Technical Contents

Engineering Guide: Cost Of A Plastic Mold

Engineering Insight: The True Cost of a Plastic Mold

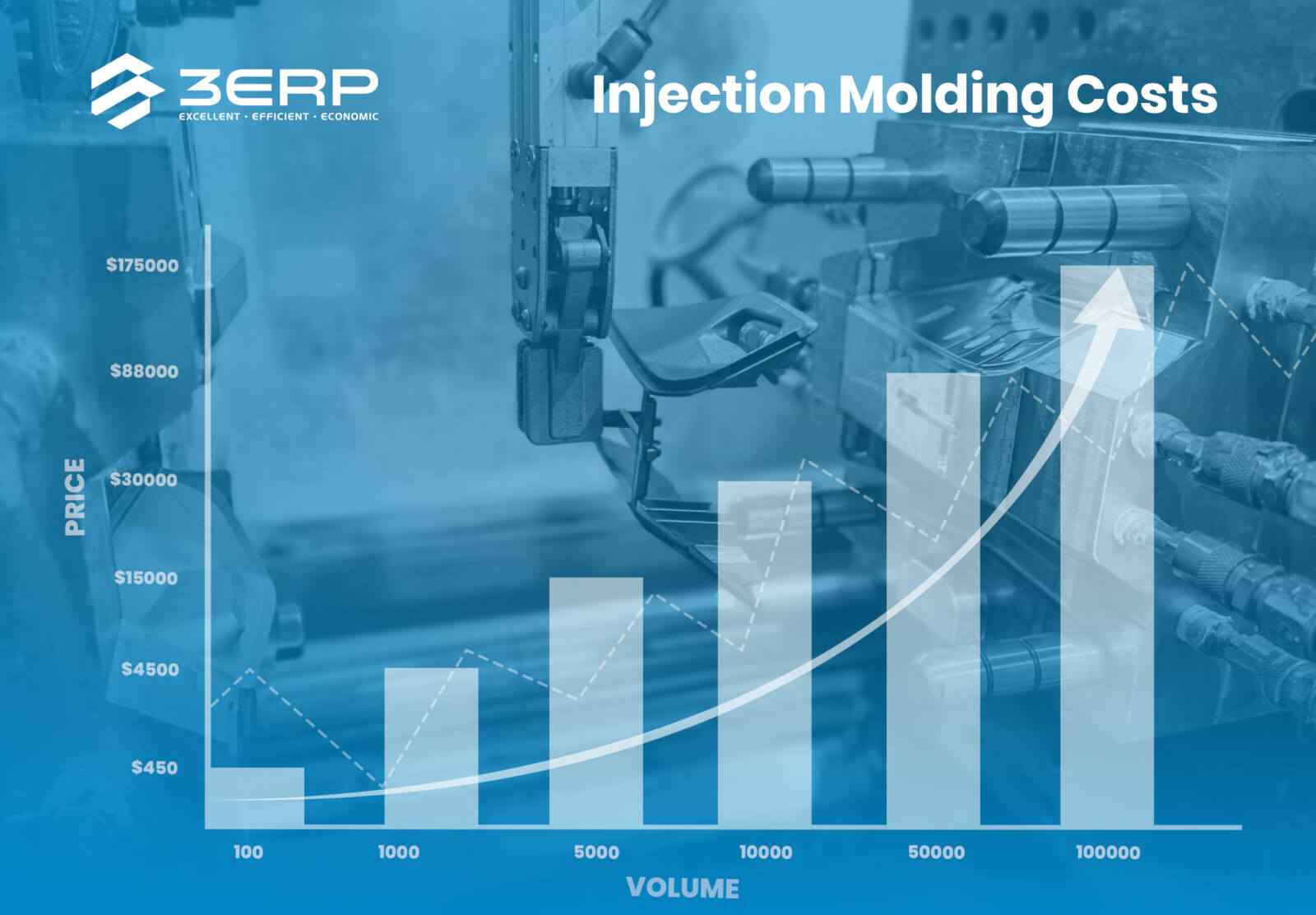

When evaluating the cost of a plastic mold, it is essential to shift focus from initial price to long-term value. In high-end custom metal manufacturing, the mold is not merely a tool—it is the foundation of product integrity, repeatability, and performance. At Wuxi Lead Precision Machinery, we understand that precision engineering directly influences the total cost of ownership. A poorly constructed mold may appear economical upfront but often leads to increased downtime, higher rejection rates, and frequent repairs, ultimately driving up production costs.

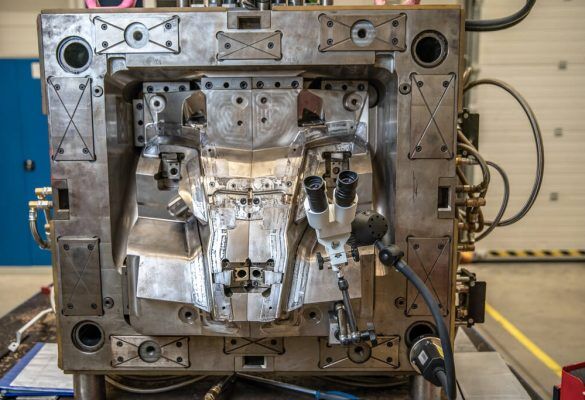

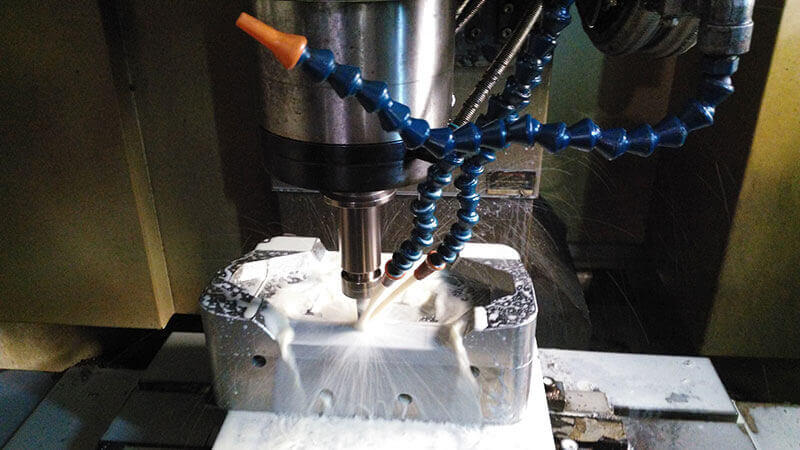

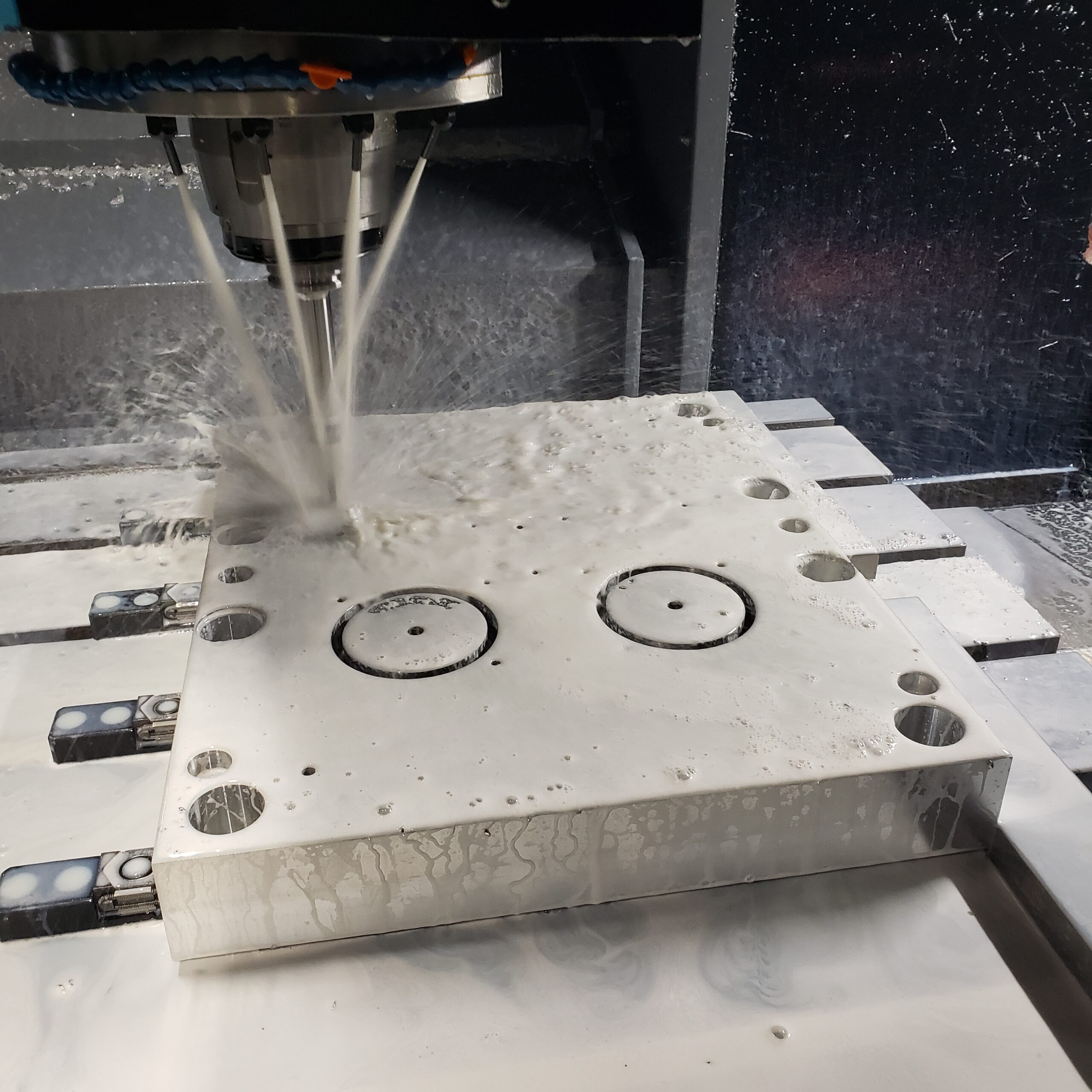

Precision in mold manufacturing ensures consistent part quality, tighter tolerances, and extended tool life. Our engineering team applies advanced CNC machining, multi-axis milling, and electrode discharge machining (EDM) techniques to achieve tolerances as tight as ±0.002 mm. This level of accuracy is not standard across the industry, but it is fundamental to clients in aerospace, medical devices, and defense—sectors where failure is not an option.

Our experience in mission-critical applications speaks to our capability. Wuxi Lead has contributed precision components for Olympic-standard equipment and military-grade systems, where reliability under extreme conditions is non-negotiable. These projects demanded not only flawless execution but also rigorous documentation, material traceability, and compliance with international standards such as ISO 9001 and AS9100. This same discipline is applied to every plastic mold we produce, regardless of application.

Material selection, mold complexity, surface finish, and expected production volume all influence cost. However, with our in-house design validation process—including mold flow analysis and structural simulation—we mitigate risks early, reducing costly revisions and delays. Our molds are built to withstand high-cycle production, often exceeding 1 million shots with minimal wear, thanks to hardened steels like S136, 2738HH, and NAK80, selected based on customer requirements.

Below are key specifications that define the performance and cost structure of a precision plastic mold manufactured at Wuxi Lead:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Standard Materials | S136, 2738HH, NAK80, 718H, P20 |

| Surface Finishes | Mirror polish (SPI A1), textured, matte, or custom |

| Mold Life | 100,000 to 1,000,000+ cycles |

| Lead Time | 4 to 12 weeks (based on complexity) |

| Standard Features | Hot runner systems, lifters, unscrewing mechanisms, cold decks |

| Quality Compliance | ISO 9001, ISO 13485 (medical), AS9100 (aerospace) |

At Wuxi Lead Precision Machinery, we do not build molds—we engineer solutions. The cost of a plastic mold reflects the expertise, technology, and quality systems behind it. When precision is paramount, the true value lies not in the quote, but in the performance.

Precision Specs & Tolerances

Technical Capabilities

Wuxi Lead Precision Machinery delivers the dimensional accuracy and surface integrity essential for high-performance plastic injection molds. Our integrated manufacturing approach centers on advanced metal processing, specifically targeting the demanding tolerances required in mold bases, cavities, cores, and critical interfaces. This precision directly influences mold longevity, part consistency, and ultimately, the total cost of ownership for your production. We achieve this through a tightly controlled workflow combining cutting-edge equipment with rigorous quality validation.

Our core manufacturing capability leverages state-of-the-art 5-axis CNC machining centers. These systems perform simultaneous multi-axis movement, enabling the precise fabrication of complex mold geometries—including deep ribs, undercuts, and organic contours—in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly improving positional accuracy between critical mold features. The result is reduced mold trial cycles, minimized manual polishing requirements, and accelerated time-to-production for your components. Material utilization is optimized through efficient toolpath strategies, contributing to cost-effective raw material usage for intricate mold components.

Quality assurance is non-negotiable and embedded at every stage. All critical mold components undergo comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols verify geometric dimensioning and tolerancing (GD&T) against the original CAD model, ensuring conformity before assembly. This systematic validation extends beyond simple dimensional checks to include form, profile, orientation, and location tolerances. Real-time data from CMM reports informs any necessary process adjustments, guaranteeing that each mold component meets the stringent specifications required for stable, high-yield plastic part production. This proactive QC prevents costly rework or mold failures during initial production runs.

The following table details our standard and tight tolerance capabilities for critical mold features, reflecting the precision achievable through our combined 5-axis machining and CMM inspection processes. These tolerances are fundamental to minimizing part variation and controlling long-term mold maintenance costs.

| Feature Category | Standard Capability (mm) | Tight Capability (mm) | Measurement Method |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.020 | ±0.005 | CMM |

| Parting Line Flatness | 0.025 | 0.010 | CMM/Height Gauge |

| Slide & Core Pin Bores | H7 (+0.015 / 0) | H6 (+0.009 / 0) | CMM/Pneumatic Gauge |

| Ejector Pin Holes | H8 (+0.022 / 0) | H7 (+0.015 / 0) | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Positional Accuracy | ±0.015 | ±0.008 | CMM |

This commitment to measurable precision ensures your mold performs reliably from the first shot, directly impacting your production efficiency and the true cost per plastic part. Wuxi Lead’s technical infrastructure provides the foundation for molds that deliver consistent quality and extended service life.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the appropriate material for a plastic injection mold is critical to ensuring durability, precision, and cost-efficiency over the production lifecycle. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exact requirements of high-volume and high-precision molding applications. The three primary materials used in mold construction—aluminum, steel, and titanium—each offer distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum molds are often chosen for low to medium production runs due to their excellent machinability and thermal conductivity. They allow for faster cooling cycles, reducing overall cycle time during injection molding. While not as wear-resistant as steel, modern high-grade aluminum alloys such as 7075-T6 provide sufficient strength and longevity for prototyping and short-run manufacturing. Aluminum is also significantly lighter, simplifying handling and installation in molding machines.

Steel remains the dominant choice for high-volume production molds. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and longevity, capable of withstanding millions of cycles with minimal degradation. These materials are ideal for complex geometries and aggressive molding resins that demand high thermal and mechanical stability. While initial machining time and cost are higher, the extended service life of steel molds delivers a lower cost per part over large production volumes.

Titanium, though less common in standard mold construction, is gaining traction in specialized applications requiring extreme corrosion resistance and high strength-to-density ratios. Its use is typically limited to critical mold components such as inserts or cores exposed to aggressive environments or where weight reduction is paramount. While costly and challenging to machine, titanium offers unparalleled performance in niche industrial and medical molding applications.

Surface finish plays a crucial role in part quality and mold maintenance. Anodizing is a widely used finish for aluminum molds, enhancing surface hardness and corrosion resistance while providing electrical insulation. Hard anodizing (Type III) can increase surface hardness up to 60 HRC, significantly improving wear performance. For steel molds, alternatives such as nitriding or chrome plating are more common, though anodizing may be applied selectively in hybrid mold designs.

Below is a comparative overview of key mold materials used in precision plastic molding:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Best Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 150 HB | 130 | 10,000 – 100,000 | Prototypes, low-volume production |

| P20 Steel | 28–32 HRC | 30 | 500,000 – 1,000,000 | Medium to high-volume production |

| H13 Steel | 48–52 HRC | 35 | 1,000,000+ | High-stress, high-temperature use |

| Titanium Grade 5 | 36 HRC | 7 | 500,000+ (components) | Corrosive environments, lightweight needs |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, resin type, and total cost of ownership. Our engineering team ensures optimal mold performance through precise material pairing and advanced surface treatment integration.

Manufacturing Process & QC

Production Process: Engineering Precision from Concept to Zero-Defect Output

Understanding the true cost of a plastic injection mold requires insight into the disciplined, integrated process that transforms design intent into flawless, high-volume production. At Wuxi Lead Precision Machinery, we execute a rigorously controlled sequence—Design, Prototyping, Mass Production—where each phase is engineered to eliminate defects at source, directly impacting long-term cost efficiency and part quality. This methodology ensures the mold investment delivers maximum value over its operational lifespan, minimizing hidden costs from scrap, rework, and downtime.

Design Phase: Foundation for Zero Defects

The process begins with comprehensive digital engineering. Our team utilizes advanced CAD/CAM/CAE software to develop not just the mold geometry, but a complete manufacturability and quality strategy. Critical factors including material flow dynamics, cooling channel optimization, stress analysis, and ejection sequencing are simulated in detail. This predictive engineering identifies potential defects—such as weld lines, sink marks, or warpage—before metal is cut. We collaborate closely with the client to refine part geometry and gating for optimal filling and dimensional stability, establishing the precise process window required for consistent output. This upfront rigor prevents costly design iterations later and forms the bedrock of mold longevity and performance.

Prototyping Phase: Validating Performance

Following design approval, we produce a high-fidelity prototype mold using the same premium tool steels and precision machining processes intended for the production tool. This is not merely a plastic model check; it is a full process validation run under production-intent conditions on our certified injection molding presses. We meticulously measure critical dimensions, surface finish, and part functionality against the original CAD data and client specifications. Every parameter—pressure, temperature, cycle time—is recorded and analyzed. Any deviation triggers immediate root-cause analysis and mold adjustment. This phase confirms the design’s viability, validates the process window, and provides tangible evidence of achievable quality, ensuring the production mold starts life with proven zero-defect capability.

Mass Production Phase: Sustained Excellence

The transition to mass production leverages all validated data from the prior phases. Our production molds are machined to exacting tolerances using multi-axis CNC centers and inspected via CMM to stringent standards. Crucially, the process parameters established during prototyping are locked in and monitored in real-time using integrated sensors on the molding press. Statistical Process Control (SPC) tracks critical dimensions continuously. Our zero-defect mandate is enforced through automated in-cavity pressure monitoring and vision systems, rejecting non-conforming parts instantly. This closed-loop system, built on the foundation of precise design and validated prototyping, guarantees consistent output meeting the highest quality benchmarks, eliminating scrap costs and maximizing return on the mold investment.

The table below illustrates how critical design and process parameters directly influence achievable tolerances and mold cost structure:

| Parameter | Standard Tolerance (mm) | High-Precision Tolerance (mm) | Impact on Mold Cost |

|---|---|---|---|

| Part Dimension (Length) | ±0.15 | ±0.025 | +35-50% |

| Flatness | ±0.10 | ±0.015 | +25-40% |

| Hole Diameter | ±0.12 | ±0.020 | +30-45% |

| Surface Finish (Ra) | 0.8 μm | 0.2 μm | +20-35% |

| Steel Grade | P20 | NAK80 / H13 | +15-30% |

This integrated approach—where Design informs Prototyping, which validates Mass Production—ensures the plastic mold is not merely a tool, but a precision-engineered system delivering predictable, zero-defect output from day one. The initial investment in process rigor directly translates to lower total cost of ownership through extended mold life, minimal scrap, and accelerated time-to-market. Wuxi Lead Precision Machinery guarantees this outcome through unwavering adherence to engineering excellence at every stage.

Why Choose Wuxi Lead Precision

When investing in high-precision plastic molds for custom metal manufacturing applications, understanding the total cost of ownership is essential. At Wuxi Lead Precision Machinery, we specialize in delivering engineered solutions that balance upfront investment with long-term performance, durability, and repeatability. Our advanced manufacturing capabilities, combined with rigorous quality control and deep technical expertise, ensure that every mold we produce meets the exacting standards of global industries—from automotive and aerospace to medical devices and consumer electronics.

The cost of a plastic mold is influenced by multiple factors, including complexity, material selection, tolerance requirements, surface finish, and production volume. While initial pricing is important, the true value lies in precision, longevity, and process efficiency. A poorly constructed mold may appear cost-effective at first but often leads to increased downtime, higher maintenance costs, and compromised part quality. At Lead Precision, we eliminate these risks through a consultative engineering approach, ensuring your mold is optimized for performance, cycle time, and lifecycle cost.

We utilize state-of-the-art CNC machining, wire EDM, and surface treatment technologies to produce molds with micron-level accuracy. Our engineering team collaborates closely with clients from concept to completion, offering design for manufacturability (DFM) analysis, material recommendations, and prototyping services to reduce time-to-market and avoid costly revisions.

Below are key specifications that influence mold cost and performance. Each project is customized based on your technical requirements.

| Specification | Details |

|---|---|

| Mold Material | P20, 718H, S136, H13, or client-specified tool steels |

| Tolerance | ±0.005 mm to ±0.02 mm, depending on part geometry |

| Surface Finish | Mirror polish, texture (VDI 10–40), or as per sample |

| Cavities | Single or multi-cavity configurations |

| Mold Base | Standard LKM or DME, or custom design |

| Lead Time | 25–45 days, based on complexity and approval cycles |

| Quality Assurance | Full inspection report (CMM, 3D scanning) provided |

| Applications | High-volume injection molding, overmolding, insert molding |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to technical excellence and on-time delivery. We serve clients across North America, Europe, and Asia, supporting low-volume prototyping and high-volume production with equal precision.

To receive a detailed quotation tailored to your specific mold requirements, contact us directly. Our engineering team is ready to review your 3D CAD files, provide DFM feedback, and deliver a transparent cost breakdown based on your production goals.

For expert guidance and a competitive quote, contact [email protected]. Let us help you optimize your mold investment with engineering precision and manufacturing integrity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.