Technical Contents

Engineering Guide: Injection Moulding Advantages

Engineering Insight: Precision as the Core Advantage in Metal Injection Moulding

Precision in metal injection moulding (MIM) transcends dimensional accuracy; it defines functional reliability in mission-critical applications. For industries like aerospace, medical, and defense, where Wuxi Lead Precision Machinery operates, tolerances measured in microns directly impact safety, performance, and compliance. Unlike traditional plastic injection moulding, MIM processes powdered metal feedstocks into complex, high-strength components—demanding uncompromising control over thermal dynamics, material flow, and sintering. At Lead Precision, we treat precision not as a target but as a systemic outcome, engineered through validated process parameters and real-time metrology. This discipline ensures parts meet ISO 13097 standards for density uniformity and mechanical properties, eliminating costly post-machining while achieving geometries impossible via CNC milling or casting.

The inherent advantage of MIM lies in its ability to consolidate multi-part assemblies into single, net-shape components. This reduces assembly errors, enhances structural integrity, and slashes material waste by up to 95% compared to subtractive methods. However, unlocking these benefits requires mastery over variables like feedstock rheology, cavity pressure distribution, and debinding kinetics. Our proprietary simulation protocols predict micro-porosity risks and warpage before tooling fabrication, ensuring first-article success. This precision-centric approach is why Lead Precision delivers components for Olympic-grade timing systems and military-grade fire control mechanisms—applications where a 0.005mm deviation risks catastrophic system failure.

Our technical capabilities reflect decades of refining MIM for extreme environments. The table below outlines core specifications achievable under our controlled processes:

| Parameter | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.05 mm | ±0.1 mm (typical MIM) |

| Material Density | 98–99.8% theoretical | 95–97% |

| Part Weight Range | 0.1 g – 250 g | 0.01 g – 100 g |

| Surface Roughness (Ra) | 0.8 µm – 3.2 µm | 3.2 µm – 6.3 µm |

| Material Options | 17-4PH, 316L, Ti-6Al-4V | Limited stainless steels |

Wuxi Lead Precision Machinery’s validation in Olympic and defense projects stems from this granular control. For instance, our MIM components in satellite guidance systems maintain stability across -196°C to 300°C thermal cycles—a result of sintering profiles calibrated to ±1.5°C. Similarly, tactical firearm triggers we produce exhibit zero fatigue after 50,000+ cycles, achieved through feedstock homogeneity verified at 500x magnification. These are not isolated feats but evidence of a culture where process capability indices (Cpk > 1.67) are non-negotiable.

In high-stakes manufacturing, precision is the currency of trust. Lead Precision’s engineering rigor transforms MIM from a production method into a strategic advantage—ensuring every component performs exactly as simulated, every time. This is how we turn material science into mission assurance.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our production infrastructure is our 5-axis CNC machining technology, which enables us to produce complex, high-precision metal components with exceptional repeatability and surface finish. Unlike conventional 3-axis systems, 5-axis CNC machining allows simultaneous movement across five axes, facilitating the machining of intricate geometries in a single setup. This reduces cumulative errors, improves part accuracy, and significantly shortens lead times.

Our 5-axis machining centers are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring optimal cutting conditions and material removal rates. This capability supports a broad range of metals, including aluminum alloys, stainless steel, titanium, and high-temperature superalloys such as Inconel. Whether producing prototype batches or high-volume production runs, our machining processes are fully scalable and designed for maximum efficiency and consistency.

To guarantee that every component meets exacting quality standards, Wuxi Lead implements a rigorous quality control protocol centered on CMM (Coordinate Measuring Machine) inspection. Our Zeiss and Hexagon CMM systems provide micron-level measurement accuracy, enabling comprehensive dimensional verification, geometric tolerance analysis, and surface integrity assessment. Each part undergoes full inspection according to customer-specified GD&T (Geometric Dimensioning and Tolerancing) requirements, with detailed inspection reports provided upon request. This closed-loop quality process ensures full traceability and compliance with ISO 9001 and IATF 16949 standards.

The precision achievable through our integrated manufacturing and inspection systems is reflected in the tight tolerances we consistently maintain. Below is a summary of our standard and advanced tolerance capabilities across key machining parameters.

| Feature | Standard Tolerance | High-Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.03 mm | ±0.01 mm |

| Flatness | 0.03 mm per 100 mm | 0.005 mm per 100 mm |

| Roundness | 0.01 mm | 0.003 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.05° | ±0.01° |

These specifications underscore our commitment to delivering components that meet the most demanding engineering requirements. By combining 5-axis CNC machining with comprehensive CMM-based quality assurance, Wuxi Lead Precision Machinery ensures that every custom metal part is manufactured to the highest standard of precision, reliability, and performance. Our technical capabilities are designed not only to meet industry benchmarks but to exceed the expectations of global OEMs and engineering partners.

Material & Finish Options

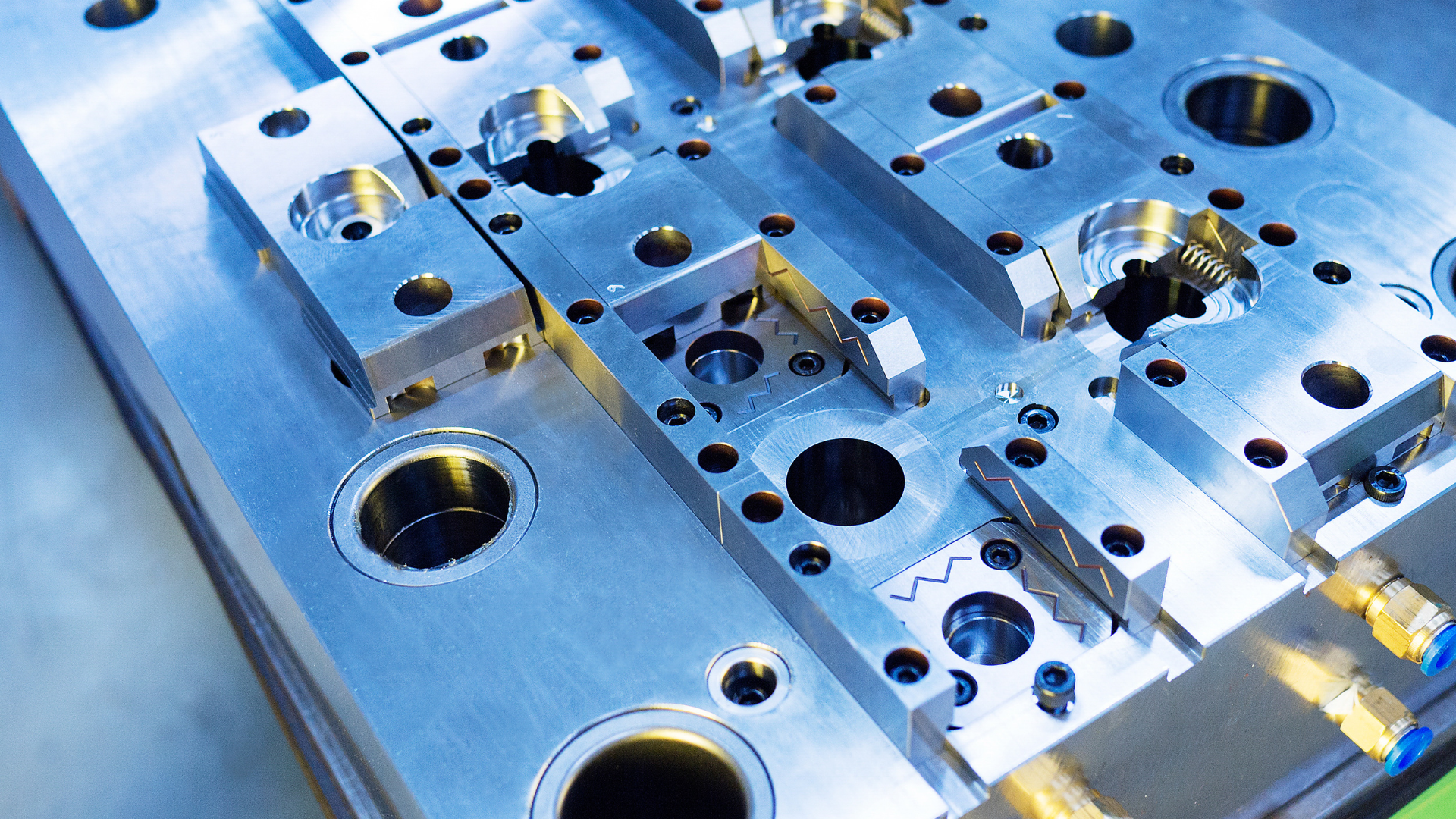

Material Selection for High-Performance Injection Molding Tooling

Material selection is a critical engineering decision directly impacting injection mold longevity, part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, our expertise in custom metal manufacturing ensures optimal material pairing for your specific application demands. Aluminum, steel, and titanium each offer distinct advantages and trade-offs requiring careful evaluation against production volume, part complexity, material being molded, and budget constraints.

Aluminum alloys, particularly 6061-T6 and 7075-T6, provide significant advantages for prototyping, low-to-medium volume production, and applications requiring rapid heat dissipation. Their lower density reduces mold weight, easing handling and machine load. Excellent machinability translates to faster lead times and lower initial tooling costs. While ultimate hardness is lower than steel, modern aluminum grades offer sufficient wear resistance for many engineering plastics over tens of thousands of cycles. Aluminum is the strategic choice when speed to market and reduced upfront investment are paramount, especially for complex geometries benefiting from its thermal conductivity.

Tool steels, including P20, H13, and stainless variants like 420, remain the industry standard for high-volume production. Their superior hardness, wear resistance, and compressive strength withstand the abrasive forces of glass-filled polymers and demanding production schedules exceeding hundreds of thousands, often millions, of cycles. Properly heat-treated steel molds maintain dimensional stability under prolonged thermal cycling, ensuring consistent part quality. The higher initial cost is justified by exceptional longevity and reduced downtime for maintenance in demanding applications. Steel is indispensable for critical automotive, medical, and consumer electronics components requiring maximum precision over extended runs.

Titanium alloys, while less common due to cost and machining complexity, serve niche high-value applications. Their exceptional strength-to-weight ratio, outstanding corrosion resistance against aggressive chemicals, and biocompatibility make them suitable for specialized medical device molding or corrosive polymer processing. Titanium’s thermal properties differ significantly from steel, requiring specific design considerations. Its use is typically reserved for scenarios where its unique properties solve specific challenges unmet by steel or aluminum.

Anodizing is a vital surface treatment primarily for aluminum molds. This electrochemical process creates a durable, corrosion-resistant oxide layer integral to the base metal. Hard anodizing (Type III) significantly enhances surface hardness, wear resistance, and lubricity, extending aluminum mold life substantially in abrasive applications. It also improves release characteristics for sticky polymers and provides an excellent base for subsequent coatings. While not typically applied to steel or titanium molds in standard practice, anodizing is a key value-add service Wuxi Lead employs to maximize aluminum tool performance and lifespan.

The following table summarizes key properties for common mold materials:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Key Advantages | Primary Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 2.81 | 503-572 | Rapid machining, excellent thermal conductivity | Prototyping, low/medium volume, complex |

| P20 Tool Steel | 7.85 | 950-1100 | Balanced toughness, good polishability | Medium/high volume, general purpose |

| H13 Tool Steel | 7.80 | 1200-1600 | Superior hot hardness, thermal fatigue resistance | High volume, high temp polymers |

| Titanium Ti-6Al-4V | 4.43 | 900-1000 | Exceptional corrosion resistance, high strength/weight | Specialized medical, corrosive environs |

Wuxi Lead Precision Machinery leverages deep material science knowledge and precision manufacturing capabilities to select and process the optimal material for your injection molding success. Contact our engineering team to discuss the precise requirements of your next project.

Manufacturing Process & QC

Injection Moulding Advantages in High-Precision Custom Metal Manufacturing

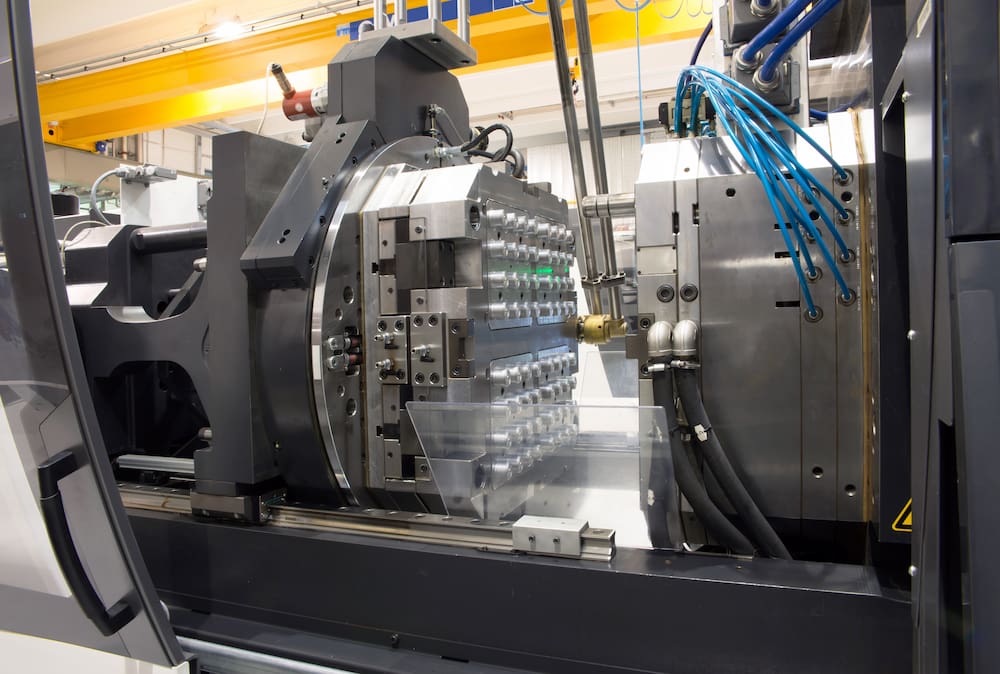

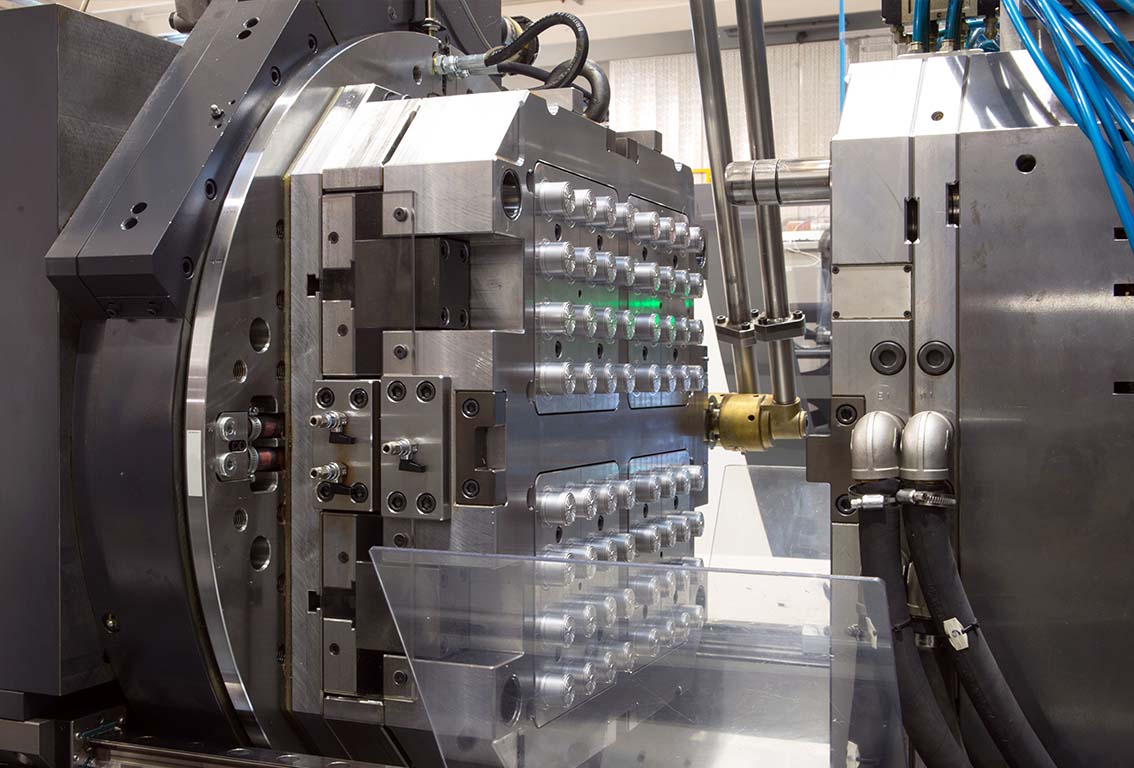

At Wuxi Lead Precision Machinery, we specialize in delivering advanced injection moulding solutions tailored for high-end custom metal manufacturing. Our integrated production process ensures precision, consistency, and zero-defect output across every stage—from design to mass production. This structured workflow not only enhances product quality but also optimizes time-to-market and cost efficiency for our global industrial clients.

The process begins with design engineering, where our team collaborates closely with clients to translate technical requirements into optimized mould designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we simulate material flow, thermal distribution, and structural integrity prior to prototyping. This digital-first approach minimizes design flaws and ensures manufacturability, forming the foundation for defect-free production.

Next, we move into precision prototyping. Using CNC-machined pre-series moulds and high-grade metal alloys, we produce functional prototypes that mirror final production conditions. These prototypes undergo rigorous testing for dimensional accuracy, mechanical performance, and surface finish. Clients receive comprehensive reports including first-article inspection (FAI) data and geometric dimensioning and tolerance (GD&T) validation. Feedback loops at this stage allow for rapid iteration, ensuring full compliance before scaling up.

Once design approval is secured, we transition seamlessly into mass production. Our state-of-the-art injection moulding lines are equipped with real-time monitoring systems that track pressure, temperature, cycle time, and part weight. Automated vision inspection and in-process gauging ensure 100% quality control, while statistical process control (SPC) algorithms detect deviations before they impact output. This proactive approach is central to our zero-defect manufacturing philosophy, enabling sustained repeatability across production runs from thousands to millions of parts.

Our facility’s integration of cold chamber die-casting technology with servo-driven presses allows for superior control over metal injection, particularly with aluminum, magnesium, and zinc alloys. Combined with lean manufacturing principles and ISO 9001-certified workflows, this results in minimal waste, reduced downtime, and unmatched process stability.

Below are key technical specifications of our injection moulding production capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | Aluminum (A380, A360, ADC12), Zinc (Zamak 3), Magnesium (AZ91D) |

| Tolerance Range | ±0.02 mm to ±0.05 mm |

| Part Weight Range | 10 g – 2,500 g |

| Mould Lifespan | Up to 1,000,000 cycles (hardened steel) |

| Production Capacity | Up to 500,000 units/month per line |

| Surface Finish Options | As-cast, polished, anodized, powder-coated |

| Quality Standards | ISO 9001, IATF 16949, RoHS, PPAP Level 3 |

| Inline Inspection Systems | Vision inspection, CMM, X-ray porosity detection |

From concept to completion, Wuxi Lead Precision Machinery delivers injection moulded metal components with uncompromising precision. Our end-to-end control over the production process ensures that every part meets the highest standards of performance and reliability—on time, at scale, and with zero defects.

Why Choose Wuxi Lead Precision

Strategic Partnership for Precision Injection Moulding Excellence

In the demanding landscape of high-precision metal component manufacturing, selecting a partner transcends mere procurement. It requires aligning with an engineering-driven organization capable of transforming complex design challenges into flawless production realities. Wuxi Lead Precision Machinery represents this critical capability, offering far more than standard injection moulding services. We deliver engineered solutions where geometric complexity, micron-level tolerances, and material integrity converge to meet the exacting demands of aerospace, medical, and advanced industrial applications. Our integrated approach—from initial design consultation through to final validation—ensures your components perform reliably in the most rigorous operational environments, mitigating risk and accelerating time-to-market.

Our technical foundation is built upon advanced multi-axis CNC machining centers, real-time process monitoring systems, and stringent ISO 9001-certified quality protocols. This infrastructure enables consistent execution of projects requiring exceptional precision and repeatability. Below outlines our core technical capabilities for metal injection moulding (MIM) and precision machining:

| Specification Category | Capability | Industry Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.025 mm |

| Material Range | Stainless Steel (17-4PH, 316L), Titanium, Inconel, Tungsten Carbide | Limited Alloy Options |

| Part Complexity | Full 5-axis capability for undercuts, thin walls (<0.5mm), micro-features | Moderate Complexity |

| Lead Time (Prototype) | 15-20 business days | 25-35 business days |

| Secondary Operations | In-house CNC finishing, laser welding, passivation, precision cleaning | External Sourcing Required |

| Quality Documentation | Full PPAP Level 3, CMM reports, material certs, SPC data | Basic Certificates |

This precision is not incidental; it stems from our dedicated engineering team’s decades of experience solving problems where failure is not an option. We engage early in your design phase to optimize for manufacturability, reducing hidden costs and potential production delays. Our facility in Wuxi leverages China’s advanced manufacturing ecosystem while maintaining Western engineering standards—providing global competitiveness without compromising on quality oversight or intellectual property security. Unlike commodity suppliers, we treat every project as a collaborative engineering effort, embedding our expertise into your development lifecycle to ensure first-article success and long-term production stability.

The true advantage lies in transforming material science and precision engineering into your competitive edge. When component failure carries unacceptable consequences, partnering with Lead Precision ensures your specifications become reality—not just on paper, but in every precisely formed part that leaves our facility. We understand the weight of responsibility your designs carry, and our processes are engineered to uphold it consistently.

Initiate a technical dialogue that moves beyond quotations to engineered outcomes. Contact our engineering team directly at [email protected] to discuss your specific application requirements. Include your design files or performance specifications for a targeted capability assessment. Let us demonstrate how Lead Precision becomes the invisible force behind your product’s reliability—where precision isn’t promised, it’s proven. Engage with engineers who speak your language and deliver solutions that meet the uncompromising standards of global industry leaders. Your next breakthrough component starts with an engineer-to-engineer conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.