Technical Contents

Engineering Guide: Cnc Machinr

Engineering Insight: The Critical Role of Precision in CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we define precision CNC machining as the disciplined convergence of engineering excellence, material science, and advanced automation. Our decades-long commitment to micron-level accuracy has positioned us as a trusted partner in industries where failure is not an option: aerospace, defense, medical technology, and high-performance industrial systems.

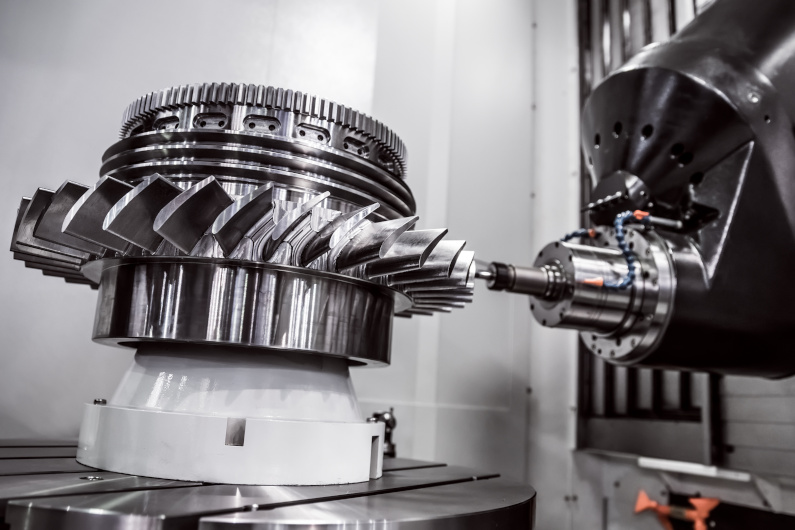

Precision in CNC machining directly influences part integrity, assembly compatibility, and operational lifespan. Even deviations measured in microns can lead to catastrophic component failure in high-stress environments. This is especially true in applications such as turbine blades, satellite components, or military-grade actuators, where thermal cycling, vibration, and mechanical load demand absolute dimensional stability. Our engineering protocols account for thermal expansion coefficients, tool deflection, and material grain structure to ensure that every machined part conforms to the tightest tolerances—consistently and repeatably.

Our expertise has been rigorously tested in mission-critical projects, including components used in Olympic-standard timing systems and precision subsystems deployed in military defense platforms. These applications demanded not only adherence to ISO and MIL-STD specifications but also the ability to innovate within extreme constraints. For instance, machining lightweight titanium alloys for aerospace use requires balancing minimal wall thickness with structural rigidity—a challenge met through advanced 5-axis toolpath optimization and real-time in-process measurement.

Wuxi Lead Precision Machinery operates a fully integrated manufacturing ecosystem, combining high-speed CNC centers with coordinate measuring machines (CMM), laser interferometry, and statistical process control (SPC) systems. This closed-loop quality assurance model ensures that every production run is traceable, repeatable, and fully documented—essential for compliance with AS9100 and ISO 13485 standards.

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, identifying potential stress concentrations, optimizing tool access, and recommending material substitutions that enhance performance without compromising precision. This proactive engagement reduces prototyping cycles and accelerates time-to-market—critical advantages in competitive global supply chains.

Below are key technical specifications that define our precision machining capabilities:

| Specification | Capability |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Tolerance Range | ±0.003 mm to ±0.01 mm (typical) |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm |

| Materials Processed | Aluminum Alloys, Titanium, Inconel, Stainless Steel, PEEK, Carbon Fiber Composites |

| Quality Standards | ISO 9001, AS9100, MIL-STD-810, ISO 13485 |

Precision is not achieved by machinery alone—it is engineered through experience, validated by performance, and proven in application. At Wuxi Lead Precision Machinery, we do not just meet specifications. We define them.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

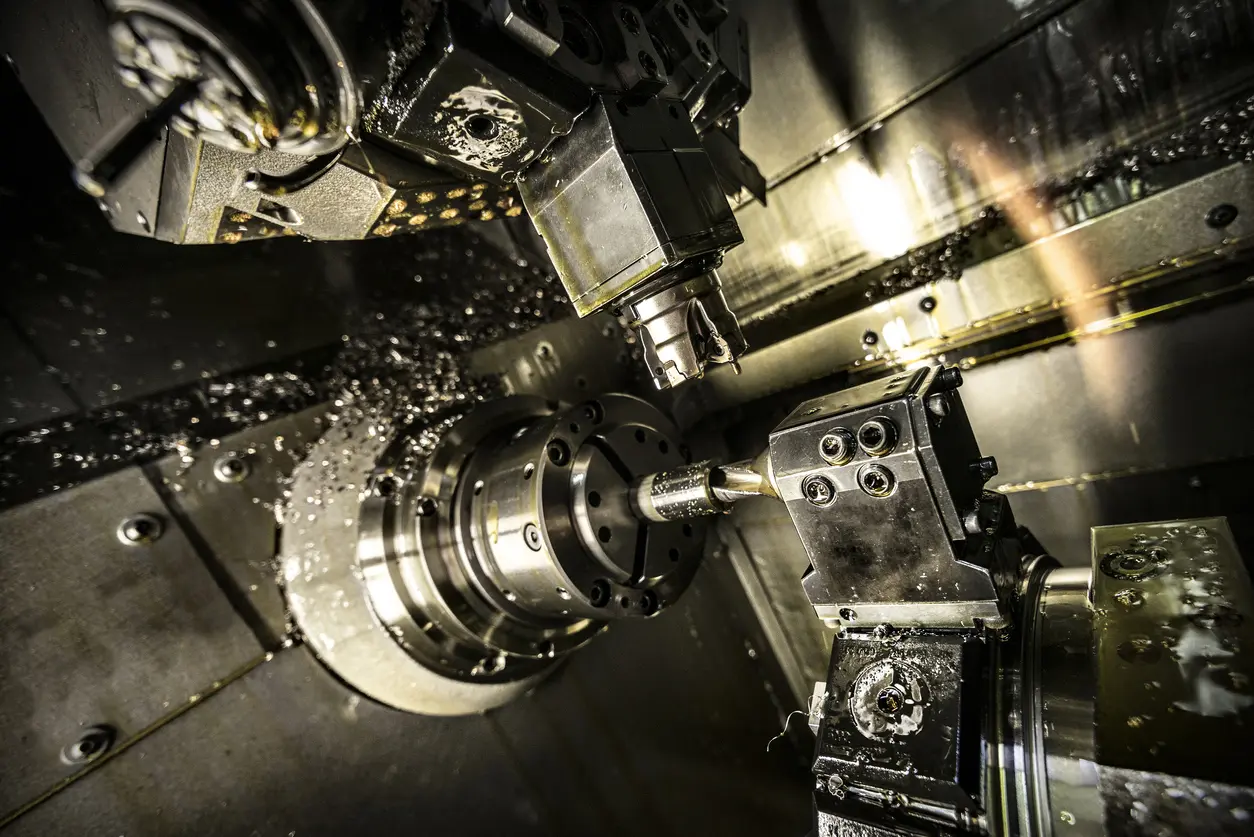

Wuxi Lead Precision Machinery operates at the forefront of advanced CNC manufacturing, leveraging state-of-the-art 5-axis machining centers to tackle the most intricate geometries demanded by aerospace, medical, and energy sectors. Our facility houses a strategic fleet of Haas UMC-750 and DMG MORI CTX beta 1250 5-axis systems, each equipped with high-torque spindles (15,000 RPM), sub-micron linear encoders, and integrated probing. This enables true simultaneous 5-axis contouring with a maximum work envelope of Ø1,250 mm x 1,000 mm, eliminating secondary operations and ensuring exceptional part integrity. Material versatility spans titanium alloys (Grade 5, Ti-6Al-4V ELI), Inconel 718, aluminum 7075-T7351, and high-performance polymers, all processed under strict environmental controls to minimize thermal drift. Our CAM programming utilizes hyperMILL and Mastercam for optimized toolpaths, achieving surface finishes down to Ra 0.4 µm while maintaining repeatability of ±0.003 mm across production runs.

Quality assurance is non-negotiable. Every component undergoes rigorous validation via Zeiss CONTURA and Hexagon GLOBAL S 1210 Coordinate Measuring Machines (CMMs), operating under ISO 17025-accredited protocols. These systems feature 0.5 µm volumetric accuracy, automated temperature compensation, and PC-DMIS software for GD&T analysis of complex contours, true positions, and profile tolerances. Full traceability is maintained through digital inspection reports linked to material certs and process parameters, with critical features verified using calibrated optical comparators and surface roughness testers. This closed-loop system ensures compliance with AS9100D and ISO 13485 standards, directly reducing client scrap rates and assembly failures.

Our precision benchmarks are defined by measurable tolerance performance across critical features, as demonstrated below:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm |

| Hole Diameter (Ø) | H7 (+0.015/0) | H5 (+0.004/0) |

| Positional Tolerance | ±0.020 mm | ±0.005 mm |

| Flatness | 0.02 mm | 0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

These capabilities translate into tangible value: reduced lead times through single-setup machining, elimination of costly assembly adjustments, and extended component service life in mission-critical applications. Wuxi Lead’s technical infrastructure ensures that design intent becomes manufacturing reality, with zero compromise on dimensional fidelity. Partner with us to transform complex engineering challenges into precision-certified solutions.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is critical in precision CNC machining, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity components from aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications. Understanding the strengths and limitations of these materials ensures optimal part functionality across aerospace, automotive, medical, and industrial equipment sectors.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is widely used in structural and mechanical applications due to its weldability and moderate strength. For higher performance demands, 7075-T6 offers superior strength, making it ideal for aerospace components. Aluminum’s low density and high thermal conductivity also make it suitable for heat sinks and lightweight enclosures. When enhanced surface durability is required, anodizing is highly recommended. Anodizing creates a protective oxide layer that improves wear resistance, corrosion protection, and allows for color coding through dye integration.

Steel, particularly in alloy and stainless forms, delivers exceptional strength, hardness, and wear resistance. 4140 alloy steel is frequently chosen for high-stress applications such as shafts and tooling due to its toughness and fatigue resistance. Stainless steel 304 and 316 are preferred in environments requiring high corrosion resistance and hygiene, including medical devices and food processing equipment. While steel is more challenging to machine than aluminum, our advanced CNC equipment ensures tight tolerances and excellent surface finishes. Post-machining treatments such as passivation or plating can further enhance performance in aggressive environments.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme conditions. Its outstanding strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace, defense, and medical implant applications. However, titanium’s low thermal conductivity and high chemical reactivity require specialized cutting strategies and tooling. At Wuxi Lead, our precision machining protocols are optimized to manage these challenges, ensuring dimensional accuracy and surface integrity.

The choice of finish significantly impacts functionality and longevity. Anodizing, particularly Type II and Type III (hard coat), is a key surface treatment for aluminum. It enhances surface hardness, electrical insulation, and aesthetic control.

Below is a comparative overview of key material properties and finishing options:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Recommended Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, Enclosures, Heat Sinks | Anodizing (Type II/III), Powder Coating |

| Steel | 4140, 304, 316 | 500–900 | 7.8–8.0 | Tooling, Shafts, Medical Devices | Passivation, Zinc Plating, Painting |

| Titanium | Ti-6Al-4V (Gr5) | 900–1000 | 4.4 | Aerospace, Implants, Marine | As-Machined, Passivation, Laser Marking |

Material and finish selection must align with operational demands, environmental exposure, and lifecycle requirements. Wuxi Lead Precision Machinery provides expert consultation to ensure your component design leverages the optimal material and surface treatment for peak performance.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero Defects Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and efficiency, transforming client specifications into flawless components through a rigorously controlled sequence. We integrate advanced methodology and proactive quality assurance at every phase, ensuring the Zero Defects standard is not a target but an inherent outcome of our workflow. This systematic approach—Design, Prototyping, Mass Production—eliminates downstream errors and guarantees performance-critical parts meet exacting global standards.

The foundation lies in collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners with clients early to review 3D CAD models, identifying potential machining complexities, material constraints, or tolerance conflicts before physical work begins. Utilizing advanced simulation software, we validate toolpaths, predict thermal deformation, and optimize fixture strategies. This preemptive engineering ensures the design is not only manufacturable but optimized for repeatability and minimal waste, directly contributing to the Zero Defects objective by resolving issues in the digital realm.

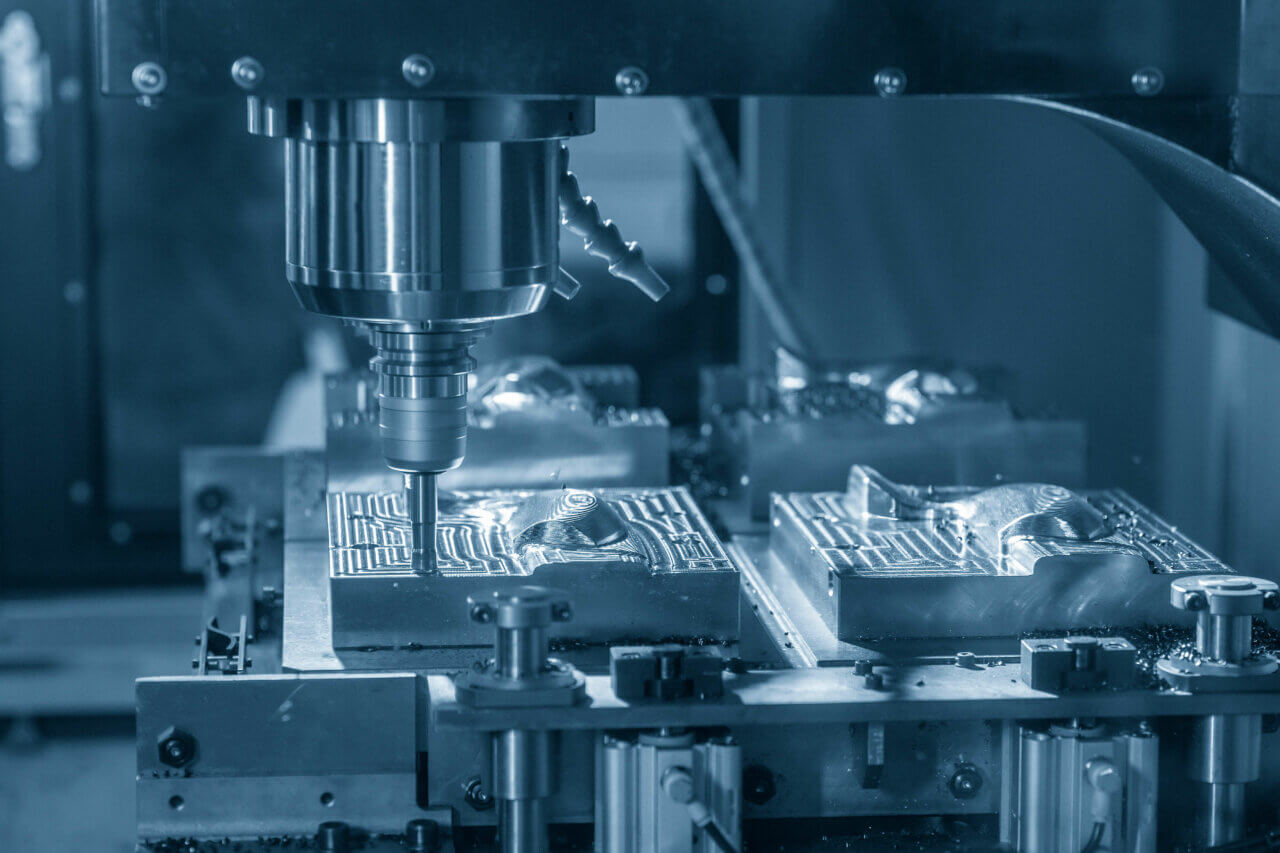

Prototyping serves as the critical physical validation step. Leveraging our high-precision 5-axis machining centers and wire EDM capabilities, we produce functional prototypes matching final production intent. Each prototype undergoes comprehensive metrology using calibrated CMMs, optical comparators, and surface roughness testers against the original CAD data and client specifications. This phase validates the DFM adjustments, confirms material behavior, and fine-tunes process parameters. Crucially, any deviation triggers immediate root-cause analysis and process correction, preventing flaws from migrating to mass production. Full material traceability and first-article inspection reports provide documented proof of conformance.

Mass Production deployment is governed by Statistical Process Control (SPC) and real-time monitoring. Approved process parameters are locked into our CNC systems, with in-process gauging and automated tool-wear compensation ensuring dimensional stability across every part. Our production floor operates under strict environmental controls, while operators perform defined checkpoint inspections using calibrated instruments. Every component batch includes full material certification and final inspection documentation. Process capability indices (Cp/Cpk) are continuously tracked, enabling preemptive correction before non-conformances occur. This closed-loop system, built on the validated prototype and robust design, is the engine of our Zero Defects commitment.

Our core production capabilities enable this precision, as demonstrated below:

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (micron level) | Zeiss CONTURA CMM, Mitutoyo height gauges |

| Surface Finish | Ra 0.1 µm to 3.2 µm | Mitutoyo SJ-410 Profilometer |

| Materials | Aluminum, Titanium, Inconel, Stainless Steel, Plastics | Mill test reports, PMI (Positive Material Identification) |

| Equipment | 5-Axis Machining Centers (DMG MORI, MAZAK), Wire EDM (Sodick) | ISO 17025 accredited calibration |

This integrated process—where design foresight, prototype validation, and SPC-driven mass production converge—ensures Wuxi Lead delivers components that perform flawlessly in the most demanding applications. Zero Defects is achieved through systemic rigor, not inspection alone, providing our clients with absolute confidence in every shipment.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and speed are not just advantages—they are requirements. As a leading provider of precision CNC machining services based in China, we specialize in delivering custom-engineered components that meet the most demanding tolerances and performance standards across aerospace, medical, automotive, and industrial automation sectors. Our commitment to quality and innovation has positioned us as a trusted manufacturing partner for global OEMs and engineering firms seeking a competitive edge.

Our state-of-the-art facility is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, supported by a team of certified engineers and machinists with over 15 years of collective experience. From prototype development to high-volume production runs, we offer end-to-end manufacturing solutions that ensure repeatability, consistency, and full compliance with international quality standards, including ISO 9001:2015 and AS9100. Whether you require complex geometries, tight tolerance machining (+/- 0.002 mm), or materials ranging from aluminum alloys and stainless steel to titanium and engineering plastics, Lead Precision delivers with precision and accountability.

We believe that true partnership goes beyond order fulfillment. That’s why our engineering team collaborates closely with your design and R&D departments during the early stages of product development, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and cost-optimized production planning. This proactive engagement reduces time-to-market, minimizes waste, and enhances overall product performance.

Our global logistics network ensures on-time delivery to North America, Europe, and Asia, backed by real-time project tracking and dedicated customer support. Every component is inspected using high-accuracy CMM (Coordinate Measuring Machine), optical comparators, and surface roughness testers, guaranteeing that what leaves our facility meets your exact specifications.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic ally committed to your success. We combine cutting-edge technology with a customer-first philosophy to deliver precision parts that perform, on schedule and within budget.

Explore how our CNC machining capabilities can elevate your production standards. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory tour. Let Lead Precision be the foundation of your next precision manufacturing breakthrough.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC Machining Centers |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Tolerance Capability | ±0.002 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Brass, PEEK, Delrin, and more |

| Secondary Operations | Deburring, Anodizing, Plating, Passivation, Laser Marking |

| Quality Standards | ISO 9001:2015, AS9100, RoHS Compliant |

| Lead Times | Prototypes: 5–7 days; Production: 10–20 days (varies by volume) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.