Technical Contents

Engineering Guide: Prototypes Inc

In the world of advanced manufacturing, precision is not merely a performance metric—it is the foundation of reliability, safety, and innovation. For high-stakes industries such as aerospace, defense, and high-performance sports equipment, even micron-level deviations can lead to catastrophic failure. At Wuxi Lead Precision Machinery, we understand that precision engineering is not just about tight tolerances; it’s about consistency, repeatability, and the integration of advanced materials and processes to meet the most demanding specifications.

With over a decade of experience serving global clients, Wuxi Lead has established itself as a trusted partner in custom metal manufacturing. Our engineering team specializes in producing mission-critical components where failure is not an option. This expertise has been rigorously tested through projects for Olympic-level athletic equipment and precision parts used in military applications. These sectors demand more than just accuracy—they require materials that perform under extreme conditions, designs that push the limits of physics, and manufacturing processes that deliver flawless results every time.

Our commitment to precision begins at the design phase. We collaborate closely with engineering teams at prototypes inc to optimize part geometry, material selection, and manufacturability. Utilizing advanced CNC machining centers with sub-micron positioning accuracy, we achieve tolerances as tight as ±0.002 mm. This level of control ensures that every component meets not only the technical drawings but also the functional requirements of its intended application.

Material integrity is another cornerstone of our process. Whether working with titanium alloys for aerospace frames or hardened steels for defense mechanisms, we apply strict quality control protocols, including in-process metrology and final inspection using coordinate measuring machines (CMM). Our facility is ISO 9001 certified, and we maintain full traceability from raw material to finished part.

The following table outlines key performance specifications achievable at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.025 mm |

| Surface Finish | Ra 0.1 µm to Ra 1.6 µm |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Tool Steels |

| Machining Processes | 3-axis, 4-axis, 5-axis CNC Milling, CNC Turning, Wire EDM |

| Quality Standards | ISO 9001, Full CMM Inspection, Material Certification |

Precision is not an outcome—it is a culture. At Wuxi Lead, every technician, engineer, and quality inspector is trained to uphold the highest standards, ensuring that every component we deliver supports the integrity of the final product. For prototypes inc, this means confidence in every prototype and production run, knowing that the parts are manufactured to perform under real-world stress and scrutiny.

When innovation meets exacting standards, the result is engineering excellence. Wuxi Lead Precision Machinery is proud to be the precision backbone behind some of the most advanced prototypes in the world today.

Precision Specs & Tolerances

Precision Manufacturing Capabilities for Mission-Critical Components

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding custom metal prototypes and low-volume production runs. Our core strength lies in integrating advanced multi-axis machining with rigorous, traceable quality assurance, specifically engineered to meet the exacting standards of aerospace, medical device, and advanced industrial sectors. We understand that dimensional accuracy and geometric integrity are non-negotiable factors in your product’s performance and regulatory compliance.

Our primary machining platform centers on state-of-the-art 5-axis simultaneous CNC machining centers, predominantly DMG MORI and MAZAK models. This technology enables the complete machining of highly complex geometries in a single setup, eliminating cumulative errors inherent in multiple fixturing operations. We routinely produce intricate contours, deep cavities, undercuts, and organic shapes from challenging materials including titanium alloys, Inconel, hardened steels, and aluminum. The capability for continuous toolpath optimization ensures superior surface finishes, reduced cycle times, and exceptional part consistency, directly translating to lower risk and faster time-to-market for your critical projects. Material removal rates are optimized without sacrificing the dimensional stability required for high-integrity components.

Quality verification is not an afterthought but an integrated pillar of our manufacturing process. Every critical feature undergoes comprehensive inspection using calibrated Zeiss CONTURA and GLOBAL S series Coordinate Measuring Machines (CMM). Our ASQ-certified metrology technicians perform full First Article Inspections (FAI) per AS9102 standards and implement rigorous in-process checks. This systematic approach generates detailed, NIST-traceable inspection reports, providing absolute confidence in conformance to your engineering specifications. We proactively identify and correct potential deviations before they impact downstream assembly or performance, safeguarding your program schedule and budget.

The following table details our standard achievable tolerance capabilities under controlled production conditions. Specific project requirements may allow for tighter control; our engineering team collaborates closely during the Design for Manufacturability (DFM) phase to optimize for precision and cost.

| Feature Type | Standard Capability | Tight Capability | Ultra-Tight Capability |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.012 mm (±0.0005″) | ±0.005 mm (±0.0002″) |

| Geometric (GD&T) | ±0.025 mm | ±0.010 mm | ±0.003 mm |

| Surface Finish (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) | 0.2 µm (8 µin) |

| Hole Position | ±0.025 mm | ±0.010 mm | ±0.005 mm |

Note: Achievable tolerances are dependent on material, part geometry, feature size, and specified surface finish. Ultra-tight capabilities require specific material condition and may impact lead time.

Partnering with Wuxi Lead means gaining a precision manufacturing extension of your engineering team. We combine cutting-edge 5-axis technology with metrology-grade verification to transform complex designs into physically perfect metal components. Our commitment is to deliver not just parts, but certified, reliable solutions that meet the highest benchmarks of quality and performance, ensuring your prototype or production run succeeds on the first attempt. Let us apply our technical rigor to de-risk your next critical metal fabrication project.

Material & Finish Options

Material Selection in Custom Metal Manufacturing: A Guide by Wuxi Lead Precision Machinery

Selecting the right material and finish is critical in custom metal manufacturing, particularly when producing high-performance prototypes and precision components. At Wuxi Lead Precision Machinery, we specialize in delivering engineered solutions using aluminum, steel, and titanium—each offering distinct mechanical properties, environmental resistance, and cost profiles. Understanding these differences ensures optimal performance, longevity, and cost-efficiency for your application.

Aluminum is widely used in aerospace, automotive, and consumer electronics due to its excellent strength-to-weight ratio and natural corrosion resistance. It is highly machinable, which reduces production time and tool wear, making it ideal for rapid prototyping and low-to-medium volume production. When paired with anodizing, aluminum gains enhanced surface hardness, wear resistance, and aesthetic versatility. Anodizing creates a durable oxide layer that can be dyed in various colors, offering both functional and visual benefits.

Steel remains the material of choice for applications requiring high tensile strength, durability, and thermal stability. Carbon steel and alloy steels are frequently used in industrial machinery, tooling, and structural components. While heavier than aluminum, steel offers superior impact resistance and load-bearing capabilities. For enhanced corrosion protection, finishes such as zinc plating, powder coating, or passivation are recommended, though anodizing is not applicable to steel.

Titanium stands at the premium end of the spectrum, offering exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. It is commonly used in medical devices, aerospace systems, and high-performance automotive components. Titanium’s resistance to extreme temperatures and aggressive environments makes it suitable for mission-critical applications. However, its high cost and challenging machinability require advanced CNC capabilities and experienced process planning—areas where Wuxi Lead excels.

The choice of finish further defines component performance. Anodizing, primarily applied to aluminum, improves surface durability and electrical insulation while allowing for precise color matching. Type II (sulfuric acid) and Type III (hardcoat) anodizing are the most common, with Type III providing thicker, harder coatings for industrial use.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Aerospace, Electronics | Anodizing, Powder Coating |

| Steel A36 | 7.8 | 400–550 | Moderate (rust-prone) | Construction, Machinery | Zinc Plating, Painting |

| Titanium Grade 5 | 4.4 | 900 | Excellent | Medical, Aerospace | Passivation, Bead Blasting |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-house engineering consultation, ensuring every prototype or production part meets exact functional and regulatory demands. Our advanced CNC machining, combined with strict quality control, guarantees precision across all material types.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Seamless Transition from Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, we engineer certainty into every custom metal component, transforming client concepts into flawless production realities. Our rigorously defined Production Process eliminates defects at origin, ensuring your project moves efficiently from initial vision to high-volume delivery without compromise. This integrated approach—Design, Prototyping, Mass Production—is the cornerstone of our Zero Defects commitment for global partners like Prototypes Inc.

The foundation is meticulous Design Engineering. Our team collaborates intensively with your engineers during the conceptual phase, applying advanced Design for Manufacturability (DFM) analysis. We scrutinize 3D models for structural integrity, material suitability, and producibility long before metal is cut. Finite Element Analysis (FEA) validates stress points, while thermal and tolerance stack-up simulations preempt potential failures. This collaborative deep dive ensures the design is not only functional but inherently manufacturable to micron-level precision, significantly reducing downstream risk. We provide actionable feedback within 72 hours, aligning expectations and establishing unambiguous quality gates.

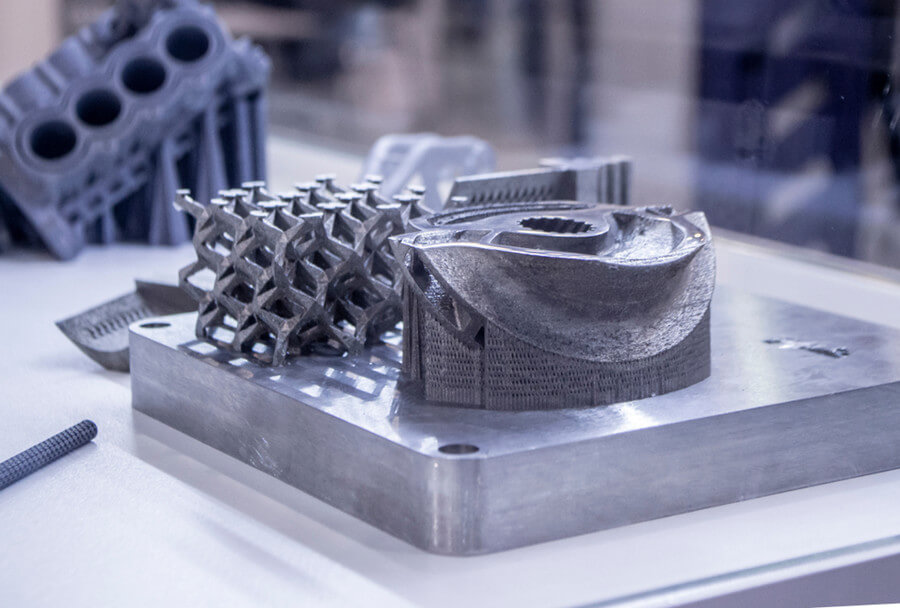

Following design validation, Prototyping transitions theory into tangible proof. Utilizing our state-of-the-art 5-axis CNC machining centers and wire EDM systems, we produce functional prototypes in your specified production-grade materials. Each prototype undergoes comprehensive Coordinate Measuring Machine (CMM) inspection against the original CAD model, verifying critical dimensions, geometric tolerances (GD&T), and surface finishes. This phase is not merely about form and fit; it is a critical validation of the entire manufacturing process chain under real production conditions. Any deviation triggers immediate root cause analysis and process refinement, ensuring the prototype is a true predictor of mass production output. Lead times for precision prototypes are consistently under 15 working days.

This rigor extends directly into Mass Production. Leveraging the validated process parameters and tooling from prototyping, we deploy Statistical Process Control (SPC) across all production lines. Real-time monitoring of critical dimensions via automated in-process gauging ensures every component remains within the strictest tolerance bands. Our ISO 9001-certified quality management system mandates 100% first-article inspection and ongoing batch validation using calibrated metrology equipment. Material traceability is absolute, from certified mill certificates through final shipment. The result is consistent, defect-free output at volumes scaling to hundreds of thousands of parts annually, with on-time delivery exceeding 98.5%.

Our technical capabilities enable this precision across diverse applications. Key production parameters include:

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Material Range | Aluminum, Steel, Stainless, Titanium, Brass, Copper | ASTM, EN, JIS, GB |

| Tolerance Control | ±0.005 mm (standard), ±0.002 mm (precision) | ISO 2768-mK, GD&T ASME Y14.5 |

| Surface Finish | Ra 0.2 µm to 3.2 µm | ISO 1302 |

| Max Part Size | 1200 x 800 x 600 mm | Custom fixtures available |

Wuxi Lead’s integrated process delivers more than parts; it delivers guaranteed outcomes. By embedding quality into every phase—from collaborative design through validated prototyping to SPC-driven mass production—we ensure your metal components meet the highest standards of performance and reliability, every time. Partner with us for manufacturing execution where zero defects is not a target, but the baseline.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, prototypes are not just early models—they are the foundation of innovation. For Prototypes Inc., where precision, speed, and reliability define success, partnering with a manufacturer that aligns with your standards is critical. As a leading custom metal manufacturing provider based in Wuxi, China, we specialize in delivering CNC-machined components with micron-level accuracy, rapid turnaround, and full traceability—engineered to meet the demands of aerospace, medical, robotics, and advanced automation sectors.

Our facility integrates state-of-the-art 3-, 4-, and 5-axis CNC machining centers with advanced quality control systems, including CMM inspection and real-time process monitoring. Every component we produce adheres to ISO 9001:2015 standards, ensuring consistency across prototypes and low-volume production runs. We work with a broad range of materials, including aluminum alloys, stainless steel, titanium, brass, and specialty engineering plastics—tailored to your exact mechanical and environmental requirements.

What sets us apart is our commitment to being an extension of your engineering team. From design for manufacturability (DFM) feedback to rapid prototyping iterations, our engineers collaborate closely with your team to reduce lead times and eliminate costly redesigns. Whether you require a single prototype or a batch of 500 precision parts, we maintain the same level of scrutiny and craftsmanship throughout.

We support global clients with end-to-end services, including material sourcing, precision machining, surface treatments (such as anodizing, passivation, and plating), and consolidated shipping with full documentation. Our logistics network ensures on-time delivery to North America, Europe, and Asia, backed by responsive customer support available across time zones.

Below are key capabilities that define our manufacturing excellence.

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-axis Swiss machining |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Copper, PEEK, Delrin |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by complexity) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports, PPAP documentation available |

| Surface Treatments | Anodizing (Type II & III), Passivation, Electroplating, Powder Coating, Bead Blasting |

When Prototypes Inc. partners with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally committed to accelerating your product development cycle without compromising quality. Let us help you turn concepts into high-performance realities.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide a detailed quote, DFM analysis, and sample timeline—ensuring your prototypes are manufactured to the highest global standards, on schedule and on budget.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.