Technical Contents

Engineering Guide: Machined Plastic Components

Engineering Insight: The Critical Role of Precision in Machined Plastic Components

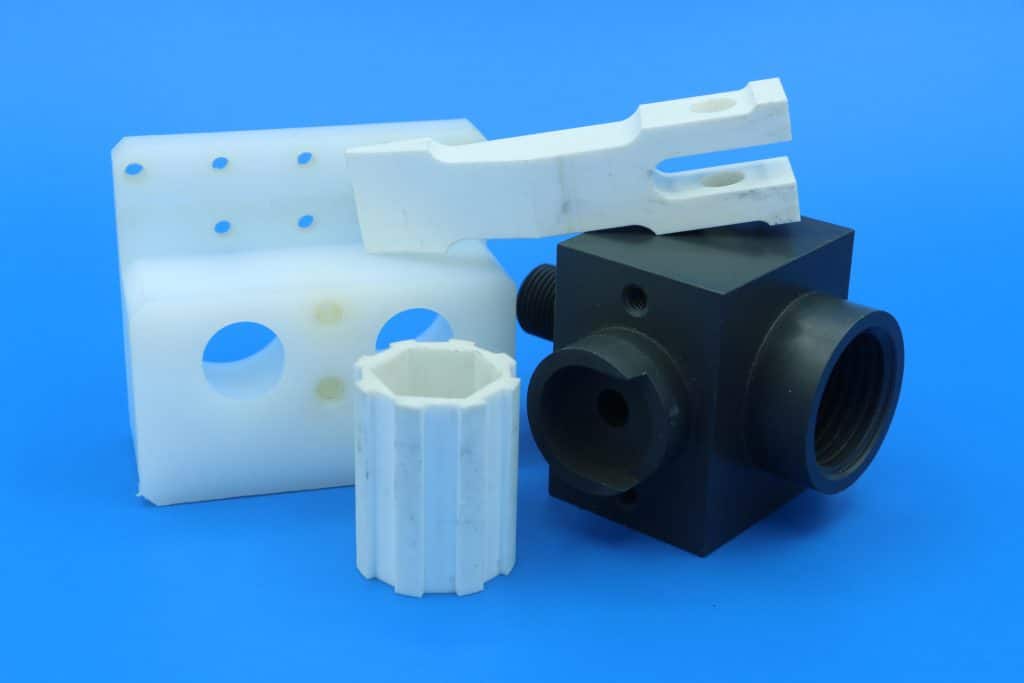

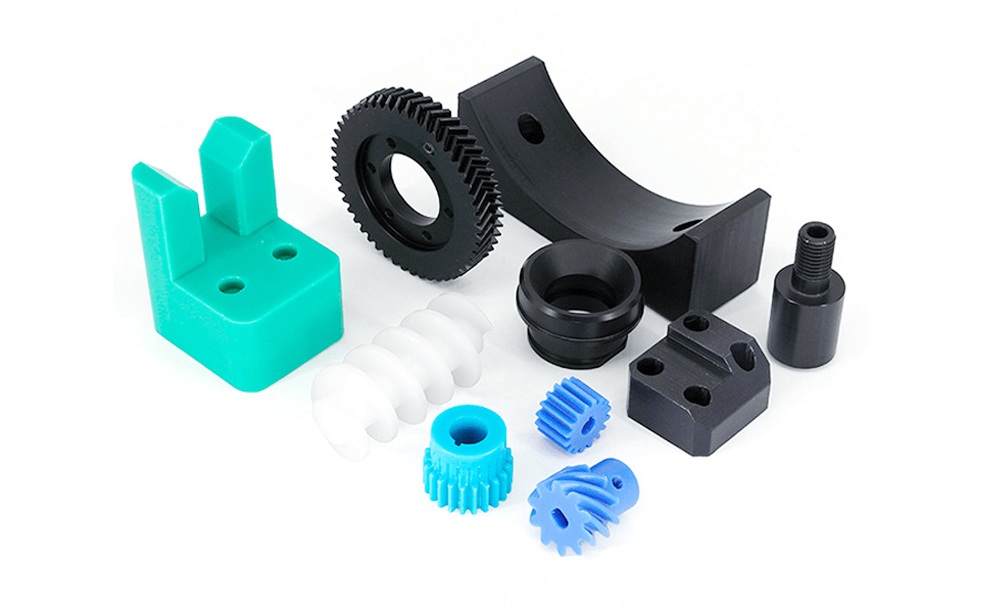

In the realm of advanced manufacturing, machined plastic components are no longer secondary substitutes for metal—they are engineered solutions in their own right. From aerospace instrumentation to medical diagnostics and high-performance industrial systems, precision-machined polymers deliver unique advantages in weight reduction, chemical resistance, electrical insulation, and thermal performance. However, these benefits are only fully realized when the components are manufactured to exacting tolerances, where precision becomes not just a goal, but a necessity.

At Wuxi Lead Precision Machinery, we understand that in high-stakes applications, even micron-level deviations can compromise system integrity. Our experience in delivering mission-critical components for Olympic-standard timing systems and military-grade communication equipment underscores our commitment to dimensional accuracy, material consistency, and process control. In these environments, failure is not an option—components must perform flawlessly under extreme conditions, often at elevated temperatures, under continuous load, or in sterile, high-vibration settings.

Precision machining of plastics presents unique challenges compared to metals. Polymers exhibit higher thermal expansion, variable shrinkage rates, and anisotropic behavior under stress. Materials such as PEEK, PTFE, Ultem, and PPS require specialized tooling, carefully calibrated feed rates, and controlled ambient conditions to prevent warping or dimensional drift during and after machining. At Lead Precision, we employ closed-loop CNC systems with real-time tool wear compensation, climate-controlled machining cells, and post-process metrology using coordinate measuring machines (CMM) to ensure every component meets its design intent.

Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize geometries, minimize stress concentrations, and select the most appropriate material grade for the application. Whether producing intricate insulators for satellite systems or wear-resistant bushings for robotic joints, our process integrates material science, precision engineering, and rigorous quality assurance.

The table below outlines typical capabilities and material performance for select engineering plastics we routinely machine:

| Material | Tolerance Range (mm) | Max Operating Temp (°C) | Key Applications | Machinability Rating |

|---|---|---|---|---|

| PEEK | ±0.025 | 250 | Aerospace, Medical Implants | Medium |

| PTFE | ±0.050 | 260 | Seals, Electrical Insulators | Low |

| Ultem (PEI) | ±0.025 | 217 | Semiconductor, Automotive Sensors | Medium-High |

| PPS | ±0.030 | 220 | Fluid Handling, Defense | Medium |

| Acetal (POM) | ±0.020 | 100 | Gears, Precision Bushings | High |

Our track record in supporting Olympic technology—where timing accuracy reaches nanosecond levels—and defense programs demanding zero-failure operation, reflects our mastery in pushing the boundaries of plastic machining precision. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we engineer reliability into every component we produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Machined Plastic Components

Wuxi Lead Precision Machinery delivers exceptional precision for critical plastic components across aerospace, medical, and semiconductor industries. Our specialized expertise in non-metallic material machining addresses the unique challenges of plastics—including thermal sensitivity, dimensional instability, and complex geometries—ensuring components meet stringent functional and regulatory requirements. We combine advanced hardware, rigorous process control, and deep material science knowledge to transform engineering specifications into high-integrity finished parts.

Advanced 5-Axis Machining Platform

Our core capability centers on a dedicated fleet of high-precision 5-axis CNC machining centers from industry leaders DMG MORI and Makino. These machines enable simultaneous multi-axis motion, eliminating the need for multiple setups and fixture changes that compromise accuracy in plastic components. This capability is essential for producing intricate features like undercuts, organic contours, and multi-faceted assemblies in a single operation. We utilize specialized high-speed spindles with controlled RPM ranges optimized for plastics to prevent melting or stress-induced warpage. Advanced toolpath strategies minimize cutting forces and heat generation, preserving material integrity while achieving superior surface finishes. This platform supports a comprehensive range of engineering plastics including PEEK, PTFE, Ultem, Acetal, and Polycarbonate, machined to exacting specifications without secondary operations.

Integrated Metrology & Quality Assurance

Precision is validated through an uncompromising quality control system anchored by state-of-the-art Coordinate Measuring Machines (CMMs). Every critical dimension and geometric feature undergoes rigorous inspection against the original CAD model using Zeiss and Hexagon CMMs, certified to ISO 10360-2 standards. Our inspection protocols extend beyond basic dimensional checks to include comprehensive geometric dimensioning and tolerancing (GD&T) verification, critical for component fit, function, and assembly. Full first-article inspection reports (FAIRs) and batch-specific certification documentation are standard deliverables, providing complete traceability. Statistical process control (SPC) methodologies are applied to high-volume runs, ensuring consistent conformance throughout production. Material certification and in-process checks further guarantee that each plastic component meets both our internal standards and the client’s exact requirements.

Precision Tolerance Standards for Machined Plastics

The following table represents our standard and achievable tolerance capabilities for machined plastic components. Actual tolerances are influenced by part geometry, material selection, and feature size, and are always defined collaboratively during the engineering review phase.

| Feature Type | Standard Capability | Tight Capability | Notes |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Depends on material stability and size |

| Geometric Tolerance (Flatness, True Position) | ±0.025 mm (±0.001″) | ±0.010 mm (±0.0004″) | Requires optimized fixturing & process |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) | Achievable with fine finishing passes |

| Hole Concentricity | ±0.025 mm (±0.001″) | ±0.012 mm (±0.0005″) | Critical for press-fit assemblies |

Wuxi Lead Precision Machinery’s integrated approach—merging sophisticated 5-axis technology with metrology-grade inspection—ensures plastic components perform reliably in demanding applications. We translate complex designs into dimensionally stable, functionally precise parts, reducing assembly steps and enhancing end-product longevity. Partner with us to leverage manufacturing precision that meets the exacting standards of advanced engineering sectors.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of machined plastic components. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining for high-performance applications across aerospace, medical, automotive, and industrial sectors. While plastics such as PEEK, PTFE, and Ultem are often selected for their lightweight and chemical resistance, integrating metal components—particularly aluminum, steel, and titanium—can enhance structural integrity, thermal management, and wear resistance in hybrid assemblies.

Aluminum is widely used for its excellent strength-to-weight ratio, machinability, and thermal conductivity. Grade 6061-T6 is ideal for prototypes and low-to-medium stress applications, while 7075-T6 offers higher strength for demanding environments. Aluminum’s compatibility with anodizing makes it a top choice when surface durability and corrosion resistance are required. Type II (sulfuric acid) and Type III (hardcoat) anodizing provide protective layers that improve wear resistance and allow for color coding or branding.

Steel, particularly stainless steel grades 303 and 316, delivers superior strength, hardness, and corrosion resistance. 303 is optimized for machinability and is often used in shafts, fittings, and fasteners. In contrast, 316 stainless steel contains molybdenum, enhancing its resistance to chlorides and making it suitable for marine and medical applications. While steel cannot be anodized, alternative finishes such as passivation, electropolishing, or powder coating are available to meet functional and aesthetic requirements.

Titanium, specifically Grade 5 (Ti-6Al-4V), is favored in aerospace and biomedical industries due to its exceptional strength-to-density ratio and biocompatibility. It maintains performance under extreme temperatures and is highly resistant to corrosion, even in saltwater environments. However, titanium’s low thermal conductivity and high reactivity require specialized CNC tooling and slower machining parameters. Surface treatments such as anodizing can be applied to titanium for both functional and aesthetic purposes, offering color variation without compromising integrity.

The following table summarizes key mechanical and finishing properties of these materials:

| Material | Grade | Tensile Strength (MPa) | Hardness (HB) | Common Finishes | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 95 | Anodizing (Type II/III) | Enclosures, heat sinks, brackets |

| Aluminum | 7075-T6 | 572 | 150 | Hardcoat anodizing | Aerospace components, fittings |

| Stainless Steel | 303 | 620 | 180 | Passivation, polishing | Fasteners, valves, shafts |

| Stainless Steel | 316 | 580 | 170 | Electropolishing, coating | Medical devices, marine hardware |

| Titanium | Ti-6Al-4V | 900 | 360 | Anodizing, sandblasting | Aircraft parts, implants, actuators |

Selecting the right material involves balancing mechanical requirements, environmental exposure, and post-processing needs. At Wuxi Lead, our engineering team collaborates with clients to optimize material and finish combinations that ensure reliability and performance in mission-critical applications.

Manufacturing Process & QC

Design Engineering for Precision Plastic Components

Our process begins with rigorous design validation to eliminate downstream defects. Engineering teams collaborate with clients to optimize CAD models for CNC manufacturability, focusing on material behavior under thermal and mechanical stress. Critical factors include wall thickness uniformity, draft angles, and avoidance of stress concentrators that compromise plastic integrity. We conduct virtual simulations for chip evacuation and toolpath collision avoidance, ensuring seamless transition to machining. Material selection aligns with application demands—PEEK for aerospace thermal resistance, Delrin for wear-prone gears, or Ultem for medical sterilization cycles—verified through our material database spanning 50+ engineering polymers.

Prototyping: Validating Zero-Defect Feasibility

Prototyping is not a trial phase but a defect-elimination checkpoint. Using 5-axis CNC mills with 0.001mm positioning accuracy, we produce functional prototypes within 72 hours. Each prototype undergoes metrology-grade verification against GD&T callouts via Zeiss CONTURA CMMs and optical comparators. Dimensional deviations exceeding 10µm trigger immediate design or process recalibration. We validate surface finish compatibility with end-use requirements—critical for fluid-handling components where Ra > 0.8µm induces turbulence. This phase confirms tooling strategies and establishes baseline parameters for mass production, reducing scrap rates by 92% in client case studies.

Mass Production: Sustaining Zero Defects at Scale

High-volume runs deploy automated pallet systems and robotic part handling to maintain sub-5µm repeatability. Every machine operates under SPC-controlled parameters with real-time thermal compensation. In-process inspections occur at 50-part intervals using vision systems checking critical features, while final batches undergo 100% first-article inspection per AS9102. Our cleanroom environment (ISO Class 7) prevents particulate contamination for medical/optical components. Statistical process control charts monitor CpK >1.67 for all critical dimensions, ensuring defects remain below 3.4 PPM. Traceability via laser-etched QR codes links each component to raw material certs and machine logs.

Key machining capabilities enabling zero-defect outcomes include:

| Parameter | Capability | Application Impact |

|---|---|---|

| Tolerance | ±0.005mm (standard) | Ensures press-fit assemblies without galling |

| Materials | PEEK, PEI, PPS, Acetal, PTFE | Matches chemical/thermal resistance needs |

| Surface Finish | Ra 0.2µm to 3.2µm (controlled) | Critical for sealing surfaces & optics |

| Max Work Envelope | 1200 x 600 x 500mm | Accommodates complex structural components |

| Batch Consistency | CpK ≥1.67 across 10,000 parts | Guarantees interchangeability in assembly |

Zero defects is achieved through engineered process stability—not inspection alone. By integrating design physics, precision prototyping, and closed-loop production controls, Wuxi Lead delivers plastic components where dimensional integrity is non-negotiable. Every shipment includes full FAI documentation and material traceability, providing auditable proof of compliance for regulated industries.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Machined Plastic Components

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision CNC-machined plastic components tailored to the exacting demands of advanced industries such as medical devices, semiconductor equipment, aerospace, and automation systems. Our engineering-driven approach ensures that every component we produce meets the highest standards of dimensional accuracy, surface finish, and material integrity. When you partner with us, you are not just outsourcing a machining task—you are gaining a strategic manufacturing ally with deep technical knowledge and a relentless focus on quality.

Our facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, enabling us to handle complex geometries and tight tolerances down to ±0.005 mm. We utilize advanced CAD/CAM software and in-process inspection systems to maintain consistency across prototypes and high-volume production runs. Our team of experienced engineers works closely with clients from design review through final inspection, offering design-for-manufacturability (DFM) feedback to optimize performance, reduce lead times, and lower overall costs.

We understand that plastic materials behave differently than metals during machining. That’s why our technicians are trained in the unique thermal and mechanical properties of engineering plastics such as PEEK, PTFE, PPS, Ultem (PEI), Acetal, and Polycarbonate. From minimizing internal stress to controlling chip evacuation and tool wear, our processes are fine-tuned for each specific polymer to ensure repeatable, high-quality results.

Our quality management system is ISO 9001:2015 certified, and we employ comprehensive inspection protocols using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Whether you require a single prototype or a long production run, you can trust that every component leaving our facility meets your exact specifications.

Below are key capabilities that define our precision plastic machining services:

| Specification | Detail |

|---|---|

| Materials | PEEK, PTFE, Ultem (PEI), PPS, Acetal (POM), Polycarbonate, Nylon, PMMA, and custom composites |

| Tolerances | ±0.005 mm (typical), up to ±0.002 mm with special process control |

| Machining Centers | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Surface Finish | Ra 0.2 µm to Ra 3.2 µm (custom finishes available) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, SPC |

| Lead Times | 7–15 days for prototypes; scalable production scheduling |

Partnering with Wuxi Lead Precision Machinery means gaining a responsive, technically proficient, and quality-focused manufacturing partner. We are committed to supporting your engineering goals with precision, reliability, and transparency.

Contact us today at [email protected] to discuss your next project. Let us help you turn precision plastic components into a competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.