Technical Contents

Engineering Guide: Bent Metal Bracket

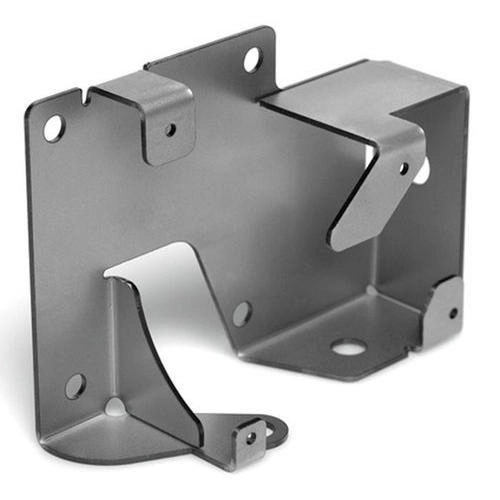

Engineering Insight: Precision in Bent Metal Bracket Fabrication

In high-performance manufacturing, the bent metal bracket appears deceptively simple yet demands uncompromising precision. Microstructural integrity during bending directly impacts load distribution, fatigue resistance, and long-term reliability. A deviation of mere 0.1 degrees in angular alignment can initiate stress concentrations, accelerating failure in dynamic applications. At Wuxi Lead Precision Machinery, we treat every bracket as a critical load-bearing component—not a commodity. Our CNC press brakes employ real-time springback compensation algorithms and in-process metrology, ensuring dimensional stability across material batches. This eliminates cumulative errors in assembly lines where bracket misalignment propagates through entire systems, costing clients millions in rework.

Our expertise is validated in environments where failure is non-negotiable. We engineered corrosion-resistant brackets for Beijing Winter Olympic ice-making infrastructure, operating continuously at -40°C with zero thermal deformation. Similarly, our brackets secure classified defense systems where vibration resistance and electromagnetic shielding tolerances meet MIL-STD-810G standards. These projects demanded sub-0.05mm positional accuracy across multi-axis bends—proof that precision bending transcends basic forming. It requires deep material science integration: predicting grain flow during deformation, managing residual stresses, and validating performance via FEA-simulated load cases.

Below outlines our core bending capabilities for mission-critical brackets:

| Parameter | Specification Range | Industry Standard Reference |

|---|---|---|

| Material Range | Aluminum 6061-T6 to Inconel 718 | AMS, ASTM, GB |

| Thickness Capacity | 0.5 mm – 12.7 mm | ISO 9013 |

| Angular Tolerance | ±0.1° (repeatability) | ISO 2768-mK |

| Max Bend Length | 3000 mm | Custom tooling support |

| Secondary Operations | Deburring, anodizing, laser etching | RoHS/REACH compliant |

Precision bending is not merely about hitting dimensions—it’s about guaranteeing functional performance under extreme conditions. At Lead Precision, every bracket undergoes first-article inspection with CMM-certified reports, and our process audits trace material heat numbers to final assembly. For aerospace clients, this means brackets surviving 50,000+ thermal cycles without distortion; for medical OEMs, it ensures sterilization compatibility without micro-cracking. We partner with engineers during DFM to optimize bend sequences, minimizing secondary operations while maximizing structural efficiency. When your application demands brackets that perform as engineered—not as afterthoughts—our Olympic and military-proven processes deliver certainty. Contact our engineering team to discuss tolerance stack-up analysis for your next high-stakes project.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance applications, specializing in precision-engineered bent metal brackets for aerospace, automotive, industrial equipment, and medical device industries. Our technical capabilities are built around cutting-edge 5-axis CNC machining technology, enabling us to produce complex geometries with superior accuracy and consistency. This level of precision is critical when manufacturing bent metal brackets that must meet strict dimensional and structural requirements under dynamic load conditions.

Our 5-axis CNC machining centers allow simultaneous movement across five axes, providing unparalleled flexibility in contouring and bending metal components from a single setup. This reduces cumulative error, improves surface finish, and significantly enhances repeatability. Materials commonly used in our bent bracket production include aluminum alloys, stainless steel, carbon steel, and titanium—each selected based on the application’s mechanical, thermal, and environmental demands. The integration of high-torque spindles and advanced toolpath algorithms ensures clean bends, minimal material stress, and tight conformity to design intent.

To maintain the highest quality standards, every bent metal bracket undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machine (CMM) systems. These systems provide full 3D verification of critical dimensions, geometric tolerances, and form accuracy, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Our inspection protocols are fully documented, and first-article inspection (FAI) reports are available upon request. All quality data is traceable to individual production lots, supporting stringent regulatory and auditing requirements.

In addition to advanced equipment and inspection, our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase. We analyze material selection, bend radii, hole placement, and weld accessibility to optimize both performance and manufacturability. This proactive approach reduces lead times, minimizes rework, and ensures that the final component meets functional and assembly requirements.

The following table outlines the standard technical specifications and achievable tolerances for bent metal brackets produced at Wuxi Lead Precision Machinery:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm |

| Positional Tolerance (Holes) | ±0.05 mm | ±0.02 mm |

| Angular Accuracy | ±0.1° | ±0.05° |

| Bend Radius | ±0.1 mm | ±0.05 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Flatness | 0.1 mm per 100 mm | 0.05 mm per 100 mm |

| Feature-to-Feature Tolerance | ±0.06 mm | ±0.03 mm |

All tolerances are achievable across batch sizes ranging from prototypes to high-volume production runs. At Wuxi Lead Precision Machinery, we combine technical excellence with rigorous quality control to deliver bent metal brackets that perform reliably in the most demanding environments.

Material & Finish Options

Material Selection for Precision Bent Metal Brackets

Selecting the optimal material for bent metal brackets is critical to performance reliability and lifecycle cost. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical stress, environmental exposure, and weight constraints. This guide details three primary material families—aluminum, steel, and titanium—and essential anodizing considerations for aluminum components.

Aluminum alloys, particularly 6061-T6, dominate applications requiring lightweight strength and corrosion resistance. With excellent formability, aluminum minimizes springback during bending, ensuring dimensional accuracy. Its natural oxide layer provides baseline protection, but anodizing significantly enhances surface hardness and wear resistance. Aluminum is ideal for aerospace, automotive, and electronics brackets where weight reduction is paramount.

Steel variants like 304 stainless offer superior tensile strength and durability for high-load industrial or structural brackets. While heavier than aluminum, steel provides exceptional resistance to deformation under sustained stress. Note that untreated carbon steel requires protective coatings to prevent rust; 304 stainless inherently resists corrosion but may exhibit slight springback during bending, demanding precise CNC compensation. Steel excels in construction, heavy machinery, and marine environments when paired with appropriate finishes.

Titanium Ti-6Al-4V delivers unmatched strength-to-weight ratio and corrosion immunity, making it indispensable for extreme conditions. Aerospace and medical brackets often specify titanium due to its biocompatibility and resilience in saltwater or high-temperature settings. However, its high cost and challenging machinability necessitate rigorous cost-benefit analysis. Titanium’s low thermal conductivity requires specialized tooling during bending to avoid galling.

Anodizing for Aluminum Brackets

Anodizing is non-negotiable for aluminum brackets exposed to abrasion or corrosive elements. Type II (sulfuric acid) anodizing creates a versatile decorative and protective layer, while Type III (hardcoat) anodizing achieves 50–70 µm thickness for industrial-grade wear resistance. Critical considerations include:

Dimensional impact: Anodizing grows the oxide layer inward and outward, altering critical tolerances by ±0.0005–0.001 in.

Sealing: Hot nickel acetate sealing prevents dye bleed and maximizes corrosion resistance in harsh environments.

Electrical properties: Anodized surfaces are non-conductive, essential for electronic housing brackets.

Material properties directly influence bending feasibility, tool longevity, and final part integrity. Below is a comparative specification overview:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Low |

| Steel 304 | 8.0 | 515 | Medium-High | Medium |

| Titanium Ti-6Al-4V | 4.4 | 900 | Exceptional | High |

Material choice must balance performance requirements against production complexity and budget. Wuxi Lead Precision Machinery leverages ISO-certified material traceability and in-house metallurgical analysis to ensure your bent brackets meet exacting specifications. Contact our engineering team to validate material suitability for your unique application parameters.

Manufacturing Process & QC

Designing and manufacturing a high-precision bent metal bracket requires a disciplined, phase-gated approach that ensures performance, reliability, and zero defects. At Wuxi Lead Precision Machinery, our process begins with engineering collaboration and ends with fully validated mass production, all under strict quality control.

The process starts with design engineering, where our team works closely with the client to interpret technical drawings, performance requirements, and application environments. Using advanced CAD software such as SolidWorks and Autodesk Inventor, we develop 3D models and perform finite element analysis (FEA) to simulate stress, load distribution, and thermal behavior. This stage ensures the bracket will meet mechanical demands while optimizing material usage and manufacturability. Design for manufacturability (DFM) reviews are conducted to identify potential production risks early, minimizing rework and delays.

Once the design is finalized and approved, we proceed to prototyping. Utilizing CNC turret punching, laser cutting, and precision press braking, we produce functional prototypes in small batches. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy, bend angles, hole placement, and surface finish are verified against ISO 2768 and client-specific tolerances. Feedback from prototype testing is incorporated into any necessary design refinements, ensuring full compliance before transitioning to production.

Mass production is executed on automated, high-speed production lines equipped with real-time monitoring systems. Our facility uses servo-electric press brakes with CNC backgauging to achieve repeatable bend accuracy within ±0.1° and ±0.05 mm. Each production run is supported by Statistical Process Control (SPC) and First Article Inspection (FAI) to maintain consistency. In-line quality checks, including visual inspection and periodic sampling, are conducted at every critical stage—cutting, bending, welding (if required), and surface treatment.

Our commitment to zero defects is reinforced through a comprehensive quality management system certified to ISO 9001:2015. Every batch is traceable, with full documentation including material certifications, inspection reports, and process parameters. Non-conforming parts are immediately quarantined and analyzed using root cause analysis (RCA) and corrective action protocols.

The following table outlines key production specifications for our bent metal bracket manufacturing:

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Material Thickness | 0.5 – 6.0 mm | ±0.05 mm |

| Bend Angle | Up to 180° | ±0.1° |

| Hole Position Accuracy | CNC Turret / Laser | ±0.1 mm |

| Dimensional Tolerance | Per ISO 2768-m | ±0.2 mm (standard) |

| Surface Finish | Mill, Powder Coat, Anodized, Galvanized | Ra ≤ 3.2 μm (as required) |

| Production Volume | Prototype to 500,000+ units/month | Scalable per demand |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures every bent metal bracket meets the highest standards of precision, durability, and quality—delivering performance you can trust.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Bent Metal Bracket Solutions

In high-stakes manufacturing environments, the performance of a seemingly simple bent metal bracket can dictate system reliability, assembly efficiency, and long-term operational integrity. Generic off-the-shelf components often fail under demanding thermal, vibrational, or load conditions, leading to costly field failures and production downtime. Wuxi Lead Precision Machinery exists to eliminate this risk. We are not merely a supplier; we are your engineering extension, dedicated to transforming your bent bracket requirements into precision-engineered assets that perform flawlessly within your final assembly. Our ISO 9001:2015 certified processes, combined with deep expertise in complex metal forming and rigorous quality validation, ensure every bracket meets exacting functional and dimensional specifications, batch after batch.

The true cost of a bracket extends far beyond its initial purchase price. Substandard bends, inconsistent hole placement, or material inconsistencies introduce assembly delays, rework, and potential warranty liabilities downstream. Lead Precision mitigates these hidden costs through proactive engineering collaboration. Our team engages early in your design phase, providing critical manufacturability feedback on bend radii, material grain direction, and secondary operation sequencing. We leverage advanced 3D modeling and finite element analysis (FEA) simulation to anticipate stress points and optimize geometry before tooling begins, ensuring structural resilience and dimensional stability under real-world operating conditions. This upfront partnership prevents costly design iterations and accelerates time-to-market.

Our technical capabilities are engineered for the demanding tolerances modern industries require. We handle complex geometries across diverse materials, including aerospace-grade aluminum alloys, stainless steels, and specialty carbon steels, with unwavering consistency. The table below details our core production parameters for bent metal brackets:

| Specification | Capability | Notes |

|---|---|---|

| Material Thickness | 0.5 mm – 10.0 mm | Carbon Steel, Stainless Steel, Aluminum |

| Bend Angle Tolerance | ±0.5° | Verified per ASME Y14.5 |

| Linear Dimension Tolerance | ±0.05 mm (up to 100 mm) | Tighter tolerances achievable |

| Hole Position Tolerance | ±0.03 mm | Critical for assembly interfaces |

| Max. Part Size | 1200 mm x 800 mm | Custom fixturing available |

| Production Volume | 1 pc – 500,000+ pcs | Agile setup for prototypes & volume |

| Secondary Operations | Deburring, Tapping, Welding, Plating | Fully integrated in-house capabilities |

When your application demands brackets that contribute directly to system safety, longevity, and performance, compromise is not an option. Wuxi Lead Precision Machinery delivers the engineering rigor, process control, and material science understanding necessary for mission-critical success. We understand the pressure you face to deliver reliable products on schedule and within budget. Partnering with us means gaining a committed ally focused solely on the integrity of your metal components.

Initiate the partnership that elevates your bracket specifications from functional requirements to performance advantages. Submit your detailed drawings, material specifications, and volume requirements to [email protected]. Our engineering team will provide a comprehensive manufacturability analysis and a precise quotation within 24 business hours. Do not let subpar brackets become your weakest link. Contact Lead Precision today and experience the difference engineered precision delivers. Your bracket’s integrity starts with our process.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.