Technical Contents

Engineering Guide: 3D Printservice

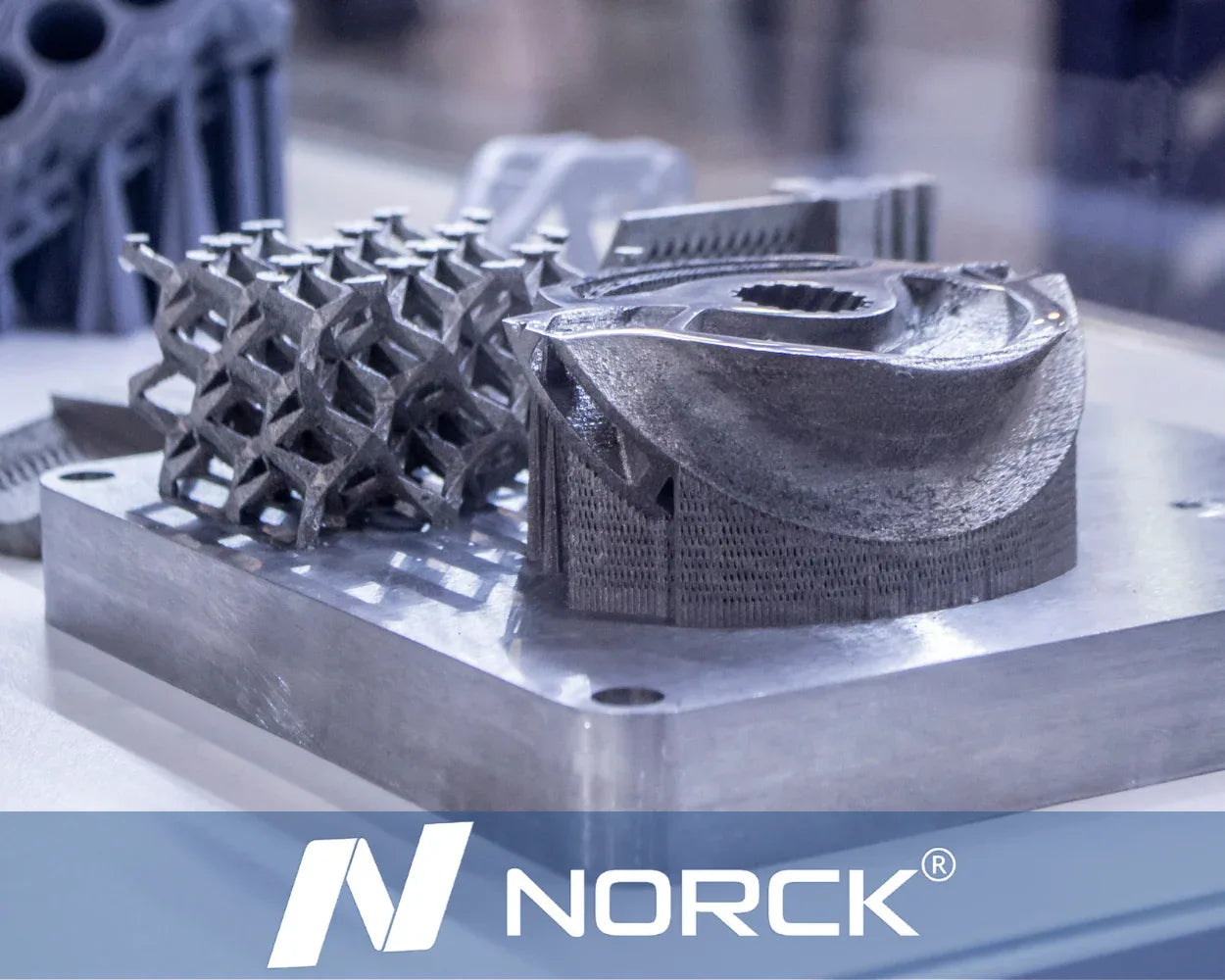

Engineering Insight Metal Additive Manufacturing Demands Absolute Precision

In industrial metal additive manufacturing, precision transcends simple dimensional tolerances. It encompasses the intricate interplay of thermal dynamics, material microstructure control, residual stress management, and surface integrity. Sub-micron deviations during the build process propagate through post-processing, ultimately dictating component fatigue life, sealing performance, and assembly functionality. For mission-critical applications in aerospace, defense, and high-performance industrial equipment, these factors are non-negotiable. Achieving true precision requires deep metallurgical understanding, advanced process simulation, and rigorous in-situ monitoring far beyond standard 3D printing service offerings. It is the foundation upon which reliability, safety, and operational longevity are built.

Wuxi Lead Precision Machinery has honed this precision discipline through demanding real-world validation. Our metal additive systems consistently deliver components meeting AS9100 and NADCAP standards, proven in environments where failure is unacceptable. We engineered titanium structural elements for Beijing Winter Olympic infrastructure, subjected to extreme cold and dynamic loads, ensuring athlete safety under global scrutiny. Similarly, our certified production of flight-critical brackets and housings for Chinese military platforms demonstrates our mastery of the stringent repeatability and material certification protocols demanded by defense authorities. These projects were not merely printed; they were engineered from powder to final inspection, incorporating iterative process validation and non-destructive testing protocols exceeding typical service bureau capabilities. This experience translates directly to commercial clients requiring zero-defect manufacturing for high-value, low-volume metal parts.

Our integrated approach combines cutting-edge hardware with proprietary process knowledge. We control the entire value chain – from material qualification and build parameter optimization to precision CNC machining, heat treatment, and final metrology – ensuring the as-built geometry aligns perfectly with functional requirements. This holistic control is essential for achieving the dimensional stability and material properties specified in demanding engineering drawings.

Key metal additive manufacturing capabilities at Wuxi Lead Precision Machinery include:

| Parameter | Specification | Industrial Significance |

|---|---|---|

| Build Volume | Up to Ø500 x 500 mm | Supports large aerospace structural parts |

| Layer Resolution | 20-60 µm | Enables fine features and smooth surfaces |

| Dimensional Accuracy | ±0.05 mm per 100 mm (post-machining) | Meets tight assembly tolerances |

| Material Range | Ti-6Al-4V, Inconel 718, AlSi10Mg, 316L | Covers high-temp, lightweight, corrosion applications |

| Post-Processing | Integrated 5-axis milling, HIP, CMM | Ensures final part geometry and integrity |

| Certifications | ISO 9001, AS9100, NADCAP (pending) | Meets aerospace and defense quality demands |

True precision in metal additive manufacturing is not an endpoint; it is a continuous engineering commitment. At Wuxi Lead Precision Machinery, we leverage our proven experience in the most challenging sectors to deliver not just printed parts, but certified, mission-ready components. Partner with us when your application demands engineering integrity you can measure and rely upon.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance industries including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometric components with exceptional accuracy and surface finish. Our machining centers operate with simultaneous multi-axis motion, allowing for reduced setup times, improved part consistency, and the ability to machine intricate contours that are unattainable with conventional 3-axis systems. This capability is essential for manufacturing mission-critical components where precision, repeatability, and material integrity are non-negotiable.

All machining operations are supported by a rigorous quality control framework centered on Coordinate Measuring Machine (CMM) inspection. Our metrology lab is equipped with high-precision CMM systems that provide full 3D verification of dimensional accuracy and geometric tolerances. Every critical feature—including position, flatness, roundness, and profile—is validated against engineering drawings and international standards. This systematic inspection process ensures full traceability and compliance with ISO 9001 and AS9100 requirements, offering our clients confidence in every delivered component.

Our facility supports a broad range of engineering alloys, including titanium, stainless steel, aluminum, Inconel, tool steels, and specialty brasses. Material selection is optimized based on functional requirements such as corrosion resistance, thermal stability, and mechanical loading. In addition to 5-axis milling, we offer complementary processes such as precision turning, drilling, tapping, and surface finishing, all performed in-house to maintain process control and reduce lead times.

Tight tolerance execution is a hallmark of our manufacturing expertise. The following table outlines our standard and precision tolerance capabilities across key machining parameters.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Angular Dimensions | ±0.1° | ±0.05° | Measured via CMM |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm | Verified on granite surface plate |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm | Achieved with fine milling or polishing |

| Hole Diameter | ±0.02 mm | ±0.008 mm | Reamed or precision bored |

| Profile Tolerance | ±0.05 mm | ±0.02 mm | Complex contours via 5-axis |

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce cost, and ensure producibility. This proactive approach minimizes iterations and accelerates time to market. With state-of-the-art equipment, certified quality systems, and decades of precision machining experience, Wuxi Lead Precision Machinery is equipped to meet the most demanding technical requirements in custom metal manufacturing.

Material & Finish Options

Precision Material Selection for Metal Additive Manufacturing

Material selection fundamentally determines the performance envelope of additively manufactured metal components. At Wuxi Lead Precision Machinery, we guide aerospace, medical, and industrial clients through critical trade-offs between aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties, thermal characteristics, and post-processing requirements essential for mission-critical applications. Understanding these nuances ensures optimal part functionality, longevity, and cost-efficiency within your production workflow.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate weight-sensitive applications requiring good strength-to-weight ratios and thermal conductivity. These alloys excel in drone frames, heat exchangers, and non-critical structural brackets. While inherently less dense than steel or titanium, aluminum demands careful handling during machining due to work hardening tendencies. Anodizing is not merely cosmetic; Type II (sulfuric acid) anodizing provides essential corrosion resistance and electrical insulation for electronic housings, while Type III (hard coat) anodizing significantly enhances surface hardness and wear resistance for mechanical interfaces. Our precision finishing lines ensure consistent anodized layer thickness and dye penetration critical for dimensional stability.

Stainless steel variants, especially 316L and 17-4 PH, deliver superior strength, high-temperature resistance, and exceptional corrosion resistance in demanding environments. 316L is the benchmark for marine and chemical processing components due to its molybdenum-enhanced passivation layer. 17-4 PH offers martensitic hardenability, achieving yield strengths exceeding 1200 MPa after heat treatment, making it ideal for high-stress valve bodies and tooling. These steels require precise thermal management during build and post-processing to prevent distortion and maintain tight tolerances. Passivation is mandatory post-machining to maximize corrosion resistance by removing free iron contamination.

Titanium Grade 5 (Ti-6Al-4V) remains the aerospace and medical implant standard, offering an unparalleled strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosive media. Its low thermal conductivity necessitates specialized CNC strategies to manage heat buildup during finishing operations. While titanium inherently forms a protective oxide layer, precision-machined surfaces often benefit from specialized cleaning protocols rather than traditional anodizing. We implement stringent cleanroom protocols for medical-grade titanium to ensure absolute surface integrity.

Material performance characteristics are non-negotiable in high-stakes manufacturing. The following table details key properties for common alloys processed through our certified metal AM and finishing systems:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Key Applications |

|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 570 | 505 | Aerospace fittings, high-stress mounts |

| Stainless 17-4 PH | 7.75 | 1300 | 1170 | Valve components, high-wear tooling |

| Titanium Ti-6Al-4V | 4.43 | 950 | 880 | Aircraft brackets, medical implants |

Selecting the optimal material requires deep understanding of your operational environment, load requirements, and lifecycle expectations. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and in-house testing to match your application with the precise alloy and surface treatment protocol. Contact our engineering team with your specific performance criteria; we will provide a validated material recommendation and finishing specification tailored to your production demands. Precision begins with the right foundation.

Manufacturing Process & QC

From Concept to Perfection: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we engineer excellence through a disciplined, end-to-end production process that transforms client designs into high-precision metal components with zero defects. Our methodology integrates advanced engineering, rigorous validation, and scalable manufacturing to deliver consistent quality for custom metal parts used in aerospace, medical, automotive, and industrial applications.

The journey begins with Design Optimization. Our engineering team collaborates directly with clients to review CAD models, assess manufacturability, and refine geometries for optimal performance and cost-efficiency. Utilizing simulation software, we analyze thermal, structural, and fatigue behavior to ensure the part meets functional requirements before any material is cut. This stage includes material selection guidance—whether titanium, stainless steel, aluminum, or high-performance alloys—ensuring compatibility with both application demands and production methods.

Next, we move to Prototyping and Validation. Employing state-of-the-art 5-axis CNC machining, wire EDM, and metal 3D printing (SLM/DMLS), we produce functional prototypes within 7–14 days. These prototypes undergo full metrology inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.005 mm. Environmental and mechanical testing—including hardness, tensile strength, and surface finish analysis—confirms performance under real-world conditions. Client feedback at this stage ensures alignment before scaling to mass production.

Mass Production is executed under a Zero Defects framework. Our ISO 9001 and IATF 16949-certified facility deploys automated production lines with real-time process monitoring. Each operation is governed by documented work instructions and first-article inspections. In-process checks occur at critical control points, while statistical process control (SPC) tracks key variables to prevent deviation. Full traceability is maintained through serialized part tracking, material certifications, and digital quality records.

Our commitment to zero defects is reinforced through continuous improvement. Any non-conformance triggers immediate root cause analysis and corrective action via our 8D problem-solving protocol. This closed-loop system ensures sustained quality across production runs from hundreds to tens of thousands of units.

All components are packaged to prevent damage during global shipment, accompanied by comprehensive inspection reports and compliance documentation.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Stainless Steel, Aluminum, Titanium, Inconel, Brass, Tool Steels |

| Tolerances | ±0.005 mm (standard), ±0.002 mm (precision) |

| Surface Finish | Ra 0.4 µm to 3.2 µm (machined), Ra 10–15 µm (as-printed) |

| Max Part Size | 800 x 500 x 400 mm (machining), 250 x 250 x 300 mm (3D printing) |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 15–30 days (depending on volume) |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAI, SPC, CMM |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures every component meets the highest standards of precision, reliability, and repeatability—guaranteeing performance in the most demanding environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Path to Manufacturing Excellence

When microns define success and production delays cost millions, your metal manufacturing partner must deliver uncompromising precision and unwavering reliability. At Wuxi Lead Precision Machinery, we engineer solutions for global industries where failure is not an option—medical, aerospace, energy, and advanced automation. We transform your most complex metal components from CAD file to certified reality, eliminating the guesswork that plagues conventional supply chains. Our integrated facility in Wuxi, China, merges 15 years of CNC mastery with Industry 4.0 intelligence, ensuring every part meets your exacting standards on time, every time.

Our commitment begins with deep technical collaboration. Share your engineering challenges—not just drawings—and our applications engineers will optimize your design for manufacturability, material efficiency, and cost control. We specialize in tight-tolerance milling, turning, and multi-axis machining of exotic alloys including Inconel, titanium, and hardened tool steels. Unlike commodity shops, we invest in your long-term success through rigorous process validation, real-time SPC monitoring, and full traceability from raw material to final inspection. This is why Fortune 500 innovators trust us for mission-critical components where ±0.0002″ tolerances are non-negotiable.

Below are core capabilities that differentiate our precision metal manufacturing ecosystem:

| Specification | Capability Detail |

|---|---|

| Tolerance Range | ±0.0002″ (5µm) for critical features |

| Materials Expertise | Titanium, Inconel 718/625, Hastelloy, 17-4PH, tool steels |

| Production Volume | Prototypes to 50,000+ units annually |

| Lead Time | 10–15 days for complex parts (avg. RFQ to shipment) |

| Certifications | ISO 9001:2015, AS9100D, NADCAP AC7102 accredited |

This operational excellence translates to tangible outcomes: reduced scrap rates, accelerated time-to-market, and supply chain resilience. We absorb the risk of complex manufacturing so you can focus on innovation. Our dedicated project managers provide transparent communication—no language barriers, no time-zone delays—with daily progress updates and proactive escalation protocols. When your project demands zero-defect delivery under compressed deadlines, our facility operates as your strategic extension, not just a vendor.

The cost of subpar precision extends far beyond rework—it erodes brand reputation and market trust. Partner with an engineering-led team that treats your specifications as sacred. Contact us today to initiate a technical consultation. Email [email protected] with your part drawings and requirements. Our engineering team guarantees a detailed process plan and competitive quotation within 24 business hours. Let Wuxi Lead Precision Machinery become the silent force behind your next breakthrough product. Your precision journey starts with one email: [email protected].

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.