Technical Contents

Engineering Guide: Sheet Metal Inserts

Engineering Insight: Precision Sheet Metal Inserts for Mission-Critical Applications

The integrity of sheet metal assemblies hinges on seemingly minor components like threaded inserts. In high-performance manufacturing, particularly within aerospace, defense, and advanced industrial equipment, the precision of these inserts is not merely desirable—it is non-negotiable. Standard off-the-shelf inserts often introduce tolerance stacks, thread stripping risks, and premature fatigue under cyclic loading or thermal stress. These failures cascade into costly field repairs, warranty claims, and reputational damage. At Wuxi Lead Precision Machinery, we engineer sheet metal inserts to eliminate these vulnerabilities. Our inserts are manufactured to exacting tolerances where ±0.02mm concentricity and thread pitch accuracy are baseline requirements, not aspirations. This level of precision ensures optimal load distribution, maximizes pull-out and torque strength, and guarantees seamless integration within automated assembly lines—critical factors when seconds count in production or failure is unacceptable in operation.

Our engineering rigor is forged in projects demanding absolute reliability. We supplied precision-insert solutions for structural components in Beijing Winter Olympics venue infrastructure, where thermal cycling and seismic loads demanded flawless performance. Similarly, our defense sector partners specify Lead Precision inserts for avionics housings and ground vehicle subsystems, where vibration resistance and long-term corrosion stability are mandated by MIL-STD-413. This experience translates to rigorous process control: CNC cold-forming instead of cutting for superior grain structure, multi-axis in-process gauging, and material traceability from certified mills. Every insert batch undergoes destructive testing against specified torque and pull-out values before shipment. We understand that an insert is only as strong as its weakest interface with the parent material; our precision ensures that interface is engineered, not incidental.

The following table outlines critical specifications achievable through our precision manufacturing process, far exceeding generic industry standards:

| Parameter | Standard Commercial | Wuxi Lead Precision Standard | Testing Method |

|---|---|---|---|

| Thread Tolerance | 6H | 4H | Go/No-Go Gauges |

| Concentricity | ±0.05mm | ±0.02mm | CMM Verification |

| Pull-Out Strength | As Per DIN 84 | +15% Minimum Over Spec | Hydraulic Test Rig |

| Torque Strength | As Per ISO 1478 | +20% Minimum Over Spec | Digital Torque Tester |

| Material Traceability | Batch Level | Individual Lot Certification | Mill Cert + Internal Log |

Precision sheet metal inserts are a strategic investment, not a commodity cost. When assemblies operate under extreme conditions—whether in a satellite assembly line or a naval combat system—the margin for error vanishes. Wuxi Lead Precision Machinery delivers inserts engineered for zero-failure performance, backed by proven experience in the world’s most demanding projects. Our commitment ensures your sheet metal fabrication achieves structural integrity that meets the uncompromising standards of Olympic venues and defense applications, safeguarding your product’s lifecycle and your brand’s reputation. Partner with engineers who treat every thread as mission-critical.

Precision Specs & Tolerances

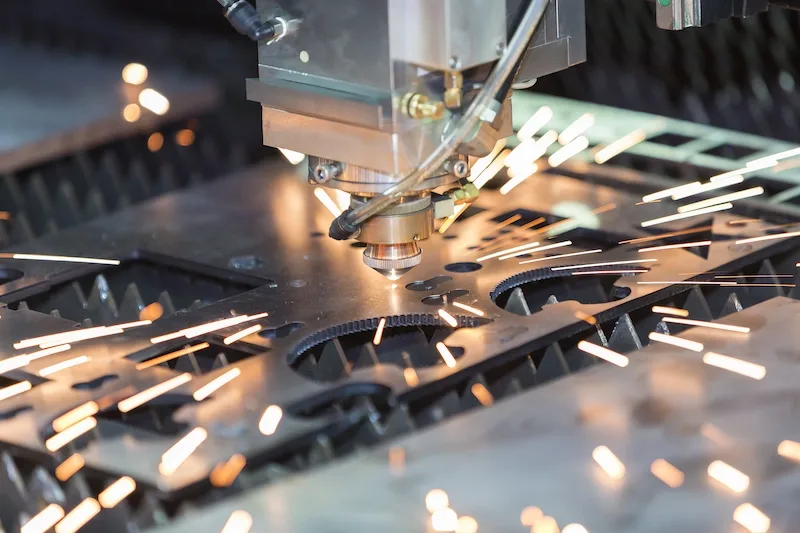

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for high-precision industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling complex geometries, tight tolerances, and superior surface finishes on a wide range of sheet metal materials. This multi-axis precision processing allows for simultaneous cutting, drilling, and contouring from multiple angles, reducing setup times and eliminating cumulative error typically associated with multi-stage operations. The result is a seamless integration of form, fit, and function in every component we produce.

Our 5-axis CNC systems are equipped with high-speed spindles and automated tool changers, supporting continuous operation with minimal downtime. These machines are programmed using advanced CAM software, ensuring optimal tool paths and material utilization. This digital workflow enhances repeatability and accuracy, particularly for low-volume, high-mix production runs common in aerospace, medical device manufacturing, and advanced automation sectors. Materials such as stainless steel, aluminum alloys, titanium, and specialty composites are routinely processed with strict adherence to dimensional and structural requirements.

Quality control is integral to our manufacturing process. Every sheet metal insert undergoes rigorous inspection using a Coordinate Measuring Machine (CMM) to verify conformance to design specifications. Our CMM systems provide micron-level measurement accuracy across three-dimensional space, capturing critical features such as hole positioning, thread alignment, and geometric tolerances. Data from each inspection is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality protocols. This closed-loop quality assurance system ensures that every part shipped meets or exceeds client expectations.

The following table outlines the standard technical specifications and tolerances achievable through our 5-axis CNC sheet metal fabrication process. These values reflect typical performance under controlled production conditions and may be further refined based on specific project requirements.

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.02 mm |

| Hole Diameter Tolerance | ±0.03 mm | ±0.01 mm |

| Positional Accuracy | ±0.03 mm | ±0.01 mm |

| Flatness (per 100 mm) | 0.05 mm | 0.02 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 1.6 μm | 0.8 μm |

| Thread Accuracy | ISO 4916 Class 6H | ISO 4916 Class 4H |

| Feature-to-Feature Alignment | ±0.04 mm | ±0.015 mm |

Wuxi Lead Precision Machinery combines cutting-edge equipment with disciplined process control to deliver sheet metal inserts that meet the most demanding engineering challenges. Our technical capabilities are designed to support innovation in precision manufacturing, ensuring reliability, consistency, and performance in every component.

Material & Finish Options

Material Selection for High-Performance Sheet Metal Inserts

Selecting the optimal base material for sheet metal inserts is critical for ensuring long-term structural integrity, corrosion resistance, and functional performance within demanding assemblies. At Wuxi Lead Precision Machinery, our precision-engineered inserts require substrates that match the operational environment and mechanical loads. Aluminum, steel, and titanium represent the primary material families, each offering distinct advantages for specific applications. Understanding their properties relative to insert performance is non-negotiable for reliable design.

Aluminum alloys, particularly 6061-T6, are the preferred choice when weight reduction is paramount without sacrificing significant strength. Its excellent machinability ensures precise thread formation during insert installation, crucial for maintaining pull-out and torque-out values. Aluminum’s natural oxide layer provides moderate corrosion resistance, but this is significantly enhanced through anodizing – a process we integrate seamlessly. It is ideal for aerospace enclosures, consumer electronics housings, and transportation components where mass efficiency is critical. However, aluminum’s lower hardness compared to steel necessitates careful consideration in high-wear or extreme load scenarios.

Carbon steel and stainless steel inserts dominate applications requiring maximum strength, wear resistance, and cost-effectiveness in non-corrosive or moderately corrosive environments. Low-carbon steel (e.g., 1018) offers high tensile strength and is economical for internal structural components. For enhanced corrosion resistance, 304 and 316 stainless steel are indispensable, especially in marine, chemical processing, or medical device applications. Stainless steel maintains integrity under high temperatures and aggressive chemicals, ensuring insert reliability where failure is not an option. The inherent hardness of steel provides superior thread durability under repeated assembly/disassembly cycles.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), deliver an exceptional strength-to-weight ratio and unparalleled corrosion resistance, particularly against chlorides and acids. This makes titanium inserts essential for the most demanding aerospace, defense, and offshore energy applications where component failure carries extreme consequences. While significantly more expensive, titanium’s longevity in harsh environments often justifies the initial investment through reduced maintenance and replacement costs. Its biocompatibility also secures its position in critical medical implants and instrumentation.

Surface finishing, especially anodizing for aluminum, is not merely cosmetic but a functional requirement for insert performance. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and paint adhesion for general use. For inserts subjected to severe wear, abrasion, or salt spray exposure, Type III (Hardcoat) anodizing is mandatory. Hardcoat anodizing creates a dense, thick, abrasive-resistant ceramic layer (typically 25-50µm) with hardness exceeding 500 HV, directly protecting the threads and surrounding material. Improper anodizing thickness or sealing can compromise thread engagement; our process control guarantees dimensional stability post-treatment.

The following table summarizes key material properties relevant to insert selection:

| Material | Typical Alloy | Tensile Strength (MPa) | Corrosion Resistance | Relative Weight | Primary Insert Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Moderate (Good w/ Anodize) | Very Low | Aerospace, Electronics, Transport |

| Carbon Steel | 1018 | 440 | Low | Medium | Internal Structures, Machinery |

| Stainless Steel | 304/316 | 515 / 620 | High | Medium-High | Marine, Medical, Chemical |

| Titanium | Ti-6Al-4V | 900 | Exceptional | Low | Aerospace, Defense, Critical Med |

Material choice directly dictates insert longevity and assembly reliability. Wuxi Lead Precision Machinery leverages ISO 9001-certified processes and deep metallurgical expertise to match the optimal substrate and finish to your specific functional requirements, ensuring every insert performs flawlessly within its operational lifecycle. Consult our engineering team for application-specific validation.

Manufacturing Process & QC

Sheet metal inserts are critical components in modern manufacturing, providing durable threaded interfaces in thin or soft base materials. At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and zero-defect delivery. We follow a tightly controlled workflow that spans from initial design through prototyping to full-scale mass production, ensuring every insert meets exacting performance and quality standards.

The process begins with design engineering, where our team collaborates closely with clients to understand functional requirements, load specifications, material compatibility, and environmental conditions. Using advanced CAD/CAM software and finite element analysis (FEA), we optimize the geometry of the insert and its integration into the sheet metal host. Design for manufacturability (DFM) principles are applied early to eliminate potential production risks, such as material deformation or thread misalignment. This phase includes tolerance stack-up analysis and interference checks to ensure seamless fit and function upon installation.

Once the design is finalized, we move to prototyping. A limited batch of inserts is manufactured using the same tooling and materials intended for mass production. These prototypes are subjected to rigorous testing, including pull-out strength, torque resistance, and fatigue cycles under simulated operational conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) and optical comparators to verify conformance to specifications. Client feedback is incorporated at this stage, allowing for design refinements before tooling sign-off. This iterative validation ensures that the final product performs reliably in real-world applications.

Mass production commences only after prototype approval and process validation. Our automated stamping, threading, and heat treatment lines operate under strict statistical process control (SPC). Each batch is traceable through our ERP system, with real-time monitoring of critical parameters such as press tonnage, thread pitch accuracy, and coating thickness. In-line vision systems and periodic destructive testing ensure ongoing compliance. All inserts are cleaned, passivated (if required), and packaged in anti-corrosive materials to maintain integrity during shipping.

Our zero-defect philosophy is enforced through ISO 9001-certified quality management systems, continuous operator training, and a closed-loop corrective action process. Every shipment is accompanied by material certifications, first-article inspection reports, and process capability data.

Below are key technical specifications for our standard sheet metal insert series:

| Parameter | Value / Range | Tolerance |

|---|---|---|

| Material | Carbon Steel, Stainless Steel (304, 316), Brass | Per ASTM/ISO |

| Insert Diameter | M3 to M12 | ±0.05 mm |

| Sheet Thickness Range | 0.8 mm to 3.0 mm | ±0.1 mm |

| Installation Method | Press-fit, Clinch, Weld | Customizable |

| Thread Type | Metric, UNC, UNF | 6H Class Fit |

| Torque Resistance | 0.8 to 12 Nm | Test Certified |

| Pull-Out Strength | 1.2 kN to 15 kN | Per DIN 58015 |

| Surface Finish | Zinc Plated, Geomet, Dacromet | 8–12 µm coating |

Wuxi Lead Precision Machinery delivers sheet metal inserts that combine structural integrity with flawless repeatability—engineered for performance, validated for trust.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Insert Performance

In high-stakes manufacturing environments where assembly integrity dictates product lifespan and safety, the reliability of sheet metal inserts is non-negotiable. Substandard inserts lead to stripped threads, component failure, and costly production halts—risks no precision-focused enterprise can afford. At Wuxi Lead Precision Machinery, we engineer sheet metal inserts to exceed the most stringent aerospace, medical, and industrial automation requirements. Our commitment begins with material science and extends through CNC-forming processes calibrated to sub-micron repeatability. We do not merely supply components; we deliver engineered solutions that integrate seamlessly into your production workflow, ensuring zero-defect assembly and long-term operational resilience.

Our proprietary manufacturing ecosystem combines German-engineered CNC turret presses with real-time in-process metrology, guaranteeing every insert meets exact geometric and mechanical specifications. Unlike generic suppliers, we control the entire value chain—from raw material sourcing of ASTM-certified alloys to final surface treatment—eliminating supply chain vulnerabilities. This vertical integration enables rapid iteration for custom geometries while maintaining batch-to-batch consistency critical for ISO 13485 and AS9100 certified production lines. The table below summarizes our core capabilities for standard and custom sheet metal inserts:

| Parameter | Specification Range |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Material Options | 304/316 Stainless Steel, Aluminum 6061-T6, Brass C3604, Titanium Grade 2 |

| Max Load Capacity | Up to 15,000 N (dependent on material & size) |

| Surface Finish | As-machined (Ra 0.8 µm), Electropolished, Passivated, Zinc-Nickel Plated |

| Insert Types Supported | Clinch, Self-Clinching, Press-Fit, Heat-Staked |

Choosing Lead Precision means aligning with a partner who treats your quality standards as our own. Our engineering team collaborates directly with your design and production staff during prototyping to resolve fitment challenges before tooling commences—reducing time-to-market by up to 30%. We implement rigorous first-article inspection (FAI) per AS9102 standards and provide full traceability via digital batch logs accessible through our customer portal. For mission-critical applications, we offer on-site technical support to validate installation processes and optimize press parameters, ensuring your assembly line achieves maximum uptime.

The true cost of sheet metal inserts lies not in the component price, but in the consequences of failure. With Lead Precision, you invest in documented reliability, responsive engineering partnership, and supply chain transparency. Let us demonstrate how our precision inserts can elevate your product’s structural integrity and reduce total cost of ownership. Contact our technical sales team at [email protected] to initiate a confidential consultation. Specify your application requirements, and we will provide a tailored capability analysis within 24 hours—including sample lead times and DFM feedback. Precision engineering begins with the right partnership. Start yours today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.