Technical Contents

Engineering Guide: Aluminium Laser Cutting Service

Engineering Insight: Precision in Aluminium Laser Cutting Services

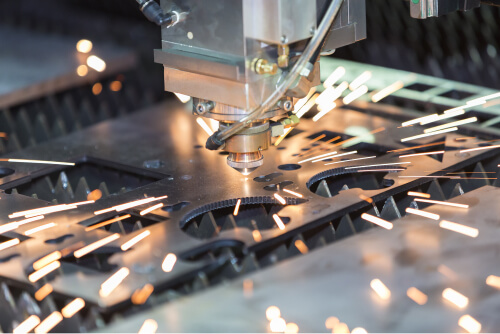

In high-end sheet metal fabrication, aluminium laser cutting stands as a cornerstone technology for industries where dimensional accuracy, edge quality, and repeatability are non-negotiable. Aluminium, with its high reflectivity, thermal conductivity, and lightweight strength, presents unique challenges in laser processing—requiring advanced equipment, refined parameters, and expert engineering oversight. At Wuxi Lead Precision Machinery, we leverage over a decade of precision manufacturing experience to deliver laser-cut aluminium components that meet the exacting standards of aerospace, defence, and high-performance industrial applications.

Precision in aluminium laser cutting is not merely a technical goal—it is an engineering imperative. Even minor deviations in kerf width, taper, or heat-affected zones can compromise part fit, structural integrity, or downstream assembly efficiency. Our fibre laser systems operate with micron-level accuracy, supported by real-time beam control, adaptive focus optics, and nitrogen-assisted cutting to minimise oxidation and ensure clean, burr-free edges. This level of control is essential when producing components for critical environments—such as satellite housings, military-grade enclosures, or structural frames for high-speed transit systems.

Our proven track record includes precision components for Olympic-standard sporting equipment and mission-critical military hardware, where failure is not an option. These projects demanded not only tight tolerances but also full traceability, material certification, and strict adherence to international quality standards. At Wuxi Lead, every laser cut is backed by rigorous process validation, in-process inspection, and post-cut metrology using coordinate measuring machines (CMM) to ensure compliance with ISO 2768-mK or customer-specific GD&T requirements.

Material selection is equally critical. We process a wide range of aluminium alloys—including 5052, 6061, and 7075—each requiring customised laser parameters to balance cutting speed, edge quality, and thermal management. Our engineering team conducts pre-production trials to optimise assist gas pressure, pulse frequency, and cutting speed, ensuring optimal results without micro-cracking or warping.

The integration of automation and intelligent nesting software further enhances precision by reducing human error and maximising material yield. Coupled with our ERP-driven production tracking, clients receive not only precision-cut parts but also full documentation for audit and compliance purposes.

For industries where performance hinges on perfection, Wuxi Lead Precision Machinery delivers more than cutting—we deliver engineered confidence.

Typical Aluminium Laser Cutting Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 20 mm |

| Laser Source | High-Power Fibre Laser (up to 12 kW) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Edge Roughness (Ra) | ≤ 3.2 µm (depending on thickness) |

| Minimum Feature Size | 1.2 x material thickness |

| Tolerance (Standard) | ISO 2768-mK (custom to ±0.05 mm achievable) |

| Assist Gas | High-Purity Nitrogen (up to 20 bar) |

| Surface Quality | Burr-free, oxide-free, ready for welding/paint |

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Laser Cutting

Wuxi Lead Precision Machinery delivers exceptional precision and versatility for demanding aluminum laser cutting applications. Our advanced manufacturing cell is engineered specifically to overcome the unique challenges presented by aluminum, including its high thermal conductivity and reflectivity. Central to our capability is a fleet of state-of-the-art 5-axis CNC fiber laser cutting systems, featuring IPG photonics resonators and Siemens 840D control platforms. These systems utilize optimized beam parameters and specialized assist gases, ensuring clean, dross-free cuts with minimal heat-affected zones across a wide range of aluminum alloys, from 1000-series pure grades to high-strength 7000-series.

The 5-axis functionality is a critical differentiator, enabling complex 3D contour cutting and beveling in a single, highly accurate setup. This eliminates cumulative errors from multiple fixturing operations, significantly reducing lead times and cost for intricate components common in aerospace, medical device, and high-end electronics manufacturing. Our integrated nesting software maximizes material yield while maintaining strict geometric integrity, crucial for expensive aluminum sheet and plate. Proven thermal management strategies within the cutting process ensure consistent edge quality and dimensional stability, even on thin gauges down to 0.5mm and up to structural plate thicknesses of 20mm.

Rigorous quality control is non-negotiable. Every critical dimension and feature on finished aluminum parts undergoes validation using our calibrated Coordinate Measuring Machine (CMM) system, operating under ISO 17025 guidelines. This metrology-grade inspection provides objective, traceable data confirming adherence to even the most stringent client specifications. Our QC protocol includes first-article inspection reports, in-process checks for high-volume runs, and full final inspection documentation, ensuring complete dimensional conformance before shipment. This systematic approach guarantees parts arrive ready for assembly, minimizing downstream scrap and rework for our clients.

The following table details our core technical specifications for aluminum laser cutting services, reflecting the precision achievable under controlled production conditions:

| Parameter | Specification | Notes |

|---|---|---|

| Material Thickness Range | 0.5 mm – 20.0 mm | Pure & Alloyed Aluminum (1xxx-7xxx) |

| Positional Accuracy | ±0.025 mm | Across full machine envelope |

| Linear Tolerance (X,Y) | ±0.05 mm / 100 mm | Typical production tolerance |

| Angular Tolerance | ±0.1° | For bevel cuts and complex contours |

| Hole Diameter Tolerance | +0.05 mm / -0.00 mm | Holes ≥ 1.0x material thickness |

| Minimum Feature Size | 0.8 mm | Hole diameter or slot width |

| Kerf Width | 0.12 mm – 0.25 mm | Varies with thickness & power setting |

| Edge Quality (Ra) | ≤ 1.6 μm (Typical) | As-cut surface, no secondary finishing |

| Surface Flatness | ≤ 0.1 mm / 100 mm | Measured per ASME Y14.5 |

This combination of advanced 5-axis laser technology, material-specific process expertise, and uncompromising CMM-based quality assurance defines Wuxi Lead Precision Machinery’s capability to produce mission-critical aluminum components with the highest levels of accuracy and reliability demanded by global high-tech industries.

Material & Finish Options

Material Selection for High-Precision Laser Cutting in Sheet Metal Fabrication

Selecting the appropriate material is critical when designing components for high-precision laser cutting applications. At Wuxi Lead Precision Machinery, we specialize in processing aluminum, steel, and titanium—each offering distinct mechanical, thermal, and aesthetic properties suited to specific industrial requirements. Understanding the behavior of these materials under laser energy ensures optimal cut quality, dimensional accuracy, and post-processing compatibility.

Aluminum is widely favored in aerospace, electronics, and transportation industries due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal and electrical conductivity. It is particularly well-suited for laser cutting, as modern fiber lasers achieve clean, burr-free edges on aluminum sheets up to 25 mm thick. However, aluminum’s high reflectivity and thermal conductivity demand precise parameter control to avoid back-reflection damage to the laser optics. We recommend using nitrogen as the assist gas for aluminum cutting to produce oxide-free, weld-ready edges ideal for downstream finishing processes such as anodizing.

Steel—particularly mild steel and stainless steel—remains a staple in structural and mechanical applications. Mild steel cuts efficiently with oxygen assist, enabling high-speed processing and a slightly oxidized edge. Stainless steel, on the other hand, benefits from nitrogen cutting to maintain its inherent corrosion resistance. The laser process preserves the material’s grain integrity, making it suitable for hygienic, architectural, and high-strength environments. Compared to aluminum, steel offers higher tensile strength and lower cost but at the expense of increased weight.

Titanium and its alloys are used in extreme environments such as aerospace, medical implants, and marine engineering. Titanium exhibits exceptional strength-to-density ratio and resistance to fatigue and corrosion. Laser cutting titanium requires strict environmental controls, often performed under inert gas shielding to prevent contamination. Due to its low thermal conductivity, heat concentrates at the cut zone, necessitating precise power modulation. Although more costly and challenging to process, titanium’s performance in critical applications justifies its use.

Post-cut surface enhancement often includes anodizing, particularly for aluminum components. Anodizing builds a durable, insulating oxide layer that improves wear and corrosion resistance while allowing for color coding. Our laser-cut parts are compatible with Type II (sulfuric acid) and Type III (hard coat) anodizing processes, with edge integrity that ensures uniform coating thickness and adhesion.

Below is a comparative summary of key material specifications for laser cutting:

| Material | Max Thickness (Fiber Laser) | Tensile Strength (MPa) | Common Alloys | Recommended Assist Gas | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 25 mm | 110–350 | 5052, 6061, 7075 | Nitrogen | Aerospace, Enclosures, Heat Sinks |

| Mild Steel | 40 mm | 370–500 | Q235, S235 | Oxygen | Industrial Frames, Machinery |

| Stainless Steel | 30 mm | 500–700 | 304, 316 | Nitrogen | Medical, Food Processing, Architecture |

| Titanium | 15 mm | 900–1100 | Grade 2, Grade 5 (Ti-6Al-4V) | Argon/Nitrogen | Aviation, Medical Implants |

Material choice directly impacts manufacturability, lifecycle performance, and total cost of ownership. At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finishing method to meet exact functional and regulatory demands.

Manufacturing Process & QC

Aluminium Laser Cutting Production Process: From Design to Zero Defect Mass Production

At Wuxi Lead Precision Machinery, our aluminium laser cutting service delivers uncompromising precision for demanding industrial applications. We implement a rigorously controlled three-phase production workflow designed to eliminate defects before they occur, ensuring your final components meet the highest standards of dimensional accuracy and surface integrity. This systematic approach transforms your concept into flawless reality.

The process begins with meticulous Design Review and Preparation. Our engineering team collaborates closely with your CAD data, verifying file integrity, optimising kerf compensation, and selecting the optimal laser parameters specific to your aluminium alloy grade and thickness. Critical factors like thermal distortion potential and nesting efficiency are analysed using advanced simulation software. This proactive step prevents costly errors downstream, ensuring the digital model is fully manufacturable and aligned with your functional requirements before any material is cut.

Prototyping serves as the critical validation phase. Utilising our high-power fibre lasers on representative production-grade aluminium stock, we produce functional prototypes under actual manufacturing conditions. Each prototype undergoes comprehensive metrology, including CMM inspection and surface roughness analysis, against your original specifications. This isn’t merely a sample check; it’s a full process validation. We measure thermal effects, edge quality consistency, and positional accuracy, fine-tuning parameters to achieve the exact finish and tolerance required. Client approval of this verified prototype is mandatory before proceeding, confirming the process is defect-proofed for scale.

Transitioning to Mass Production, the validated parameters are locked into our ISO 9001-certified production system. Our automated material handling feeds sheets consistently, while real-time process monitoring tracks laser power, gas pressure, and beam focus. Multi-stage in-process verification occurs at defined intervals, including automated edge detection and periodic CMM spot checks on critical features. This continuous feedback loop, combined with our operators’ deep expertise in managing aluminium’s reflective properties and thermal behaviour, guarantees every part meets the prototype’s exacting standard. Zero Defects is achieved through prevention, not detection, embedded into every step from initial design scrutiny to final packaging.

Our core laser cutting capabilities for aluminium alloys are engineered to support this stringent workflow:

| Parameter | Capability | Tolerance/Performance |

|---|---|---|

| Max Sheet Size | 3015 mm x 1510 mm | Full bed capacity |

| Thickness Range | 0.5 mm – 12.0 mm | Optimised for 6061, 7075 |

| Positional Accuracy | ± 0.05 mm per meter | Verified per ISO 2768-mK |

| Edge Quality | Burr-free, minimal dross | Ra < 3.2 µm typical |

| Material Handling | Automated sheet loader/unloader | Integrated with nesting SW |

This integrated Design-Prototype-Production methodology, underpinned by certified processes and cutting-edge technology, ensures Wuxi Lead delivers not just parts, but guaranteed performance for your most critical aluminium components. We transform precision engineering into tangible manufacturing excellence.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for unmatched excellence in aluminium laser cutting services. As a leading innovator in sheet metal fabrication, we specialize in delivering high-precision, high-efficiency solutions tailored to the exacting demands of global industries including aerospace, automotive, energy, and advanced electronics. Our state-of-the-art facility in Wuxi, China, is engineered for performance, integrating advanced fiber laser technology with rigorous quality control protocols to ensure every component meets the highest standards of dimensional accuracy and surface finish.

Aluminium presents unique challenges in laser cutting—high thermal conductivity, reflectivity, and sensitivity to edge quality—requiring specialized expertise and equipment. At Lead Precision, we have optimized our processes specifically for aluminium alloys, from 1000 to 7000 series, including hard-to-machine variants such as 6061-T6 and 7075. Our experienced engineering team applies deep material science knowledge to fine-tune cutting parameters, ensuring clean, burr-free edges with minimal dross and excellent repeatability across both prototypes and high-volume production runs.

Our commitment to precision is backed by advanced automation and real-time monitoring systems. With multi-axis CNC laser platforms and intelligent beam delivery, we achieve tolerances down to ±0.05 mm and cut aluminium sheets up to 20 mm in thickness with exceptional edge squareness and consistency. Whether your project involves intricate contours, tight radii, or large-format panels, our capabilities scale seamlessly to meet your requirements.

We understand that in high-end manufacturing, specifications matter. Below are the technical parameters that define our aluminium laser cutting service:

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminium alloys (1000–7000 series), including 5052, 6061, 6082, 7075 |

| Maximum Cutting Thickness | 20 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Minimum Hole Diameter | ≥1.0 × material thickness |

| Edge Quality | Burr-free, low dross, Ra ≤ 6.3 µm (typical) |

| Tolerance Range | ±0.05 mm (standard), tighter upon request |

| Laser Source | High-power fiber laser (up to 12 kW) |

| Sheet Size Capacity | Up to 4000 × 2000 mm |

| Production Capacity | High-volume automation with robotic loading/unloading |

Partnering with Wuxi Lead Precision Machinery means gaining a fabrication ally built on engineering integrity, transparency, and on-time delivery. We support international clients with full documentation, material traceability, and quality certifications aligned with ISO 9001 standards. Our team collaborates closely with your engineers to optimize designs for manufacturability, reduce lead times, and lower total production costs.

For precision you can trust and service that exceeds expectations, contact us today. Send your drawings, specifications, or inquiries to [email protected] and discover how our aluminium laser cutting service can elevate your next manufacturing project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.