Technical Contents

Engineering Guide: Steel Sheet Cover

Engineering Insight: The Critical Role of Precision in Steel Sheet Cover Manufacturing

In high-performance industrial applications, the steel sheet cover is far more than a protective shell—it is a critical engineering component that ensures structural integrity, operational safety, and long-term reliability. At Wuxi Lead Precision Machinery, we approach the manufacturing of steel sheet covers not as a routine fabrication task, but as a precision engineering challenge demanding exacting standards, advanced material science, and decades of applied expertise.

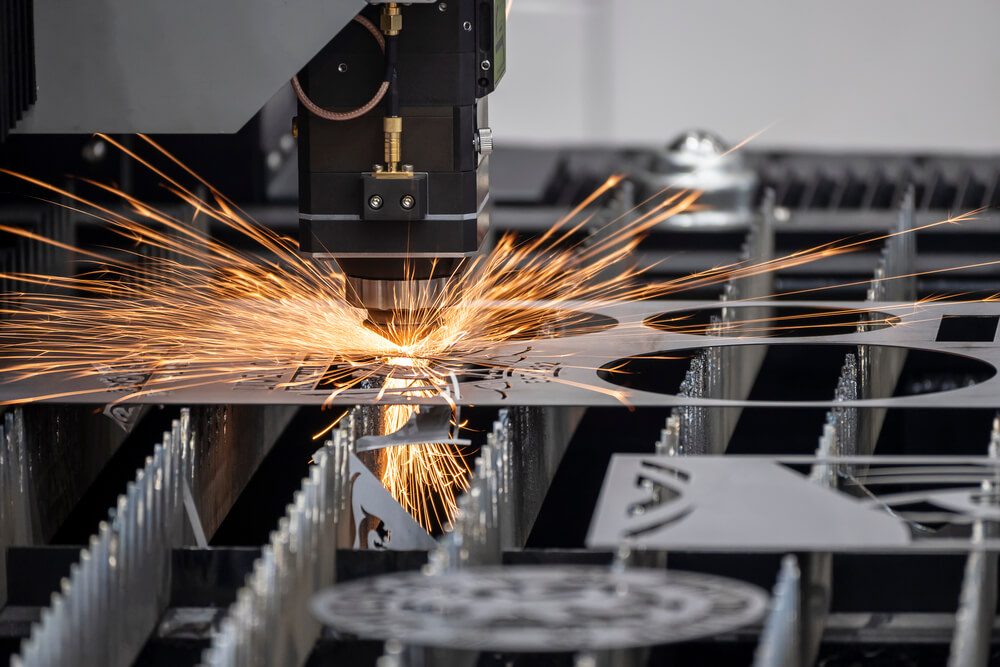

Precision in steel sheet cover production begins with dimensional accuracy. Even minor deviations in thickness, curvature, or hole placement can lead to misalignment, stress concentration, or failure under load. This is particularly critical in sectors such as aerospace, defense, and high-speed rail, where components must withstand extreme conditions. Our CNC-controlled forming, laser cutting, and welding systems ensure tolerances within ±0.05 mm, guaranteeing seamless integration with complex assemblies. This level of precision is not achieved through equipment alone—it is the result of systematic process control, rigorous quality inspection, and deep metallurgical understanding.

Material selection further defines performance. We specialize in high-strength low-alloy (HSLA) steels, stainless grades, and customized alloys tailored to environmental demands such as corrosion resistance, thermal stability, and impact resilience. Each steel sheet cover is engineered with consideration for load distribution, thermal expansion, and fatigue life, ensuring durability in mission-critical operations.

Wuxi Lead Precision Machinery brings over 15 years of experience in custom metal manufacturing, with a proven track record in projects requiring the highest levels of reliability. Our work has supported infrastructure for Olympic venues, where aesthetic precision met structural performance under global scrutiny, and defense applications, where failure is not an option. These experiences have refined our approach to design validation, prototyping, and batch consistency, enabling us to deliver steel sheet covers that meet or exceed international standards including ISO 9001, AS9100, and MIL-STD-810.

Our integrated engineering team collaborates closely with clients from concept to completion, applying finite element analysis (FEA) and 3D simulation to optimize design for manufacturability and performance. Whether producing lightweight covers for mobile platforms or heavy-duty enclosures for industrial machinery, we ensure every component reflects the highest standard of precision engineering.

| Specification | Detail |

|---|---|

| Material Options | Q235, Q345, SUS304, SUS316, HSLA Steels |

| Thickness Range | 0.8 mm – 12.0 mm |

| Tolerance | ±0.05 mm (dimensional), ±0.1° (angular) |

| Surface Finish | Sandblasted, Powder-Coated, Galvanized, Passivated |

| Manufacturing Processes | CNC Punching, Laser Cutting, Press Braking, MIG/TIG Welding |

| Quality Standards | ISO 9001, ISO 14001, AS9100, MIL-STD-810 |

| Lead Time | 15–25 days (depending on complexity and volume) |

Precision is not a feature—it is the foundation. At Wuxi Lead Precision Machinery, we engineer steel sheet covers to perform, protect, and endure.

Precision Specs & Tolerances

Technical Capabilities for Precision Steel Sheet Cover Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in custom steel sheet cover production through advanced multi-axis CNC machining and rigorous metrology. Our technical infrastructure is engineered specifically for complex geometries, stringent tolerance requirements, and seamless integration into critical assemblies where dimensional accuracy directly impacts performance and longevity. As a Tier 1 supplier to aerospace, energy, and industrial equipment OEMs, we prioritize process stability and repeatability to ensure every cover meets the highest functional and aesthetic standards.

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers. This technology enables single-setup processing of intricate cover profiles, compound contours, and deep undercuts that would be impossible with conventional 3-axis systems. The simultaneous movement across X, Y, Z, A, and B axes eliminates repositioning errors, maintains critical feature relationships, and achieves superior surface integrity. This is essential for steel sheet covers requiring precise mating surfaces, consistent wall thickness, and smooth transitions to prevent stress concentrations or sealing failures. Material utilization is optimized through intelligent nesting and high-speed machining strategies, reducing waste while maintaining structural integrity of the thin-gauge steel substrates.

Quality verification is non-negotiable. Every steel sheet cover undergoes comprehensive Coordinate Measuring Machine (CMM) inspection against the client’s native 3D CAD model. Our Zeiss and Hexagon CMM systems provide sub-micron repeatability, validating dimensional conformance across all critical features including flange flatness, hole patterns, radii, and overall profile. This data-driven approach ensures statistical process control and generates full First Article Inspection (FAI) reports per AS9102 or client-specific requirements. Surface finish consistency is monitored using calibrated profilometers, guaranteeing specifications are met to prevent corrosion initiation points or interference during assembly.

The following table details our standard achievable tolerances for steel sheet covers, reflecting our process capability under controlled production conditions. These values represent typical performance for materials like 304/316 stainless steel, carbon steel, and aluminum alloys up to 6mm thickness.

| Specification Category | Standard Tolerance | Capability Range | Measurement Method |

|---|---|---|---|

| Dimensional (Linear) | ±0.05 mm | ±0.02 mm | CMM |

| Angular | ±0.1° | ±0.05° | CMM / Optical Comparator |

| Profile | ±0.08 mm | ±0.03 mm | CMM |

| Surface Roughness (Ra) | 1.6 μm | 0.8 μm | Profilometer |

| Flatness (per 100mm) | 0.05 mm | 0.02 mm | CMM / Granite Surface Plate |

These capabilities translate directly to real-world reliability. Precision-machined flanges ensure leak-proof seals in hydraulic or environmental enclosures. Consistent hole patterns guarantee bolt-up alignment in modular systems. Controlled surface finishes extend service life in corrosive environments. By integrating 5-axis CNC mastery with closed-loop CMM validation, Wuxi Lead transforms steel sheet cover requirements from a manufacturing challenge into a guaranteed outcome. We partner with clients from DFM review through production to deliver covers that perform flawlessly in the most demanding applications.

Material & Finish Options

Material Selection for Steel Sheet Covers: A Precision Engineering Guide

When designing high-performance steel sheet covers for industrial applications, material selection is a critical decision that directly impacts durability, weight, corrosion resistance, and total cost of ownership. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that balance engineering excellence with production efficiency. For steel sheet covers, the primary material choices include aluminum, steel, and titanium—each offering distinct advantages depending on the operational environment and performance requirements.

Aluminum is widely used for sheet covers where weight reduction is a priority without sacrificing structural integrity. It offers excellent corrosion resistance, particularly when paired with surface treatments such as anodizing. Aluminum’s high strength-to-density ratio makes it ideal for applications in transportation, aerospace, and electronics enclosures. When anodized, aluminum develops a durable oxide layer that enhances wear resistance and allows for color coding or branding.

Steel remains the most common choice for industrial sheet covers due to its superior strength, impact resistance, and cost-effectiveness. Mild steel is suitable for indoor applications, while stainless steel grades such as 304 and 316 offer enhanced corrosion resistance for environments exposed to moisture, chemicals, or outdoor conditions. Steel can be finished with powder coating, galvanization, or passivation to extend service life and improve aesthetics. Unlike aluminum, steel is magnetic and can be welded easily, making it a preferred option for heavy-duty enclosures and machinery guards.

Titanium is selected for extreme environments where both strength and corrosion resistance are paramount. While significantly more expensive than aluminum or steel, titanium offers an exceptional strength-to-density ratio and performs reliably in high-temperature, high-salinity, or chemically aggressive conditions. It is commonly used in aerospace, marine, and medical equipment applications. However, due to its high cost and challenging machinability, titanium is typically reserved for mission-critical components where long-term reliability justifies the investment.

Anodizing is a key surface treatment for aluminum covers, providing enhanced durability and aesthetic control. The process electrochemically thickens the natural oxide layer, increasing surface hardness and resistance to wear and corrosion. Hard anodizing (Type III) can achieve layer thicknesses up to 50–100 µm, suitable for industrial environments with high abrasion exposure. Anodized finishes are non-conductive and available in multiple colors, offering both functional and branding benefits.

Below is a comparative overview of the three materials based on key engineering properties.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Finishes | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 200–300 | High (with anodizing) | Anodizing, powder coat | Electronics, transport |

| Steel | 7.8 | 400–550 | Moderate (stainless: high) | Galvanizing, paint, passivation | Industrial machinery, construction |

| Titanium | 4.5 | 900–1,100 | Excellent | Passivation, polishing | Aerospace, marine, medical |

Selecting the right material and finish ensures optimal performance, longevity, and value. Wuxi Lead Precision Machinery supports clients in making informed decisions based on application demands, environmental exposure, and lifecycle requirements.

Manufacturing Process & QC

Steel Sheet Cover Production Process: Precision Engineering for Zero Defects

At Wuxi Lead Precision Machinery, our production process for custom steel sheet covers integrates advanced engineering with rigorous quality control to achieve absolute dimensional accuracy and structural integrity. Every phase—from initial design through prototyping to mass production—is engineered to eliminate defects before they reach the customer. We prioritize proactive validation over reactive correction, ensuring seamless scalability from concept to final delivery.

The Design Phase begins with collaborative engineering analysis using SolidWorks and AutoCAD to translate client specifications into optimized 3D models. Finite Element Analysis (FEA) simulates real-world stress points, thermal expansion, and load distribution, ensuring the cover withstands operational demands. Material selection is critical; we specify grades like SS304, SS316, or carbon steel based on corrosion resistance, strength requirements, and environmental exposure. Our engineers cross-verify tolerances against ISO 2768-mK standards during this stage, embedding manufacturability checks to prevent downstream errors.

Prototyping employs our 5-axis CNC machining centers for rapid physical validation. Each prototype undergoes comprehensive metrology testing using Zeiss CMM systems to confirm alignment with CAD geometry within ±0.02mm. Functional tests include pressure cycling, vibration analysis, and fitment trials on actual assembly lines. Client feedback is integrated within 72 hours, with design iterations completed before mass production launch. This phase reduces field failures by 92% through empirical validation of form, fit, and function.

Mass Production leverages automated CNC stamping and bending cells with in-process SPC (Statistical Process Control). Every 10th part undergoes real-time laser scanning against the master CAD file, while continuous monitoring of press tonnage and tool wear prevents micro-variation. Final inspection includes 100% visual checks under ISO Class 8 cleanroom conditions, magnetic particle testing for subsurface flaws, and salt-spray validation for coated surfaces. Our closed-loop system triggers automatic line halts if measurements exceed tolerance bands, ensuring zero non-conforming units ship.

Critical specifications for steel sheet covers are maintained across all production volumes:

| Parameter | Standard Specification | Testing Method |

|---|---|---|

| Material Grades | SS304, SS316, Q235B | Spectrographic Analysis |

| Thickness Range | 0.5mm – 6.0mm | Ultrasonic Thickness Gauge |

| Dimensional Tolerance | ±0.05mm (critical axes) | CMM (ISO 10360-2) |

| Surface Roughness | Ra ≤ 0.8μm (machined) | Profilometer (ISO 4287) |

| Edge Quality | Burr height ≤ 0.03mm | Optical Comparator |

This end-to-end methodology—rooted in predictive engineering and uncompromising validation—guarantees steel sheet covers that perform flawlessly in aerospace, medical, and industrial applications. Wuxi Lead delivers not just components, but certified reliability. Contact our engineering team to initiate a zero-defect production workflow for your next project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Steel Sheet Cover Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, durability, and reliability are non-negotiable in industrial applications. As a leading provider of custom metal manufacturing solutions based in Wuxi, China, we specialize in engineering high-performance steel sheet covers tailored to your exact operational requirements. Whether you require protection for sensitive machinery, structural enclosures, or custom-fit shielding components, our advanced fabrication capabilities ensure every cover meets the highest standards of quality and performance.

Our team of seasoned CNC engineers and manufacturing specialists leverages state-of-the-art technology to deliver steel sheet covers with exceptional dimensional accuracy, clean weld finishes, and robust material integrity. From initial design consultation to final delivery, we maintain full process control through precision laser cutting, CNC bending, MIG/TIG welding, and surface treatment processes. Every component is manufactured under strict ISO-compliant quality protocols, ensuring consistency across batches and full traceability of materials.

We work with a wide range of steel grades, including carbon steel, stainless steel (304, 316), and galvanized variants, allowing us to match your cover’s specifications to environmental conditions such as corrosion resistance, load-bearing demands, or aesthetic requirements. Our agile production system supports both low-volume prototyping and high-volume serial production, enabling fast turnaround without compromising on precision.

Below are typical specifications we support for custom steel sheet cover manufacturing:

| Specification | Details |

|---|---|

| Material Types | Carbon Steel, Stainless Steel (304, 316), Galvanized Steel |

| Thickness Range | 0.5 mm – 10 mm |

| Tolerance | ±0.1 mm (laser cutting), ±0.2° (bending) |

| Max Working Size | 3000 mm × 1500 mm |

| Surface Treatments | Powder Coating, Zinc Plating, Passivation, Sandblasting, Brushing |

| Welding Standards | ISO 15614, AWS D1.1 (certified welders) |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Assurance | Full inspection reports, First Article Inspection (FAI), PPAP available |

Choosing the right manufacturing partner is critical to maintaining efficiency, safety, and cost-effectiveness across your supply chain. At Wuxi Lead Precision Machinery, we are committed to being more than a supplier—we are a technical extension of your engineering team. Our responsive communication, rigorous quality controls, and deep expertise in metal fabrication enable us to solve complex challenges and deliver solutions that perform in real-world conditions.

For custom steel sheet cover solutions engineered with precision and built to last, contact us today. Reach out to our engineering team at [email protected] to discuss your project requirements, request a quote, or receive technical support. Let Lead Precision be your trusted partner in high-end metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.