Technical Contents

Engineering Guide: Prototype Service

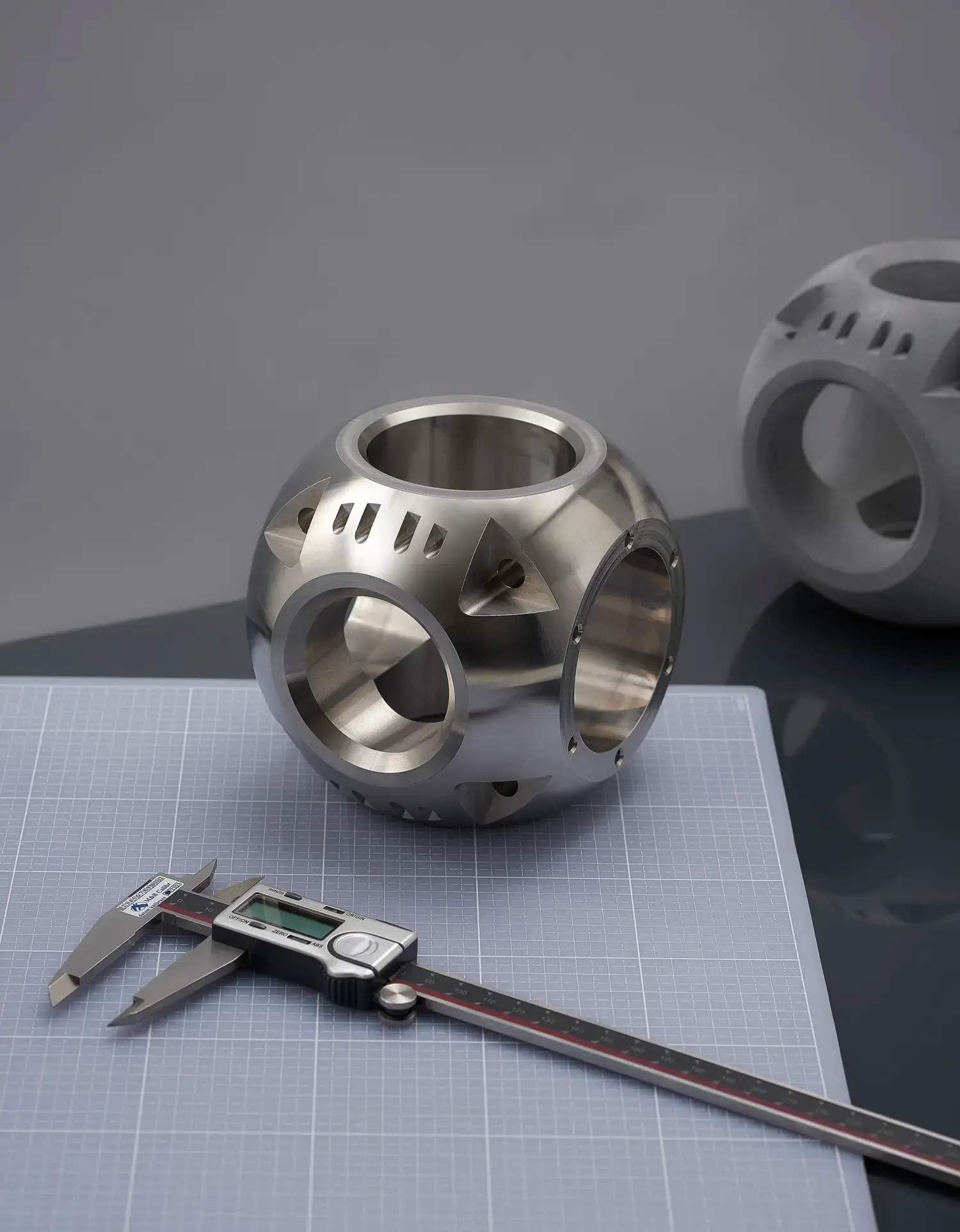

Engineering Insight: The Critical Role of Precision in Prototype Development

In the realm of custom metal manufacturing, the prototype phase is not merely a preliminary step—it is the foundation upon which product success is built. At Wuxi Lead Precision Machinery, we understand that a high-fidelity prototype serves as both a functional validation tool and a strategic asset in accelerating time-to-market. Precision in prototyping ensures that design intent, material behavior, and mechanical performance are accurately represented, minimizing costly revisions and production delays.

Precision engineering in prototype development demands more than advanced machinery—it requires deep technical expertise, rigorous process control, and an unwavering commitment to quality. Our facility in Wuxi integrates state-of-the-art CNC machining centers, multi-axis turning, and coordinate measuring machines (CMM) to achieve tolerances as tight as ±0.002 mm. This level of accuracy is not incidental; it is engineered into every stage of the process, from material selection to final inspection.

Our experience in delivering mission-critical components for Olympic-standard equipment and military-grade systems has refined our approach to prototyping. These high-stakes applications demand zero margin for error, teaching us that consistency, repeatability, and material integrity are non-negotiable. Whether producing a single prototype or a limited pre-production run, we apply the same exacting standards that define our work in aerospace and defense sectors.

Prototypes built to imprecise specifications can mislead design teams, leading to flawed assumptions about fit, function, and durability. Conversely, a precision-engineered prototype provides reliable data for stress testing, thermal analysis, and assembly validation. This fidelity reduces risk during scale-up and ensures smoother transitions into full production.

At Lead Precision, we also emphasize collaboration during the prototyping phase. Our engineering team works closely with clients to review design for manufacturability (DFM), recommend material optimizations, and identify potential failure points before metal is cut. This proactive approach not only enhances prototype performance but also streamlines downstream manufacturing processes.

Below are key technical specifications that define our prototype service capabilities:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Carbon Steel |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (polished) |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester |

| Lead Time (Prototype) | 7–15 days (depending on complexity) |

| Certifications | ISO 9001:2015, Military-Grade Quality Audits |

Precision in prototyping is not a luxury—it is a necessity for innovation in high-performance industries. With our proven track record in Olympic and military projects, Wuxi Lead Precision Machinery delivers prototype services that combine accuracy, reliability, and engineering insight, ensuring your product meets the highest standards from the very first part.

Precision Specs & Tolerances

Technical Capabilities: Precision Prototyping for Critical Applications

Wuxi Lead Precision Machinery delivers advanced prototype manufacturing through integrated 5-axis CNC machining, engineered to transform complex designs into functional, production-intent metal components. Our HAAS UMC-750 and DMG MORI CTX beta 1250 5-axis platforms eliminate the need for multiple setups, enabling single-operation machining of intricate geometries such as aerospace turbine blades, medical implant fixtures, and hydraulic manifolds. This capability ensures dimensional stability while reducing lead times by up to 40% compared to traditional 3-axis methods. We support a full spectrum of engineering alloys including 7075-T6 aluminum, Inconel 718, 316L stainless steel, and Ti-6Al-4V, with material certifications traceable to mill test reports.

All prototype workflows incorporate in-process CMM inspection using our Zeiss CONTURA G2 coordinate measuring machines, operating under ISO 17025-accredited protocols. This is not a final-step verification but an embedded quality gate: critical features are validated mid-machining to prevent scrap and ensure first-article conformance. Our engineers utilize PC-DMIS software to generate AS9102-compliant first-article inspection reports, including full GD&T analysis against client CAD models. This proactive approach identifies deviations before material investment escalates, directly supporting design validation and regulatory submissions.

Tolerance execution forms the core of our prototype reliability. The table below defines achievable standards across common materials, reflecting our machine calibration cycles and environmental controls (20°C ±0.5°C). Tighter tolerances are attainable through iterative process refinement for mission-critical features.

| Tolerance Type | Standard Capability | Tight Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Geometric (Flatness) | 0.025 mm | 0.005 mm |

| Geometric (Concentricity) | 0.012 mm | 0.003 mm |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm |

| Hole Position | ±0.015 mm | ±0.008 mm |

Our technical advantage lies in synchronizing design-for-manufacturability analysis with machining strategy development. Before cutting metal, our engineering team conducts virtual process validation using Mastercam Simulator, identifying potential collisions or tool access issues in complex cavities. This reduces physical trial iterations and accelerates prototype sign-off. For clients requiring rapid iteration, we offer concurrent engineering sessions to optimize part geometry for both function and manufacturability.

The integration of 5-axis precision, real-time CMM validation, and disciplined tolerance control ensures your prototype meets not only dimensional requirements but also functional performance criteria. This de-risks the transition from prototype to production, minimizing costly redesigns and accelerating time-to-market for engineered metal components. Wuxi Lead’s capabilities provide the technical foundation for prototypes that accurately predict final production behavior under operational loads.

Material & Finish Options

Material Selection for Precision Prototyping: Aluminum, Steel, and Titanium

Selecting the right material is critical in high-precision prototype development. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on performance, durability, and manufacturability. For prototyping applications, aluminum, steel, and titanium are the most frequently specified materials due to their distinct mechanical properties and suitability for various end-use environments.

Aluminum is widely favored for prototypes requiring a lightweight structure with good strength-to-density ratio. It offers excellent machinability, thermal conductivity, and corrosion resistance—particularly when enhanced with surface treatments like anodizing. Grade 6061-T6 is commonly used for general-purpose prototypes, while 7075-T6 is selected for high-stress applications such as aerospace components. Aluminum’s low weight and ease of post-processing make it ideal for iterative design validation and functional testing.

Steel remains the material of choice when high strength, wear resistance, and structural integrity are paramount. We offer both carbon and stainless steel variants. 4140 alloy steel provides excellent toughness and is often used in load-bearing prototypes, while 17-4 PH stainless steel delivers corrosion resistance with high yield strength, making it suitable for medical and industrial applications. Steel prototypes benefit from additional finishing processes such as passivation, plating, or powder coating, depending on environmental exposure.

Titanium, particularly Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-weight ratio and outstanding resistance to extreme temperatures and corrosive environments. It is commonly used in aerospace, defense, and high-performance automotive sectors. While more challenging to machine than aluminum or steel, titanium’s longevity and performance under stress justify its use in mission-critical prototypes. Our CNC machining centers are optimized to handle titanium with precision tooling and controlled cutting parameters to ensure dimensional accuracy and surface integrity.

Anodizing as a Finish for Aluminum Prototypes

Anodizing is a key surface treatment for aluminum components, enhancing wear resistance, corrosion protection, and aesthetic quality. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, allowing for color dyeing (commonly black, red, or blue). Type III, or hard anodizing, produces a thicker, harder oxide layer suitable for high-wear environments. At Wuxi Lead, we offer tight control over coating thickness and sealing processes to meet MIL-A-8625 standards.

Below is a comparison of key material properties for common prototyping alloys:

| Material | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 276 | 2.70 | Enclosures, brackets, fixtures |

| Aluminum | 7075-T6 | 572 | 503 | 2.81 | Aerospace, high-stress parts |

| Steel | 4140 | 655 | 415 | 7.85 | Tooling, shafts, structural parts |

| Stainless Steel | 17-4 PH | 1000 | 860 | 7.75 | Medical devices, valves |

| Titanium | Ti-6Al-4V | 950 | 880 | 4.43 | Aerospace, defense, motorsports |

Material and finish selection directly impacts prototype performance, manufacturability, and cost. Our engineering team collaborates closely with clients to recommend optimal combinations based on functional requirements, environmental conditions, and production scalability.

Manufacturing Process & QC

Precision Manufacturing Process: From Design to Zero Defect Mass Production

At Wuxi Lead Precision Machinery, our production process is engineered for absolute reliability, transforming conceptual designs into flawless end products through a rigorously controlled sequence. We integrate Design Validation, Prototyping, and Mass Production into a single continuum where Zero Defects is not an aspiration but a measurable outcome. This integrated approach eliminates costly iterations and ensures seamless scalability from initial concept to high-volume delivery, directly addressing the core risk of manufacturing defects in critical metal components.

The foundation is meticulous Design Validation. Our engineering team collaborates with clients to scrutinize CAD models for manufacturability, analyzing geometric complexity, material suitability, and tolerance stack-ups using advanced simulation software. This phase identifies potential weaknesses before metal is cut, ensuring the design aligns with both functional requirements and our precision machining capabilities. Critical dimensions and interfaces are locked down, establishing the non-negotiable quality baseline for all subsequent stages.

Prototyping is where theoretical validation becomes empirical proof. Utilizing our multi-axis CNC milling and turning centers, we produce functional prototypes with the same materials and near-identical processes intended for mass production. This phase is not merely about form and fit; it is a comprehensive stress test of the manufacturing process itself. We validate toolpaths, fixture designs, and inspection methodologies, measuring dimensional conformity against the approved design with calibrated CMMs and optical comparators. Any deviation triggers immediate root cause analysis and process refinement. Prototyping at Wuxi Lead is the critical checkpoint ensuring the production process is inherently capable of Zero Defects before significant resources are committed.

Transitioning to Mass Production leverages the validated process without compromise. The exact tooling, fixturing, and inspection protocols proven during prototyping are deployed at scale. Real-time in-process monitoring, statistical process control (SPC) with stringent process capability indices (Cp/Cpk > 1.67), and 100% critical feature inspection guarantee dimensional stability and material integrity batch after batch. Our closed-loop quality system feeds data from production directly back to engineering, enabling continuous micro-optimizations that sustain the Zero Defects standard. This seamless handoff, rooted in prototyping validation, is why our clients achieve consistent first-pass yields exceeding 99.98%.

The following table outlines the critical specifications differentiating our prototyping phase from mass production, demonstrating the continuity and heightened control required for Zero Defects output.

| Parameter | Prototyping Phase | Mass Production Phase |

|---|---|---|

| Tolerance Capability | ±0.005 mm (standard) | ±0.002 mm (standard) |

| Material Options | Full range (Al, SS, Ti, Brass, Exotics) | Confirmed production material only |

| Lead Time | 7-15 days (incl. validation) | Optimized per volume (e.g., 25 days for 500 pcs) |

| Process Validation | Full SPC setup, fixture/tool proofing | Continuous SPC, real-time monitoring |

| Defect Rate Target | ≤ 0.5% (focus on process refinement) | ≤ 0.02% (Zero Defects execution) |

This disciplined progression—from validated design through rigorously tested prototyping to controlled mass production—is the Wuxi Lead guarantee. We do not manufacture parts; we deliver certified precision, eliminating defects at the source for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Your Next Precision Prototype Project

When it comes to custom metal manufacturing, especially in the development phase of high-performance components, selecting the right partner is critical. At Wuxi Lead Precision Machinery, we specialize in delivering prototype services that bridge the gap between concept and full-scale production. Our engineering-driven approach ensures that every prototype we produce is not only dimensionally accurate but also functionally representative of the final part—enabling faster validation, reduced time to market, and lower overall development costs.

With over 15 years of experience serving industries such as aerospace, medical devices, automation, and advanced robotics, we understand the demands of precision, reliability, and confidentiality. Our state-of-the-art facility in Wuxi, China, is equipped with advanced CNC machining centers, multi-axis turning machines, and coordinate measuring systems that guarantee tolerances as tight as ±0.002 mm. Whether you require a single prototype or a small batch for testing and certification, our team works closely with your engineers to ensure design integrity, material compatibility, and manufacturability from the outset.

We support a wide range of metals including aluminum alloys, stainless steel, titanium, brass, and specialty materials such as Inconel and tool steels. Our in-house capabilities span precision milling, turning, grinding, drilling, tapping, surface finishing, and optional heat treatment—all under one roof. This vertical integration allows us to maintain full control over quality, lead time, and process traceability.

Our prototype service is designed for speed without compromising precision. With rapid quoting, DFM feedback within 12 hours, and typical prototype lead times of 5–7 days, we enable agile product development cycles. Every project is managed by a dedicated engineering coordinator who ensures seamless communication, real-time updates, and full documentation including inspection reports, material certifications, and dimensional reports.

Below are key specifications of our prototype manufacturing capabilities

| Feature | Specification |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Minimum Tolerance | ±0.002 mm |

| Surface Finish | As low as Ra 0.4 µm (polished options available) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Tool Steel, and more |

| Machining Processes | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, precision grinding |

| Inspection Equipment | CMM, optical comparators, surface roughness testers, micrometers, calipers |

| Lead Time (Prototype) | 5–7 working days (standard), expedited options available |

| Certifications | ISO 9001:2015 compliant processes |

We invite you to experience the Wuxi Lead difference—where engineering excellence meets manufacturing precision. For your next prototype project, contact us today at [email protected]. Our technical team is ready to review your CAD files, provide instant feedback, and deliver prototypes that meet the highest standards of quality and performance. Partner with a manufacturer you can trust—Lead Precision Machinery, your global partner in precision metal components.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.