Technical Contents

Engineering Guide: Tin Man Sheet Metal

Engineering Insight: The Precision Imperative in Tin Man Sheet Metal Fabrication

In the realm of industrial manufacturing, tin man sheet metal work—commonly referred to as sheet metal fabrication for ductwork, enclosures, and structural housings—demands far more than basic forming and cutting. At Wuxi Lead Precision Machinery, we define tin man fabrication as a high-precision engineering discipline where tolerances, repeatability, and material integrity directly influence system performance, safety, and longevity. Whether serving HVAC, aerospace, defense, or industrial equipment sectors, precision in every bend, weld, and perforation is non-negotiable.

Sheet metal components often serve as critical subsystems within larger mechanical or environmental control systems. A seemingly minor deviation in flange alignment or seam tolerance can cascade into airflow inefficiencies, structural weaknesses, or electromagnetic interference in sensitive enclosures. This is especially critical in high-stakes applications such as military-grade environmental housings or Olympic-standard ventilation systems, where Wuxi Lead has delivered mission-critical components. Our involvement in projects supporting Olympic infrastructure and defense logistics underscores the necessity of micron-level accuracy and rigorous quality validation.

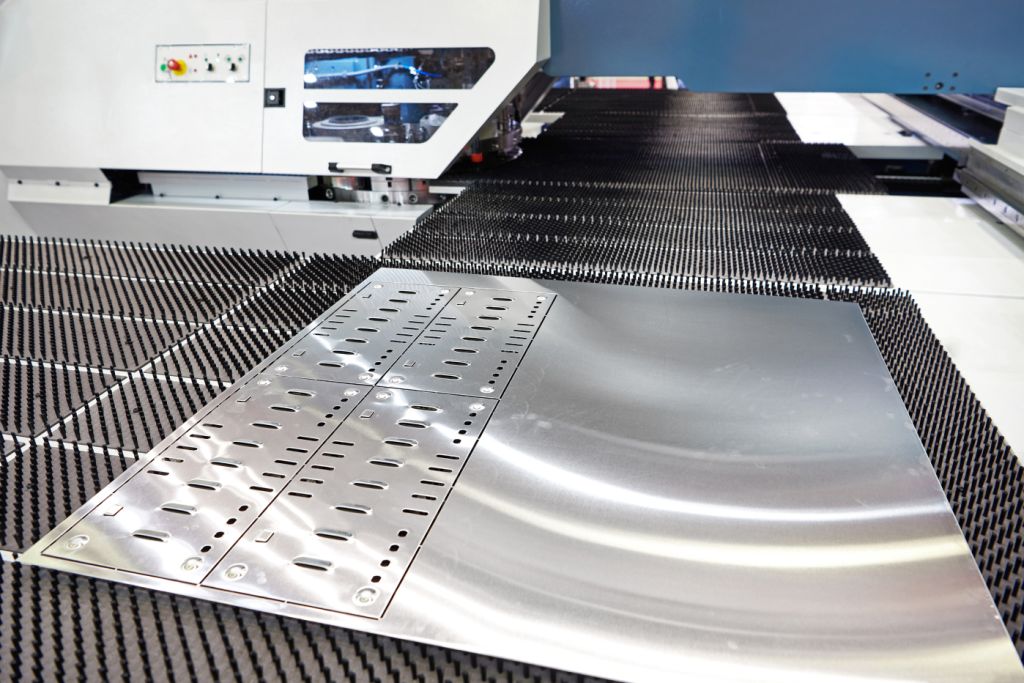

Precision begins at the design stage. Our engineering team utilizes advanced 3D modeling and finite element analysis (FEA) to simulate stress points, thermal expansion, and assembly dynamics before any metal is cut. This proactive approach minimizes rework and ensures first-time-right production. Coupled with CNC-controlled laser cutting, automated bending cells, and robotic welding, our process guarantees dimensional consistency across high-volume runs.

Material selection further amplifies the need for precision. Tin man fabrication often involves galvanized steel, stainless alloys, and aluminum—each with unique spring-back characteristics and thermal behaviors. Our machinery is calibrated to account for these variables, ensuring that every bend angle and hole placement meets ISO 2768-fine or customer-specified standards.

At Wuxi Lead, we treat every sheet as a functional component, not just a formed part. This philosophy has enabled us to support clients where failure is not an option.

Typical Fabrication Specifications at Wuxi Lead Precision Machinery

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm | 0.8 mm – 4.0 mm |

| Tolerance (Cutting) | ±0.1 mm | ±0.05 mm |

| Tolerance (Bending) | ±0.2° / ±0.5 mm | ±0.1° / ±0.2 mm |

| Minimum Hole Diameter | 1.0 mm (steel) | 0.6 mm (stainless) |

| Surface Finish (Ra) | ≤3.2 µm (standard) | ≤1.6 µm (polished/coated) |

| Welding Processes | TIG, MIG, Spot Welding | Laser Welding, Orbital TIG |

| Quality Standards | ISO 9001, ISO 14001 | MIL-STD-2036, AS9100 (on request) |

Our track record in delivering precision tin man sheet metal solutions for Olympic venues and military applications reflects our commitment to engineering excellence. At Wuxi Lead Precision Machinery, we don’t just fabricate—we engineer confidence into every component.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in thin sheet metal fabrication, engineered for mission-critical aerospace, medical, and semiconductor applications. Our integrated manufacturing ecosystem combines cutting-edge 5-axis CNC technology with rigorous quality validation protocols to transform complex designs into dimensionally stable components. We specialize in processing materials ranging from 0.5 mm to 6.0 mm thickness, including stainless steel alloys, aluminum 5052/6061, copper, and specialty composites, with consistent repeatability down to ±0.025 mm.

Our 5-axis CNC machining centers eliminate geometric limitations inherent in traditional 3-axis systems. Simultaneous multi-axis movement enables single-setup fabrication of intricate contours, deep cavities, and compound angles—reducing secondary operations by up to 70% while maintaining critical feature alignment. This capability is essential for components requiring seamless integration of milled features, formed edges, and precision holes within thin substrates. Advanced collision avoidance algorithms and thermal compensation systems ensure uninterrupted production stability across extended runs, even for low-volume, high-mix orders demanding rapid changeovers.

Quality assurance is embedded at every process stage through our closed-loop inspection framework. All critical dimensions undergo first-article validation using Zeiss CONTURA CMM systems with 0.0005 mm probe resolution, certified to ISO 17025 standards. Real-time SPC data from in-process gauging feeds directly into our MES platform, enabling immediate corrective action before deviations exceed 50% of tolerance bands. Dimensional reports include full GD&T analysis against CAD models, with surface roughness verification via Mitutoyo SJ-410 profilometers. This methodology ensures 100% traceability from raw material certification to final shipment documentation.

The following table defines our standard and precision tolerance capabilities for sheet metal work:

| Feature Category | Standard Tolerance (mm) | Precision Tolerance (mm) | Process Verification Method |

|---|---|---|---|

| Linear Dimensions | ±0.10 | ±0.025 | CMM / Optical Comparator |

| Hole Diameter | ±0.05 | ±0.015 | Air Gaging / Pin Gages |

| Hole Position | ±0.15 | ±0.05 | CMM (GD&T True Position) |

| Flatness | 0.15 per 100mm | 0.05 per 100mm | Granite Surface Plate |

| Bend Angle | ±0.5° | ±0.2° | Digital Angle Gauge |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Profilometer |

This technical infrastructure supports rapid prototyping through serial production with zero compromise on dimensional integrity. Our engineers collaborate directly with client design teams during DFM analysis to optimize manufacturability—anticipating springback, tooling constraints, and inspection accessibility before cutting metal. Every component shipped from Wuxi Lead undergoes final conformance verification against your engineering specifications, documented in our AS9100-certified quality management system. Partner with us to convert demanding sheet metal requirements into field-proven reliability.

Material & Finish Options

Material Selection in High-Precision Sheet Metal Fabrication

Selecting the appropriate material is a foundational decision in sheet metal fabrication, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision engineering for demanding industrial applications, where material properties must align with functional requirements such as strength-to-weight ratio, corrosion resistance, thermal stability, and machinability. Among the most widely used materials in advanced fabrication are aluminum, steel, and titanium—each offering distinct advantages depending on the application environment.

Aluminum is favored in industries requiring lightweight yet robust components, such as aerospace, transportation, and electronics. Its high electrical and thermal conductivity, combined with excellent corrosion resistance, makes it ideal for enclosures, heat sinks, and structural frames. The material’s low density reduces overall system weight without compromising rigidity, and it responds well to CNC cutting, bending, and welding processes.

Steel remains the backbone of heavy-duty manufacturing due to its superior strength, availability, and cost-effectiveness. Carbon steel is commonly used in structural components and machinery frames, while stainless steel variants (such as 304 and 316) offer enhanced resistance to oxidation and chemical exposure, making them suitable for food processing, medical devices, and marine environments. Steel’s versatility across forming, welding, and finishing operations ensures consistent performance in high-load applications.

Titanium stands at the premium end of the spectrum, selected for extreme conditions involving high temperatures, aggressive chemicals, or stringent weight constraints. With a strength-to-density ratio surpassing both aluminum and steel, titanium is indispensable in aerospace, defense, and high-performance automotive systems. Though more challenging to machine and cost-intensive, its unparalleled durability and biocompatibility justify its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing, particularly for aluminum, is a controlled electrochemical process that thickens the natural oxide layer, significantly improving wear and corrosion resistance. It also allows for color coding and aesthetic customization without compromising dimensional accuracy. Hard anodizing (Type III) is often specified for industrial parts subjected to abrasion or electrical insulation requirements.

Understanding these material and finish characteristics enables optimized design and production outcomes. The table below summarizes key mechanical and fabrication properties of the three core materials.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Forms (Sheet Thickness Range) | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | 0.5 mm – 12.7 mm | Aerospace, electronics, transport |

| Stainless Steel 304 | 8.0 | 505 | Very High | 0.8 mm – 10.0 mm | Medical, food processing, marine |

| Titanium Grade 2 | 4.5 | 345 | Exceptional | 0.8 mm – 6.0 mm | Aerospace, defense, chemical plants |

At Wuxi Lead, our engineering team collaborates closely with clients to match material and finish selections with operational demands, ensuring optimal performance and lifecycle value in every fabricated component.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: The Zero Defects Production Framework

Precision sheet metal fabrication demands rigorous process control from initial concept to final shipment. At Wuxi Lead Precision Machinery, our integrated workflow—Design, Prototyping, Mass Production—is engineered to eliminate defects before they occur, ensuring every component meets exacting aerospace, medical, and industrial standards. This systematic approach transforms client specifications into flawless physical products while minimizing risk and cost.

The Design phase establishes the foundation for zero defects. Our engineering team utilizes advanced CAD/CAM software (SolidWorks, Siemens NX) to conduct comprehensive design for manufacturability (DFM) analysis. We scrutinize material selection, bend allowances, tooling requirements, and geometric dimensioning early in the process. Critical tolerances are validated through virtual simulation, identifying potential stress points or assembly conflicts before any metal is cut. Client collaboration is continuous, ensuring alignment on functional requirements and surface finish specifications. This proactive engineering review prevents 95% of potential production errors at the source.

Prototyping transitions virtual designs into physical validation. We deploy rapid CNC laser cutting, precision press brake forming, and robotic welding to produce functional prototypes within 72 hours. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, measuring all critical dimensions against the original CAD model using coordinate measuring machines (CMMs). Material properties, weld integrity, and assembly fit are verified. This stage is not merely validation—it is a critical learning loop where process parameters are fine-tuned. Any deviation triggers immediate root-cause analysis and process correction, ensuring mass production begins with statistically validated parameters.

Mass Production executes the perfected process at scale with embedded quality assurance. Our production floor integrates automated material handling, real-time machine monitoring, and in-process inspection stations. Every 50th part undergoes full CMM verification, while key characteristics are checked hourly via calibrated gauges. Statistical process control (SPC) charts track critical dimensions, enabling predictive adjustments before out-of-tolerance conditions arise. Final inspection includes 100% visual examination for surface defects and functional testing where applicable. This layered quality system—combining automation, human expertise, and data analytics—guarantees consistent output meeting our zero-defects commitment.

Our core production capabilities ensure this framework delivers exceptional results across diverse applications:

| Process Stage | Key Parameters | Performance Metrics |

|---|---|---|

| Laser Cutting | Material Thickness: 0.5-25mm | Tolerance: ±0.05mm |

| Max Bed Size: 4000x2000mm | Edge Quality: ISO 9013 Class F1 | |

| Press Brake Forming | Max Force: 1000T | Angular Tolerance: ±0.2° |

| Max Length: 6000mm | Repeatability: ±0.03mm/m | |

| Robotic Welding | Material Types: Steel, SS, Al, Cu | Defect Rate: <0.1% |

| Processes: MIG, TIG, Laser | NDT Compliance: ASME IX |

This closed-loop production system transforms design intent into defect-free reality. By embedding quality at every stage—from virtual validation through statistical process control—we eliminate costly rework and delays. Partner with Wuxi Lead to convert your sheet metal requirements into precision assets that perform reliably in the most demanding applications. Zero defects is not our goal; it is our operational standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Trusted Source for High-End Sheet Metal Fabrication

In the competitive landscape of precision manufacturing, selecting the right partner for sheet metal fabrication is critical to maintaining product integrity, reducing time-to-market, and controlling production costs. At Wuxi Lead Precision Machinery, we specialize in delivering advanced, high-end sheet metal solutions tailored to the exacting demands of global industries including aerospace, medical equipment, automation, and industrial machinery. Our commitment to engineering excellence, material integrity, and process precision ensures that every component we produce meets the highest international standards.

With over 15 years of experience in precision metalworking, our facility in Wuxi, China, is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems. We integrate lean manufacturing principles with rigorous quality control protocols, including ISO 9001-certified processes and comprehensive in-process inspections. From prototyping to high-volume production, our team of senior engineers and manufacturing specialists work closely with clients to optimize designs for manufacturability, durability, and cost-efficiency.

We understand that modern OEMs and system integrators require more than just parts—they require a strategic manufacturing partner capable of ensuring consistency, scalability, and technical collaboration. Our engineering team provides detailed design for manufacturing (DFM) feedback, material selection guidance, and rapid prototyping services to accelerate your development cycle. Whether you are working with stainless steel, aluminum, carbon steel, or specialty alloys, we maintain strict tolerances and surface finish control across all production runs.

Our facility supports full-service sheet metal fabrication, from initial laser cutting with ±0.1 mm accuracy to complex multi-stage bending and robotic welding. We also offer precision assembly, surface treatment, and custom packaging solutions, ensuring your components arrive ready for integration.

Below are key technical capabilities that define our production capacity:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 – 6.0 mm |

| Max Sheet Size | 1500 × 3000 mm |

| Laser Cutting Tolerance | ±0.1 mm |

| Punching Accuracy | ±0.05 mm |

| Bending Tolerance | ±0.2°, ±0.1 mm |

| Welding Processes | TIG, MIG, Spot Welding |

| Surface Treatments | Anodizing, Powder Coating, Zinc Plating, Passivation |

| Quality Standards | ISO 9001:2015, First Article Inspection, FAI Reports, PPAP Support |

At Wuxi Lead Precision Machinery, we pride ourselves on transparency, responsiveness, and long-term partnership. Our global client base relies on us not only for precision but for seamless communication, on-time delivery, and continuous improvement.

If you are seeking a reliable, high-capability sheet metal fabrication partner, we invite you to contact us today. Send your inquiries, drawings, or project specifications to [email protected]. Our engineering team will respond within 12 hours to discuss your requirements, provide technical feedback, and deliver a competitive quotation. Let Lead Precision become your strategic manufacturing advantage in the tin man sheet metal sector.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.