Technical Contents

Engineering Guide: Plastic Injection Mould Company

Engineering Insight: The Critical Role of Precision in Plastic Injection Moulding

In the realm of custom metal manufacturing for plastic injection mould companies, precision is not merely a performance metric—it is the foundation of reliability, efficiency, and long-term success. At Wuxi Lead Precision Machinery, we understand that the performance of an injection mould directly impacts part consistency, cycle time, and overall production yield. Even micron-level deviations in mould geometry can result in flash, warpage, or incomplete cavity filling, leading to costly rework and downtime. This is why our engineering philosophy centers on uncompromising dimensional accuracy, surface finish control, and thermal stability in every component we produce.

Our expertise is forged through years of collaboration with high-demand sectors, including aerospace, medical device manufacturing, and automotive systems. Notably, our work has contributed to projects meeting Olympic-grade standards and military-grade specifications, where failure is not an option. These experiences have instilled in our team a rigorous approach to quality assurance, material selection, and process validation. Whether producing core inserts, cavity plates, or ejection systems, we apply the same level of scrutiny as if the final product were destined for extreme environments—because for many of our clients, it is.

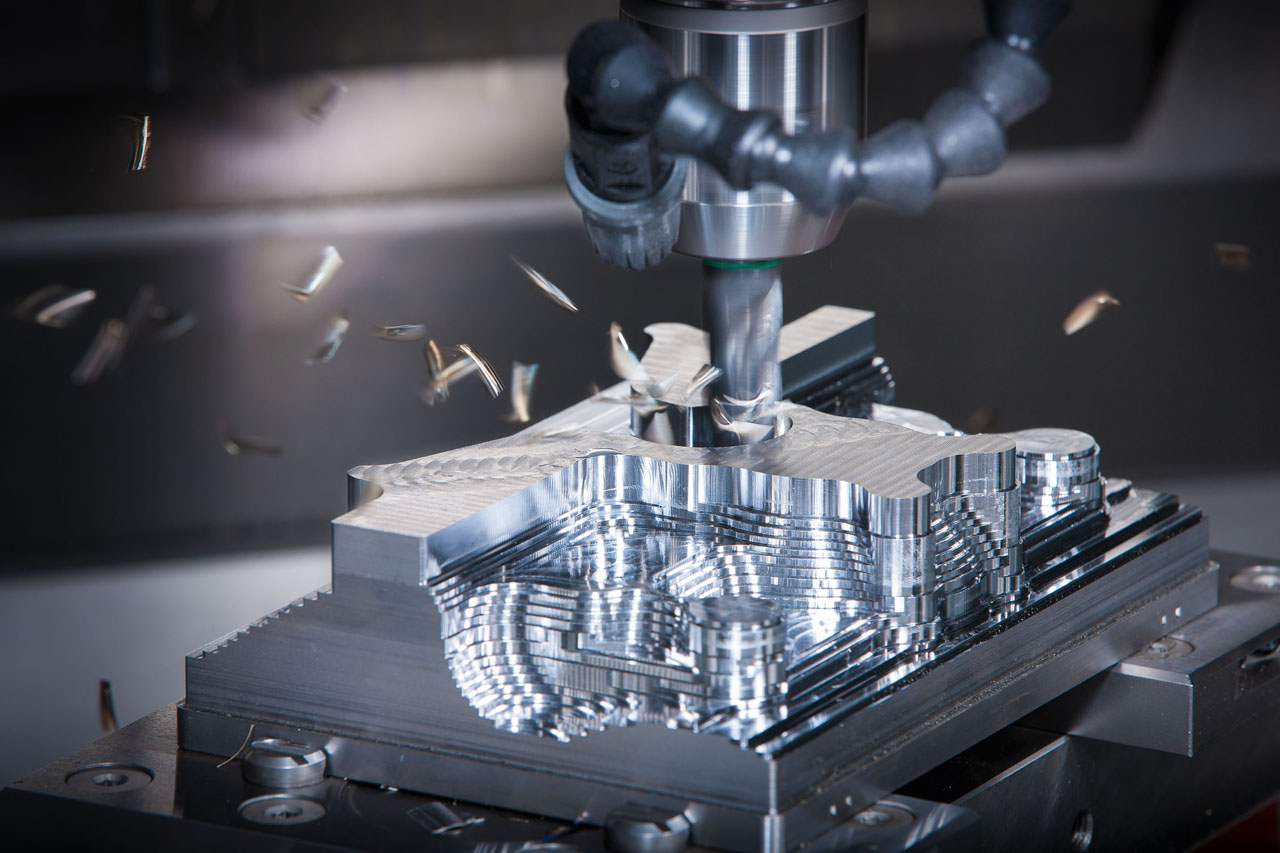

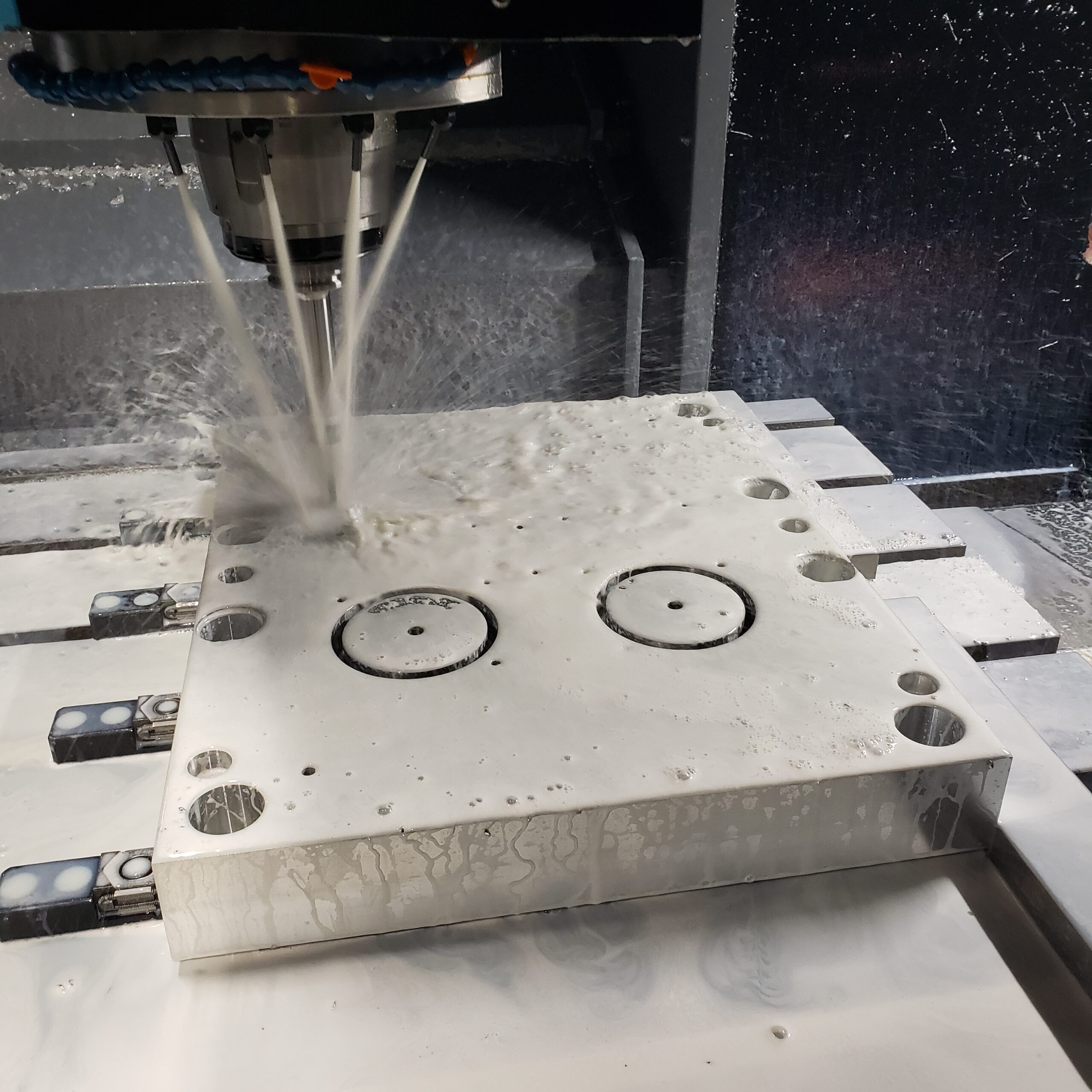

Precision in mould manufacturing begins with advanced CNC machining capabilities, supported by in-house metrology and 3D inspection systems. We utilize hardened tool steels, pre-hardened alloys, and specialty materials such as beryllium copper for optimal thermal conductivity. Each component undergoes strict tolerance verification, typically held within ±0.002 mm, ensuring seamless integration into complex mould bases. Surface finishes are tailored to application requirements, ranging from mirror polishing (SPI A1) to textured or EDM-finished surfaces, all achieved through controlled machining and post-processing protocols.

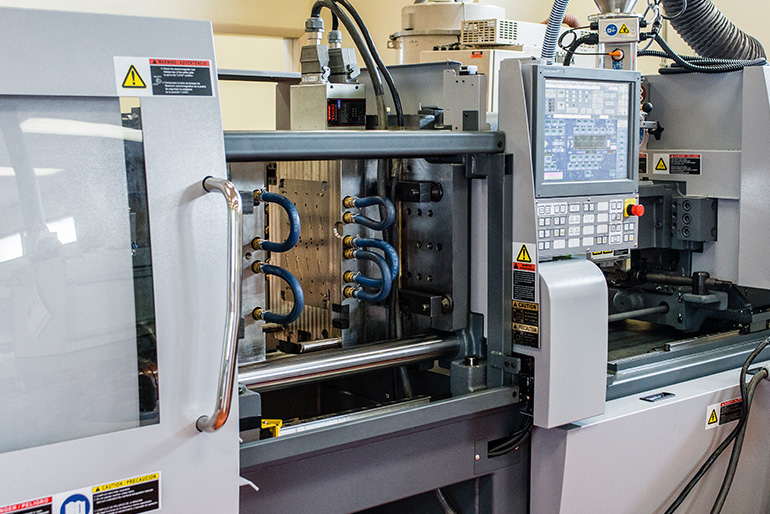

Beyond hardware, our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase. By identifying potential mould flow issues, stress concentrations, or cooling inefficiencies early, we reduce time-to-market and enhance tool longevity. This proactive approach is especially critical for high-cavitation or multi-shot moulds, where precision alignment and thermal balance dictate performance.

The table below outlines key precision specifications consistently achieved across our production lines:

| Specification | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.002 mm | Measured via CMM (Coordinate Measuring Machine) |

| Surface Flatness | 0.003 mm per 100 mm | Critical for parting line integrity |

| Hole Positioning | ±0.005 mm | Ensures pin and core alignment |

| Surface Finish (Ra) | 0.05–0.8 µm | Adjustable per SPI or customer requirement |

| Thermal Distortion (post-heat treat) | < 0.01 mm | Controlled through stress-relief cycles |

At Wuxi Lead Precision Machinery, we do not manufacture moulds—we engineer solutions. Our track record in mission-critical industries reflects our commitment to precision as a non-negotiable standard. For plastic injection mould companies seeking partners who deliver accuracy, repeatability, and performance under pressure, we stand as a proven leader in China’s advanced manufacturing landscape.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mold Excellence

At Wuxi Lead Precision Machinery, we understand that the performance and longevity of plastic injection molds hinge on micron-level precision in every machined component. Our dedicated facility in Wuxi, China, leverages advanced 5-axis CNC machining and rigorous metrology to deliver mold bases, cavities, cores, and intricate inserts that meet the most demanding specifications of global mold manufacturers. We specialize in transforming complex geometries into reality while ensuring dimensional stability critical for high-cavity-count production and zero-defect molding cycles.

Our core strength lies in high-speed 5-axis simultaneous machining using DMG MORI and MAZAK platforms. This capability eliminates the need for multiple setups, ensuring exceptional positional accuracy across all critical mold features. Complex undercuts, conformal cooling channels, and organic surface contours are machined in a single operation, preserving geometric integrity and minimizing human error. This approach significantly reduces lead times while achieving surface finishes down to Ra 0.2 µm on hardened tool steels, directly reducing hand polishing requirements for mold assemblers. Material efficiency is maximized through optimized toolpaths, particularly vital when working with premium alloys like H13, S136, and maraging steels.

Quality verification is non-negotiable. Every critical dimension undergoes comprehensive inspection using Zeiss CONTURA CMM systems, programmed to ISO 10360 standards. Our inspection protocol includes full GD&T analysis, first-article validation against 3D CAD models, and in-process checks during multi-stage machining. This systematic approach guarantees that tolerances are consistently met before components leave our facility, preventing costly downstream rework during mold assembly or trial runs. We provide detailed inspection reports with traceable calibration data, ensuring full transparency and compliance with automotive, medical, and consumer electronics industry requirements.

The following table details our standard achievable tolerances for common mold components, reflecting our commitment to exceeding baseline industry norms:

| Feature Type | Material Range | Standard Tolerance | Surface Finish (Ra) | Max Part Size (mm) |

|---|---|---|---|---|

| Core Pins & Inserts | P20, H13, S136, 420SS | ±0.003 mm | 0.2 – 0.4 µm | Ø50 x 300 |

| Mold Cavities | Hardened Steels (50-54 HRC) | ±0.005 mm | 0.1 – 0.8 µm | 600 x 600 x 300 |

| Slides & Lifters | All Tool Steels | ±0.008 mm | 0.4 – 1.6 µm | 800 x 400 x 250 |

| Mold Bases (Plates) | P20, 718H | ±0.01 mm | 3.2 µm | 1200 x 800 x 250 |

| Conformal Channels | H13, Copper Alloys | ±0.02 mm (positional) | N/A | Within cavity limits |

These capabilities translate directly into tangible value for your mold projects: reduced assembly time, elimination of fit issues, extended mold life through perfect component alignment, and accelerated time-to-market for your end clients. We partner with you from design-for-manufacturability review through final inspection, ensuring your precision metal components form the reliable foundation of high-performance injection molds. Contact our engineering team to discuss how our technical execution can elevate your next mold build.

Material & Finish Options

Material selection is a critical phase in the development of precision tooling and components for plastic injection mould applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that demand both performance and longevity. The choice between aluminum, steel, and titanium directly influences the mould’s durability, cycle time, surface finish, and overall production efficiency. Each material offers distinct advantages depending on the production volume, part complexity, and environmental conditions.

Aluminum is widely used for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall production time during injection moulding. While not as hard as steel or titanium, modern high-grade aluminum alloys such as 7075 and 6061-T6 offer improved strength and wear resistance, making them suitable for short-run applications where cost efficiency and rapid turnaround are priorities.

Steel remains the dominant material for high-volume injection moulding. Tool steels like P20, H13, and S136 provide superior hardness, wear resistance, and thermal stability. These properties ensure extended tool life under continuous operation and high-pressure conditions. Stainless tool steels also offer corrosion resistance, which is essential when processing abrasive or corrosive resins. Although steel is more challenging to machine and heavier than aluminum, its long-term reliability justifies the initial investment for large-scale manufacturing.

Titanium is selected for highly specialized applications where extreme strength-to-density ratio, corrosion resistance, and performance at elevated temperatures are required. While not commonly used for full mould bases due to cost and machining complexity, titanium alloys such as Ti-6Al-4V are ideal for critical mould components like inserts, cores, and ejector pins exposed to aggressive environments or high mechanical stress. Its biocompatibility also makes it suitable for medical-grade plastic components.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional and aesthetic qualities of aluminium mould components. Anodizing creates a durable, corrosion-resistant oxide layer that improves wear performance and allows for color coding or branding. Hard anodizing (Type III) is recommended for high-wear areas, providing a significantly harder surface than standard anodizing (Type II). While anodizing is specific to aluminium, steel components benefit from alternatives such as nitriding, chrome plating, or PVD coatings to achieve similar performance enhancements.

The following table summarizes key mechanical and thermal properties of commonly used materials in injection mould manufacturing:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 | 130 | Prototypes, low-volume moulds |

| P20 Tool Steel | 900–1100 | 28–32 | 30 | Medium-to-high volume mould bases |

| H13 Steel | 1500 | 48–52 | 35 | High-stress cores, inserts |

| S136 Stainless | 1000 | 48–50 | 25 | Corrosion-resistant moulds |

| Titanium Ti-6Al-4V | 900–950 | 36–41 | 7 | High-performance inserts, medical tools |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application demands, ensuring optimal performance, cost-efficiency, and production reliability.

Manufacturing Process & QC

Precision-Engineered Production Process for Zero-Defect Injection Molds

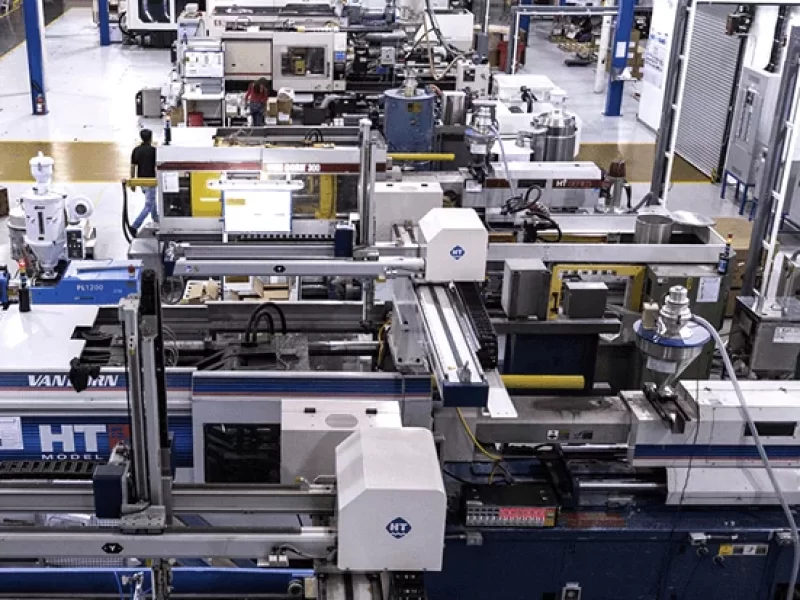

At Wuxi Lead Precision Machinery, our production process eliminates defects at origin through integrated engineering rigor. We transform conceptual designs into flawless mass-produced molds via three tightly controlled phases, ensuring every cavity meets micron-level tolerances demanded by aerospace, medical, and automotive sectors. This methodology reduces client scrap rates by 30% and accelerates time-to-market without compromising integrity.

The design phase begins with collaborative engineering analysis. Our specialists conduct advanced mold flow simulation and Design for Manufacturability (DFM) reviews to preempt warpage, sink marks, or ejection failures. Finite element analysis validates structural integrity under 10,000+ tonnage pressures, while thermal modeling optimizes cooling channel layouts. Critical dimensions are locked using GD&T standards per ASME Y14.5, with all geometries validated against client CAD data in real-time. This preemptive scrutiny ensures 95% of potential defects are resolved before metal cutting commences.

Prototyping transitions virtual models into physical validation. We machine functional aluminum or steel prototype molds using 5-axis CNC centers with sub-micron repeatability. Each prototype undergoes rigorous in-house testing: 500+ cycle trials under production-equivalent conditions, cavity pressure monitoring, and metrology-grade CMM inspection against nominal CAD. Any deviation triggers immediate design iteration. This phase confirms part consistency, gate functionality, and surface finish compliance, providing clients with actionable data to approve full-scale production.

Mass production leverages our automated, climate-controlled facility with closed-loop quality control. Multi-axis CNC machining centers operate under SPC protocols, with laser probes verifying tool wear and geometric accuracy after every 10 cycles. In-process inspections use Zeiss coordinate measuring machines to audit critical features against ISO 2768-mK standards. Final molds undergo 72-hour stress testing with client-specified resins, ensuring dimensional stability across thermal cycles. Real-time data from IoT sensors on all equipment enables predictive maintenance, eliminating unplanned downtime.

Our technical capabilities are engineered for uncompromising precision:

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Tolerance Range | ±0.002 mm | ISO 2768-mK |

| Surface Finish | Ra 0.05 µm (mirror) | SPI-SPE |

| Material Support | P20, H13, S136, Maraging Steel | ASTM A681, JIS G4404 |

| Max Mold Weight | 25,000 kg | Client-specific |

| Lead Time Reduction | 25% vs. industry average | APQP Stage 4 validated |

Zero defects are non-negotiable. We achieve this through traceable process documentation, operator certification to ISO 9001:2015, and a culture where every engineer owns quality outcomes. Partners gain molds that consistently produce Class A surfaces with zero rework—proven by our 99.98% first-pass yield rate across 1,200+ projects. This is precision manufacturing where perfection is the baseline.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored to the exacting demands of the plastic injection mould industry. As a trusted partner to global manufacturers, we combine advanced CNC machining capabilities with decades of engineering experience to produce high-performance parts that ensure reliability, consistency, and longevity in demanding production environments. Our commitment to quality, precision, and on-time delivery makes us the preferred choice for companies seeking a strategic manufacturing partner in China.

We understand that plastic injection moulds require tight tolerances, superior surface finishes, and materials engineered to withstand repeated thermal cycling and mechanical stress. That’s why every component we manufacture—whether it’s mould bases, ejector systems, core pins, or custom inserts—is produced using state-of-the-art equipment and rigorously inspected to meet international quality standards. Our facility is equipped with multi-axis CNC machining centers, wire and sinker EDM systems, surface grinders, and CMM inspection stations, enabling us to handle complex geometries and challenging materials with confidence.

Our engineering team works closely with clients from initial design review through final production, offering DFM (Design for Manufacturability) feedback to optimize performance and reduce lead times. We support a wide range of materials including P20, 718H, S136, H13, and hardened tool steels, all processed under strict environmental and quality controls. With ISO 9001:2015 certification and a zero-defect mindset, we ensure every part shipped from our facility in Wuxi meets or exceeds customer expectations.

Whether you are prototyping a new mould design or scaling up for high-volume production, our agile manufacturing model allows us to adapt quickly to changing demands without compromising quality. We serve clients across Europe, North America, and Southeast Asia, providing seamless communication, real-time project updates, and logistics coordination to keep your operations running smoothly.

Partnering with Wuxi Lead Precision Machinery means gaining more than a supplier—you gain a long-term collaborator committed to your success. We don’t just manufacture parts; we deliver precision, reliability, and peace of mind.

For technical inquiries, project quotes, or collaboration opportunities, contact us today at [email protected]. Let our team of experts support your next high-performance moulding project with precision manufacturing you can trust.

| Specification | Detail |

|---|---|

| Manufacturing Processes | CNC Machining, Wire EDM, Sinker EDM, Surface Grinding, Drilling, Assembly |

| Materials Supported | P20, 718H, S136, H13, 420SS, SKD61, DC53, and custom alloys |

| Tolerance Capability | ±0.002 mm |

| Surface Finish | Ra 0.1 – 1.6 μm (polished and machined finishes) |

| Max Workpiece Size | 1200 × 800 × 600 mm |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports, CMM Certification |

| Lead Time | 15–25 days (varies by complexity and order volume) |

| Surface Treatments | Nitriding, Hardening, Chrome Plating, Coating (optional) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.