Technical Contents

Engineering Guide: Prototype Machine Shop Georgia

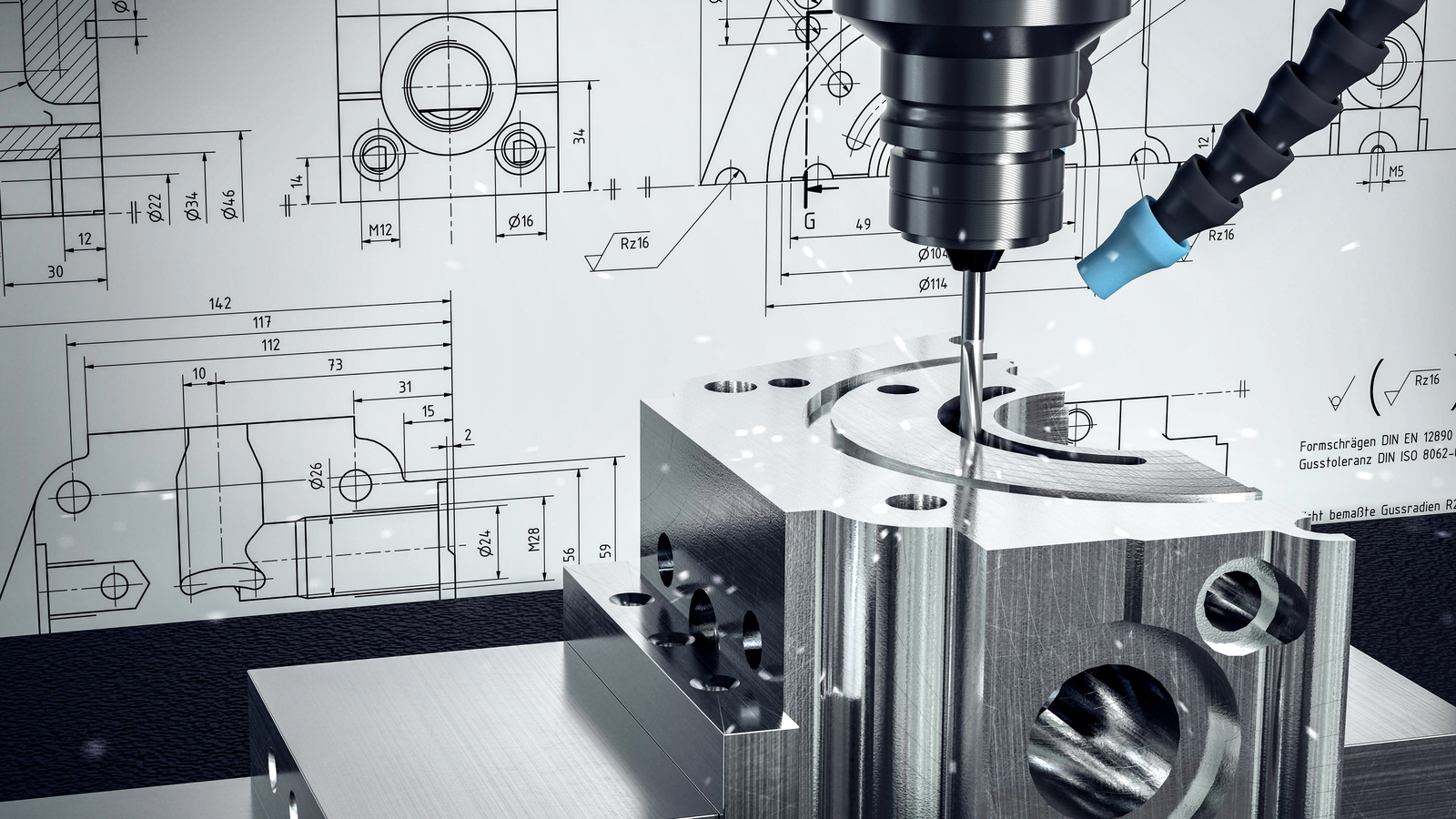

Engineering Insight: The Critical Role of Precision in Prototype Machine Shop Operations

In the competitive landscape of advanced manufacturing, the role of precision in prototype development cannot be overstated. For industries operating in aerospace, defense, medical technology, and high-performance automotive sectors, the difference between success and failure often lies in microns. A prototype machine shop in Georgia serving these markets must not only possess state-of-the-art equipment but also demonstrate a deep-rooted engineering culture focused on repeatability, accuracy, and material integrity. This level of precision ensures that early-stage components accurately reflect final production intent, reducing time-to-market and minimizing costly redesigns.

At Wuxi Lead Precision Machinery, we understand that precision is more than a technical specification—it is a philosophy embedded in every stage of the manufacturing process. With over 15 years of experience delivering mission-critical components for Olympic-grade equipment and military defense systems, our team has mastered the balance between innovation and exacting standards. These high-stakes applications demand zero tolerance for deviation, where a tolerance of ±0.001 mm can determine operational success. Our work on precision motion control systems for Olympic timing devices and ruggedized housings for defense electronics underscores our capability to meet and exceed the most stringent requirements.

When selecting a prototype machine shop, whether in Georgia or globally, clients must evaluate not only technical capacity but also proven expertise in managing complex geometries, exotic alloys, and tight tolerance stacks. At Lead Precision, we utilize 5-axis CNC machining centers, coordinate measuring machines (CMM), and in-process inspection systems to ensure dimensional accuracy across both one-off prototypes and low-volume production runs. Our engineers collaborate closely with design teams to optimize manufacturability, ensuring that prototypes are not only precise but also scalable for future production.

The integration of advanced metrology and real-time process control allows us to maintain consistency across international supply chains. This is particularly critical for U.S.-based clients in Georgia who require rapid iteration cycles without compromising quality. By partnering with a manufacturer that adheres to ISO 13485, AS9100, and ITAR-compliant practices, engineering teams gain confidence that their prototypes meet both performance and regulatory benchmarks.

Below are key technical capabilities that define our precision manufacturing standards:

| Specification | Capability |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Aluminum 7075, Titanium Grade 5, Inconel 718, Stainless Steel 316L, Brass, PEEK |

| Surface Finish | As low as Ra 0.2 µm (polished) |

| Tolerance Range | IT6 to IT8 per ISO 286 |

| Certifications | ISO 9001, ISO 13485, AS9100, ITAR Registered |

Precision is not merely a measurement—it is a commitment to excellence. For prototype machine shop operations serving high-demand industries, partnering with a globally experienced manufacturer like Wuxi Lead Precision Machinery ensures that every component meets the highest standards of performance, reliability, and accuracy.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Prototyping

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions specifically engineered for demanding prototype requirements. Our core strength lies in integrating high-precision multi-axis machining with rigorous quality control, ensuring prototypes meet exacting functional and dimensional specifications critical for successful product development and validation. We understand that Georgia-based engineering teams require prototypes that accurately represent final production intent, enabling reliable testing and seamless transition to volume manufacturing.

Our primary production platform centers on state-of-the-art 5-axis CNC machining centers. These systems provide unparalleled capability for machining complex geometries in a single setup, eliminating cumulative errors inherent in multiple operations. This capability is essential for producing intricate aerospace components, medical device housings, and fluid dynamics prototypes common in Georgia’s advanced manufacturing sectors. Utilizing simultaneous 5-axis motion, we efficiently machine undercuts, organic contours, and deep cavities from solid billet in materials ranging from aluminum alloys and titanium to high-temperature superalloys and engineered plastics. This reduces lead times significantly compared to traditional 3-axis methods requiring multiple fixtures while ensuring superior part integrity and surface finish consistency.

Precision is non-negotiable in prototyping. Every component undergoes comprehensive dimensional verification using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems perform full-spectrum inspection against CAD models, generating detailed reports that validate critical features, geometric dimensioning and tolerancing (GD&T), and surface characteristics. This systematic approach guarantees that dimensional accuracy is not an afterthought but an integral, documented part of the manufacturing process. Our quality technicians are certified to interpret complex engineering drawings and apply industry-standard inspection protocols, providing Georgia clients with absolute confidence in prototype fidelity.

The following table details our standard achievable tolerances and surface finishes, reflecting our commitment to precision across common prototyping processes. These values represent typical production capabilities under controlled conditions for features within standard size ranges.

| Process | Standard Tolerance | Typical Surface Finish (Ra) | Key Application Focus |

|---|---|---|---|

| 5-Axis Milling | ±0.005 mm (±0.0002″) | 0.8 – 3.2 µm (32 – 125 µin) | Complex geometries, tight GD&T |

| Precision Turning | ±0.003 mm (±0.0001″) | 0.4 – 1.6 µm (16 – 63 µin) | Shafts, bearings, concentric features |

| Micro-Machining | ±0.001 mm (±0.00004″) | 0.2 – 0.8 µm (8 – 32 µin) | Small features, medical components |

| General Machining | ±0.010 mm (±0.0004″) | 1.6 – 6.3 µm (63 – 250 µin) | Structural brackets, housings |

All tolerances comply with or exceed ISO 2768 medium precision standards unless otherwise specified. Surface finishes are achievable on appropriate materials with optimized toolpaths and tooling. Our engineering team collaborates closely with Georgia clients during the Design for Manufacturability (DFM) phase to optimize part geometry for precision machining, ensuring prototype performance aligns with functional requirements while maintaining cost and schedule efficiency. This integrated capability—combining advanced 5-axis technology with metrology-grade inspection—provides Georgia innovators with prototypes that reliably validate design intent and accelerate time-to-market. We deliver not just parts, but verified, production-intent components ready for critical evaluation.

Material & Finish Options

Material selection is a critical step in precision manufacturing, especially when developing prototypes or low-volume production parts for industries such as aerospace, medical, and high-performance automotive. At Wuxi Lead Precision Machinery, we guide our clients through informed decisions based on mechanical requirements, environmental exposure, and finishing needs. Among the most widely used metals in custom machining are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly favored in aerospace and consumer electronics where lightweight components are essential. The 6061 and 7075 aluminum alloys are commonly specified, with 6061 offering good weldability and moderate strength, while 7075 delivers higher strength suitable for demanding structural applications. Aluminum’s natural oxide layer provides baseline corrosion protection, but for enhanced durability and aesthetic control, anodizing is highly recommended.

Steel, particularly in its stainless (303, 304, 316) and alloy (4140, 4340) forms, is selected when strength, wear resistance, and thermal stability are paramount. Stainless steels offer excellent corrosion resistance and are ideal for medical and food-grade environments. Alloy steels are often heat-treated to achieve high tensile strength, making them suitable for shafts, gears, and tooling. While steel is denser than aluminum or titanium, its mechanical robustness and cost-effectiveness in many applications make it a staple in precision manufacturing.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice when extreme strength-to-density ratios and resistance to high temperatures and corrosion are required. Commonly used in aerospace, defense, and biomedical implants, titanium is challenging to machine due to its low thermal conductivity and tendency to gall. However, with proper tooling and process control, titanium components can achieve tight tolerances and excellent surface integrity.

Anodizing is a key surface treatment for aluminum, enhancing both performance and appearance. The process grows a controlled oxide layer on the surface, improving wear and corrosion resistance. Type II anodizing (sulfuric acid anodize) is ideal for decorative and moderate-duty applications, while Type III (hardcoat anodizing) provides a thicker, harder surface suitable for industrial and aerospace use. Anodized layers are porous and can be dyed in various colors for identification or branding purposes.

Below is a comparative overview of key material properties and finishing options.

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310 – 570 | 2.7 | Lightweight, corrosion resistant, easily machined | Aerospace, electronics, automotive |

| Stainless Steel | 304, 316, 4140 | 500 – 1200 | 7.8 – 7.9 | High strength, corrosion resistance, heat resistant | Medical, industrial, marine |

| Titanium | Ti-6Al-4V (Grade 5) | 900 – 1000 | 4.5 | High strength-to-weight, excellent corrosion resistance | Aerospace, defense, medical |

At Wuxi Lead Precision Machinery, we support clients in Georgia and beyond with expert material and finish recommendations tailored to project specifications. Our precision CNC capabilities ensure that every prototype meets exacting standards in form, fit, and function.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Precision Production Process for Georgia Prototype Machine Shop Partners

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence specifically engineered for high-integrity custom metal components demanded by Georgia’s advanced manufacturing sector. Our process transcends simple part fabrication; it is a closed-loop system designed from inception to guarantee zero defects in final deliverables. This begins with intensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates directly with Georgia clients during the design phase, scrutinizing CAD models for potential manufacturability issues, material suitability, and geometric feasibility. We identify stress points, optimal tool paths, and fixture requirements before metal is cut, preventing costly downstream errors and ensuring the design aligns with achievable precision standards. This proactive collaboration is fundamental to defect prevention.

The prototyping phase is not merely a sample run; it is a critical validation checkpoint. Utilizing our advanced 5-axis CNC milling and turning centers, we produce functional prototypes under full production conditions. Every prototype undergoes exhaustive First Article Inspection (FAI) against the original CAD data and client specifications. This includes comprehensive dimensional verification using Coordinate Measuring Machines (CMM), material property testing, and functional assessment. Any deviation triggers immediate root cause analysis and process adjustment. This phase validates the DFM inputs, confirms process capability, and provides tangible evidence of conformity before committing to mass production tooling and setup.

Mass production leverages the validated process parameters established during prototyping. Our facility operates under strict ISO 9001 and IATF 16949 quality management systems. Production runs employ Statistical Process Control (SPC) with real-time monitoring of critical dimensions. In-process inspections occur at defined intervals using calibrated optical comparators and CMMs, ensuring continuous dimensional conformity. Final inspection is 100% for critical features on all parts, not just random sampling. Traceability is maintained from raw material certification through every machining stage to final shipment. This integrated approach, combining proven process stability with relentless verification, is how we achieve and sustain zero-defect output for our Georgia partners, ensuring parts arrive ready for immediate integration into their assemblies.

Wuxi Lead Precision Production Capabilities for Georgia Clients

| Specification Category | Capability Detail |

|---|---|

| Material Expertise | Aluminum Alloys (6061, 7075), Stainless Steel (303, 304, 316, 17-4PH), Titanium (Gr2, Gr5), Brass, Carbon Steel, Plastics (PEEK, Delrin) |

| Dimensional Tolerance | Standard: ±0.005mm (0.0002″) |

| Primary Equipment | 5-Axis CNC Machining Centers (Makino, DMG MORI), CNC Turning Centers (Mazak, Okuma), Swiss-Type Lathes |

| Critical Inspection | Zeiss CONTURA CMMs, Optical Comparators, Surface Roughness Testers, Hardness Testers, In-Process SPC Monitoring |

| Quality Certification | ISO 9001:2015, IATF 16949:2016, Full FAI Reports (AS9102), Material Certifications (Mill Certs), PPAP Support |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your project demands precision, reliability, and advanced engineering capabilities, Wuxi Lead Precision Machinery stands as your trusted global partner. Specializing in high-end CNC machining, custom metal fabrication, and rapid prototyping, we deliver mission-critical components to industries including aerospace, medical devices, energy, and advanced automation. As a leading prototype machine shop based in China, we serve clients across North America—including Georgia—by providing scalable, cost-efficient solutions without compromising on quality or lead time.

Our state-of-the-art facility in Wuxi is equipped with multi-axis CNC machining centers, Swiss-type lathes, wire EDM, and 5-axis milling systems, enabling us to produce complex geometries with tolerances as tight as ±0.005 mm. Whether you require a single prototype or low-to-mid volume production runs, our agile manufacturing ecosystem ensures rapid turnaround and seamless scalability. We work with a broad spectrum of materials, including aluminum alloys, stainless steel, titanium, brass, and engineered plastics, supporting your design intent from concept to final part.

What sets Lead Precision apart is our engineering-first approach. Our team of seasoned CNC programmers and manufacturing engineers collaborates directly with your design team to optimize part geometry, material selection, and manufacturability—often reducing cost and cycle time before production begins. We support full documentation packages, First Article Inspections (FAI), and PPAP submissions, ensuring compliance with ISO 9001:2015 and other industry-specific standards.

For engineering firms and OEMs in Georgia seeking a reliable offshore partner, we offer a seamless integration model. With digital workflows, real-time project tracking, and time-zone-friendly communication, we eliminate the friction often associated with international manufacturing. Our logistics network ensures on-time delivery to Atlanta, Savannah, and beyond, with DDP (Delivered Duty Paid) shipping options available.

Explore how we can accelerate your next project with precision-engineered components built to perform.

| Specification | Detail |

|---|---|

| Machining Capabilities | 3-axis to 5-axis CNC milling, CNC turning, Swiss machining, Wire EDM, Surface & Cylindrical Grinding |

| Tolerances | ±0.005 mm (±0.0002″) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Copper, Inconel, PEEK |

| Max Work Envelope | 1200 x 800 x 600 mm (47″ x 31.5″ x 23.6″) |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days |

| Quality Standards | ISO 9001:2015, FAI, PPAP, CMM inspection reports |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation |

Contact us today to discuss your next prototype or production run. Email [email protected] and receive a competitive quote within 4 business hours. Let Wuxi Lead Precision Machinery be your extension in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.