Technical Contents

Engineering Guide: Custom Metal Milling Georgia

Engineering Insight: Custom Metal Milling in Georgia — The Role of Precision in Advanced Manufacturing

In the competitive landscape of modern manufacturing, custom metal milling in Georgia has emerged as a critical hub for industries demanding high-performance components. From aerospace to defense and industrial automation, the region’s growing ecosystem relies on precision engineering to meet exacting standards. At the heart of this demand lies a fundamental requirement: micron-level accuracy, repeatability, and material integrity. These are not merely performance indicators—they are non-negotiables in applications where failure is not an option.

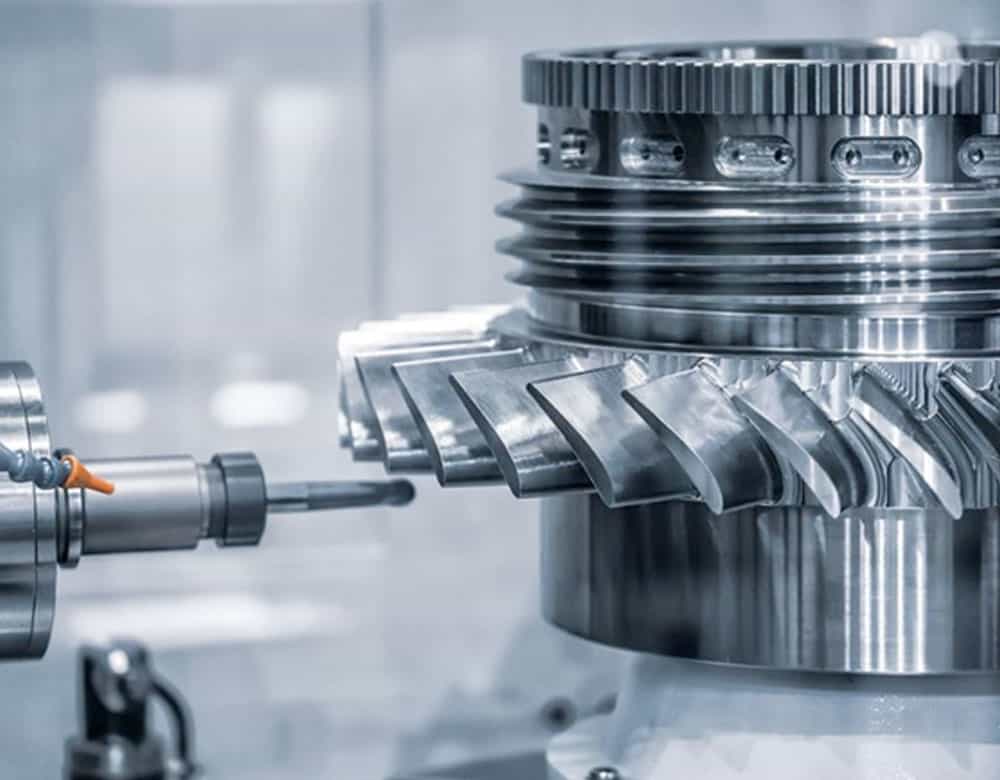

Wuxi Lead Precision Machinery brings over 15 years of advanced CNC machining expertise to support Georgia’s industrial growth. Our specialization in custom metal milling is rooted in a rigorous engineering philosophy that prioritizes dimensional stability, surface finish quality, and tight tolerance control. With state-of-the-art 3-, 4-, and 5-axis CNC milling centers, we deliver complex geometries in materials ranging from aerospace-grade aluminum alloys to hardened steels and titanium—materials commonly specified across Georgia’s defense and energy sectors.

Precision milling is more than cutting metal; it is a science that integrates toolpath optimization, thermal compensation, and real-time quality verification. At Lead Precision, every machining cycle undergoes comprehensive process validation, supported by ISO 9001:2015 and AS9100D-certified quality systems. Our experience extends to mission-critical components for Olympic-standard timing systems and military-grade communication enclosures, where even a 5-micron deviation can compromise system integrity. These projects underscore our capability to meet and exceed the expectations of high-stakes industries operating in and around Georgia.

Our engineering team employs adaptive machining strategies that respond dynamically to material variance and tool wear, ensuring consistent output across production runs. In collaboration with clients across North America, we provide Design for Manufacturability (DFM) analysis, reducing lead times and minimizing waste without sacrificing precision.

Below are key technical capabilities that define our custom metal milling services:

| Specification | Detail |

|---|---|

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Materials Processed | Aluminum 6061, 7075; Stainless Steel 303, 316; Titanium Grade 5; Inconel 718; Tool Steels |

| Tolerance Range | ±0.01 mm (standard), down to ±0.003 mm (tight-tolerance) |

| Quality Standards | ISO 9001:2015, AS9100D, GD&T compliant |

Custom metal milling in Georgia benefits significantly from global partnerships with precision-focused manufacturers like Wuxi Lead. By combining local industry needs with international-grade engineering rigor, we enable faster time-to-market, improved reliability, and scalable production—all anchored in precision. For OEMs and Tier-1 suppliers, the choice of machining partner directly impacts product performance. At Lead Precision, we engineer not just parts, but trust.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery: Advanced Technical Capabilities for Georgia Precision Milling

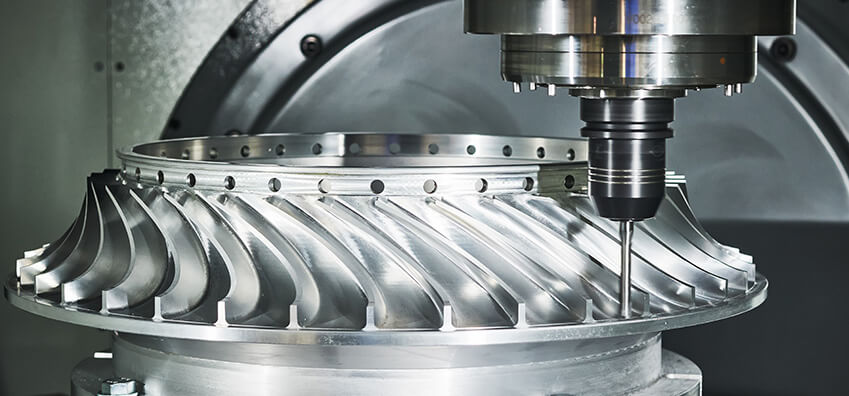

Wuxi Lead Precision Machinery delivers uncompromising precision for Georgia’s demanding manufacturing sector through state-of-the-art multi-axis CNC milling. Our core strength lies in mastering complex geometries and tight-tolerance components essential for aerospace, medical, and energy applications prevalent in Georgia’s industrial landscape. Central to this capability is our strategic deployment of advanced 5-axis CNC machining centers. These systems utilize simultaneous multi-axis interpolation, enabling the precise machining of intricate contours, deep cavities, and undercuts in a single setup. This eliminates cumulative error from multiple fixtures, significantly reduces lead times, and ensures superior part consistency critical for high-value Georgia production runs. Our DMG MORI and Makino 5-axis platforms feature high-speed spindles, rigid constructions, and sophisticated thermal compensation systems, guaranteeing micron-level accuracy even during extended production cycles on challenging materials like titanium, Inconel, and hardened steels common in Georgia’s advanced manufacturing.

Rigorous quality control is non-negotiable in precision metal milling. Every component undergoes a comprehensive inspection regimen anchored by Zeiss CONTURA and GLOBAL Advantage Coordinate Measuring Machines (CMMs). These metrology-grade systems provide full 3D verification against CAD models, capturing critical dimensions, complex surface profiles, and stringent GD&T requirements. Our inspection process integrates in-process checks using machine-integrated Renishaw probes for immediate dimensional validation during machining, followed by final first-article and batch inspections on the CMM. This dual-layer approach ensures deviations are identified and corrected in real-time, preventing non-conforming parts from progressing. All inspection data is meticulously documented, providing Georgia clients with full traceability and certified reports meeting AS9100 and ISO 13485 standards. Our quality lab operates under strict environmental controls, maintaining temperature stability to eliminate measurement drift and uphold the highest metrological integrity.

Our commitment to precision is quantifiable through consistently achieved tolerances across diverse materials and part complexities. The following table details our standard achievable capabilities for custom metal milling projects serving Georgia clients:

| Material Type | Dimensional Tolerance | Geometric Tolerance (GD&T) |

|---|---|---|

| Aluminum Alloys | ±0.0001 in (±0.0025 mm) | ±0.0002 in (±0.005 mm) |

| Stainless Steels | ±0.00015 in (±0.004 mm) | ±0.0003 in (±0.008 mm) |

| Titanium Alloys | ±0.0002 in (±0.005 mm) | ±0.0004 in (±0.010 mm) |

| High-Temp Alloys (Inconel) | ±0.00025 in (±0.006 mm) | ±0.0005 in (±0.013 mm) |

These capabilities are validated through final CMM inspection reports provided with every shipment. Wuxi Lead Precision Machinery bridges the gap between Georgia’s engineering demands and flawless execution, leveraging advanced 5-axis technology and uncompromising metrology to deliver components that meet the most stringent performance requirements. Partner with us for custom metal milling where precision is not just promised, but precisely measured and guaranteed.

Material & Finish Options

Material Selection for Custom Metal Milling in Georgia: Aluminum, Steel, and Titanium

Selecting the right material is critical in precision CNC machining, especially when serving high-performance industries such as aerospace, medical, and industrial automation. For manufacturers and engineers in Georgia seeking custom metal milling solutions, understanding the mechanical properties, machinability, and finishing compatibility of aluminum, steel, and titanium ensures optimal component performance and cost-efficiency. Wuxi Lead Precision Machinery, a leader in CNC machining from China, provides expert guidance on material and surface treatment selection to meet stringent U.S. industrial standards.

Aluminum is a preferred choice for applications requiring lightweight strength, excellent thermal conductivity, and good corrosion resistance. Grade 6061-T6 is widely used due to its balanced mechanical properties and ease of machining. It is ideal for structural components, enclosures, and heat sinks. When paired with anodizing, aluminum achieves enhanced surface hardness and wear resistance. Type II (sulfuric acid) anodizing is commonly applied for decorative and protective finishes, while Type III (hardcoat anodizing) delivers superior durability in demanding environments.

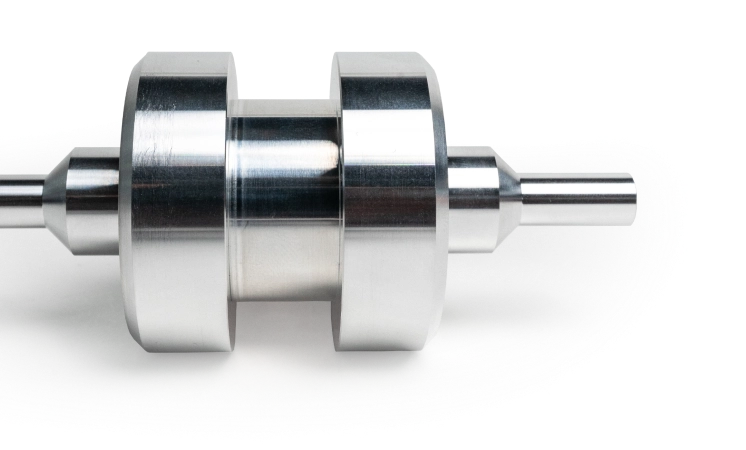

Steel, particularly alloy steels like 4140 and 1018, offers high tensile strength, durability, and excellent weldability. These materials are suitable for heavy-duty mechanical parts, shafts, and tooling fixtures. While steel is more challenging to machine than aluminum due to higher tool wear, our advanced CNC milling centers ensure tight tolerances and smooth surface finishes. Post-machining treatments such as passivation, powder coating, or zinc plating are often recommended to prevent oxidation and extend service life.

Titanium, specifically Grade 5 (Ti-6Al-4V), is favored in aerospace and medical applications for its exceptional strength-to-density ratio and outstanding biocompatibility. Despite its low thermal conductivity and high chemical reactivity, which complicate machining, Wuxi Lead employs specialized tooling and cooling techniques to maintain precision. Titanium components typically do not anodize in the traditional sense but can undergo color anodizing for identification or aesthetic purposes, leveraging oxide layer interference rather than hardness enhancement.

The following table summarizes key material properties and finishing compatibility:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310 – 570 | 2.7 | Excellent | Full (Type II & III) |

| Steel | 1018, 4140 | 440 – 850 | 7.8 | Moderate | Not applicable |

| Titanium | Ti-6Al-4V (Gr5) | 900 – 1,000 | 4.5 | Poor to Moderate | Decorative only |

Material selection directly impacts performance, longevity, and manufacturing cost. At Wuxi Lead Precision Machinery, we combine material science expertise with advanced CNC milling technology to deliver custom-machined parts that meet the rigorous demands of Georgia’s industrial clients. Partnering with a precision-focused manufacturer ensures optimal material utilization, consistent quality, and on-time delivery for every project.

Manufacturing Process & QC

Integrated Production Process for Zero-Defect Custom Metal Milling

At Wuxi Lead Precision Machinery, our production process for custom metal milling projects destined for Georgia manufacturers is engineered for seamless integration and unwavering quality. We eliminate traditional handoffs between stages, ensuring Design, Prototyping, and Mass Production function as a single, optimized system. This integrated approach is the foundation of our Zero Defects guarantee, critical for Georgia’s demanding aerospace, medical, and industrial equipment sectors where component failure is not an option.

The process begins with collaborative Design refinement. Our engineering team in Wuxi works directly with Georgia client engineers, utilizing shared CAD/CAM platforms and conducting thorough Design for Manufacturability (DFM) analysis. We identify potential machining challenges early, optimizing toolpaths, material selection, and fixture strategies before metal is cut. This proactive step prevents costly revisions later and ensures the design is fully manufacturable to the tightest tolerances required by Georgia’s high-specification industries. Clear communication across time zones is maintained through structured virtual reviews, aligning expectations precisely.

Prototyping transitions directly from the validated design. We utilize the exact same CNC mills, tooling, and quality protocols planned for production to create functional prototypes. This is not a separate exercise; it is the first validated run of the production process. Georgia clients receive prototypes within compressed timelines, often within 7-10 days, enabling rapid physical validation against specifications. Any minor adjustments identified during prototype inspection feed directly back into the final production program, ensuring the first mass-produced part meets all requirements. Our proximity to major Georgia aerospace hubs allows for efficient physical sample delivery when required.

Mass Production leverages the perfected process from prototyping under our stringent Zero Defects framework. Every component undergoes a four-stage inspection protocol: in-process checks via integrated probes on the CNC machine, comprehensive CMM verification of critical features, 100% visual inspection, and final cross-departmental audit against the original client blueprint. Statistical Process Control (SPC) monitors key parameters in real-time, enabling immediate correction before deviations occur. This systematic vigilance, combined with our engineers’ deep expertise in milling challenging alloys like titanium and Inconel, ensures consistent output where every part shipped to Georgia meets or exceeds specifications. Traceability from raw material to finished good is absolute.

Our commitment to Zero Defects is quantifiable through the capabilities below:

| Critical Specification | Wuxi Lead Precision Capability |

|---|---|

| Standard Tolerance | ±0.0002 inches (5 microns) |

| Surface Finish (Ra) | As low as 0.4 µm |

| Materials Expertise | Aluminum, Steel, Stainless, Titanium, Inconel, Brass, Plastics |

| Max Work Envelope (Milling) | 2000 x 1000 x 800 mm |

| Key Certifications | ISO 9001:2015, ISO 13485, NADCAP (compliant processes) |

| Primary Quality Focus | Zero Defects Guarantee |

For Georgia manufacturers demanding flawless metal components, Wuxi Lead delivers through an integrated, transparent process where design intent becomes production reality without compromise. Our Zero Defects system ensures your supply chain reliability, reducing your total cost of quality and accelerating time-to-market for critical applications. Partner with us for precision milling where perfection is the only acceptable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Milling in Georgia and Beyond

When precision matters, global manufacturers turn to Wuxi Lead Precision Machinery for advanced CNC milling solutions that meet the most demanding specifications. While our physical operations are based in Wuxi, China, our reach extends to key industrial markets worldwide—including Georgia, where aerospace, defense, medical, and energy sectors require uncompromising quality in custom metal components. Partnering with Lead Precision means accessing state-of-the-art CNC milling capabilities, ISO-certified quality control, and engineering expertise—all delivered with the responsiveness and reliability your production timeline demands.

Our facility specializes in high-tolerance, complex geometry milling for materials such as aluminum alloys, stainless steel, titanium, and exotic superalloys. Whether you require low-volume prototypes or high-volume production runs, our vertical and 5-axis CNC machining centers ensure repeatability down to ±0.001 mm. With integrated CAD/CAM programming and in-process inspection, we eliminate guesswork and deliver parts that meet or exceed your engineering requirements—on time, every time.

For companies in Georgia seeking a strategic offshore partner without sacrificing quality or communication, Lead Precision offers a seamless collaboration model. Our engineering team works directly with your design staff to review DFM (Design for Manufacturability), optimize tool paths, and ensure first-article approval with detailed inspection reports. We maintain strict confidentiality and IP protection, and our project managers provide real-time updates in your time zone, ensuring alignment across every phase of production.

Below are the key technical capabilities that define our custom metal milling services:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm (47.2 x 31.5 x 23.6 in) |

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Axis Configuration | 3-axis, 4-axis, and 5-axis simultaneous milling |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels, Exotic Alloys |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Tolerances | ±0.005 mm typical, down to ±0.001 mm for critical features |

| Quality Standards | ISO 9001:2015 certified, First Article Inspection (FAI), PPAP available |

We understand that choosing a manufacturing partner is not just about technical specs—it’s about trust, transparency, and long-term performance. That’s why we treat every client as a strategic collaborator, not just a customer. From initial quote to final delivery, our team is committed to exceeding expectations.

Ready to elevate your manufacturing outcomes? Contact us today at [email protected] to discuss your custom metal milling project. Let Lead Precision be the partner behind your next breakthrough in precision engineering.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.