manufacturing expertise and advanced CNC capabilities to guide clients through this critical phase. Our engineers evaluate your application’s environmental exposure, mechanical loads, aesthetic needs, and volume requirements to recommend the optimal material-finish combination, ensuring seamless integration with our precision molding processes and global supply chain. Consult our technical team early in the design phase to maximize part integrity and production efficiency.

Manufacturing Process & QC

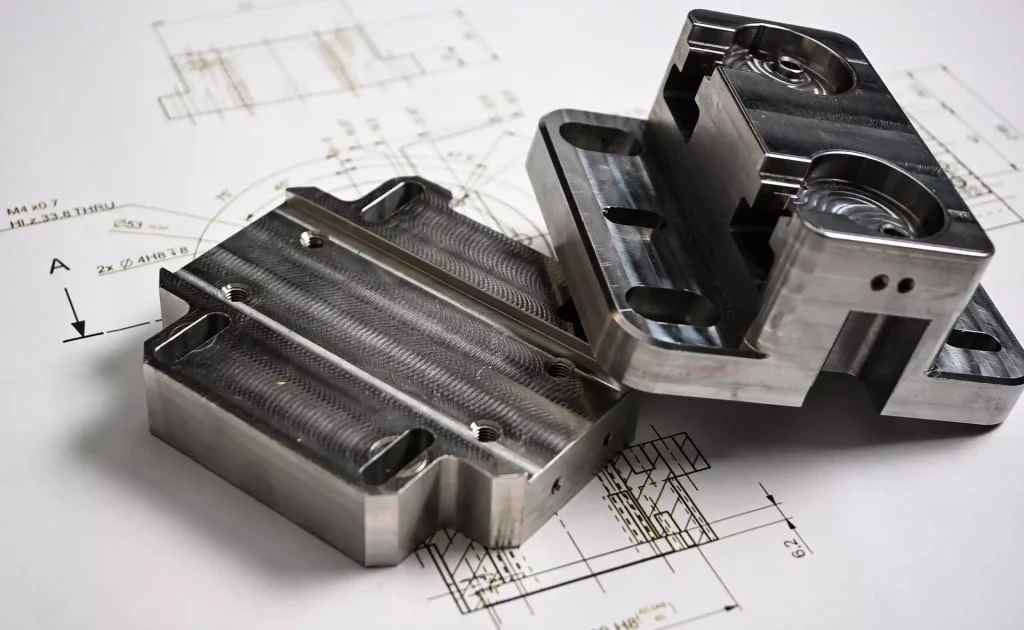

Design: The Foundation of Precision Finish Molding

At Wuxi Lead Precision Machinery, the finish molding process begins with a meticulously engineered design phase. This stage integrates advanced CAD/CAM software with deep metallurgical expertise to translate client specifications into manufacturable, high-tolerance components. Our engineering team collaborates directly with clients to assess functional requirements, material compatibility, and geometric complexity. Finite element analysis (FEA) and mold flow simulation are applied to predict deformation, stress distribution, and material behavior under high-pressure molding conditions. This proactive modeling ensures optimal mold design, minimizes post-production corrections, and aligns the component’s microstructure with performance demands. All designs adhere to ISO 9001:2015 standards and are documented with full traceability for audit and revision control.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using the same tooling and materials intended for mass production. This ensures consistency and realism in performance evaluation. Prototypes are machined on our precision CNC systems and subjected to rigorous metrological inspection using Zeiss coordinate measuring machines (CMM) and 3D laser scanning. Dimensional accuracy, surface finish, and mechanical properties are validated against the original specifications. Any deviations trigger an immediate root cause analysis and design refinement loop. This closed-loop validation is critical to achieving zero defects in final production. Clients receive a comprehensive prototype report, including material test certifications, geometric deviation maps, and functional test results, enabling informed approval before scaling.

Mass Production: Consistency Through Automation and Control

With design and prototype approval secured, Wuxi Lead initiates mass production under a fully controlled manufacturing environment. Our facility employs automated molding cells equipped with real-time process monitoring. Each cycle is tracked for temperature, pressure, and dwell time, with data logged for every unit produced. Inline vision systems and automated dimensional gauging ensure 100% inspection of critical features. We utilize Statistical Process Control (SPC) to maintain process capability indices (Cp/Cpk > 1.67) across production runs. All operators are certified to ISO 13381 standards, and every batch undergoes final QA review before shipment. Traceability is maintained via laser-etched part IDs linked to production data, enabling full lifecycle tracking.

Key Process Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Roughness (Ra) | 0.2 – 1.6 µm | ISO 1302 |

| Material Options | 316L, 17-4PH, Inconel 718, Titanium Gr5 | ASTM/AMS |

| Production Capacity | Up to 500,000 units/month | Scalable |

| Process Yield | ≥ 99.98% | Zero Defect Target |

| Inspection Coverage | 100% critical dimensions | ISO 14253-1 |

Wuxi Lead Precision Machinery ensures that every stage—from design to delivery—is engineered for precision, repeatability, and zero-defect output, meeting the highest demands of aerospace, medical, and advanced industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Finish Molding Excellence

Achieving flawless surface integrity and dimensional accuracy in final metal components demands more than standard machining. Finish molding represents the critical convergence of ultra-precise CNC capabilities, advanced material science, and rigorous process control. At Wuxi Lead Precision Machinery, we engineer this convergence specifically for high-stakes applications where surface finish, micro-geometry, and material consistency directly impact performance, safety, and regulatory compliance. Our dedicated finish molding division operates beyond conventional manufacturing tolerances, leveraging purpose-built equipment and proprietary calibration protocols developed through deep collaboration with leaders in aerospace, medical implant, and semiconductor equipment sectors. We understand that a single micron deviation can compromise an entire assembly – which is why our processes are designed to eliminate variability at the source, not merely inspect it post-production.

Our technical partnership begins with a thorough analysis of your component’s functional requirements, material behavior under finishing stresses, and end-use environmental factors. This ensures the selected process – whether multi-axis micro-milling, precision grinding, or specialized honing – is optimized for your specific surface topology and metallurgical needs. We integrate real-time in-process metrology with closed-loop compensation systems, guaranteeing that every part meets or exceeds the most stringent finish and flatness specifications before leaving our facility. This systematic approach to finish molding delivers not only superior part quality but also significant reductions in scrap rates and downstream assembly costs for our clients.

The following table outlines our core finish molding capabilities for critical metal components:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | ISO 2768-mK |

| Surface Roughness (Ra) | 0.05 µm to 0.8 µm (2 µin to 32 µin) | ISO 4287 / ASME B46.1 |

| Flatness / Form Accuracy | ≤ 0.0005 mm per 25 mm (≤ 0.00002″ per 1″) | ISO 1101 |

| Material Compatibility | Titanium Alloys, Inconel, Stainless Steels (300/400 series), Tool Steels, Aluminum Alloys | AMS, ASTM, EN Standards |

| Max Work Envelope | Ø 300 mm x 150 mm Height |

These specifications represent our baseline performance under controlled production conditions, not theoretical maximums. Each project undergoes tailored process validation using client-supplied samples or first-article prototypes, ensuring seamless integration into your existing supply chain. Our facility maintains ISO 9001:2015 and IATF 16949 certifications, with dedicated cleanroom environments available for medical and semiconductor applications requiring particulate control.

Initiate your precision finish molding project with engineering rigor, not generic quotations. Contact our technical sales engineering team directly at [email protected] with your component drawings, material specifications, and critical surface requirements. Include any relevant application context regarding load conditions, sealing interfaces, or regulatory standards. We will respond within 24 business hours with a targeted assessment of process feasibility, preliminary capability analysis, and a clear pathway to first-article validation. Partner with Wuxi Lead Precision Machinery to transform finish molding from a production challenge into a competitive advantage – where micron-level precision becomes your standard of quality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.